Professional Documents

Culture Documents

Cecomp: Cecomp Battery Powered Digital Pressure Gauges DPG1000B, F4B

Cecomp: Cecomp Battery Powered Digital Pressure Gauges DPG1000B, F4B

Uploaded by

Marco PantojaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cecomp: Cecomp Battery Powered Digital Pressure Gauges DPG1000B, F4B

Cecomp: Cecomp Battery Powered Digital Pressure Gauges DPG1000B, F4B

Uploaded by

Marco PantojaCopyright:

Available Formats

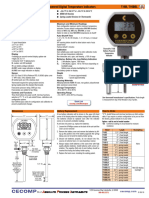

Cecomp® Battery Powered Digital Pressure Gauges

Quick Link: cecomp.com/bat DPG1000B, F4B

Ranges and Resolution Accuracy O ±0.25% Test Gauge Accuracy

Resolution is fixed and limited by number of display digits. 2, 20, Accuracy includes linearity, hysteresis, repeatability

Standard accuracy: ±0.25% of full scale ±1 least significant digit

O 316L Stainless Steel Wetted Parts

200, or 2000 ranges display 1.999, 19.99, 199.9, or 1999 respective-

ly. Please specify if vacuum gauge requires a minus sign. Contact HA accuracy option: ±0.1% FS ±1 LSD, see ranges for availability O Pressure, Vacuum, or Compound

factory for special engineering units. For models with more display Sensor hysteresis: ±0.015% FS, included in accuracy

O Ruggedized Design, Simple Operation

resolution or HA availability see F16B, F20B, F22B or CTP series. Sensor repeatability: ±0.01% FS, included in accuracy H H H H H H

H H H H H

Display

H H H H H H

G gauge reference pressure * 4 digit range

H H H H H

H H H H H H

H H H H H

H H H H H H

H H H H H

VAC gauge reference vacuum ‡ HA option not available 3 readings per second nominal display update rate

H H H H H H

A absolute reference Ranges to 2000: 3.5 digit (1999) LCD, 0.5" H digits

PSI Res inHg/PSI Res mmH2O Res Ranges >2000: 4 digit LCD, 0.5" H digits, Made in USA

3PSIG‡ .01 –30V15PSIG‡ .1 2000MMH2OG‡ 1 5 character 0.25" H alphanumeric lower display

BL models: Red LED display backlight

5PSIG‡ .01 –30V100PSIG‡ .1 cmH2O Res

Batteries, Low Battery Indication, Battery Life

15PSIA .01 –30V200PSIG‡ .1 200CMH2OG‡ .1

Two AA alkaline included

15PSIVAC‡ .01 inH2O Res 350CMH2OG‡ 1 Low battery indication on display (battery life is approximate)

±15PSIG‡ .1 85INH2OG‡ .1 1000CMH2OA 1 B ranges to 2000: 2500 hours

15PSIG .01 140INH2OG‡ .1 1000CMH2OVAC‡ 1 B ranges >2000: 2000 hours

BBL ranges to 2000: 180 hours

30PSIA‡ .1 400INH2OA 1 ±1000CMH2OG‡ 1

BBL ranges >2000: 150 to 1500 hours

30PSIG‡ .1 400INH2OVAC‡ 1 1000CMH2OG 1

Controls

60PSIG .1 ±400INH2OG‡ 1 2000CMH2OA 1 B ranges to 2000: Front button turns gauge on/off, starts auto

100PSIA .1 400INH2OG 1 2000CMH2OG 1 shutoff timer DPG1000B DPG1000B 4 Digit Ranges

–15V100PSIG‡ .1 830INH2OA 1 kPa Res BL ranges to 2000: Front button turns gauge on/off, starts auto

100PSIG .1 830INH2OG 1 20KPAG‡ .01 shutoff timer, backlight is on when gauge is on.

B ranges >2000: Front button turns gauge on/off, starts auto

–15V200PSIG‡ .1 ftH2O Res 35KPAG‡ .1 shutoff timer, zeros display (gauge ref. only)

200PSIG .1 7FTH2O‡ .01 100KPAA .1 BL ranges >2000: Front button turns gauge on/off, starts auto

300PSIG‡ 1 12FTH2O‡ .01 100KPAVAC‡ .1 shutoff timer, activates backlighting for one

500PSIG 1 35FTH2O‡ .1 ±100KPAG‡ .1 minute, zeros display (gauge ref. only)

1000PSIG 1 70FTH2O .1 100KPAG .1 Auto Shutoff

Factory set to 5, 10, 30 minutes, or on/off

2000PSIG 1 140FTH2O .1 200KPAA .1

Calibration

3000PSIG* 1 230FTH2O‡ 1 200KPAG .1

Ranges to 2000: Front calibration potentiometers, non-interactive

5000PSIG* 1 460FTH2O 1 400KPAG 1 zero and span, ±10% range

oz/in2 Res 700FTH2O 1 700KPAA 1 Ranges >2000: Internal calibration buttons, non-interactive F4B, NEMA 4X F4B, NEMA 4X 4 Digit Ranges

48ZING‡ .1 1150FTH2O 1 700KPAG 1 zero, span, and linearity, ±10% of range

80ZING‡ .1 mmHg Res –100V700KPAG‡ 1 Housing How to Specify Type

DPG1000B: Extruded aluminum case, epoxy powder coated, ABS/ DPG1000B range - time - options Standard housing

240ZINA‡ 1 150MMHGG‡ .1 1400KPAG 1

polycarbonate bezel (aluminum bezel optional), front and rear gas- Standard housing, backlit

240ZINVAC‡ 1 260MMHGG‡ 1 –100V1400KPAG‡ 1 DPG1000BBL range - time - options

kets, polycarbonate label. NEMA 2. display

±240ZING‡ 1 760MMHGA 1 2000KPAG 1 F4B range - time - options NEMA 4X housing

F4B: UV stabilized ABS/polycarbonate case, polycarbonate display

240ZING‡ 1 760MMHGVAC‡ 1 MPa Res window, polycarbonate front label, rear gasket, s ix stainless steel cover NEMA 4X housing,

F4BBL range - time - options

480ZINA 1 ±760MMHGG‡ 1 1.4MPAG .001 screws. NEMA 4X, not intended for permanent outdoor installations. backlit display

480ZING 1 760MMHGG 1 –0.1V1.4MPAG‡ .001 Weight Range: See table at left

inHg Res 1600MMHGA 1 2MPAG .001 Approximately 9 ounces, shipping weight 1 pound.

Time—auto shutoff time (factory programmed)

6INHGG‡ .01 1600MMHGG 1 3.5MPAG‡ .01 Connection and Material 5 5 minutes. Default if not specified.

10INHGG‡ .01 Torr Res 7MPAG .01 1/4" NPT male fitting, 316L stainless steel

All wetted parts are 316L stainless steel 10 10 minutes

30INHGA‡ .1 760TORRA 1 14MPAG .01 30 30 minutes

Overpressure, Burst, Vacuum

30INHGVAC‡ .1 760TORRVAC‡ 1 20MPAG .01 ON No auto shutoff. On/off via front button.

Ranges using 3000 psig sensor: 5000 psig

±30INHGG‡ .1 1600TORRA 1 35MPAG‡ .1 Ranges using 5000 psig sensor: 7500 psig Options—add to end of model number. Factory installed only.

30INHGG‡ .1 mbar Res g/cm2 Res All others: 2 X pressure range See cecomp.com/accessories for details.

60INHGA .1 200MBARG‡ .1 200GCMG‡ .1 3000 psi, 5000 psi, and 4 digit ranges 112.5% full scale out-of- HA High accuracy, ±0.1% FS ±1 LSD. See range table.

60INHGG .1 350MBARG‡ 1 350GCMG‡ 1 range display: 1– – – or I –.–.–.– PM Panel mount, 4.1" x 4.1", n/a NEMA 4X, factory installed.

120INHGG .1 1000MBARA 1 1000GCMA 1 4 X sensor burst pressure rating, or 10,000 psi, whichever is less Sealed housing and CC for high humidity food process-

FP

200INHGA .1 1000MBARVAC‡ 1 1000GCMVAC‡ 1 Vacuum service: 15 psia, ±15 psig, 15 psig, 30 psia, ing applications. NEMA 4X absolute ref. ranges only.

–30V200INHGG‡ .1 ±1000MBARG‡ 1 ±1000GCMG‡ 1 100 psig, 100 psia, 200 psig sensors MC Metal front cover instead of plastic, n/a NEMA 4X

200INHGG .1 1000MBARG 1 1000GCMG 1 Environmental Temperatures CS Case bottom stiffener plate, n/a NEMA 4X

Storage temperature: –40 to 203°F (–40 to 95°C) CC Moisture resistant circuit board conformal coating

–30V400INHGG‡ 1 2000MBARA 1 2000GCMA 1

Operating (3.5 digit versions): –40 to 185°F (–40 to 85°C) TP Top port, gauge port on top of case, n/a NEMA 4X

400INHGG 1 2000MBARG 1 2000GCMG 1 Operating (4 digit versions): –4 to 185°F (–20 to 85°C)

SM Surface mount plate, n/a NEMA 4X

600INHGG 1 bar Res kg/cm2 Res Sensor compensated range: 32 to 158°F (0 to 70°C)

Calibration Cert. Options—add to end of model number

1000INHGG 1 1BARA .001 1KGCMA .001

CD Calibration data, 5 test points and date

2000INHGG 1 1BARVAC‡ .001 1KGCMVAC‡ .001

NC NIST traceability documentation, 5 points and date

atm Res ±1BARG‡ .001 ±1KGCMG‡ .001

2.88" 3.0"

1ATMA .001 1BARG .001 1KGCMG .001

±1ATMG‡ .001 2BARA .001 2KGCMA .001 3.5 digit TP

models only F4B Top gauge port. Primarily used with tire pressure

1ATMG .001 2BARG .001 2KGCMG .001 NEMA 4X applications. Not available with NEMA 4X models.

2ATMA .001 4BARG .01 4KGCMG .01 Span Zero

2ATMG .001 7BARA .01 7KGCMA .01 Accessories—order separately

4ATMG .01 7BARG .01 7KGCMG .01 RB

7ATMA .01 –1V7BARG‡ .01 –1V7KGCMG‡ .01 0.75" High visibility orange rubber boot protects gauge

¼" NPT Turn at hex

fitting

7ATMG .01 14BARG .01 14KGCMG .01 only! for portable applications. Not available with NEMA

3.38" 1.65" 2.0" 4X models.

14ATMG .01 –1V14BARG‡ .01 –1V14KGCMG‡ .01

3.5 digit models use plastic caps on potentiometers, F4 covers are SCR14SS

20ATMG .01 20BARG .01 20KGCMG .01 nylon screws with o-rings. 4 digit models use internal buttons. Filter screen fitting keeps debris out of gauge

34ATMG† .1 35BARG‡ .1 35KGCMG‡ .1 sensor. For food vacuum packaging applications.

70ATMG .1 70BARG .1 70KGCMG .1 Examples 303SS body, 100 micron 304SS screen.

140ATMG .1 140BARG .1 140KGCMG .1 DPG1000B100PSIG-5-HA: 100.0 psig, 5 min. shutoff, high accuracy CON14SS

200ATMG .1 200BARG .1 200KGCMG .1 F4BBL–100V700KPAG-ON: NEMA 4X, backlit display, –100 to Quick connector to install or remove gauge with-

700 kPa, on/off via front button out tools. 304 stainless steel, urethane seal.

340ATMG‡ 1 350BARG‡ 1 350KGCMG‡ 1

CE C O MP Div. of ABSOLUTE PROCESS INSTRUMENTS 1220 American Way Libertyville, IL 60048

800-942-0315 cecomp.com © 08-20

Instructions DPG1000B, F4B

Types of Gauges The full-scale range is indicated and the display is tested. Calibration, 4 Digit Models

Gauge reference types read zero with the gauge port open. Continue to press the button until ooo o is displayed and then Entering Calibration Mode

Bipolar ranges read positive pressure and vacuum in the same release the button. The gauge is now zeroed and ready for use. Remove the rear cover to gain access to the UP and DOWN buttons

units, and zero with the gauge port open. Attempting to zero the gauge with pressure greater than approxi- located near the lower right and left corners of the circuit board.

1000 psi and higher sensor are a sealed reference type. They read mately 3% of full-scale applied will result in an error condition,

zero with the gauge port open are internally referenced to 14.7 psi and the display will alternately indicate Err0 and the actual

and are functionally similar to gauge reference models. measured pressure. The gauge must be powered down to reset

the error condition.

Absolute reference gauges read zero at full vacuum and atmo-

spheric pressure with the gauge port open. Open port readings will During normal operation, the pressure reading is updated approxi-

vary continuously due to the effects of barometric pressure. mately 3 times per second. The auto shutoff timer starts when the

gauge is powered up or whenever the button is pushed, unless

Precautions the gauge was ordered without an auto shutoff time (-ON option).

4 Gauges are not intended for permanent outdoor use. Protect from If excessive vacuum is applied to a pressure-only gauge, the

weather and excessive humidity. NEMA 4X models are suitable for display will indicate –E rr until the vacuum is released. Applying

temporary outdoor use and wash down areas. vacuum to a gauge designed for pressure may damage the pres-

4 Protect gauge from damage by weather, temperature sure sensor. If excessive pressure is applied (112.5% over range),

extremes, humidity, or impact. an out-of-range indication of I – – – or I –.–.–.– will be displayed

4 Read and understand all instruction sheet information. Contact depending on model.

your dealer for help, instructions, or repairs. BL model display backlighting can be turned on by momentarily

DOWN UP

4 Avoid sensor damage! Never insert objects into the gauge port pressing the button whenever the gauge is on. The backlight will

or blow out with compressed air. turn on for one minute and then automatically shut off. This also

4 Avoid sensor damage! Do not apply vacuum to non-vacuum restarts the auto shutoff timer. The display backlighting will not be With the gauge off, press and hold the DOWN calibration button,

gauges or hydraulic vacuum to any gauges. Positive displacement apparent under bright lighting conditions. and also press the front button.

liquid pumps must include devices to protect gauge from pressure To shut off the gauge at any time, press and hold the button until The full-scale pressure range and display test is shown, and then

spikes, acceleration head, and vacuum extremes. the display indicates OFF (about 5 seconds) and then release. CAL is displayed to indicate that the calibration mode is enabled.

4 For contaminated media, use a screen or filter to avoid clogging For gauges with auto shutoff, the display indicates OFF five Release all buttons. The gauge enters and remains in the calibration

gauge port with debris. seconds prior to auto shutoff. The button can be pressed to keep mode until restarted manually or power is removed. Features not

4 Thread sealant should be used to ensure leak-free operation. the gauge on. The auto shutoff and backlight (if equipped) timers related to calibration are disabled. If the battery pack is unplugged

are reset whenever the button is pressed and released. or the power removed during calibration, settings will not be saved.

Do not exceed pressure range indicated on gauge label.

If the gauge was ordered without auto shutoff (-ON option) it will The display will indicate the current pressure reading, updating

Remove system pressure before removing or installing gauge. stay on until manually shut off or until the batteries are depleted. approximately 3 times per second.

Use fittings appropriate for the pressure range of the gauge. Turn gauge off when not in use to conserve battery life.

Each press of the UP or DOWN button makes a small correction,

Only gauges marked as Intrinsically Safe can be used in haz- Battery Replacement which may not always be indicated on the display. Press and hold

ardous locations or in the presence of flammable or explosive the button for one second or longer to make larger corrections.

A low battery indication (either LOBAT or a symbol depending on the

substances, or atmospheres. The gauge's display is adjusted to match the calibrator’s reading.

model) will be shown in the upper left corner of the display when

Media being measured must be compatible with 316L stainless the battery voltage falls sufficiently. The battery should be replaced Gauge Reference Ranges (3 Points)

steel. soon after the indicator comes to prevent unreliable readings. With the gauge port open to atmosphere, the character display will

Media temperature and gauge ambient tempera- WARNING: Batteries must be changed in a non-hazardous location alternate between ZERO and CAL. Press the UP and DOWN buttons

Do not

ture must be within specified ranges. force only. Do not mix different batteries or fresh batteries with old. to obtain a display indication of zero.

Gauges are not for oxygen service. Accidental housing! Replace both batteries with new ones at the same time. Apply full-scale pressure (or vacuum for vacuum gauges). The

Use a

rupture of sensor diaphragm may cause silicone wrench 1. Remove the 6 Phillips screws on the back of the gauge. character display will alternate between +SPAN and CAL. Press

oil inside sensor to react with oxygen. on hex the UP and DOWN buttons to obtain a display indication equal to

fitting to 2. Remove battery retainer clip.

Use specified batteries or power as shown in the install or full-scale pressure.

3. Remove batteries by lifting up the positive end of the battery

instructions. Improper voltages will damage the remove. Apply 50% of full-scale pressure. The character display will

(opposite the spring) taking care not to bend the spring.

gauge. Gauges do not contain user-serviceable alternate between +MID and CAL. Use the UP and DOWN buttons

parts. 4. Discard old batteries properly. See battery manufacturer's to obtain a display indication equal to 50% of full-scale pressure.

recommendations for disposal or recycling.

Cecomp maintains a constant effort to upgrade and improve its products. Absolute Reference Ranges (3 Points)

Specifications are subject to change without notice. See cecomp.com for 5. Install batteries with correct orientation. Insert the negative (flat) Apply full vacuum to the gauge. The character display will alternate

latest product information. Consult factory for your specific requirements. end of each battery first towards the battery holder spring. between ZERO and CAL. Press the UP and DOWN buttons to obtain

WARNING: This product can expose you to chemicals includ- 6. Replace the clip and back cover, including the rubber gasket. a display indication of zero.

ing nickel and chromium, which are known to the State of Cal-

ifornia to cause cancer or birth defects or other reproductive Calibration Preparation Apply full-scale pressure. The character display will alternate

harm. For more information go to www.P65Warnings.ca.gov Gauges are factory calibrated at approximately 23°C using NIST between +SPAN and CAL. Press the UP and DOWN buttons to obtain

traceable calibration equipment. Calibration is not required before a display indication equal to full-scale pressure.

Disposal of Electrical & Electronic Equipment Applicable

in the European Union and other European countries. using the gauge. Calibration intervals depend on your quality stan- Apply 50% of full-scale pressure. The character display will alter-

dards, but annual re-calibration is customary. Calibration should nate between +MID and CAL. Press the UP and DOWN buttons to

This product should not be treated as household waste

only be performed by qualified individuals using appropriate cali- obtain a display indication equal to 50% of full-scale pressure.

when you wish to dispose of it. Please contact your local

bration standards and procedures. Bipolar (±) and Compound Ranges (4 or 5 Points)

waste disposal authority for information and collection

location for recycling electrical and electronic equipment. Calibration equipment is not required to zero gauge reference With the gauge port open to atmosphere, the character display will

You may also return this product via pre-paid shipping ranges. Absolute reference ranges may be zeroed with application alternate between ZERO and CAL. Press the UP and DOWN buttons

to Absolute Process Instruments or your supplier for proper disposal. of full vacuum. to obtain a display indication of zero.

Operation, 3.5 Digit Models Span calibration should only be performed using calibration stan- Apply full-scale positive pressure. The character display will alter-

dards that are at least four times more accurate than the gauge nate between +SPAN and CAL. Press the UP and DOWN buttons to

Press the button on the front of the gauge to activate the display.

being calibrated. obtain a display indication equal to full-scale pressure.

The gauge can be shut off at any time by pressing the button again.

The calibration system must be able to generate and measure pres- Apply 50% of full-scale positive pressure. The character display will

The gauge will stay on for a period of time determined by the auto sure/vacuum over the full range of the gauge. A vacuum pump able alternate between +MID and CAL. Press the UP and DOWN buttons

shutoff time. If the gauge was ordered without auto shutoff (-ON) to produce a vacuum of 100 microns (0.1 torr or 100 millitorr) or to obtain a display indication equal to 50% of full-scale pressure.

it will stay on until the button is pressed or until the batteries are lower is required for vacuum and absolute gauges. Apply full vacuum. The character display will alternate between –

depleted.

Install fresh batteries before calibrating battery-powered gauges. SPAN and CAL. Press the UP and DOWN buttons to obtain a display

Display backlighting for BL models is on whenever the gauge is indication equal to the full vacuum reading.

Allow the gauge to equalize to normal room temperature for

on. The backlighting will not be apparent under bright lighting

approximately 20 minutes before calibration. Gauges using a ±15 psig sensor have a –MID calibration point.

conditions.

Calibration, 3.5 Digit Models Apply 50% of the full-scale vacuum range (for example, –7.4 psi

Turn gauge off when not in use to conserve batteries. for a ±15 psi gauge). The character display will alternate between

Remove the front covers to access the zero and span calibration

Operation, 4 Digit Models –MID and CAL. Press the UP and DOWN buttons to obtain a display

potentiometers. F4B models use nylon cover screws.

Press and hold the front button for approximately 1 second. indication equal to 50% of full-scale vacuum.

Gauges may be re-zeroed without affecting the span calibration. For

The full-scale range is indicated, the display is tested, and the read- Exit Calibration Mode and Verify Calibration

gauge reference models the gauge port must be open to the ambi-

ing and units are displayed. Exit the calibration mode and save the calibration data by pressing

ent. For absolute reference models full vacuum must be applied.

and holding the front button until the display indicates OFF.

The gauge may be zeroed at power-up. The temporary zero correc- Adjust the zero control until the gauge reads zero with the minus (–)

tion is erased when the gauge is shut off. Verify readings at 0%, 25%, 50%, 75%, and 100% of full scale.

sign occasionally flashing.

Absolute reference gauges do not use the zero feature since they Replace the rear cover and screws, taking care not to pinch the

Zero calibration must be done before span calibration. Using the

normally read atmospheric pressure. battery leads between the case and the rear cover.

appropriate pressure standards, record readings at three to five

Expose the gauge port to normal atmospheric pressure. Press and points over the range of gauge and adjust span control to minimize

hold the front button. error and meet specifications.

CE C O MP Div. of ABSOLUTE PROCESS INSTRUMENTS 1220 American Way Libertyville, IL 60048

800-942-0315 cecomp.com

You might also like

- Control Basic Pool Baeza: Installation ManualDocument32 pagesControl Basic Pool Baeza: Installation ManualJ M E60% (5)

- Level CalculationDocument11 pagesLevel Calculationkali bangonNo ratings yet

- Cecomp t16bDocument2 pagesCecomp t16bkriss05No ratings yet

- Cecomp Gas KitsDocument2 pagesCecomp Gas KitsbasarNo ratings yet

- DM7442A BCD To Decimal Decoder: General Description FeaturesDocument4 pagesDM7442A BCD To Decimal Decoder: General Description FeaturesMahmoud SakkalNo ratings yet

- DM7442A BCD To Decimal Decoder: General Description FeaturesDocument4 pagesDM7442A BCD To Decimal Decoder: General Description FeaturesPedroNo ratings yet

- Large Screen U3000Document1 pageLarge Screen U3000Francisco OrtizNo ratings yet

- HHP240Document1 pageHHP240Kiran KarthikNo ratings yet

- 74hc154 PDFDocument7 pages74hc154 PDFjpana3467No ratings yet

- 74 HC 42Document6 pages74 HC 42Kiran ParuNo ratings yet

- DM7445 BCD To Decimal Decoders/Drivers: General Description FeaturesDocument4 pagesDM7445 BCD To Decimal Decoders/Drivers: General Description FeaturesSyaiful RahmanNo ratings yet

- 3 To 8 Line Decoder (Inverting) : Order CodesDocument10 pages3 To 8 Line Decoder (Inverting) : Order CodesMahmoud SakkalNo ratings yet

- MM74HC4538 Dual Retriggerable Monostable Multivibrator: General DescriptionDocument10 pagesMM74HC4538 Dual Retriggerable Monostable Multivibrator: General DescriptionAlex WongNo ratings yet

- 9601/DM9601 Retriggerable One Shot: General Description FeaturesDocument6 pages9601/DM9601 Retriggerable One Shot: General Description FeaturesMiguel Angel Pinto SanhuezaNo ratings yet

- Dpi330 335Document4 pagesDpi330 335marketing.socintecNo ratings yet

- General Specifications: EJA118E Diaphragm Sealed Differential Pressure TransmitterDocument22 pagesGeneral Specifications: EJA118E Diaphragm Sealed Differential Pressure Transmittersumit kumarNo ratings yet

- Creatine Kinase: InstrumentDocument1 pageCreatine Kinase: InstrumentEnrique DuarteNo ratings yet

- HD74HC147: 10-To-4-Line Priority EncoderDocument6 pagesHD74HC147: 10-To-4-Line Priority EncoderPerumal NamasivayamNo ratings yet

- Brochure Yumizen H500 GBDocument4 pagesBrochure Yumizen H500 GBAniket dubeyNo ratings yet

- Smart Calling Bell ProjectDocument9 pagesSmart Calling Bell ProjectShanzida AkterNo ratings yet

- GS Eja 430e Ed 10Document14 pagesGS Eja 430e Ed 10mu khaledNo ratings yet

- 430a-3 Gs01c31e01-01en - 006Document14 pages430a-3 Gs01c31e01-01en - 006Yoyok WiratmoNo ratings yet

- Haier Hl24xd2 Ver.a00Document46 pagesHaier Hl24xd2 Ver.a00Cheo ParraNo ratings yet

- Broad Line-Up of The New H7E SeriesDocument33 pagesBroad Line-Up of The New H7E SeriesFarich Putra GunawanNo ratings yet

- Broad Line-Up of The New H7E SeriesDocument33 pagesBroad Line-Up of The New H7E SeriesRifki IrawanNo ratings yet

- HI 902 Titrator Wine ApplicationsDocument4 pagesHI 902 Titrator Wine Applicationsalex_giaanNo ratings yet

- SDVC31 ManualDocument48 pagesSDVC31 ManualMartin GandaraNo ratings yet

- PAMB10/11: Precision Pressure IndicatorsDocument2 pagesPAMB10/11: Precision Pressure IndicatorsEliana GuzmanNo ratings yet

- Alanine Aminotransferase (Alt/Gpt) : InstrumentDocument1 pageAlanine Aminotransferase (Alt/Gpt) : InstrumentEnrique DuarteNo ratings yet

- HD74HC83: 4-Bit Binary Full Adder (With Fast Carry)Document7 pagesHD74HC83: 4-Bit Binary Full Adder (With Fast Carry)SaibNo ratings yet

- DM7490A Decade and Binary Counter: General Description FeaturesDocument6 pagesDM7490A Decade and Binary Counter: General Description FeaturessalNo ratings yet

- Ic DatasheetDocument20 pagesIc DatasheetINTAN ARDELIANo ratings yet

- General Specifi Cations: EJA430E Gauge Pressure TransmitterDocument15 pagesGeneral Specifi Cations: EJA430E Gauge Pressure TransmitterRam KumarNo ratings yet

- Categorizing Faults Via DGA: GE Grid Solutions M&DDocument30 pagesCategorizing Faults Via DGA: GE Grid Solutions M&DMurali KrishnaNo ratings yet

- Rotronic HygroPalm HP32 User ManualDocument5 pagesRotronic HygroPalm HP32 User ManualJimena LavigneNo ratings yet

- Medical LCD Monitor: EJ-MLA26E - EJ-MLA32E-WDocument6 pagesMedical LCD Monitor: EJ-MLA26E - EJ-MLA32E-WarturoNo ratings yet

- LitoLite 5C USER MANUAL (NANLITE)Document22 pagesLitoLite 5C USER MANUAL (NANLITE)hannugrenNo ratings yet

- Auto Hematology Analyzer: Minimum Size, Maximum CapabilityDocument2 pagesAuto Hematology Analyzer: Minimum Size, Maximum CapabilityAmine Arabi0% (1)

- Yumizen H500 Brochure enDocument4 pagesYumizen H500 Brochure enPopov100% (1)

- Gs01c31e01 01enDocument16 pagesGs01c31e01 01enElectro TractrixNo ratings yet

- Oracle™: Rapid NMR Fat AnalyzerDocument12 pagesOracle™: Rapid NMR Fat AnalyzerMelanyNo ratings yet

- Co Hi2211-2210 en 280211Document4 pagesCo Hi2211-2210 en 280211Ali RizviNo ratings yet

- MM54HC155/MM74HC155 Dual 2-To-4 Line Decoder/Demultiplexers: General DescriptionDocument4 pagesMM54HC155/MM74HC155 Dual 2-To-4 Line Decoder/Demultiplexers: General DescriptionORIONNo ratings yet

- PH 100 PH Meter 3 Point CalDocument2 pagesPH 100 PH Meter 3 Point CalSunny Balyan BhajjuNo ratings yet

- Huai I Electronics Co., LTD.: SpecificationDocument6 pagesHuai I Electronics Co., LTD.: SpecificationLuis Otavio TrindadeNo ratings yet

- Phep Hi 98107 Instruction ManualDocument2 pagesPhep Hi 98107 Instruction ManualJunaid AhmadNo ratings yet

- Druck - Dpi 705 SeriesDocument4 pagesDruck - Dpi 705 Seriesbugoff700No ratings yet

- CA ArsenazoDocument1 pageCA ArsenazoEnrique DuarteNo ratings yet

- GS01C31C01 01en PDFDocument21 pagesGS01C31C01 01en PDFfeliza semeleketeNo ratings yet

- Connect Directly To Your Computer: Px409-Usbh SeriesDocument4 pagesConnect Directly To Your Computer: Px409-Usbh SeriesSergio Belmar CrisostoNo ratings yet

- Cosmo Converter PDFDocument11 pagesCosmo Converter PDFIsmail ElisNo ratings yet

- Anel Overview: Front Panel Overview Display ControlsDocument6 pagesAnel Overview: Front Panel Overview Display ControlsLois Louie Follosco ArcellanaNo ratings yet

- Demo 22Document3 pagesDemo 22MitpdfNo ratings yet

- Che PDFDocument1 pageChe PDFEnrique DuarteNo ratings yet

- Cholinesterase: InstrumentDocument1 pageCholinesterase: InstrumentEnrique DuarteNo ratings yet

- 74ALS138 - DemultiplexerDocument6 pages74ALS138 - DemultiplexerDwp BhaskaranNo ratings yet

- Datasheet HCH-1000 PDFDocument4 pagesDatasheet HCH-1000 PDFJAIR ALBERTO ORTIZ AREVALONo ratings yet

- NationalSemiconductorDocument2 pagesNationalSemiconductorkowalmat2002No ratings yet

- Top 12 Hex Inverter ICs - All You Should KnowDocument13 pagesTop 12 Hex Inverter ICs - All You Should KnowjackNo ratings yet

- MP Industrial Development CorporationDocument8 pagesMP Industrial Development Corporationkuldeep_jain01100% (1)

- Evo 8GR00003600-52BDocument12 pagesEvo 8GR00003600-52BMACHINo ratings yet

- EV5 Midterm Test 2ADocument6 pagesEV5 Midterm Test 2Arenato aquinoNo ratings yet

- fr150 Series User Manual en v1.2Document131 pagesfr150 Series User Manual en v1.2Hendrewel Ferreira NunesNo ratings yet

- Electronic Troll System Using RfidDocument38 pagesElectronic Troll System Using RfidJashwanth ReddyNo ratings yet

- TX - Tektronix - 4.0 Test Procedure 1 - 0 PDFDocument50 pagesTX - Tektronix - 4.0 Test Procedure 1 - 0 PDFYou TimNo ratings yet

- RaychemTraceTek TTSIM2 ModuleDocument3 pagesRaychemTraceTek TTSIM2 ModuleKevin WokNo ratings yet

- Innovations O2D Image Sensor: Fluid Sensors and Diagnostic SystemsDocument4 pagesInnovations O2D Image Sensor: Fluid Sensors and Diagnostic SystemssandeshshivaNo ratings yet

- Tiduby 4 ADocument47 pagesTiduby 4 ArichatNo ratings yet

- Everyday Electronics 1978 12Document68 pagesEveryday Electronics 1978 12Bimbike81No ratings yet

- Perhitungan Tata SuaraDocument2 pagesPerhitungan Tata SuaraIHSAN ROHMATULLAH 2021No ratings yet

- UENR90610001Document58 pagesUENR90610001wrya hussainNo ratings yet

- ELEXDocument14 pagesELEXHazel Grace del MonteNo ratings yet

- WGMD 60 5m Quotation SheetDocument1 pageWGMD 60 5m Quotation SheetAldo VillacortaNo ratings yet

- Fluxometer Spray Fluxing PaperDocument17 pagesFluxometer Spray Fluxing PaperPankaj ChoureNo ratings yet

- Lab 3 DMM and DC Power SupplyDocument11 pagesLab 3 DMM and DC Power SupplyNabeeL 6669No ratings yet

- A Guide To DCCDocument32 pagesA Guide To DCCVed NarsekarNo ratings yet

- CH10 Voltage AmplifierDocument58 pagesCH10 Voltage Amplifierjhonrey ebonesNo ratings yet

- Department of Electronics Engineering: Experiment NoDocument7 pagesDepartment of Electronics Engineering: Experiment NoPratik TelangNo ratings yet

- MDFu 74Document47 pagesMDFu 74Rhishidas PuthiyavalappilNo ratings yet

- Tle9 Q2mod6 Electrical-Schematic Drawings Simeon Pongtan v1Document25 pagesTle9 Q2mod6 Electrical-Schematic Drawings Simeon Pongtan v1ISABEL GASES100% (1)

- Magnetic Effects of Electric Current Class 10 Notes Science Chapter 13 - Learn CBSEDocument16 pagesMagnetic Effects of Electric Current Class 10 Notes Science Chapter 13 - Learn CBSEKanish ChourasiaNo ratings yet

- Manual Garmin 35Document41 pagesManual Garmin 35Inttec ltdaNo ratings yet

- 6KW Hybrid Sardar AyazDocument1 page6KW Hybrid Sardar Ayazzaka chNo ratings yet

- Mini Offline UPSDocument13 pagesMini Offline UPSGadhiya KhimjiNo ratings yet

- PDF Program Kerja It Rsu XXX - CompressDocument10 pagesPDF Program Kerja It Rsu XXX - CompressBabarNews Bangka BaratNo ratings yet

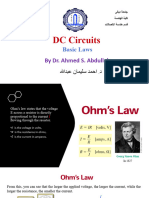

- Basic LawsDocument13 pagesBasic LawsjubahewashereNo ratings yet

- Exp Section-ADocument10 pagesExp Section-ABilal MalikNo ratings yet

- Practical Electronics September 2019 Avxhm - SeDocument86 pagesPractical Electronics September 2019 Avxhm - SellonllonNo ratings yet