Professional Documents

Culture Documents

Sierpinski Triangle - Stress Testi 1-1

Sierpinski Triangle - Stress Testi 1-1

Uploaded by

Cad Cam'lik NesnelerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sierpinski Triangle - Stress Testi 1-1

Sierpinski Triangle - Stress Testi 1-1

Uploaded by

Cad Cam'lik NesnelerCopyright:

Available Formats

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2, 34515

Esenyurt/İstanbul

Phone: +90 (541)-945-2005

alpermat06.wixsite.com

Simulation of Part2

Date: 28 Mart 2021 Pazar

Designer: Amir Hossein Safarinejad

Study name: Stress Testi 1

Analysis type: Static

Table of Contents

Description...........................................1

Assumptions..........................................2

Model Information..................................2

Study Properties.....................................3

Units..................................................3

Material Properties.................................4

Loads and Fixtures..................................4

Connector Definitions..............................5

Contact Information................................5

Mesh information....................................6

Sensor Details........................................7

Description Resultant Forces....................................8

Testing a Sierpinski Triangle Beams.................................................8

Study Results........................................9

Conclusion..........................................12

Analyzed with SOLIDWORKS Simulation Simulation of Part2 1

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2,

34515 Amir Hossein Safarinejad

Esenyurt/İstanbul 28.03.2021

Assumptions

Model Information

Model name: Part2

Current Configuration: Varsayılan

Solid Bodies

Document Name and Document Path/Date

Treated As Volumetric Properties

Reference Modified

Loft1

Mass:53,33 kg

Volume:0,333333 m^3

28 Mart 2021

Solid Body Density:159,99 kg/m^3

Weight:522,634 N

Analyzed with SOLIDWORKS Simulation Simulation of Part2 2

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2,

34515 Amir Hossein Safarinejad

Esenyurt/İstanbul 28.03.2021

Study Properties

Study name Stress Testi 1

Analysis type Static

Mesh type Solid Mesh

Thermal Effect: On

Thermal option Include temperature loads

Zero strain temperature 298 Kelvin

Include fluid pressure effects from Off

SOLIDWORKS Flow Simulation

Solver type FFEPlus

Inplane Effect: Off

Soft Spring: Off

Inertial Relief: Off

Incompatible bonding options Automatic

Large displacement Off

Compute free body forces On

Friction Off

Use Adaptive Method: Off

Result folder SOLIDWORKS document

(c:\users\hp\appdata\local\temp)

Units

Unit system: SI (MKS)

Length/Displacement mm

Temperature Kelvin

Angular velocity Rad/sec

Pressure/Stress N/m^2

Analyzed with SOLIDWORKS Simulation Simulation of Part2 3

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2,

34515 Amir Hossein Safarinejad

Esenyurt/İstanbul 28.03.2021

Material Properties

Model Reference Properties Components

Name: Balsa SolidBody 1(Loft1)(Part2)

Model type: Linear Elastic Isotropic

Default failure Unknown

criterion:

Yield strength: 2e+07 N/m^2

Elastic modulus: 3e+09 N/m^2

Poisson's ratio: 0,29

Mass density: 159,99 kg/m^3

Shear modulus: 3e+08 N/m^2

Curve Data:N/A

Loads and Fixtures

Fixture name Fixture Image Fixture Details

Entities: 1 face(s)

Type: Fixed Geometry

Fixed-1

Resultant Forces

Components X Y Z Resultant

Reaction force(N) 89,4421 44,7233 -0,0010224 100

Reaction Moment(N.m) 0 0 0 0

Load name Load Image Load Details

Entities: 1 face(s)

Type: Apply normal force

Value: 100 N

Force-1

Analyzed with SOLIDWORKS Simulation Simulation of Part2 4

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2,

34515 Amir Hossein Safarinejad

Esenyurt/İstanbul 28.03.2021

Sensor Details

No Data

Resultant Forces

Reaction forces

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N 89,4421 44,7233 -0,0010224 100

Reaction Moments

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N.m 0 0 0 0

Free body forces

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N -0,00656819 0,0015686 -0,00227825 0,00712685

Free body moments

Selection set Units Sum X Sum Y Sum Z Resultant

Entire Model N.m 0 0 0 1e-33

Analyzed with SOLIDWORKS Simulation Simulation of Part2 5

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2,

34515 Amir Hossein Safarinejad

Esenyurt/İstanbul 28.03.2021

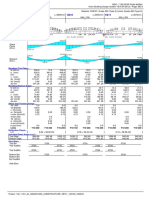

Study Results

Name Type Min Max

Stress1 VON: von Mises Stress 4,960e+01N/m^2 4,576e+02N/m^2

Node: 10898 Node: 10960

Part2-Stress Testi 1-Stress-Stress1

Name Type Min Max

Displacement1 URES: Resultant Displacement 0,000e+00mm 1,533e-04mm

Node: 1 Node: 250

Analyzed with SOLIDWORKS Simulation Simulation of Part2 6

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2,

34515 Amir Hossein Safarinejad

Esenyurt/İstanbul 28.03.2021

Name Type Min Max

Part2-Stress Testi 1-Displacement-Displacement1

Name Type Min Max

Strain1 ESTRN: Equivalent Strain 1,861e-08 1,056e-07

Element: 1762 Element: 4121

Analyzed with SOLIDWORKS Simulation Simulation of Part2 7

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2,

34515 Amir Hossein Safarinejad

Esenyurt/İstanbul 28.03.2021

Name Type Min Max

Part2-Stress Testi 1-Strain-Strain1

Name Type

Displacement1{1} Deformed shape

Analyzed with SOLIDWORKS Simulation Simulation of Part2 8

Aspanda STEM

Mevlana, Yıldırım Beyazıt Cd. No:3/2,

34515 Amir Hossein Safarinejad

Esenyurt/İstanbul 28.03.2021

Name Type

Part2-Stress Testi 1-Displacement-Displacement1{1}

Analyzed with SOLIDWORKS Simulation Simulation of Part2 9

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Deformations of Reinforced Concrete Members at Yielding and UltimateDocument84 pagesDeformations of Reinforced Concrete Members at Yielding and Ultimateazita1380No ratings yet

- Geomechanics Course BAKER HUGHES 2007 PDFDocument671 pagesGeomechanics Course BAKER HUGHES 2007 PDFFernandoAntonioAlvarezPacheco100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CPB30503 Petrochemicals & Petroleum Refining Technology Experiment 3: Determination of Viscosity of Oil Full Lab ReportDocument16 pagesCPB30503 Petrochemicals & Petroleum Refining Technology Experiment 3: Determination of Viscosity of Oil Full Lab ReportSiti Hajar Mohamed50% (2)

- Experiment Molar Volume of OxygenDocument10 pagesExperiment Molar Volume of OxygenJohn JosephNo ratings yet

- A Review of Water Hammer Theory and PracticeDocument12 pagesA Review of Water Hammer Theory and PracticeLuiz CamargoNo ratings yet

- Pressure Reducing Valves LunchBox Sessions 2Document1 pagePressure Reducing Valves LunchBox Sessions 2Nguyễn ĐạtNo ratings yet

- Test Report of TEST - 05 Strength of Materials (SOM03) - GATE (CE)Document8 pagesTest Report of TEST - 05 Strength of Materials (SOM03) - GATE (CE)himanshiNo ratings yet

- Distribution of Cooling To Avionics PDFDocument76 pagesDistribution of Cooling To Avionics PDFpuhumightNo ratings yet

- 6 MindmapDocument1 page6 MindmapHILMAN NAZRINo ratings yet

- Engineering Thermodynamics Lecture Notes (Draft) : Wayne HackerDocument24 pagesEngineering Thermodynamics Lecture Notes (Draft) : Wayne Hackerrkadiraj7011No ratings yet

- Rooftop VAV System PDFDocument6 pagesRooftop VAV System PDFMohamed ElarabiNo ratings yet

- Chapter 2 - Losses in Piping SystemsDocument30 pagesChapter 2 - Losses in Piping SystemsNicholas EmildasNo ratings yet

- Suction Head CalcDocument5 pagesSuction Head CalcNghiaNo ratings yet

- CH 18 TestDocument13 pagesCH 18 TestflorenciashuraNo ratings yet

- Pompa Booster 2X100LPM@10M (Mhi 402-1 - 0,55KW - 2900RPM)Document1 pagePompa Booster 2X100LPM@10M (Mhi 402-1 - 0,55KW - 2900RPM)Rinaldy AkbarNo ratings yet

- Stability Lect 1Document15 pagesStability Lect 1بركان معتصم مطشرNo ratings yet

- Reply To The Discussion by Robertson On Liquefaction Potential of Silts From Cptu''Document4 pagesReply To The Discussion by Robertson On Liquefaction Potential of Silts From Cptu''Diana DamianNo ratings yet

- 08 - Overall Momentum BalanceDocument16 pages08 - Overall Momentum BalanceClaire dela CruzNo ratings yet

- MMP-CKL-0007 PID Check ListDocument5 pagesMMP-CKL-0007 PID Check ListQWAS111No ratings yet

- Propiedades de RefrigerantesDocument70 pagesPropiedades de RefrigerantesBeatriz ReyesNo ratings yet

- ICEngine Cooling System PDFDocument9 pagesICEngine Cooling System PDFNavneet HannurkarNo ratings yet

- Borealis Po-Blown-Film-ApplicationsDocument4 pagesBorealis Po-Blown-Film-ApplicationsHafiani HichamNo ratings yet

- Friction Loss, Properties & Standard PipesDocument12 pagesFriction Loss, Properties & Standard PipesAyaEzzNo ratings yet

- BEAM DESIGN - As Per DTADocument4 pagesBEAM DESIGN - As Per DTAmuhammed sabir v aNo ratings yet

- Fluid Kinematics - 75Document13 pagesFluid Kinematics - 75prasaddeshmukh2312No ratings yet

- Pumps CalculationsDocument9 pagesPumps CalculationsahmadNo ratings yet

- AttachmentDocument58 pagesAttachmentBompoetseNo ratings yet

- Determining Erodibility and RSS NumbersDocument2 pagesDetermining Erodibility and RSS NumbersAngel PadillaNo ratings yet

- AssignmentDocument9 pagesAssignmentNikhita BeganiNo ratings yet

- Elmer TutorialsDocument152 pagesElmer TutorialsfabianoconbrasNo ratings yet