Professional Documents

Culture Documents

Mott Macdonald: Tee To Cancel

Mott Macdonald: Tee To Cancel

Uploaded by

ramanna kodandaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mott Macdonald: Tee To Cancel

Mott Macdonald: Tee To Cancel

Uploaded by

ramanna kodandaCopyright:

Available Formats

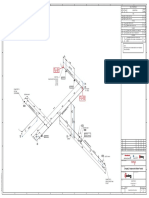

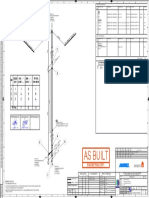

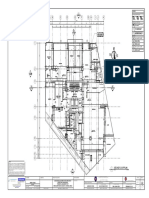

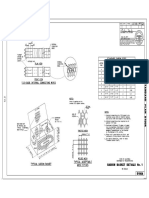

A B C D E F G H J K

ELEMENT DESCRIPTION ND QUANTITY

(in)

PIPING

1 PIPE, PE, S-80, ASME B36.10M, ASTM A106 Gr.B 1.1/2 11328 MM

N FITTINGS

2 CONCENTRIC SWAGED NIPPLE, PBE, S-80 x S-80, MSS SP-95, ASTM A234 2X1.1/2 1

33 Gr.WPB, SEAMLESS

8 8

5 3 TEE, SW, CL3000, ASME B16.11, ASTM A105 1.1/2X 1

90° 33 34 1.1/2

4 REDUCING INSERT, SW, CL3000, MSS SP-79, ASTM A105 1.1/2X1/2 1

13 5 90º ELBOW, SW, CL3000, ASME B16.11, ASTM A105 1.1/2 11

206 6 3

2

22 31 1.1/2X1.1/2"DN

6 45º ELBOW, SW, CL3000, ASME B16.11, ASTM A105 1.1/2 1

33 22 24 33 7 REDUCING INSERT, SW, CL3000, MSS SP-79, ASTM A105 1/2X1/4 1

1 E 10157511

FLANGES

5 1 23 N 8887086

25 EL +2283

Tee to cancel 8 SOCKET FLANGE, Class 150, RF, ASME B16.5, ASTM A105 2 1

90° 28 GASKETS

1 27 4 76

20 1 33 9 ASBESTOS FREE FIBER REINFORCED GASKET, 1.5 MM, 150 Lbs, RF, ASME 2 1

26

6 B16.21

29 33

21

45° 1 BOLTS & NUTS

33

18 23

22 2012.01.23 10 STUDBOLTS, ASME B18.2.1, ASTM A193 Gr.B7, BICHROMATED - 76.2 mm

Length

5/8 4

5 5 7 19

240

7 30 18 1/2X1/4"DN 5 11 HEAVY HEXAGONAL NUT, ASME B18.2.2, ASTM A194 Gr.2H, BICHROMATED 5/8 8

7

13 90°

1

1.1/2"DN 1 CONTINUE ON ISO:

9

24MKG30BR305 18

E 10157511

N 8887086

CONTINUE ON EQUIPMENT: EL +2214 1 33

H2 GAS SKID

13

Nozzle : TP#91 13

1.5 in RFFE CL150 S-80

E 10156959 5 17

N 8887473 90°

EL +2000

6 16 33 6

CONTINUEONEQUIPMENT:

GTG OMEGA COOLER:

CONTINUE ON ISO: Nozzle:TP#015(PURGEGASBOTTOMMANIFOLD)

33 2 in RFFECL150S-STD

24MKG30BR305

E 10154346

N 8882643

EL +4045

1

F8 G9 B10/11

5 33 5

90° 90°

31 EL +2283

22

5 25 33 5

12 5

13 1

1 33

5 15 14 11 DIMENSIONS_/_LEVELS_/_COORDINATES PROJECTION

443 5

90° 1. All Dimensions are in mm unless otherwise specified.

2. All Ground Levels, Elevation Levels are in millimeters.

CONTINUE ON EQUIPMENT: 33 3. All Coordinates are as per DUBAL / EMAL Grids.

GTG OMEGA COOLER 10

Nozzle : TP#015 (PURGE GAS BOTTOM MANIFOLD)

2 in RFFE CL150 S-STD 33

E 10154197 33

30 33

33 33

N 8881002 40 1

EL +4045 66 1

40 165 Rev. Date Description Drawn Checked App-1 App-2

4 33 22 33

27

9 4

2 33

15 5

Consultant Logo / Name

2X1.1/2"DN 90°

33 165 1 Mott MacDonald

5 5 197 33

The red pipeline is the changed pipeline 90° 33

Contractor / Supplier Logo / Name Contractor Consultant Logo/Name

1.1/2"DN 10 33 Subsupplier Logo/Name

33

5

The Contractor declares that this submission has passed the Contractor's

72 QA/QC procedure and is in accordance with the requirements of the Contract

90° Contractor / Supplier Document No. Sheet No. Revision

33

1

EL +3849 N/A

988

1

Equipment TAG Number :

17

51 Equipment Description :

3 3

Contractor's drawing review 1. Work may proceed

for conformity with

2. Revise and resubmit. Work may proceed subject to

specifications and design

resolution of indicated comments

drawing.

3. Revise and resubmit. Work may not proceed

This Review does not

4. Review not required or For Information

33 relieve the Contractor of his

responsibility for errors in 5. As-Built certified

design and detailing as

5 detailed in the contract.

6. Cancelled

90° 7. Incorporate Mark-ups & submit final As-Built or Certified

33 EL +2794 Reviewed by : Signature : Date :

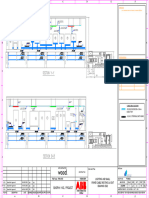

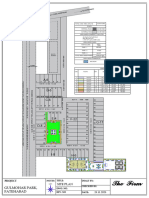

Client: JA POWER AND WATER CO. LLC

2 2

Area

Project

DUBALCCPP

H-Class Combined Cycle Power Plant

Drawing Title

GENERAL NOTES

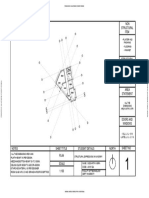

1.- RELATIVE LEVEL +0.00m IS ACCORDING TO ABSOLUTE LEVEL OF +6.00m DMD.

2.- WELDS IN STRAIGHT SPOOLS ARE NOT INDICATED IN THE DRAWING.

3.- FOR PIPES ≤2" COUPLINGS SHALL BE INSTALLED WHERE REQUIRED.

4.- ALL DIMENSIONS, COORDINATES AND ELEVATIONS ARE TO BE FIELD VERIFIED PRIOR TO CONSTRUCTION.

24MKG78BR010

1 5.- ALL THE PIPES SHALL BE DESIGNED AND ERECTED ACCORDING TO B31.1. 1

6.- FOR PAINTING DETAILS REFER TO DOC. JAS101-TK4004P-A33-1000 COLOUR CODE AND PAINTING SPECIFICATION. GENERAL: Area / Facility / Sub Facility : Sheet No.

7.- FOR PIPING CHARACTERISTICS REFER TO DOC. JAS101-TK4004P-P13-1000 PIPING CLASS SPECIFICATION. 1 F4 G7 B8/9 POSITION NUMBER ACC. PART LIST

11LAB11BR002-BQ001 KKS SUPPORT NUMBER Scale : N/A Dwg.Size : A1 File Name : 24MKG78BR010 REV 1/1

8.- FOR VALVES CHARACTERISTICS REFER TO DOC. JAS101-TK4004P-P13-1001 VALVE CLASS SPECIFICATION.

9.- FOR NDT REQUIREMENTS REFER TO CHAPTER VI OF B31.1. WELD_TYPE: Source / Project No. Package No. VDR Code Sequence No. Sub.

SLOPE

INSULATION_TYPE: P&ID : JAS101-TK4004P-I01-1015 PIPING CLASS / ø : 1A1 / 1 1/2 in OPERATING TEMPERATURE (°C) : 70.00 DESIGN TEMPERATURE (°C) : 75.00

10.- FOR WELDING DETAILS REFER TO B31.1 AND DWG. JAS101-TK4004P-P06-1000 PIPING BUTTWELDING ENDS • BUTTWELD H: HEAT INSULATION

PREPARATION DRAWINGS. FLOW DIRECTION JAS101 TK4004P P06

• SOCKETWELD P: HEAT PROTECTION PAINT(SYSTEM/COLOUR) : YELLOW OCHRE 1002 TYPE / INSULATION THICK. (mm) : P / 25.00 TEST PRESSURE (barg) : 24.00 OPERATING PRESSURE (barg) : 8.00 DESIGN PRESSURE (barg) : 16.00

A B C D E F G H J K

You might also like

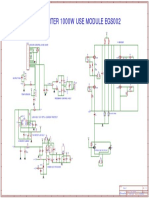

- Power Supply CEM842A Orion TV29LB929Document2 pagesPower Supply CEM842A Orion TV29LB929Traian Miclau100% (3)

- 05 - ETS Layout DWG (Rev.01) PDFDocument1 page05 - ETS Layout DWG (Rev.01) PDFVISHALNo ratings yet

- Orrong - LG-L3 (Merged)Document3 pagesOrrong - LG-L3 (Merged)kumarguide4626No ratings yet

- Ne1-10-Em-Eai-Drw-Scc (M) - 02552-01 10QFB21BR003Document1 pageNe1-10-Em-Eai-Drw-Scc (M) - 02552-01 10QFB21BR003NITHIN MATHEWNo ratings yet

- SA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42008-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- 12lba52br002 Rev0Document1 page12lba52br002 Rev0ruralashishNo ratings yet

- SA04C2-03-WP-D-42013-01-5: 3. FJ - Field Joint 4. SJ - Shop JointDocument4 pagesSA04C2-03-WP-D-42013-01-5: 3. FJ - Field Joint 4. SJ - Shop JointABAID ULLAHNo ratings yet

- Tupi BV: Cosco (Dalian)Document5 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- S3GDT01BR004 32" T4Document2 pagesS3GDT01BR004 32" T4ABAID ULLAHNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- 1 1/2" X 3/4" REDUCER, APPETON #RB150-75A: Internal Volume and Wire Fill For Appleton FittingsDocument1 page1 1/2" X 3/4" REDUCER, APPETON #RB150-75A: Internal Volume and Wire Fill For Appleton Fittingsimrancola5191No ratings yet

- J3BGDF02BR030 07 02Document1 pageJ3BGDF02BR030 07 02Nauman TahirNo ratings yet

- BISHOFTU FOR Medical EL FIN 02-06-2022-EL-POLT5Document1 pageBISHOFTU FOR Medical EL FIN 02-06-2022-EL-POLT5Sintayehu TerefeNo ratings yet

- Tupi BV: Cosco (Dalian)Document3 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Tupi BV: Cosco (Dalian)Document4 pagesTupi BV: Cosco (Dalian)Robles DreschNo ratings yet

- Shuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001Document1 pageShuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001ABAID ULLAHNo ratings yet

- Lighting and Small Power Cable Routing Layout Drawing-Ss02Document1 pageLighting and Small Power Cable Routing Layout Drawing-Ss02RaeesNo ratings yet

- J3BGDF02BR025 01 01Document1 pageJ3BGDF02BR025 01 01saleem naheedNo ratings yet

- FL3B-474-P-2603 As BuiltDocument1 pageFL3B-474-P-2603 As BuiltAlbet MulyonoNo ratings yet

- 560 000 ST S 004 - 0 - EscalerVerticalDocument1 page560 000 ST S 004 - 0 - EscalerVerticalRenzo Amiquero CrispinNo ratings yet

- Lotizacion Intihuatana-A1555Document1 pageLotizacion Intihuatana-A1555Fanel CalderonNo ratings yet

- 3 P 132 9301 1a3a N 01 - Rev01Document1 page3 P 132 9301 1a3a N 01 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- 3 P 132 9301 1a3a N 04 - Rev01Document1 page3 P 132 9301 1a3a N 04 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Ground FloorDocument1 pageGround Floor18AR083 VISHAAL SNo ratings yet

- 01, Landscape Site PlanDocument1 page01, Landscape Site PlanMohit ArchitectsNo ratings yet

- 20GHB20-BR001-03 Rev0 0001 240426 141615Document2 pages20GHB20-BR001-03 Rev0 0001 240426 141615philippeballina2810No ratings yet

- J3BGDF02BR030 09 02Document1 pageJ3BGDF02BR030 09 02Nauman TahirNo ratings yet

- B01 Ae102p Ae102p1Document1 pageB01 Ae102p Ae102p1Amr NEMEZIZNo ratings yet

- Asurion Clark - Scheme 12 - Floorplan & RCP - 09feb2023Document8 pagesAsurion Clark - Scheme 12 - Floorplan & RCP - 09feb2023JohnNo ratings yet

- Mosaic Townhomes MapDocument1 pageMosaic Townhomes MapPatricia May Valente CarayapNo ratings yet

- FJ-02 Fj-02-A: SPL-03 S.JDocument2 pagesFJ-02 Fj-02-A: SPL-03 S.JABAID ULLAHNo ratings yet

- Ar-02 2nd Floor PlanDocument1 pageAr-02 2nd Floor PlanSharlene MadridNo ratings yet

- 12LBD52BR002 Rev0Document1 page12LBD52BR002 Rev0ruralashishNo ratings yet

- V-41112 Pi PDFDocument1 pageV-41112 Pi PDFVivek VNo ratings yet

- 2047 1803 Ecv Dla 1004 - CDocument1 page2047 1803 Ecv Dla 1004 - CphanikrishnabNo ratings yet

- 3 P 132 9501 1a3a N 02 - Rev01Document1 page3 P 132 9501 1a3a N 02 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Custom Precast Solutions: For Civil Infrastructure ProjectsDocument4 pagesCustom Precast Solutions: For Civil Infrastructure ProjectsariNo ratings yet

- Plot Plan PDFDocument1 pagePlot Plan PDFBadredine Farah100% (1)

- As Found Floor Plan Proposed Floor Plan: LegendDocument1 pageAs Found Floor Plan Proposed Floor Plan: LegendVincent FilomenaNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- J3BGDF11BR001 01 04Document1 pageJ3BGDF11BR001 01 04Nauman TahirNo ratings yet

- Circuit Diagram Ultima CoupleDocument4 pagesCircuit Diagram Ultima CouplehoriNo ratings yet

- Schematic - Inverter Iron Mini - 2021!05!10Document1 pageSchematic - Inverter Iron Mini - 2021!05!10RoshanNo ratings yet

- 270 S.J. S.J.: ID QTY DN Description Sch/Cla SSDocument2 pages270 S.J. S.J.: ID QTY DN Description Sch/Cla SSABAID ULLAHNo ratings yet

- Batubulan House Interior DesignDocument25 pagesBatubulan House Interior DesignCV. Miliars Indotama100% (1)

- 3 P 132 9401 1a3a N 03 - Rev01Document1 page3 P 132 9401 1a3a N 03 - Rev0146 JOSHI SWAPNIL OMNo ratings yet

- Standard Gabion Sizes: Plan ViewDocument1 pageStandard Gabion Sizes: Plan ViewXbal MeiprastyoNo ratings yet

- Dma 28 MampangDocument1 pageDma 28 MampangIronhide EraacNo ratings yet

- Responsi 10. RENCANA BUKAAN, SIRKULASI DAN DETAIL BUKAAN - NADIA SALSABILA 20515018Document4 pagesResponsi 10. RENCANA BUKAAN, SIRKULASI DAN DETAIL BUKAAN - NADIA SALSABILA 20515018NADIA SALSABILANo ratings yet

- Aer P01 0500 0006Document1 pageAer P01 0500 0006Andi SandraNo ratings yet

- Job No. 26418: CollahuasiDocument1 pageJob No. 26418: Collahuasicutcnc.concepcionNo ratings yet

- Remarks:: Drainage Standard Details SHEET-01Document1 pageRemarks:: Drainage Standard Details SHEET-01Engineering WavesNo ratings yet

- Siddharth AdminDocument1 pageSiddharth AdminFan FollowingNo ratings yet

- 172 I1909e 000 46 DW 0109Document2 pages172 I1909e 000 46 DW 0109Jose Carlos Moraga LópezNo ratings yet

- Girder Shop Splice Transition Details: Web Thickness Flange Thickness Flange WidthDocument1 pageGirder Shop Splice Transition Details: Web Thickness Flange Thickness Flange WidthProfessor PuppiesNo ratings yet

- 10lba50br001 SHT1 Rev0Document1 page10lba50br001 SHT1 Rev0ruralashishNo ratings yet

- 172 I1909e 000 46 DW 0370Document1 page172 I1909e 000 46 DW 0370Romel Fuentes GutiérrezNo ratings yet

- Right: SCALE 1:2Document1 pageRight: SCALE 1:2Sekar NaikNo ratings yet

- T Ird Rpan: A B C 7 D EDocument1 pageT Ird Rpan: A B C 7 D EJOHN CARLO AZORESNo ratings yet

- Caterpillar C280 Series Engine Product GuideDocument221 pagesCaterpillar C280 Series Engine Product GuideIvan Aditya100% (1)

- N 2N2 20 as-SE.: March 3, 1959 A. Thomas 2,876,368Document4 pagesN 2N2 20 as-SE.: March 3, 1959 A. Thomas 2,876,368Aaron LuoNo ratings yet

- 06 - Chapter 3Document28 pages06 - Chapter 3Tech NestNo ratings yet

- Main Valve Block, DescriptionDocument13 pagesMain Valve Block, DescriptionWesley MonsaNo ratings yet

- Human Resource Management (HRM or Simply HR) Is The Management of AnDocument58 pagesHuman Resource Management (HRM or Simply HR) Is The Management of AnS Prabu RajNo ratings yet

- The Periodic Table CDocument177 pagesThe Periodic Table Cmarius1966No ratings yet

- KEMELIX 3504X-LQ - (RB) : Safety Data SheetDocument9 pagesKEMELIX 3504X-LQ - (RB) : Safety Data SheetLuigi NicoraNo ratings yet

- Englis 8Document17 pagesEnglis 8Muhammad RafiNo ratings yet

- The Seed Underground by Janisse Ray - IntroductionDocument7 pagesThe Seed Underground by Janisse Ray - IntroductionChelsea Green Publishing100% (1)

- 12 Chapter2Document48 pages12 Chapter2Arinta Purwi Suharti100% (1)

- Pros and Cons of Medical Marijuana Informative Speech OutlineDocument4 pagesPros and Cons of Medical Marijuana Informative Speech OutlineJayla LadsonNo ratings yet

- Company Event Hosting AgreementDocument1 pageCompany Event Hosting AgreementliveturabioNo ratings yet

- SAMAP 15 ProceedingsDocument84 pagesSAMAP 15 ProceedingsOm Parkash SharmaNo ratings yet

- FDQ Level 2 Diploma For Proficiency in Brewing Industry Skills 501.1054.8 12.12.2019Document11 pagesFDQ Level 2 Diploma For Proficiency in Brewing Industry Skills 501.1054.8 12.12.2019AnshulNo ratings yet

- 3 Day Trial Pack Manual USENDocument13 pages3 Day Trial Pack Manual USENCristiano AraujoNo ratings yet

- Viva Voice M.yanadiraoDocument74 pagesViva Voice M.yanadiraoBharath PonnuriNo ratings yet

- 8 Science NCERT Chapter 6Document13 pages8 Science NCERT Chapter 6Priyanshu Priyadarshi MeherNo ratings yet

- Biphasic Liquid Dosage FromDocument8 pagesBiphasic Liquid Dosage FromSwaroopSinghJakhar100% (1)

- The Poison Tree - Marwa RakhaDocument116 pagesThe Poison Tree - Marwa RakhaMohamed Hamdy100% (4)

- Chapter 3 in Space ScienceDocument13 pagesChapter 3 in Space ScienceMarwan TamerNo ratings yet

- Riyadus Saliheen - Hadeeth No. 35 (Woman of Paradise)Document13 pagesRiyadus Saliheen - Hadeeth No. 35 (Woman of Paradise)Abdul Qadir QadriNo ratings yet

- Application of Geochemical Methods in Geothermal ExplorationDocument12 pagesApplication of Geochemical Methods in Geothermal ExplorationJuan JoseNo ratings yet

- Water Treatment ChemicalsDocument33 pagesWater Treatment ChemicalsMutasim Hasan MehranNo ratings yet

- Ingilizce Mini Deneme 1Document8 pagesIngilizce Mini Deneme 1dgffNo ratings yet

- Human Resource Management - 1 Prof. Kalyan Chakravarti Department of Basic Courses Indian Institute of Technology, KharagpurDocument35 pagesHuman Resource Management - 1 Prof. Kalyan Chakravarti Department of Basic Courses Indian Institute of Technology, KharagpurIvani KatalNo ratings yet

- TWI Passivation Report July 2013Document7 pagesTWI Passivation Report July 2013sakshi patilNo ratings yet

- 07017-0014-023-EN-03 - D20003 FAdC MaintenanceDocument13 pages07017-0014-023-EN-03 - D20003 FAdC Maintenancevishu4urNo ratings yet

- IB Merger ModelDocument12 pagesIB Merger Modelkirihara95100% (1)

- Course Syllabus in SuccessionDocument16 pagesCourse Syllabus in SuccessionCharina BalunsoNo ratings yet

- ProjectDocument24 pagesProjectVamsi KrishnaNo ratings yet