Professional Documents

Culture Documents

Ethanol: Trommel 4-50 / 5-50 Hammermill Capacities

Ethanol: Trommel 4-50 / 5-50 Hammermill Capacities

Uploaded by

acceso herradaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ethanol: Trommel 4-50 / 5-50 Hammermill Capacities

Ethanol: Trommel 4-50 / 5-50 Hammermill Capacities

Uploaded by

acceso herradaCopyright:

Available Formats

TROMMEL HAMMERMILL CAPACITIES

4-50 / 5-50 MEDIUM TO FINE PARTICLE SIZE GMO CORN

Carter Day has been manufacturing quality processing equip- 4-564th 6-864th 10-1264th 14-1664th 20-2464th

ment for over 100 years. We Model Motor

Range

Hammers

&Pattern

Screen

Area

Venting

CFM

Lbs/Hp/Hr

Corn 56

Lbs/Hp/Hr

Corn 56

Lbs/Hp/Hr

Corn 56

Lbs/Hp/Hr

Corn 56

Lbs/Hp/Hr

Corn 56

continue this tradition of quality equipment with the TROM-

MEL. MZH 4216 75-100 3x2 C 1270 1600 96-105 150-200 220-270 280-320 390-430

MZH 4222 100-150 3x2 C 1795 2300 “ “ “ “ “ “ “ “ “ “

MZH 4232 150-200 3x2 C 2583 3300 “ “ “ “ “ “ “ “ “ “

The Carter Day Trommel is a high capacity cylindrical MZH 4241 250-300 3x2 C 3370 4300 “ “ “ “ “ “ “ “ “ “

screen separator used for initial or rough cleaning for virtual- MZH 4250 300-350 3x2 C 4158 5200 “ “ “ “ “ “ “ “ “ “

ly any scalping or cleaning need in processing wheat, oats,

MEDIUM TO FINE PARTICLE SIZE STOVER

rice, corn, sunflower, barley, soybean, etc. and most other

1464th 1664th 2064th 2464th 2864th

free flowing granular materials. It features a shaftless cylin-

ETHANOL

Model Motor Hammers Screen Venting Lbs/Hp/Hr Lbs/Hp/Hr Lbs/Hp/Hr Lbs/Hp/Hr Lbs/Hp/Hr

der in either 36” or 50” diameter. The Trommel is available in Range &Pattern Area CFM Stover Stover Stover Stover Stover

4 or 5 cylinder sections which are covered by patented MZH 4216 75-100 3x2 C 1270 1600 50-55 55-60 60-65

screen segments. Cylinder screen arrangements provide MZH 4222 100-150 3x2 C 1795 2300 “ “ “ “ “ “ “ “ “ “

multiple combinations of sift and / or scalp combinations.

The slope is fixed at either 2o or 6o with optional adjustable

MZH

MZH

4232

4241

150-200

250-300

3x2

3x2

C

C

2583

3370

3300

4300

“

“

“

“

“

“

“

“

“

“

“

“

“

“

“

“

“

“

“

“ PRE CLEANING AND HAMERMILLING

MZH 4250 300-350 3x2 C 4158 5200 “ “ “ “ “ “ “ “ “ “

telescoping legs.

MEDIUM TO FINE PARTICLE SIZE COBB

2” Round No Screen

Model Motor Hammers Screen Venting Lbs/Hp/Hr Lbs/Hp/Hr

Range &Pattern Area CFM Cobb Cobb

MZH 4216 75-100 3x2 C 1270 1600 190-193 210-225

MZH 4222 100-150 3x2 C 1795 2300 “ “ “ “ “ “ “ “ “ “

MZH 4232 150-200 3x2 C 2583 3300 “ “ “ “ “ “ “ “ “ “

MZH 4241 250-300 3x2 C 3370 4300 “ “ “ “ “ “ “ “ “ “

The modular design of the cylinder sections maintains structural MZH 4250 300-350 3x2 C 4158 5200 “ “ “ “ “ “ “ “ “ “

integrity and fatigue resistance by using angle iron longitudinal

stringers and rods for circumfrential cross bracing. The unique cylin- MEDIUM TO FINE PARTICLE SIZE SWITCH GRASS

der design is supported by a stub shaft at the discharge end and 1064th 1664th 2064th 2264th 2464th

Model Motor Hammers Screen Venting Lbs/Hp/Hr Lbs/Hp/Hr Lbs/Hp/Hr Lbs/Hp/Hr Lbs/Hp/Hr

three trunnion wheels at the unrestricted inlet sealed by a "V" ring Range &Pattern Area CFM S.Grass S. Grass S. Grass 5 S.Grass S. Grass

seal (no center shaft or bearing in the product flow). The Trommel MZH 4216 75-100 3x2 C 1270 1600 60-70 160-170 200-210

cylinder can be configured in four or five modular cylinder sections MZH 4222 100-150 3x2 C 1795 2300 “ “ “ “ “ “ “ “ “ “

MZH 4232 150-200 3x2 C 2583 3300 “ “ “ “ “ “ “ “ “ “

with multiple screen segments on each section for structural integrity. MZH 4241 250-300 3x2 C 3370 4300 “ “ “ “ “ “ “ “ “ “

MZH 4250 300-350 3x2 C 4158 5200 “ “ “ “ “ “ “ “ “ “

POCKET FEEDER CAPACITIES ON WHOLE GRAINS

THE PRODUCT FLOW SYSTEM offers a baffle plate at the Machine Hammermill Feeder Number Number Lb/hr Lbs/hr Lbs/hr Lbs/Hr Lbs/H/Hr

inlet to provide a slow down of product for proper screen Combination

MZH 4216

Motor-R

75-100

Model

10”RF

of Rows

5

Pockets

40

Corn 56

22800-43500

Wheat 60

15600-46400

Barley 48

13200-36700

Canola

14300-46400

Sorghum

19200-43500

exposure; While the patented melonite hardened segmented MZH 4222 100-150 10”RF 7 56 30400-60500 20800-64500 17600-51100 19000-64500 25600-60500

MZH 4232 150-200 10”RF 10 80 45600-86200 31200-92000 26400-72800 28500-92000 38400-86200

screen design provides unique structural integrity and the MZH 4241 250-300 10”RF 13 104 76000-111800 52000-119200 44000-94400 47500-119200 64000-111800

MZH 4250 300-350 10”RF 16 128 91200-137200 62400-146400 52800-115900 57000-146400 76800-137200

flexibility of screen configuration in the field. Each cylinder MZH Dimensions HP RPM WT/No Motor Useable ScreenArea Hammer Tip Speed ft/min Standard Hammer Size

MZH 4216 75-100 1800/1200 4700 1270SQ IN 19242/1800,12645/1200 1/4x2.5x10”

section can be configured for either scalp or sift by simply MZH 4222 100-150 “ “ 5300 1795 SQ IN “ “ “ “

MZH 4232 150-200 “ “ 6000 2583SQ IN “ “ “ “

changing screen segments. The wooden rollers make the MZH 4241 250-300 “ “ 7100 3370 SQ IN “ “ “ “

US Patent 5,507,396

screens self cleaning by gently dislodging the product back MZH 4250 300-350 “ “ 8300 4158 SQIN “ “ “ “

into the cylinder for continued processing. Retarder rings on

Jacobson Hammermill

the last section of the cylinder increase the efficiency of the

Corn Cleaning Capacity

Sift and Scalp cleaning process by holding the product in the cylinder until

Notes On Above Capacities:

4-50 5-50 the scalping process is complete. Hammermill capacities are in Pounds to be converted to pounds per horse power per hour.

BU/MT BU/MT Moisture Content not to exceed 13%

4200/106 6000/152 Product Identification: Corn is GMO Corn,Grain Identified by Bushel weight, Hulls and Meal lbs/cu/ft.

See Trommel Brochure

ADJUSTABLE LEGS TO ALLOW Full Scale Customer Product Testing Available.

ADDITIONAL SLOPE ADJUSTMENT The 42 Series XLT is not shown in the capacities charts above but is still available for order at this time.

CARTER DAY INTERNATIONAL CARTER DAY INTERNATIONAL

500 73rd Ave. N.E. Minneapolis, Minnesota 55432 Tel: (763) 571-1000 Fax: (763) 571-3012 500 73rd Ave. N.E. Minneapolis, Minnesota 55432 Tel: (763) 571-1000 Fax: (763) 571-3012

MULTI-ZONE HAMMERMILL HAMMERMILL ROTOR DESIGN CORN PRECLEANING

US Patent 7 025,294 B2 24” Modular Scalperator

The MZH Hammermill is used for grinds that require medi-

um to fine particle size reduction. It can be used on all free The design of our stub shaft rotor assembly is unique: For more than 75 years Carter Day has been manu-

flowing granular materials ranging from alfalfa to wheat. facturing quality equipment. We continue this tradition

10 times stronger bending and torsional stiffness than conventional with the 24” Scalperator for high capacity, one pass

rotors. cleaning of incoming or outgoing grains, seeds, and

The Dual Rotation Multi-Zone Hammermill consist of a double

radius cutting plate with staggered slotted rows and offset rotor 18% lighter rotor, yet provides 18% greater stored kinetic energy rice.

with 3/16” hammer to cutting plate clearance .

Increased diameter of spacer rings eliminates need for hammer The 24” Scalperator features scalping, rescalping and

bumper rods. aspiration in a single machine to provide a high capac-

The cutting plates offer significant size reduction prior to the prod-

ucts contact to the screen making size reduction more effective. Stub shaft design allows for lower cost replacement ity method for removing roughage, light fines and chaff

in a single pass. Incoming grain passes through a

We also use a Secondary Cutting Plate at the screen carriage dis- Patent Pending rotating wire mesh scalping reel eliminating roughage

charge offering product flow interruption sending it back into the and other oversized materials, a rescalping reel

hammers path for further size reduction . Hammermills need CFM in order to perform to their fullest potential so we offer the following options: reclaims any good material from the overs, and high

Air discharge sub-base are designed for each of our models which include an air velocity control damper. volume aspiration then removes the light materials.

Since we are using cutting plates to perform a significant portion of the size reduction, we are able to

FEED ROLL DRIVE

use larger screen perforations. Larger hole allows thicker screens for extended screen life and We have Bin-Vent System designed for each of our MZH Models. PRODUCT INLET

reduced air venting volumes required. We provide the system less the product collector.

The hammer tip speed is up to 19,200 feet per minute which gives optimum grinding performance We also have many alliances with Product Collector companies ROCK PLATE

when used in conjunction with our cutting plate system. who can assist you. ASPIRATION

SCALPING REEL

VELOCITY

In conclusion, compared to other mills all of this offers you a higher pounds per horsepower per hour CONTROL

production or horsepower savings in production. RESCALPING REEL

POCKET FEEDER AND FEED OPTIONS ASPIRATION

The drive package is factory aligned to a rigid tubular frame for accurate alignment of motor and mill. SCALPINGS

CHAMBER

DISCHARGE

STAINLESS STEEL POCKET FEEDER TO HANDLE ALL FREE FLOWING GRANULAR MATERIALS. CLOSED CIRCUIT

We use a direct drive coupling which allows for exceptional alignment and reliability. The stub shaft

THE FEEDER OFFERS THE FOLLOWING:

bearings are of the highest industrial grade providing long life and reliability. MAJOR FEATURES

5-16 Rows covering all our hammermill designs Molded Urethane Feed Roll AIR INLET

SIFTING

THE SERVICEABILITY OF THIS MACHINE MATCHES ITS Adjustable gate for product blow by or FM Blow By HTD Drive SCREEN LIFTINGS

PRODUCT OUTLET

EXCEPTIONAL SIZE REDUCTION CAPABILITIES: Rock Plate (CLEAN) (HEAVY)

Product flow magnet with stripper plate.

Double roller glide doors Operator friendly machine controls CORN CLEANING CAPACITY

Two point pivotal screen carriage design Pneumatic control or manual control magnet system. 28 56 84 112

Performance-engineered aspiration BU/MT BU/MT BU/MT BU/MT

Shaft mounted gear reduction drive (direct drive) 1700/43.1 13400/ 86.4 5100/129.6 6800/172.8

Two piece screen design for easy replacement Self Contained Closed Circuit

Side slide out rotor access Pocket liners for high fat low flow products 24” Modular Scalper

Easy Hammer replacement Inlet Air Flow Control Same features as the 24” Scalper less

ADDITIONAL FEED OPTIONS AVAILABLE:

the aspiration chamber.

Easy Pin and Collar Replacement Destoner bolt on option for MZH, XLT and

Full Rotor Removal from Drive end for service.

Keyed Bearing Replacement Commander

Scalping Reel - mesh or perforated round

Collector Tray for tramp metals Inlet with magnet for MZH,XLT and Commander

Highest quality Hammers and Screens Sift Screen - many sizes available

Screw feeder option available for light bulk density

Optional Load Minder for MZH,COMMANDER AND XLT product.

Replaceable AR Wear Liner Kits Available

Carter Day Lab

CARTER DAY INTERNATIONAL CARTER DAY INTERNATIONAL CARTER DAY INTERNATIONAL

500 73rd Ave. N.E. Minneapolis, Minnesota 55432 Tel: (763) 571-1000 Fax: (763) 571-3012 500 73rd Ave. N.E. Minneapolis, Minnesota 55432 Tel: (763) 571-1000 Fax: (763) 571-3012 500 73rd Ave. N.E. Minneapolis, Minnesota 55432 Tel: (763) 571-1000 Fax: (763) 571-3012

You might also like

- 2004-2007 Yamaha Waverunner FX 1100 High Output Service Manual PDFDocument515 pages2004-2007 Yamaha Waverunner FX 1100 High Output Service Manual PDFMatt Wilson100% (4)

- Yamaha FX HO Service ManualDocument515 pagesYamaha FX HO Service ManualDanijal Korajkic66% (35)

- Sany-Product-Family 230704 153456Document2 pagesSany-Product-Family 230704 153456Osama Ehtawish0% (1)

- R3 EvoDocument2 pagesR3 EvopingohrNo ratings yet

- 2018 Merlo 2PP P38.13RQDocument2 pages2018 Merlo 2PP P38.13RQPronto AccessNo ratings yet

- Form Daily CheckerDocument6 pagesForm Daily CheckerAbenturazaleNo ratings yet

- Cube 160Document1 pageCube 160Gregorio AndradeNo ratings yet

- Gebruiksaanwijziging: Pro EquipmentDocument6 pagesGebruiksaanwijziging: Pro Equipment9kjk8bhfbrNo ratings yet

- 7th Presentation-3Document2 pages7th Presentation-3widhi.ti07No ratings yet

- 4.4 Surface M /CM /MM X FT /inch: Basic Engineering Design DataDocument1 page4.4 Surface M /CM /MM X FT /inch: Basic Engineering Design DataTAHIR MAHMOODNo ratings yet

- Zelda Medley For 2 Harps PDFDocument9 pagesZelda Medley For 2 Harps PDFPikaShiduUwuFeikNo ratings yet

- Persona Brochure PDFDocument2 pagesPersona Brochure PDFZahiri MohamadNo ratings yet

- Aerosila NPP JSC: Gas Turbine Power PlantsDocument30 pagesAerosila NPP JSC: Gas Turbine Power PlantsSatish Babu Garikapati100% (2)

- Thule Rapid System Kit 1513Document4 pagesThule Rapid System Kit 1513marieNo ratings yet

- Instructions: Thule Rapid System Kit 1426Document4 pagesInstructions: Thule Rapid System Kit 1426Afzal ImamNo ratings yet

- Cube 180Document1 pageCube 180Gregorio AndradeNo ratings yet

- Fields of Operation: Mediterranean SeaDocument1 pageFields of Operation: Mediterranean SeaAli NAJJARNo ratings yet

- DSVR 20231113Document2 pagesDSVR 20231113lanzcruzzzNo ratings yet

- 13 Q Driveability Questionaire PDFDocument1 page13 Q Driveability Questionaire PDFisshmangNo ratings yet

- Hard Disk DriveDocument1 pageHard Disk Drivebatam tamtamNo ratings yet

- XV. 473 Engine and Liandian Electric Injection SystemDocument1 pageXV. 473 Engine and Liandian Electric Injection SystemJose Luis Velasquez Romero100% (1)

- D3 Space ProgDocument27 pagesD3 Space ProgBryan GonzalesNo ratings yet

- RIE93266 Instruction GuideDocument1 pageRIE93266 Instruction GuideMarco Antonio CastilloNo ratings yet

- EngRange Industry 06Document1 pageEngRange Industry 06FRANCISCO JAVIER BARRIENTOS GONZALESNo ratings yet

- DB DetailDocument2 pagesDB Detailmknegi@zapakmail.comNo ratings yet

- U4.40 Becker Vacuum PumpDocument8 pagesU4.40 Becker Vacuum Pump啊No ratings yet

- Fmp63cps t15nnv 安装尺寸图 ModelDocument1 pageFmp63cps t15nnv 安装尺寸图 ModelihydraulicsNo ratings yet

- SHB 6503 1000165866Document1 pageSHB 6503 1000165866Piotr PogorzelczykNo ratings yet

- Jenfold Tematic Pro A4 ENDocument6 pagesJenfold Tematic Pro A4 ENRodrigo PerezNo ratings yet

- Car Park VentilationDocument3 pagesCar Park VentilationBayhonElmer67% (3)

- RC-4 and RC-4HCDocument1 pageRC-4 and RC-4HCHaman EdilbertoNo ratings yet

- TWS 1300 and Others Performance DataDocument3 pagesTWS 1300 and Others Performance DatasantanuaNo ratings yet

- Iriz BrochureDocument2 pagesIriz BrochureARVIN ARSENALNo ratings yet

- Savisagar Jalahalli Model Model 2Document1 pageSavisagar Jalahalli Model Model 2migroup034No ratings yet

- AT11DNDocument1 pageAT11DNJohn GarnetNo ratings yet

- GA Drawing of 7.5T X 36mtr X (8+30) 38mtr DG Goliath CraneDocument1 pageGA Drawing of 7.5T X 36mtr X (8+30) 38mtr DG Goliath CraneAJAY SHINDENo ratings yet

- Physchrometric Chart5Document2 pagesPhyschrometric Chart5Josue HernandezNo ratings yet

- Instructions: Thule Rapid System Kit 1651Document4 pagesInstructions: Thule Rapid System Kit 1651Ivan PolataykoNo ratings yet

- Instructions: Thule Rapid System Kit 1651Document4 pagesInstructions: Thule Rapid System Kit 1651Ivan PolataykoNo ratings yet

- Pump PutzmeisterDocument6 pagesPump PutzmeisterCamila AponteNo ratings yet

- Primavera Vivaldi Bandolim e Cavaco 1Document2 pagesPrimavera Vivaldi Bandolim e Cavaco 1kayandra AraújoNo ratings yet

- Thule InstructionsDocument4 pagesThule InstructionsAl LopNo ratings yet

- Aficio MP 3500 - MP 4500Document6 pagesAficio MP 3500 - MP 4500hectoriusNo ratings yet

- HempToday Magazine Q4 2021Document56 pagesHempToday Magazine Q4 2021MNo ratings yet

- Mod.9349 X1 2017 by Verlag Aenne Burda GMBH & Co. KGDocument23 pagesMod.9349 X1 2017 by Verlag Aenne Burda GMBH & Co. KGVinga50% (2)

- LongtrainrunningDocument1 pageLongtrainrunningPascal PingouinNo ratings yet

- Gago-Trompete em BBDocument2 pagesGago-Trompete em BBMicael PereiraNo ratings yet

- Thule 1594 Kit PDFDocument4 pagesThule 1594 Kit PDFveronicaklein1982No ratings yet

- Flow Rate (Q) Total Head (H) Isi Di Kotak Berwarna Saja:: 4,0 M /jam: 22,7 MTRDocument1 pageFlow Rate (Q) Total Head (H) Isi Di Kotak Berwarna Saja:: 4,0 M /jam: 22,7 MTRinfonetsmgNo ratings yet

- Minisplit Inverter R-410a YJHJZCDocument3 pagesMinisplit Inverter R-410a YJHJZCjuanNo ratings yet

- EM6400 ConzervDocument4 pagesEM6400 ConzervPRABHU SHANKAR MNo ratings yet

- COPIADORA DSm735 - DSm745 - Brochure PDFDocument6 pagesCOPIADORA DSm735 - DSm745 - Brochure PDFfernandihnoNo ratings yet

- Boxmaking PDFDocument1 pageBoxmaking PDFLuis Felipe ArenasNo ratings yet

- BoxMaking PDFDocument1 pageBoxMaking PDFShanmathi DNo ratings yet

- NECMicrocontroller GuideDocument8 pagesNECMicrocontroller GuideAldemir Fernando BattagliaNo ratings yet

- PotpourriPart Violin 2-1-3Document3 pagesPotpourriPart Violin 2-1-3Lucas Johnny da SilvaNo ratings yet

- MisumiDocument1 pageMisumiMoonzaRNo ratings yet

- LAPERRITA COKETA 2022-Trombón - 220912 - 130917Document1 pageLAPERRITA COKETA 2022-Trombón - 220912 - 130917Ricardo RamirezNo ratings yet

- R70pf0027ed1700 AutomotiveDocument6 pagesR70pf0027ed1700 AutomotiveVanHieu LuyenNo ratings yet

- Instructions: Thule Rapid System Kit 1458Document4 pagesInstructions: Thule Rapid System Kit 1458Bruh BroNo ratings yet

- Village Map: Taluka: Wai District: SataraDocument1 pageVillage Map: Taluka: Wai District: Satarakantilal chunilalNo ratings yet

- 2001 USDM Subaru Outback Service Manual BE-BHDocument4,267 pages2001 USDM Subaru Outback Service Manual BE-BHgigabyte3235840No ratings yet

- PSS Inv Manual 2020Document1,117 pagesPSS Inv Manual 2020ArifAzriNo ratings yet

- Ethanol: Trommel 4-50 / 5-50 Hammermill CapacitiesDocument2 pagesEthanol: Trommel 4-50 / 5-50 Hammermill Capacitiesacceso herradaNo ratings yet

- 4EAT Phase II Automatic TransmissionDocument36 pages4EAT Phase II Automatic TransmissionSam Park100% (12)

- Chapter-1: Remote Control GateDocument61 pagesChapter-1: Remote Control Gatevara prasadNo ratings yet

- K111 Continuously Variable Transaxle: DescriptionDocument35 pagesK111 Continuously Variable Transaxle: Descriptionhungchagia1100% (2)

- "Automatic Sliding Gate": Prajakta Desai, Iptesam Aga, Arti Patil, Jeba WathareDocument6 pages"Automatic Sliding Gate": Prajakta Desai, Iptesam Aga, Arti Patil, Jeba WathareDeepika AndraNo ratings yet

- 3600-4176 05 b3 CatDocument40 pages3600-4176 05 b3 CatmarkoNo ratings yet

- Subaru-Legacy 2005 EN Manual de Taller Sistema Transmision Embrague Caja Automatica 1dbe02a483Document45 pagesSubaru-Legacy 2005 EN Manual de Taller Sistema Transmision Embrague Caja Automatica 1dbe02a483miguelNo ratings yet

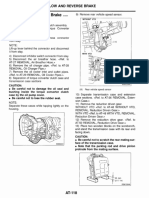

- Low and Reverse Brake: Automatic TransmissionDocument7 pagesLow and Reverse Brake: Automatic TransmissionAnton FortovNo ratings yet

- Drive Pinion Shaft: Automatic TransmissionDocument7 pagesDrive Pinion Shaft: Automatic TransmissionAnton FortovNo ratings yet

- Subaru M41, M41a 3-SpeedDocument8 pagesSubaru M41, M41a 3-SpeedHectorNo ratings yet

- Seminar ReportDocument31 pagesSeminar ReportShivam Sharma100% (2)

- MSA5T0128A34681Document2 pagesMSA5T0128A34681miguelNo ratings yet

- Ultramite Ub Type - Nomenclature and Interchange GuideDocument24 pagesUltramite Ub Type - Nomenclature and Interchange GuideARTHURS316No ratings yet

- Customer Name: Canal Sugar: Project N°: Pidno: Manufacturer: DateDocument22 pagesCustomer Name: Canal Sugar: Project N°: Pidno: Manufacturer: DateHassan SleemNo ratings yet

- Subaru Automatic Transmissions 4EAT Phase II Module 302 Technicians Reference BookletDocument36 pagesSubaru Automatic Transmissions 4EAT Phase II Module 302 Technicians Reference BookletFábio Silva de OliveiraNo ratings yet

- Pratt & Whitney Wasp Manual PDFDocument353 pagesPratt & Whitney Wasp Manual PDFsjd40100% (22)

- Agglomerator BrochureDocument1 pageAgglomerator BrochureArturoNo ratings yet

- Reduction Drive Gear 55,059, C: Disassembly: Automatic TransmissionDocument3 pagesReduction Drive Gear 55,059, C: Disassembly: Automatic TransmissionAnton FortovNo ratings yet