Professional Documents

Culture Documents

Product Data Sheet An Cal PP906-C

Product Data Sheet An Cal PP906-C

Uploaded by

Anh Minh0 ratings0% found this document useful (0 votes)

57 views2 pagesPP906-C is a polypropylene-based masterbatch containing 85% calcium carbonate. It can be mixed with polypropylene resin for injection molding, extrusion, and other processes. PP906-C improves heat resistance, tensile strength, size stability, and printability while reducing heat release and environmental pollution during burning. Test results show the product meets specifications for calcium carbonate content, density, moisture content, melting flow index, particle size, and appearance.

Original Description:

Original Title

PRODUCT DATA SHEET AN CAL PP906-C

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPP906-C is a polypropylene-based masterbatch containing 85% calcium carbonate. It can be mixed with polypropylene resin for injection molding, extrusion, and other processes. PP906-C improves heat resistance, tensile strength, size stability, and printability while reducing heat release and environmental pollution during burning. Test results show the product meets specifications for calcium carbonate content, density, moisture content, melting flow index, particle size, and appearance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

57 views2 pagesProduct Data Sheet An Cal PP906-C

Product Data Sheet An Cal PP906-C

Uploaded by

Anh MinhPP906-C is a polypropylene-based masterbatch containing 85% calcium carbonate. It can be mixed with polypropylene resin for injection molding, extrusion, and other processes. PP906-C improves heat resistance, tensile strength, size stability, and printability while reducing heat release and environmental pollution during burning. Test results show the product meets specifications for calcium carbonate content, density, moisture content, melting flow index, particle size, and appearance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

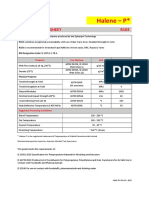

PRODUCT DATA SHEET

Filler Master Batch

Grade: PP906-C

(Test result is recorded right after production)

I- Applications

1. PP injection molding

2. PP Flat yarn extrusion, blow molding, extrusion molding.

II- Features

1. PP906-C is a poly propylene based masterbatch containing 85% calcium carbonate. It is natural

white with excellent dispersibility.

2. It can be mixed with Poly propylene resin for injection, extrusion, thermal forming, etc. and is

easy to disperse with good compatibility. It functions as a modifier to improve the heat resistance,

tensile strength, size stability and printability. It also reduces heat release from burning and there

force prevents further environmental pollution.

III- Physical Properties: (Test result is recorded after production)

About result

Item code: PP906-C Test Method Unit Result

allowed

Carrier resin ASH TESTER PP

CaCO3 Content ASH TESTER % 85.0 84.0 - 86.0

Density ASTM D1506 g/cm3 1.8

Moisture content IR % ≤ 0.15

Melting flow index (230°C/2.16 kg) ASTM D1238 g/10mins 56.0 51.0 – 60.0

Particle size Caliper mm 2.2 2.0 – 2.4

Appearance White Oval

CaCO3 Powder Size Malvern 3000E Micromet 15

IV- Processing suggestions

1. In general, the recommended loading ratio is from 5 – 40 % depending on

technology, products or machines..e

2. The processing temperature is set from 200oC - 280oC according to resin’s processing

temperature.

V- Package, Transportation and Storage suggestions:

1. Please kindly note to avoid moisture, isolation and breakage in transportation and

storage.

2. The product is sensitive to moisture. Make sure to use product immediately after

opening bags. Please dry materials by hot air recycle machine under 90oC for at least

30 minutes in case of or to remove moisture.

3. Packing: 25 kgs/bag printed or non-printed (or Jumbo bag)

An Tien Industries JSC would not give warranty to bad storage conditions which may

lead to quality deterioration such as color change, bad smell and inadequate product

performance. It is advisable to process PP filler within 3 months after delivery date.

----------------------------------------------------------------------------------------------------------------

You might also like

- Emcekrete EP: High Performance Self-Leveling Epoxy GroutDocument2 pagesEmcekrete EP: High Performance Self-Leveling Epoxy Groutwilian liNo ratings yet

- TDS - NSRP All Grades UpdatedDocument4 pagesTDS - NSRP All Grades UpdatedJimmy Nguyen100% (2)

- Product Data Sheet An Cal PP902WDocument2 pagesProduct Data Sheet An Cal PP902WAnh MinhNo ratings yet

- TDS If-Pp80x.i3Document2 pagesTDS If-Pp80x.i3HD TalababuNo ratings yet

- TDS If-Pp80xc.iDocument2 pagesTDS If-Pp80xc.iHD TalababuNo ratings yet

- Product Information and Data SheetDocument2 pagesProduct Information and Data SheethelenNo ratings yet

- TDS If-Pp112uDocument2 pagesTDS If-Pp112uHD TalababuNo ratings yet

- Master Reducer NH - 1024Document1 pageMaster Reducer NH - 1024AndyNo ratings yet

- Product Information and Data SheetDocument1 pageProduct Information and Data SheetMichael PetersonNo ratings yet

- CaCO3 - EFPP1001 - 9744Document1 pageCaCO3 - EFPP1001 - 9744JUAN SEBASTIAN BUSTOS GARNICANo ratings yet

- Polypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer BOPP Films: Provisional Technical DatasheetMohit MohataNo ratings yet

- TDS - MT 950 - enDocument2 pagesTDS - MT 950 - enTo RaNo ratings yet

- CRP 100NDocument2 pagesCRP 100NbaharehestekiNo ratings yet

- j1400 Eng 1874Document2 pagesj1400 Eng 1874ervin87No ratings yet

- TDS - Premix Marine ThixotropeDocument3 pagesTDS - Premix Marine ThixotropegmNo ratings yet

- TDS - Mosten - MA 745 - enDocument2 pagesTDS - Mosten - MA 745 - enTo RaNo ratings yet

- HF10TQ: IPP Film GradeDocument2 pagesHF10TQ: IPP Film GradeLaili AzkiyahNo ratings yet

- Post Tensioned Concrete Floor S KhanDocument9 pagesPost Tensioned Concrete Floor S KhanSachin SharmaNo ratings yet

- Epsilon-Caprolactone Capromer™ PolycaprolactonesDocument4 pagesEpsilon-Caprolactone Capromer™ Polycaprolactonesian lesterNo ratings yet

- Europlas Efpe 1001-1 TdsDocument1 pageEuroplas Efpe 1001-1 Tdsyesenia flores rosadoNo ratings yet

- Pinhas TDS Lushan AR493Document2 pagesPinhas TDS Lushan AR493Zirve PolimerNo ratings yet

- PE-UHMW - Celanese - GUR 5129Document2 pagesPE-UHMW - Celanese - GUR 5129bobNo ratings yet

- Roduct Ata Heet Chivacure TPODocument2 pagesRoduct Ata Heet Chivacure TPOmario3312No ratings yet

- Data Sheet PMB PPC 112pDocument1 pageData Sheet PMB PPC 112pAurum ChemicalsNo ratings yet

- Haldia PP Raffia - R103 DatasheetDocument2 pagesHaldia PP Raffia - R103 DatasheetNarender RawatNo ratings yet

- PVC - Food & Pharmaceutical UseDocument3 pagesPVC - Food & Pharmaceutical UseARINDAM SETTNo ratings yet

- Astman NPG Glycol: Powder Coating Resin PC-17-4N Based OnDocument4 pagesAstman NPG Glycol: Powder Coating Resin PC-17-4N Based OnRAZA MEHDINo ratings yet

- Datasheet EFPE 1001Document1 pageDatasheet EFPE 1001Mỹ Hạnh BùiNo ratings yet

- Polypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetDocument2 pagesPolypropylene Random Co Polymer Injection Molding & ISBM: Provisional Technical DatasheetMohit MohataNo ratings yet

- Reprocessed Polypropylene CopolymerDocument2 pagesReprocessed Polypropylene Copolymernatuan74No ratings yet

- Linear Low Density Polyethylene Injection MoldingDocument2 pagesLinear Low Density Polyethylene Injection MoldingakshayNo ratings yet

- Hopelex Pc-1100uDocument2 pagesHopelex Pc-1100uChu ChuNo ratings yet

- Polypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Impact Co Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- TDS NF-334pDocument2 pagesTDS NF-334pamp.kaunasNo ratings yet

- Spesifikasi Teknis Katalok BarangDocument15 pagesSpesifikasi Teknis Katalok BarangLiondo PurbaNo ratings yet

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- TWO H Chem LTD.: Nova-P Nova-PDocument2 pagesTWO H Chem LTD.: Nova-P Nova-PKingsley BaptistaNo ratings yet

- SABIC® LLDPE - MG500026 - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - MG500026 - Global - Technical - Data - Sheetabhimanyu.xplastNo ratings yet

- Part 6 - Asphalt TestingDocument36 pagesPart 6 - Asphalt TestingSanjeev ViswambharanNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Datasheet EFPE 1003ANDocument1 pageDatasheet EFPE 1003ANAhyoria ZapataNo ratings yet

- Test Report C5Document1 pageTest Report C5janakaNo ratings yet

- TDS Resin SHCP268-1Document3 pagesTDS Resin SHCP268-1wongpengchiong7205100% (1)

- TDS Chemflake Glass Flake SuggestedDocument5 pagesTDS Chemflake Glass Flake SuggestedShankar Pl GowdaNo ratings yet

- PP Mosten EH 501: Technical DatasheetDocument2 pagesPP Mosten EH 501: Technical DatasheetBanupriya BalasubramanianNo ratings yet

- POM Celcon M270Document3 pagesPOM Celcon M270Er Shashi SinghNo ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- PP Trilene He2.0tfDocument2 pagesPP Trilene He2.0tfLaili AzkiyahNo ratings yet

- Utek PYJ9114 SMC SHEETDocument2 pagesUtek PYJ9114 SMC SHEETFrederik TjonnelandNo ratings yet

- Technical Data Sheet: Name: Filler Masterbatch Grade: PE 85LDocument1 pageTechnical Data Sheet: Name: Filler Masterbatch Grade: PE 85LPlastex EcuadorNo ratings yet

- Polypropylene Impact Co Polymer Injection MoldingDocument2 pagesPolypropylene Impact Co Polymer Injection MoldingMohit MohataNo ratings yet

- Lotte Titanvene HD5401GADocument2 pagesLotte Titanvene HD5401GAifah0% (1)

- Barrier 80.TDS - Eng PDFDocument5 pagesBarrier 80.TDS - Eng PDFSanjay PatelNo ratings yet

- CPE7012-B REX Coursework Brief 2020Document13 pagesCPE7012-B REX Coursework Brief 2020Prashant PrashantNo ratings yet

- Palatal A408-972 (E) For PultrusionDocument1 pagePalatal A408-972 (E) For Pultrusionbourne029No ratings yet

- SABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFDocument2 pagesSABIC® FORTIFY™ - C3080 - Global - Technical - Data - Sheet PDFvishal mehtaNo ratings yet

- Mechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsFrom EverandMechanical Properties of Polycarbonate: Experiment and Modeling for Aeronautical and Aerospace ApplicationsNo ratings yet

- TCVN 13114-2020-Chat Deo PHSHDocument19 pagesTCVN 13114-2020-Chat Deo PHSHAnh MinhNo ratings yet

- Change Readiness Questionnaire TemplateDocument4 pagesChange Readiness Questionnaire TemplateAnh MinhNo ratings yet

- 20180724-SAP-Stakeholder Matrix-V02Document8 pages20180724-SAP-Stakeholder Matrix-V02Anh MinhNo ratings yet

- Luc Phuong Anh - Bai Tap PMBOKDocument2 pagesLuc Phuong Anh - Bai Tap PMBOKAnh MinhNo ratings yet

- E 481 - 03 - RTQ4MQDocument6 pagesE 481 - 03 - RTQ4MQAnh MinhNo ratings yet

- E 481 - 97 - Rtq4ms1sruqDocument8 pagesE 481 - 97 - Rtq4ms1sruqAnh MinhNo ratings yet

- E 261 - 03 - Rti2mqDocument10 pagesE 261 - 03 - Rti2mqAnh MinhNo ratings yet

- E 266 - 02 - Rti2ngDocument3 pagesE 266 - 02 - Rti2ngAnh MinhNo ratings yet

- E 385 - 90 R02 - RTM4NQDocument7 pagesE 385 - 90 R02 - RTM4NQAnh MinhNo ratings yet

- E 265 - 98 R02 - Rti2nqDocument6 pagesE 265 - 98 R02 - Rti2nqAnh MinhNo ratings yet

- Pyrometric Cone Equivalent (PCE) of Fireclay and High Alumina Refractory MaterialsDocument5 pagesPyrometric Cone Equivalent (PCE) of Fireclay and High Alumina Refractory MaterialsAnh MinhNo ratings yet

- 1table of ContentsDocument14 pages1table of ContentsAnh MinhNo ratings yet

- D 4332 - 99 - RdqzmzitotkDocument3 pagesD 4332 - 99 - RdqzmzitotkAnh MinhNo ratings yet

- Refractories: Standard Terminology Relating ToDocument5 pagesRefractories: Standard Terminology Relating ToAnh MinhNo ratings yet

- Fireclay and High-Alumina Refractory Brick: Standard Classification ofDocument2 pagesFireclay and High-Alumina Refractory Brick: Standard Classification ofAnh MinhNo ratings yet

- C 24 - 89 r99 - Qzi0ltg5ujk5rteDocument4 pagesC 24 - 89 r99 - Qzi0ltg5ujk5rteAnh MinhNo ratings yet

- D 4332 - 01 - RdqzmzitmdeDocument3 pagesD 4332 - 01 - RdqzmzitmdeAnh MinhNo ratings yet

- Section 1-Introduction-Process Descriptions-Pilot Plant DescriptionsDocument25 pagesSection 1-Introduction-Process Descriptions-Pilot Plant DescriptionsAnh MinhNo ratings yet

- CO DMA 1072 Numerical Control ProgrammingDocument9 pagesCO DMA 1072 Numerical Control ProgrammingfarizanNo ratings yet

- A Review: Speed Control of Brushless DC Motor: December 2017Document7 pagesA Review: Speed Control of Brushless DC Motor: December 2017Gopu MayyalaNo ratings yet

- Nebosh Igc-1 Important Questions and Answers: Element 2 Health and Safety Management Systems 1 - Policy Q1Document6 pagesNebosh Igc-1 Important Questions and Answers: Element 2 Health and Safety Management Systems 1 - Policy Q1Wafula RobertNo ratings yet

- Inclined Rock StrataDocument4 pagesInclined Rock Stratamabjalwamohale03No ratings yet

- Costbenefit Analysis 2015Document459 pagesCostbenefit Analysis 2015TRÂM NGUYỄN THỊ BÍCHNo ratings yet

- Manual For Sperre X090Document72 pagesManual For Sperre X090AcruzbNo ratings yet

- Comparative Efficacy and Safety of New Surgical Treatments For Benign Prostatic Hyperplasia Systematic Review and NetwoDocument11 pagesComparative Efficacy and Safety of New Surgical Treatments For Benign Prostatic Hyperplasia Systematic Review and NetwoMahesa Kurnianti PutriNo ratings yet

- Q Mobile PresDocument4 pagesQ Mobile PresSaba Ilyas67% (3)

- 4.2 Lean The 5SDocument21 pages4.2 Lean The 5Shaidar khadourNo ratings yet

- Unit-10 Relationship MarketingDocument342 pagesUnit-10 Relationship MarketingNama DesalewNo ratings yet

- The Engineering Handbook: ManufacturingDocument7 pagesThe Engineering Handbook: ManufacturingChertong WangNo ratings yet

- Motor CatalogDocument85 pagesMotor CatalogHarshad AthawaleNo ratings yet

- Library Management SystemDocument6 pagesLibrary Management SystemNaana SmartNo ratings yet

- 001-BS Iso 247 (2006) Rubber - Determination of AshDocument10 pages001-BS Iso 247 (2006) Rubber - Determination of AshQuality MSIPLNo ratings yet

- PYL101 QM Lecture 6Document16 pagesPYL101 QM Lecture 6mukeshNo ratings yet

- Mobile Phones - The Effect of Its Presence On Learning and MemoryDocument12 pagesMobile Phones - The Effect of Its Presence On Learning and MemoryJohana VangchhiaNo ratings yet

- Optimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFDocument19 pagesOptimizing Impeller Geometry For Performance Enhancement of A Centrífugal Pump PDFEnrique Javier González HenríquezNo ratings yet

- Early Childhood DevelopmentDocument100 pagesEarly Childhood DevelopmentJoviner Yabres LactamNo ratings yet

- Construction Engineering AND ManagementDocument15 pagesConstruction Engineering AND ManagementDanika Kaye GornesNo ratings yet

- Oil Specs Silver State BrandDocument1 pageOil Specs Silver State BrandAllen WilburNo ratings yet

- NH 6035448106 PreviewDocument51 pagesNH 6035448106 PreviewYesenia Gpe Vega0% (1)

- Exploring Arcobjects PDFDocument2 pagesExploring Arcobjects PDFElenaNo ratings yet

- Manual de Taller - Yamaha Crux 2005Document0 pagesManual de Taller - Yamaha Crux 2005Insomnia Dj ChileNo ratings yet

- NST32031-Practical For Wireless Network: Department of ICT Faculty of Technology South Eastern University of Sri LankaDocument9 pagesNST32031-Practical For Wireless Network: Department of ICT Faculty of Technology South Eastern University of Sri Lankaaiz15563No ratings yet

- Walter Dso ProjectDocument59 pagesWalter Dso Projectzte00000No ratings yet

- Start - Smart - 1 (Teacher's Guide)Document44 pagesStart - Smart - 1 (Teacher's Guide)kame_rainNo ratings yet

- Short Term Plan Template LitDocument2 pagesShort Term Plan Template Litapi-3829502No ratings yet

- WW3 - Long QuizDocument3 pagesWW3 - Long QuizOLIVEROS DESIREE L.No ratings yet

- Holistic DevelopmentDocument24 pagesHolistic DevelopmentMary Rose LlamasNo ratings yet

- Influencer Yearbook 2021Document42 pagesInfluencer Yearbook 2021Ali RahmanNo ratings yet