Professional Documents

Culture Documents

en GB FactSheet Main 01

en GB FactSheet Main 01

Uploaded by

Chandra YudistiraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

en GB FactSheet Main 01

en GB FactSheet Main 01

Uploaded by

Chandra YudistiraCopyright:

Available Formats

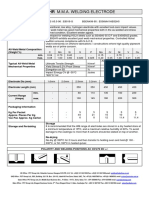

COVERED (STICK) ELECTRODES (SMAW)

LOW ALLOY ELECTRODES

OK 76.98

OK 76.98 is a low-hydrogen electrode for welding modified 9 Cr steels like T91/P91. The electrode is suitable for all-positional welding in pipes and plates. The

mechanical properties stated here are after two hours of heat treatment at 750°C.

Classifications SFA/AWS A5.5 : E9015-B91 (nearest)

EN ISO 3580-A : E CrMo91 B 4 2 H5

Approvals CE EN 13479

NAKS/HAKC 2.5-4.0 mm

VdTÜV 07687

Seproz UNA 272580

Approvals are based on factory location. Please contact ESAB for more information.

Welding Current DC+

Diffusible Hydrogen < 5.0 ml/100g

Alloy Type Low alloyed (9 % Cr, 1 % Mo + Ni / V / Nb)

Coating Type Basic covering

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

ISO

PWHT 2hr 755°C 720 MPa 820 MPa 21 %

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

ISO

PWHT 2hr 755°C 20 °C 50 J

Typical Weld Metal Analysis %

C Mn Si Ni Cr Mo V Nb

0.1 0.8 0.35 0.7 9 1 0.24 0.06

Deposition Data

Diameter Current Voltage Number of Fusion time per Deposition Deposition Rate @

electrodes/ electrode at 90% I Efficiency % 90% I max

kg weld metal max

2.5 x 350.0 mm 70-100 A 21 V 71.4 56 sec 66 % 0.9 kg/h

3.2 x 350.0 mm 90-135 A 22 V 45.5 68 sec 60 % 1.2 kg/h

4.0 x 450.0 mm 130-200 A 23 V 22.6 85 sec 64 % 1.9 kg/h

410540-en_GB-FactSheet_Main-01 2021-05-25

esab.com/fillermetals

You might also like

- How To Build A Paracord FloggerDocument9 pagesHow To Build A Paracord FloggerReaperGod 245No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pagePipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesMohammad AdilNo ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- Ok 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 MpaDocument1 pageOk 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 Mpamitesh prajapatiNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel Electrodestarun kaushalNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesXQNo ratings yet

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- ESABDocument1 pageESABXQNo ratings yet

- Ok Ni-Ci: Repair and Maintenance Cast Iron AlloysDocument1 pageOk Ni-Ci: Repair and Maintenance Cast Iron AlloysAmR ZakiNo ratings yet

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNo ratings yet

- WeartrodDocument1 pageWeartrodBhavik PatelNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Covered (Stick) Electrodes (Smaw) Nickel Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Nickel Alloy Electrodes: Typical Tensile PropertiesKaung Sett LynnNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- E10018d2-Eng LINCOLNDocument1 pageE10018d2-Eng LINCOLNBenfil ViernezNo ratings yet

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- RO4400 PrepregDocument2 pagesRO4400 Prepreggcohen03No ratings yet

- TT - Electronics 898 3 R100K Datasheet PDFDocument4 pagesTT - Electronics 898 3 R100K Datasheet PDFelnegritoheberNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Informationw elhaj abdallaNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- SL20GDocument2 pagesSL20Gridho_48No ratings yet

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument3 pagesDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Resistor ArrayDocument5 pagesResistor ArrayJuampa ChruscielNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- Esab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Specification: 7/8" Coaxial Cable Type RF 7/8"-50 RF 7/8"-50BHF ConstructionDocument2 pagesSpecification: 7/8" Coaxial Cable Type RF 7/8"-50 RF 7/8"-50BHF ConstructionLee Anh VinhNo ratings yet

- Shield Bright 309L-1Document1 pageShield Bright 309L-1adanmeneses1No ratings yet

- Wb2318e E9018-MDocument1 pageWb2318e E9018-McwiksjNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- SRD-5VDC-SL-C Relay DatasheetDocument3 pagesSRD-5VDC-SL-C Relay DatasheetHaidil EdiNo ratings yet

- Model L Series: Thick Film Low Profile SIP Conformal Coated Resistor NetworksDocument5 pagesModel L Series: Thick Film Low Profile SIP Conformal Coated Resistor NetworksKaren MkrtchyanNo ratings yet

- Relé RY SchrackDocument4 pagesRelé RY SchrackRogério PereiraNo ratings yet

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62No ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

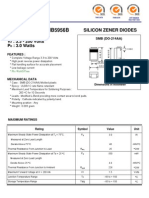

- 1SMB5913B - 1SMB5956B: Silicon Zener DiodesDocument3 pages1SMB5913B - 1SMB5956B: Silicon Zener Diodesanurag2006agarwalNo ratings yet

- Esab 28: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageEsab 28: Covered (Stick) Electrodes (Smaw) Mild Steel Electrodesraghubhaimantra4136No ratings yet

- SRD 05VDC SL C Datasheet PDFDocument2 pagesSRD 05VDC SL C Datasheet PDFMuhammad FatihNo ratings yet

- HKDSE Chemistry 2014 Paper1ADocument12 pagesHKDSE Chemistry 2014 Paper1ABILLYNG33050% (2)

- C7. SlabsDocument77 pagesC7. SlabsDavid Moreno SanchezNo ratings yet

- Is 3600Document5 pagesIs 3600marceloscarpariNo ratings yet

- Argex - Lightweight SCC - PresentationDocument13 pagesArgex - Lightweight SCC - Presentationrobert_alarNo ratings yet

- 8 - AP Chemistry Unit 2 Worksheet Practice ProblemsDocument6 pages8 - AP Chemistry Unit 2 Worksheet Practice ProblemsNesrine LaradjiNo ratings yet

- Exogeneous Processes and The Rock Cycle: Ii. Lesson ObjectivesDocument9 pagesExogeneous Processes and The Rock Cycle: Ii. Lesson ObjectivesRiguel Jameson AllejeNo ratings yet

- Well Workover and InterventionDocument27 pagesWell Workover and InterventionAndrewNo ratings yet

- Corrosion Performance of Mild Steel and GalvanizedDocument18 pagesCorrosion Performance of Mild Steel and GalvanizedNarasimha DvlNo ratings yet

- Fire Suppression by Water SprayDocument52 pagesFire Suppression by Water Spraythawdar100% (2)

- RWGS Catalysis Review Daza, YolandaDocument17 pagesRWGS Catalysis Review Daza, YolandaDanielNo ratings yet

- SIPs Frequently Asked QuestionsDocument10 pagesSIPs Frequently Asked QuestionsJoe DinglasanNo ratings yet

- Nitoprime 25 TDS PDFDocument2 pagesNitoprime 25 TDS PDFgalih mahardikaNo ratings yet

- Mat 2640 For Suppliers PDFDocument3 pagesMat 2640 For Suppliers PDFbaskaran ayyapparajNo ratings yet

- AntifreezeDocument7 pagesAntifreezebobNo ratings yet

- Ejercicio Final - Api1104 PDFDocument6 pagesEjercicio Final - Api1104 PDFMau Atenas PerezNo ratings yet

- Learn About Your Plastic SheetDocument3 pagesLearn About Your Plastic SheetGhina Fatikah SalimNo ratings yet

- Cochrane, Nathan - Iatrogenic Damage To Enamel During Fixed Orthodontic TreatmentDocument1 pageCochrane, Nathan - Iatrogenic Damage To Enamel During Fixed Orthodontic TreatmentmalifaragNo ratings yet

- Physical Properties of Sucrose SolutionDocument23 pagesPhysical Properties of Sucrose Solutionbùi tuấn tùngNo ratings yet

- R (N) TSCGEWÖU 3,6/6 KV: Medium Voltage Reeling CablesDocument5 pagesR (N) TSCGEWÖU 3,6/6 KV: Medium Voltage Reeling CablesGoran MladenovicNo ratings yet

- PA9T GenstarDocument23 pagesPA9T Genstarsasikumar T MNo ratings yet

- Thermite Welding PDFDocument4 pagesThermite Welding PDFAmiableimpexNo ratings yet

- The - Treatment - of - Arsenic - Bearing - Ores Alkaline PDFDocument10 pagesThe - Treatment - of - Arsenic - Bearing - Ores Alkaline PDFSteven DziobaNo ratings yet

- Lak Nbs 25 10 XX T A 3005 A4 c01 Spec WllcvrngsDocument12 pagesLak Nbs 25 10 XX T A 3005 A4 c01 Spec WllcvrngsSofoniyas WorknehNo ratings yet

- As 2291-2007 Metallic Materials - Tensile Testing at Elevated TemperaturesDocument7 pagesAs 2291-2007 Metallic Materials - Tensile Testing at Elevated TemperaturesSAI Global - APACNo ratings yet

- BOQ & Methodolgy of RepairsDocument2 pagesBOQ & Methodolgy of Repairsswapnil gandhiNo ratings yet

- Tutorial 2 SPMDocument9 pagesTutorial 2 SPMYana JainNo ratings yet

- J Type Heat ExchangerDocument5 pagesJ Type Heat ExchangerAhmet Samet ÖzdilekNo ratings yet

- LPF Brochure 2021Document4 pagesLPF Brochure 2021André LaraNo ratings yet

- Benzalkonium ChlorideDocument1 pageBenzalkonium ChlorideVaibhav SankheNo ratings yet