Professional Documents

Culture Documents

Vacuum Truck Plant Pre-Acceptance Checklist

Vacuum Truck Plant Pre-Acceptance Checklist

Uploaded by

حماية منتجCopyright:

Available Formats

You might also like

- BS en 1808 2015 Suspended Access PlatformsDocument136 pagesBS en 1808 2015 Suspended Access Platformsyamen sayedNo ratings yet

- S3EMIA - 315 - PR1 - Working On and Near WaterDocument7 pagesS3EMIA - 315 - PR1 - Working On and Near WaterSiwaNo ratings yet

- 1-Coveralls, 2-Gloves, 3-Safety Boots, 4-Safety Hard Hat 5-Safety Glasses, 6-Full Body Safety Harness & 7-Derrickman's BeltDocument3 pages1-Coveralls, 2-Gloves, 3-Safety Boots, 4-Safety Hard Hat 5-Safety Glasses, 6-Full Body Safety Harness & 7-Derrickman's BeltkhurramNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Eye Wash Inspection ChecklistDocument1 pageEye Wash Inspection Checklistkenneth.b0% (1)

- HSE Training ProgramDocument5 pagesHSE Training Programbotahra0% (1)

- LOLER Inspection Checklist - SafetyCultureDocument25 pagesLOLER Inspection Checklist - SafetyCultureTatak Bay AhmedNo ratings yet

- Safe Lifting Operations in The WorkplaceDocument14 pagesSafe Lifting Operations in The WorkplacetlalovićNo ratings yet

- Fitout RaDocument14 pagesFitout RaАлёна Драчева100% (1)

- Finlay Training Services Ad24a98430Document1 pageFinlay Training Services Ad24a98430Christian MakandeNo ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- Procedure For Vehicle and Mobile Equipment OperationDocument18 pagesProcedure For Vehicle and Mobile Equipment OperationAtiq MoghulNo ratings yet

- OSHAD-SF - TG - Dealing With Adverse Weather Conditions For School Transportaiton v3.0 EnglishDocument10 pagesOSHAD-SF - TG - Dealing With Adverse Weather Conditions For School Transportaiton v3.0 EnglishNiel Brian VillarazoNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Safety ProgramDocument21 pagesSafety ProgramSits RdddNo ratings yet

- Dismantling of Concrete Pump TowerDocument1 pageDismantling of Concrete Pump TowerChandruNo ratings yet

- Risk Management and AssessmentDocument50 pagesRisk Management and Assessmentfaik395No ratings yet

- LSR Confined Space Toolbox TalkDocument14 pagesLSR Confined Space Toolbox TalkThura Aung100% (1)

- Stabbing Board Alert 4Document2 pagesStabbing Board Alert 4Luiz Felipe LobatoNo ratings yet

- HSE Human Factors Briefing Note No. 5 Emergency Response: SourceDocument4 pagesHSE Human Factors Briefing Note No. 5 Emergency Response: SourceMargaretta WijayantiNo ratings yet

- 10 Percent Acid Washing SOP TemplateDocument5 pages10 Percent Acid Washing SOP TemplatekofinyameNo ratings yet

- 1 ST Quater Drill ScenarioDocument2 pages1 ST Quater Drill ScenarioSk MehbobNo ratings yet

- Petro Supply-Mobile Crane 80 TonDocument12 pagesPetro Supply-Mobile Crane 80 TonbasdNo ratings yet

- WSHC - Landscape and Horticulture Guidelines - 16 Jan 2012Document69 pagesWSHC - Landscape and Horticulture Guidelines - 16 Jan 2012lwin_oo2435No ratings yet

- Project Safety ChecklistDocument4 pagesProject Safety ChecklistAejaz Mujawar100% (1)

- JSA-070 Desert Road TripDocument4 pagesJSA-070 Desert Road TripMoaatazz NouisriNo ratings yet

- Guidelines For Personal Protective Equipment (Ppe) : JUNE 2020Document40 pagesGuidelines For Personal Protective Equipment (Ppe) : JUNE 2020Tanri Andita Wicaksono100% (1)

- Solutions For Tree Care HazardsDocument2 pagesSolutions For Tree Care HazardsTerex14253No ratings yet

- Safety Drilling Rig Inspection ChecklistDocument3 pagesSafety Drilling Rig Inspection ChecklistJion MujionoNo ratings yet

- Management of Construction and DemolitionabudhabiDocument37 pagesManagement of Construction and DemolitionabudhabiMelete GashawNo ratings yet

- Vehicle Exam & Fitness PakistanDocument7 pagesVehicle Exam & Fitness PakistanAkhtar QuddusNo ratings yet

- Msds Diesel PDFDocument11 pagesMsds Diesel PDFSooraj PoochaliNo ratings yet

- Fire Prevention Safety ChecklistDocument1 pageFire Prevention Safety ChecklistCINQO HSENo ratings yet

- Fall Protection Program: Reviewed: May 2011Document20 pagesFall Protection Program: Reviewed: May 2011Marvin ReggieNo ratings yet

- Night Work ProcedureDocument22 pagesNight Work ProcedureKhaled ElsayedNo ratings yet

- Hard Land Scape Risk AssessmentDocument4 pagesHard Land Scape Risk AssessmentvivekanandhanNo ratings yet

- Fire Water TankDocument1 pageFire Water TankAnonymous yCpjZF1rF100% (1)

- Noise Monitorining Management Plan (Ctgo)Document13 pagesNoise Monitorining Management Plan (Ctgo)rockstone9466No ratings yet

- Office Safety PosterDocument2 pagesOffice Safety PosterAndrei MargaritNo ratings yet

- Road HaulageDocument3 pagesRoad HaulageNorman AinomugishaNo ratings yet

- Life Saving Rules Engagement Final Pack June - 2022Document40 pagesLife Saving Rules Engagement Final Pack June - 2022vinil radhakrishna100% (1)

- Construction Assessment Checklist: Green TagDocument2 pagesConstruction Assessment Checklist: Green TagRyan GillespieNo ratings yet

- Unity Health Safety ManualDocument19 pagesUnity Health Safety ManualKakaraparti SatishNo ratings yet

- RISK ASSESSMENT - Carpentry WorkDocument6 pagesRISK ASSESSMENT - Carpentry WorkbalajiNo ratings yet

- Job Safety Analysis Sheet: Mechanical ExcavationDocument1 pageJob Safety Analysis Sheet: Mechanical ExcavationjoshuaNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- TBT RegisterDocument189 pagesTBT RegisterAmir Zad KhanNo ratings yet

- Welding Procedure: PurposeDocument14 pagesWelding Procedure: Purposeinfos2magi856No ratings yet

- Cutting & Welding Job JSADocument1 pageCutting & Welding Job JSADeepak PatelNo ratings yet

- Safety Index Calculation Work Sheet - 1Document4 pagesSafety Index Calculation Work Sheet - 1Agung WibowoNo ratings yet

- TPF RAG Violation AnalysisDocument2 pagesTPF RAG Violation AnalysisImran Khan100% (1)

- Confind Space RCDocument11 pagesConfind Space RCIrfan ashrafNo ratings yet

- Falling Hazards in The Workplace - Protection & OSHA Standards PDFDocument4 pagesFalling Hazards in The Workplace - Protection & OSHA Standards PDFMuhammad MalikNo ratings yet

- Confind SpaceDocument11 pagesConfind Spacesolomonbeg100% (1)

- Lessons Learnt - Trench CollapseDocument2 pagesLessons Learnt - Trench CollapseEhab SaadNo ratings yet

- Assessment For - RiggersDocument3 pagesAssessment For - RiggersShakeb RahmanNo ratings yet

- Lifting Procedure With AttachmentDocument16 pagesLifting Procedure With AttachmentIshak MalimNo ratings yet

- Avial 1Document1 pageAvial 1max.st2003No ratings yet

- F1310301fill inDocument3 pagesF1310301fill inHope A HaydenNo ratings yet

- Manual On Safety SeaDocument108 pagesManual On Safety SeaLuis Miguel Blanco TovarNo ratings yet

- Vio55-6a Parts ManualDocument303 pagesVio55-6a Parts ManualJason Serwa100% (1)

- Togo 2017 Bac Anglais Series C Et DDocument3 pagesTogo 2017 Bac Anglais Series C Et DFOOVI Komlan MawuliNo ratings yet

- Geomecanica Aplicada Al Planeamiento y Explotacion de Yacimiento de Mineria Subterranea Parte 5Document11 pagesGeomecanica Aplicada Al Planeamiento y Explotacion de Yacimiento de Mineria Subterranea Parte 5malvinas49No ratings yet

- 14 - CPL Questions - Communication ProcDocument24 pages14 - CPL Questions - Communication ProcMoshiurRahmanNo ratings yet

- NAG1 Operation & DiagnosisDocument211 pagesNAG1 Operation & DiagnosisSalvador PinedaNo ratings yet

- List of Maritime Enterprises Under MC 186 As of Aug. 2020Document12 pagesList of Maritime Enterprises Under MC 186 As of Aug. 2020Arnul MalinaoNo ratings yet

- Unimog U 2150 Specifications & Technical Data (1998-2002)Document1 pageUnimog U 2150 Specifications & Technical Data (1998-2002)Papeda PapuaNo ratings yet

- Ford 3000Document810 pagesFord 3000Tim BrittNo ratings yet

- BC 5.0% (Grading-I) PMB PG-76E-10 - 04.12.2021 (Modified)Document55 pagesBC 5.0% (Grading-I) PMB PG-76E-10 - 04.12.2021 (Modified)sandeep nanda100% (1)

- Critical Lift WorksheetDocument1 pageCritical Lift WorksheetShafie ZubierNo ratings yet

- DPSS-16-E-101 - Remanufactured Diesel Injectors - Pub DDSU151D - NMDocument2 pagesDPSS-16-E-101 - Remanufactured Diesel Injectors - Pub DDSU151D - NMOrtega Isaac TeodoroNo ratings yet

- BoardingCard 228839774 ATH VIEDocument1 pageBoardingCard 228839774 ATH VIEVilly ParaskevopoulosNo ratings yet

- TVS Iqube STTechnical - SpecificationsDocument2 pagesTVS Iqube STTechnical - SpecificationsRaghuNo ratings yet

- TorcUP AP 1000 Manual 2013 04Document26 pagesTorcUP AP 1000 Manual 2013 04ZulferiNo ratings yet

- Denso Price ListDocument16 pagesDenso Price ListJoby MathewNo ratings yet

- D-Line: Operation ManualDocument134 pagesD-Line: Operation Manualabduallah muhammadNo ratings yet

- 1 Siemens WinCC Open Architecture PDFDocument19 pages1 Siemens WinCC Open Architecture PDFMitrita ZanetNo ratings yet

- eSID2 Swedish Saab 9-3 2007-2014Document1 pageeSID2 Swedish Saab 9-3 2007-2014Tudor PopescuNo ratings yet

- Vento Ga1455Document4 pagesVento Ga1455Tinkle BellNo ratings yet

- p810495 A1b PDFDocument82 pagesp810495 A1b PDFYanyan2009No ratings yet

- Permanent Magnet Motor Speed Controller: Models 1228Document5 pagesPermanent Magnet Motor Speed Controller: Models 1228Jose Manuel Pereira López100% (1)

- Automobile HistoryDocument10 pagesAutomobile Historywagom2000No ratings yet

- Information Technology Implementation Across National Highways and Urban InfrastructureDocument6 pagesInformation Technology Implementation Across National Highways and Urban InfrastructureDhruv SuriNo ratings yet

- Airline Industry Irland CaseDocument8 pagesAirline Industry Irland Casecolorful anaNo ratings yet

- Toyota: Global Expansion StrategiesDocument38 pagesToyota: Global Expansion StrategiesDewesh ThakurNo ratings yet

- P1251 Nissan Tino DTC Code PDFDocument2 pagesP1251 Nissan Tino DTC Code PDFJoaquin Enrique Rivas HungNo ratings yet

Vacuum Truck Plant Pre-Acceptance Checklist

Vacuum Truck Plant Pre-Acceptance Checklist

Uploaded by

حماية منتجOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vacuum Truck Plant Pre-Acceptance Checklist

Vacuum Truck Plant Pre-Acceptance Checklist

Uploaded by

حماية منتجCopyright:

Available Formats

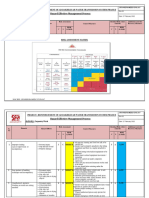

VACUUM TRUCK PLANT PRE-ACCEPTANCE CHECKLIST

PLANT DETAILS

Plant Owner: Address: Ph:

Plant Make: Plant Model: Plant Serial No: Hours / KM’s:

Roads Reg No: Reg Expiry: Project Registration No: Project Asset No:

Last Service Date / Hrs: Next service Date / Hrs:

MINIMUM REQUIREMENTS (If the minimum requirements are not met, a plant sticker will not be issued and the item of plant is not to commence work)

Verif Check Requirement Verify Chec Requirement

y k

Operator and Maintenance Manual available Plant Hazard Assessment Sighted & Current (within 2 yrs):

Logbook / Service Records (checked ok): Plant Hazard Assessment Inspection Date: / /

Audible Alarm and other Warning Devices fitted, operable and Daily Prestart Inspection Checklist is available for use.

suitable for site conditions

Fire Extinguisher Fitted and charged

Revision No: 1 Document Number: JH-FRM-PAE-001-46 Page 1 of 3

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 07/04/2014

Verify Check Vacuum pump and accessories

Access points hand rails and steps

fitted and secured

VACUUM TRUCK PLANT PRE-ACCEPTANCE CHECKLIST Hoses / Piping / Connectors secure

Ram if fitted

Signage e.g. Do use for drinking

water

Pins / Mounting

Verify Check Air / Water System

Water Valves

Verif Water Pump secure and operational

Verify Check Cabin Check Environmental

y Air compressor secure and

Cleanliness operational

Clean, free of organic materials (mud, dirt, weeds or

Door operational seeds) prior to arrival Hoses secure and not leaking

Deadman Pedal /Switch operational Engine baffling or noise reduction equipment fitted Connections secure

Handrails and ladders fitted and secure as per manufacturers specifications Water tank not leaking

Seat – adjustments operational secure Smoke from internal combustion engines should not

Verify Check Engine

be visible for more than ten seconds

Seat belt fitted and in good working order Engine Mountings

TYRES – Record Tread Depth (if required)

UHF Radio Fitted (If not fitted, has a hand Engine Guarding

held radio been supplied)

POS 1 (LF) ____mm POS 2 (RF) ____mm Exhaust Guarding

Operation instruction for machine setup on Oil Leaks/check levels

outriggers present POS 3 (LF2) ____mm POS 4 (RF2) ____mm

Coolant Leaks/check levels

First Aid Kit, triangle and road reflectors

available POS 5 (LR3) ____mm POS 6 (RR3) ____mm Coolant System

Warning devices and other lights (flashing, Vee Belt Condition

POS 7 (LR4) ____mm POS 8 (RR4) ____mm

head, tail, etc) are appropriate for the Air Cleaner System

environment in which plant is being used. POS 9 (LR5) ____mm POS 10 (RR5) ____mm Battery Condition / Mounting

(check environment noise criteria particularly if

working out of hours) POS 11 (LR6) ____mm POS 8 (RR6) ____mm

Instruments operational & labelled

Cabin water / air controls operational

Pedals in good condition

Air conditioning operational

Wipers / Washers operational

Rear View Mirrors

Windows not damaged

Warning Signs - Seat belt must be worn

Warning Signs - Danger – Beware Overhead

Wires

Verify Check Running Gear

Tyres / Wheels undamaged

Brakes system operational

Park brake is operational

Instructions: Verify Box to be ticked by Owner / Supplier / Operator prior to arrival onsite. Check Box to be ticked after visual inspection by the project

Revision No: 1 Document Number: JH-FRM-PAE-001-46 Page 2 of 3

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 07/04/2014

VACUUM TRUCK PLANT PRE-ACCEPTANCE CHECKLIST

PLANT OWNER / OCCUPIER

PLANT VERIFIER

I certify that the described plant has met the inspection criteria stipulated within this checklist and is being serviced and maintained in accordance with the manufacturer’s specifications

I certify that I have verified that the described plant has met the inspection criteria stipulated within this checklist and is being serviced and maintained in accordance with the manufacturer’s specifications

Name: Signature: Date:

Name: Signature: Date:

Revision No: 1 Document Number: JH-FRM-PAE-001-46 Page 3 of 3

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 07/04/2014

You might also like

- BS en 1808 2015 Suspended Access PlatformsDocument136 pagesBS en 1808 2015 Suspended Access Platformsyamen sayedNo ratings yet

- S3EMIA - 315 - PR1 - Working On and Near WaterDocument7 pagesS3EMIA - 315 - PR1 - Working On and Near WaterSiwaNo ratings yet

- 1-Coveralls, 2-Gloves, 3-Safety Boots, 4-Safety Hard Hat 5-Safety Glasses, 6-Full Body Safety Harness & 7-Derrickman's BeltDocument3 pages1-Coveralls, 2-Gloves, 3-Safety Boots, 4-Safety Hard Hat 5-Safety Glasses, 6-Full Body Safety Harness & 7-Derrickman's BeltkhurramNo ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- Eye Wash Inspection ChecklistDocument1 pageEye Wash Inspection Checklistkenneth.b0% (1)

- HSE Training ProgramDocument5 pagesHSE Training Programbotahra0% (1)

- LOLER Inspection Checklist - SafetyCultureDocument25 pagesLOLER Inspection Checklist - SafetyCultureTatak Bay AhmedNo ratings yet

- Safe Lifting Operations in The WorkplaceDocument14 pagesSafe Lifting Operations in The WorkplacetlalovićNo ratings yet

- Fitout RaDocument14 pagesFitout RaАлёна Драчева100% (1)

- Finlay Training Services Ad24a98430Document1 pageFinlay Training Services Ad24a98430Christian MakandeNo ratings yet

- Confined Space PlanDocument25 pagesConfined Space PlanPokiko MikotoNo ratings yet

- Procedure For Vehicle and Mobile Equipment OperationDocument18 pagesProcedure For Vehicle and Mobile Equipment OperationAtiq MoghulNo ratings yet

- OSHAD-SF - TG - Dealing With Adverse Weather Conditions For School Transportaiton v3.0 EnglishDocument10 pagesOSHAD-SF - TG - Dealing With Adverse Weather Conditions For School Transportaiton v3.0 EnglishNiel Brian VillarazoNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Safety ProgramDocument21 pagesSafety ProgramSits RdddNo ratings yet

- Dismantling of Concrete Pump TowerDocument1 pageDismantling of Concrete Pump TowerChandruNo ratings yet

- Risk Management and AssessmentDocument50 pagesRisk Management and Assessmentfaik395No ratings yet

- LSR Confined Space Toolbox TalkDocument14 pagesLSR Confined Space Toolbox TalkThura Aung100% (1)

- Stabbing Board Alert 4Document2 pagesStabbing Board Alert 4Luiz Felipe LobatoNo ratings yet

- HSE Human Factors Briefing Note No. 5 Emergency Response: SourceDocument4 pagesHSE Human Factors Briefing Note No. 5 Emergency Response: SourceMargaretta WijayantiNo ratings yet

- 10 Percent Acid Washing SOP TemplateDocument5 pages10 Percent Acid Washing SOP TemplatekofinyameNo ratings yet

- 1 ST Quater Drill ScenarioDocument2 pages1 ST Quater Drill ScenarioSk MehbobNo ratings yet

- Petro Supply-Mobile Crane 80 TonDocument12 pagesPetro Supply-Mobile Crane 80 TonbasdNo ratings yet

- WSHC - Landscape and Horticulture Guidelines - 16 Jan 2012Document69 pagesWSHC - Landscape and Horticulture Guidelines - 16 Jan 2012lwin_oo2435No ratings yet

- Project Safety ChecklistDocument4 pagesProject Safety ChecklistAejaz Mujawar100% (1)

- JSA-070 Desert Road TripDocument4 pagesJSA-070 Desert Road TripMoaatazz NouisriNo ratings yet

- Guidelines For Personal Protective Equipment (Ppe) : JUNE 2020Document40 pagesGuidelines For Personal Protective Equipment (Ppe) : JUNE 2020Tanri Andita Wicaksono100% (1)

- Solutions For Tree Care HazardsDocument2 pagesSolutions For Tree Care HazardsTerex14253No ratings yet

- Safety Drilling Rig Inspection ChecklistDocument3 pagesSafety Drilling Rig Inspection ChecklistJion MujionoNo ratings yet

- Management of Construction and DemolitionabudhabiDocument37 pagesManagement of Construction and DemolitionabudhabiMelete GashawNo ratings yet

- Vehicle Exam & Fitness PakistanDocument7 pagesVehicle Exam & Fitness PakistanAkhtar QuddusNo ratings yet

- Msds Diesel PDFDocument11 pagesMsds Diesel PDFSooraj PoochaliNo ratings yet

- Fire Prevention Safety ChecklistDocument1 pageFire Prevention Safety ChecklistCINQO HSENo ratings yet

- Fall Protection Program: Reviewed: May 2011Document20 pagesFall Protection Program: Reviewed: May 2011Marvin ReggieNo ratings yet

- Night Work ProcedureDocument22 pagesNight Work ProcedureKhaled ElsayedNo ratings yet

- Hard Land Scape Risk AssessmentDocument4 pagesHard Land Scape Risk AssessmentvivekanandhanNo ratings yet

- Fire Water TankDocument1 pageFire Water TankAnonymous yCpjZF1rF100% (1)

- Noise Monitorining Management Plan (Ctgo)Document13 pagesNoise Monitorining Management Plan (Ctgo)rockstone9466No ratings yet

- Office Safety PosterDocument2 pagesOffice Safety PosterAndrei MargaritNo ratings yet

- Road HaulageDocument3 pagesRoad HaulageNorman AinomugishaNo ratings yet

- Life Saving Rules Engagement Final Pack June - 2022Document40 pagesLife Saving Rules Engagement Final Pack June - 2022vinil radhakrishna100% (1)

- Construction Assessment Checklist: Green TagDocument2 pagesConstruction Assessment Checklist: Green TagRyan GillespieNo ratings yet

- Unity Health Safety ManualDocument19 pagesUnity Health Safety ManualKakaraparti SatishNo ratings yet

- RISK ASSESSMENT - Carpentry WorkDocument6 pagesRISK ASSESSMENT - Carpentry WorkbalajiNo ratings yet

- Job Safety Analysis Sheet: Mechanical ExcavationDocument1 pageJob Safety Analysis Sheet: Mechanical ExcavationjoshuaNo ratings yet

- Jha Rig Up Hwu Equipment & Surface Line N-U and N-D BopDocument7 pagesJha Rig Up Hwu Equipment & Surface Line N-U and N-D BopHSE PULAI A100% (1)

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 pageNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiNo ratings yet

- TBT RegisterDocument189 pagesTBT RegisterAmir Zad KhanNo ratings yet

- Welding Procedure: PurposeDocument14 pagesWelding Procedure: Purposeinfos2magi856No ratings yet

- Cutting & Welding Job JSADocument1 pageCutting & Welding Job JSADeepak PatelNo ratings yet

- Safety Index Calculation Work Sheet - 1Document4 pagesSafety Index Calculation Work Sheet - 1Agung WibowoNo ratings yet

- TPF RAG Violation AnalysisDocument2 pagesTPF RAG Violation AnalysisImran Khan100% (1)

- Confind Space RCDocument11 pagesConfind Space RCIrfan ashrafNo ratings yet

- Falling Hazards in The Workplace - Protection & OSHA Standards PDFDocument4 pagesFalling Hazards in The Workplace - Protection & OSHA Standards PDFMuhammad MalikNo ratings yet

- Confind SpaceDocument11 pagesConfind Spacesolomonbeg100% (1)

- Lessons Learnt - Trench CollapseDocument2 pagesLessons Learnt - Trench CollapseEhab SaadNo ratings yet

- Assessment For - RiggersDocument3 pagesAssessment For - RiggersShakeb RahmanNo ratings yet

- Lifting Procedure With AttachmentDocument16 pagesLifting Procedure With AttachmentIshak MalimNo ratings yet

- Avial 1Document1 pageAvial 1max.st2003No ratings yet

- F1310301fill inDocument3 pagesF1310301fill inHope A HaydenNo ratings yet

- Manual On Safety SeaDocument108 pagesManual On Safety SeaLuis Miguel Blanco TovarNo ratings yet

- Vio55-6a Parts ManualDocument303 pagesVio55-6a Parts ManualJason Serwa100% (1)

- Togo 2017 Bac Anglais Series C Et DDocument3 pagesTogo 2017 Bac Anglais Series C Et DFOOVI Komlan MawuliNo ratings yet

- Geomecanica Aplicada Al Planeamiento y Explotacion de Yacimiento de Mineria Subterranea Parte 5Document11 pagesGeomecanica Aplicada Al Planeamiento y Explotacion de Yacimiento de Mineria Subterranea Parte 5malvinas49No ratings yet

- 14 - CPL Questions - Communication ProcDocument24 pages14 - CPL Questions - Communication ProcMoshiurRahmanNo ratings yet

- NAG1 Operation & DiagnosisDocument211 pagesNAG1 Operation & DiagnosisSalvador PinedaNo ratings yet

- List of Maritime Enterprises Under MC 186 As of Aug. 2020Document12 pagesList of Maritime Enterprises Under MC 186 As of Aug. 2020Arnul MalinaoNo ratings yet

- Unimog U 2150 Specifications & Technical Data (1998-2002)Document1 pageUnimog U 2150 Specifications & Technical Data (1998-2002)Papeda PapuaNo ratings yet

- Ford 3000Document810 pagesFord 3000Tim BrittNo ratings yet

- BC 5.0% (Grading-I) PMB PG-76E-10 - 04.12.2021 (Modified)Document55 pagesBC 5.0% (Grading-I) PMB PG-76E-10 - 04.12.2021 (Modified)sandeep nanda100% (1)

- Critical Lift WorksheetDocument1 pageCritical Lift WorksheetShafie ZubierNo ratings yet

- DPSS-16-E-101 - Remanufactured Diesel Injectors - Pub DDSU151D - NMDocument2 pagesDPSS-16-E-101 - Remanufactured Diesel Injectors - Pub DDSU151D - NMOrtega Isaac TeodoroNo ratings yet

- BoardingCard 228839774 ATH VIEDocument1 pageBoardingCard 228839774 ATH VIEVilly ParaskevopoulosNo ratings yet

- TVS Iqube STTechnical - SpecificationsDocument2 pagesTVS Iqube STTechnical - SpecificationsRaghuNo ratings yet

- TorcUP AP 1000 Manual 2013 04Document26 pagesTorcUP AP 1000 Manual 2013 04ZulferiNo ratings yet

- Denso Price ListDocument16 pagesDenso Price ListJoby MathewNo ratings yet

- D-Line: Operation ManualDocument134 pagesD-Line: Operation Manualabduallah muhammadNo ratings yet

- 1 Siemens WinCC Open Architecture PDFDocument19 pages1 Siemens WinCC Open Architecture PDFMitrita ZanetNo ratings yet

- eSID2 Swedish Saab 9-3 2007-2014Document1 pageeSID2 Swedish Saab 9-3 2007-2014Tudor PopescuNo ratings yet

- Vento Ga1455Document4 pagesVento Ga1455Tinkle BellNo ratings yet

- p810495 A1b PDFDocument82 pagesp810495 A1b PDFYanyan2009No ratings yet

- Permanent Magnet Motor Speed Controller: Models 1228Document5 pagesPermanent Magnet Motor Speed Controller: Models 1228Jose Manuel Pereira López100% (1)

- Automobile HistoryDocument10 pagesAutomobile Historywagom2000No ratings yet

- Information Technology Implementation Across National Highways and Urban InfrastructureDocument6 pagesInformation Technology Implementation Across National Highways and Urban InfrastructureDhruv SuriNo ratings yet

- Airline Industry Irland CaseDocument8 pagesAirline Industry Irland Casecolorful anaNo ratings yet

- Toyota: Global Expansion StrategiesDocument38 pagesToyota: Global Expansion StrategiesDewesh ThakurNo ratings yet

- P1251 Nissan Tino DTC Code PDFDocument2 pagesP1251 Nissan Tino DTC Code PDFJoaquin Enrique Rivas HungNo ratings yet