Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

24 viewsThe Qualifications and Requirements Required For Being Part of The Service Crew Management

The Qualifications and Requirements Required For Being Part of The Service Crew Management

Uploaded by

Franchesca ValerioThe document discusses the 6 Ms of operation management - Money, Manpower, Machinery, Materials, Methods, and Management. It provides details on each:

1) Money - A street food business earns $183,250 per month.

2) Manpower - Skilled workers are needed for complex manufacturing processes. Training helps increase productivity.

3) Machinery - Precise, reliable, and durable machines create lean processes and reduce waste.

4) Materials - Quality materials prevent defects and improve performance while clean materials eliminate waste.

5) Methods - Establishing effective processes avoids wasted time and labor.

6) Management - Proper management keeps a business running efficiently with minimal

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- IMO Manual On Oil Pollution - Section II Contingency PlanningDocument81 pagesIMO Manual On Oil Pollution - Section II Contingency PlanningSatria 'igin' Girindra Nugraha100% (2)

- Architecture and SportDocument44 pagesArchitecture and SportNeitherboth73% (11)

- Annotated BibliographyDocument6 pagesAnnotated Bibliographyapi-581682791No ratings yet

- Lean and Agile Manufacturing: Prepared By: Pallavi JoshiDocument25 pagesLean and Agile Manufacturing: Prepared By: Pallavi Joshipallaveejoshi100% (1)

- E-Games (Valorant)Document10 pagesE-Games (Valorant)Franchesca ValerioNo ratings yet

- IMRAD - Black HolesDocument8 pagesIMRAD - Black HolesFranchesca ValerioNo ratings yet

- Letter To PostmasterDocument2 pagesLetter To Postmastermary100% (2)

- Productivity Tool EssayDocument1 pageProductivity Tool EssayJohnelyn Porlucas MacaraegNo ratings yet

- Fairview Program PDFDocument36 pagesFairview Program PDFMargo Crawford50% (2)

- 4 MsDocument3 pages4 MsFranchesca Valerio0% (1)

- 5M For PlanningDocument7 pages5M For PlanningalaminNo ratings yet

- TPM BookletDocument26 pagesTPM Bookletamishraioc100% (5)

- Self Notes Pom Unit 1Document17 pagesSelf Notes Pom Unit 1Darshna ChaudharyNo ratings yet

- Lect 1 2010Document20 pagesLect 1 2010Mona FatimaNo ratings yet

- Chapter 4Document16 pagesChapter 4Mary Neilene PerezNo ratings yet

- Lean Manufacturing: College of Engineering, BBSRDocument24 pagesLean Manufacturing: College of Engineering, BBSRSmileyNo ratings yet

- Coatings and Construction Components (EU)Document20 pagesCoatings and Construction Components (EU)Shahid MirzaNo ratings yet

- JD Maintenance Engineer InstrumentationDocument2 pagesJD Maintenance Engineer InstrumentationsamcruiseatcNo ratings yet

- Chapter 4Document15 pagesChapter 4Bea Dela PeniaNo ratings yet

- Four Process StrategyDocument10 pagesFour Process StrategyChandria FordNo ratings yet

- Total Productive Maintenance (TPM) : Prevent Inefficiencies and Enhance Safety Through The Power of The TPM SystemDocument16 pagesTotal Productive Maintenance (TPM) : Prevent Inefficiencies and Enhance Safety Through The Power of The TPM SystemjjfmedNo ratings yet

- Production Notes (Summary)Document2 pagesProduction Notes (Summary)NeenaNo ratings yet

- OM Chapter 4Document14 pagesOM Chapter 4abdulwahab kemalNo ratings yet

- Factory JDDocument16 pagesFactory JDSatyam DixitNo ratings yet

- Operations Esterline Case Report Bog1 04 Feb 2012 PDF FreeDocument4 pagesOperations Esterline Case Report Bog1 04 Feb 2012 PDF FreeJonathan OngNo ratings yet

- Graduate School: BA 235: Production Operations Management Assignment Number 1Document8 pagesGraduate School: BA 235: Production Operations Management Assignment Number 1neilbryan bolañoNo ratings yet

- The Seven Questions You Should Ask Before Selecting Your Manufacturing PartnerDocument30 pagesThe Seven Questions You Should Ask Before Selecting Your Manufacturing PartnersrujanodayNo ratings yet

- 7 Lean Manufacturing 1 1 Five S and Visual ControlDocument44 pages7 Lean Manufacturing 1 1 Five S and Visual Controlmax hopus100% (1)

- LEAN SystemDocument29 pagesLEAN SystemАлексей БеломестныйNo ratings yet

- Print PDFDocument10 pagesPrint PDFsoniNo ratings yet

- Operation ManagementDocument18 pagesOperation Managementjeonlei02No ratings yet

- Apply Quality StandardsDocument41 pagesApply Quality StandardsMher RiveroNo ratings yet

- LeanDocument23 pagesLeanfatim1987No ratings yet

- LeanDocument23 pagesLeanfatim1987No ratings yet

- Production and Operation ManagementDocument8 pagesProduction and Operation ManagementMerari ValenciaNo ratings yet

- A Product of Jaivin SurfactantsDocument12 pagesA Product of Jaivin SurfactantsRupesh NaiduNo ratings yet

- Reviewer OmDocument8 pagesReviewer Omピヤ メイNo ratings yet

- Operation Management - I (MFT4CCOQ01) Individual Assignment - IDocument9 pagesOperation Management - I (MFT4CCOQ01) Individual Assignment - IComplete AramNo ratings yet

- Saswat Kumar Mohapatra: Profile SummaryDocument3 pagesSaswat Kumar Mohapatra: Profile SummarySAMSON GLOBALNo ratings yet

- Group 1Document25 pagesGroup 1romalyn purificacionNo ratings yet

- Production AssistantDocument1 pageProduction AssistantMjay Chris BangNo ratings yet

- Wa0000.Document9 pagesWa0000.manikdarshanNo ratings yet

- Industrial Production: Is - The Industrial Sector Includes,, andDocument6 pagesIndustrial Production: Is - The Industrial Sector Includes,, andDoãn VyNo ratings yet

- Nilesh Panchal ResumeDocument3 pagesNilesh Panchal ResumeShanaNo ratings yet

- The Ugly Truth About Paper-Based QMS - Making The Switch To eQMSDocument19 pagesThe Ugly Truth About Paper-Based QMS - Making The Switch To eQMScivicbladeNo ratings yet

- CI CloudDocument2 pagesCI CloudAnurag BahugunaNo ratings yet

- POM Midterm ReviewerDocument8 pagesPOM Midterm ReviewerDaniel HunksNo ratings yet

- SALIHU Ibrahim RESUMEA - 001Document5 pagesSALIHU Ibrahim RESUMEA - 001favowritesNo ratings yet

- Product Quality Management 101:: A Guide For Non-Tech FoundersDocument9 pagesProduct Quality Management 101:: A Guide For Non-Tech FoundersDon RodrigueNo ratings yet

- Product Quality Management 101:: A Guide For Non-Tech FoundersDocument9 pagesProduct Quality Management 101:: A Guide For Non-Tech FoundersDon RodrigueNo ratings yet

- Group 5 - Chapter 6Document137 pagesGroup 5 - Chapter 6Jessa IlaoNo ratings yet

- Production Management New Unit 1Document47 pagesProduction Management New Unit 1Saif Ali KhanNo ratings yet

- Production of Goods & ServicesDocument35 pagesProduction of Goods & ServicesShahannah DOOKHAN100% (1)

- Operator Milling Machine - NOV CareersDocument5 pagesOperator Milling Machine - NOV CareersMFNo ratings yet

- Asset 1Document7 pagesAsset 1sarahmdqNo ratings yet

- Lean Vs TraditionalDocument3 pagesLean Vs TraditionalmuhammadajkhanNo ratings yet

- Indian Oil Corporation LTD Guwahati RefineryDocument27 pagesIndian Oil Corporation LTD Guwahati Refineryelectram67% (6)

- TPM-Presentation ModifiedDocument33 pagesTPM-Presentation Modifiedmathan.kNo ratings yet

- Operations ManagementDocument48 pagesOperations Managementfrancine olilaNo ratings yet

- Set 10-12 @12Document20 pagesSet 10-12 @12Cj EllazarNo ratings yet

- Introduction To Operations Management: Dr. Erlita C. Guerra, Mba, MpaDocument30 pagesIntroduction To Operations Management: Dr. Erlita C. Guerra, Mba, MpaJessa BasadreNo ratings yet

- TQM LessonDocument23 pagesTQM LessonJastine HularNo ratings yet

- Production ProcessDocument3 pagesProduction Processpenelope plushNo ratings yet

- Introduction To Our in House Manufacturing ShopDocument8 pagesIntroduction To Our in House Manufacturing ShopsalmansharifNo ratings yet

- (New) Industrial Manufacuring ProcessesDocument74 pages(New) Industrial Manufacuring ProcessesEnigma YTNo ratings yet

- Job BriefDocument2 pagesJob BriefCOLLINS OCHIENGNo ratings yet

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- Pasay City West High SchoolDocument33 pagesPasay City West High SchoolFranchesca ValerioNo ratings yet

- Learning Task: Matrix Completion: Name: Pedroso, Roane Joy Q. Section: OBTEC I-24Document4 pagesLearning Task: Matrix Completion: Name: Pedroso, Roane Joy Q. Section: OBTEC I-24Franchesca ValerioNo ratings yet

- I-24 Group7 Chapter Review Chapter6Document5 pagesI-24 Group7 Chapter Review Chapter6Franchesca ValerioNo ratings yet

- Tasking No.2 - Rizal'S Life, Works and Writings: Reflective Essay On "Ganito Kami Nuon, Paano Kayo Ngayon?"Document3 pagesTasking No.2 - Rizal'S Life, Works and Writings: Reflective Essay On "Ganito Kami Nuon, Paano Kayo Ngayon?"Franchesca Valerio100% (1)

- Analysis A and BDocument4 pagesAnalysis A and BFranchesca ValerioNo ratings yet

- Historical Foundations of Education: Education During The Ancient TimesDocument5 pagesHistorical Foundations of Education: Education During The Ancient TimesFranchesca ValerioNo ratings yet

- Pasay City West High School: Executive SummaryDocument30 pagesPasay City West High School: Executive SummaryFranchesca ValerioNo ratings yet

- The Math Behind The Virus' Dangerous Spread - Inquirer BusinessDocument6 pagesThe Math Behind The Virus' Dangerous Spread - Inquirer BusinessFranchesca ValerioNo ratings yet

- Wekullo 2018Document32 pagesWekullo 2018Franchesca ValerioNo ratings yet

- Analyzing Katipunan DocumentsDocument16 pagesAnalyzing Katipunan DocumentsFranchesca ValerioNo ratings yet

- To Bomb, or Not To BombDocument3 pagesTo Bomb, or Not To BombFranchesca ValerioNo ratings yet

- Wiring A Web For A Global Good: Reaction PaperDocument3 pagesWiring A Web For A Global Good: Reaction PaperFranchesca Valerio100% (1)

- TangledDocument3 pagesTangledFranchesca ValerioNo ratings yet

- Types of Medical Imaging Procedures and Effectiveness of Radiation DosesDocument9 pagesTypes of Medical Imaging Procedures and Effectiveness of Radiation DosesFranchesca ValerioNo ratings yet

- Globalization and How It Affected My Daily LifeDocument4 pagesGlobalization and How It Affected My Daily LifeFranchesca ValerioNo ratings yet

- Background of The Research ProblemDocument2 pagesBackground of The Research ProblemFranchesca ValerioNo ratings yet

- Normal Distribution Application in The Pandemic by Aiyesha Dela PeñaDocument2 pagesNormal Distribution Application in The Pandemic by Aiyesha Dela PeñaFranchesca ValerioNo ratings yet

- Purposive Communication Listening Reading Writing March 2021Document15 pagesPurposive Communication Listening Reading Writing March 2021Franchesca ValerioNo ratings yet

- 1 5 Chapter Complete Na YesDocument59 pages1 5 Chapter Complete Na YesFranchesca ValerioNo ratings yet

- Winsem2018 19 Course Allocation 10 Nov 2018Document239 pagesWinsem2018 19 Course Allocation 10 Nov 2018ayushi singhNo ratings yet

- Project Proposal LahamanDocument8 pagesProject Proposal LahamanNuraina NasirNo ratings yet

- Artificial Intelligence Research CenterDocument20 pagesArtificial Intelligence Research Centerpatmos666No ratings yet

- Understanding Learner - Sissy EntrekinDocument2 pagesUnderstanding Learner - Sissy Entrekinapi-404363060No ratings yet

- Reviewer in RWS 11Document4 pagesReviewer in RWS 11Arch GarciaNo ratings yet

- APJ Abdul KalamDocument15 pagesAPJ Abdul KalamAtharv Jaiswal100% (1)

- FINAL Parent Handbook AitchisonDocument68 pagesFINAL Parent Handbook AitchisonSaeed AhmedNo ratings yet

- What Is Evidence-Based Reading Instruction and How Do You Know It When You See ItDocument13 pagesWhat Is Evidence-Based Reading Instruction and How Do You Know It When You See ItTaranisaNo ratings yet

- Usha MTTDocument4 pagesUsha MTTUsha.R Primary ACONo ratings yet

- Protecting InnonationDocument16 pagesProtecting Innonationalessandro genoveseNo ratings yet

- Maharashtra University of Health Sciences, Nashik: II Year Post Basic B.SC NursingDocument25 pagesMaharashtra University of Health Sciences, Nashik: II Year Post Basic B.SC NursingshivaNo ratings yet

- BS Applied Physics (Materials Physics)Document2 pagesBS Applied Physics (Materials Physics)Jenny SagisiNo ratings yet

- Presentation On Marketing MixDocument11 pagesPresentation On Marketing MixTriciaGay DaleyNo ratings yet

- Clean Up Drive: Narrative ReportDocument5 pagesClean Up Drive: Narrative ReportNorie Jose100% (1)

- The Adult Probation LawDocument3 pagesThe Adult Probation LawAngel Urbano100% (1)

- Individualized Education Program (Iep)Document20 pagesIndividualized Education Program (Iep)api-302050301No ratings yet

- Internal Audit PolicyDocument7 pagesInternal Audit PolicyRUBELNo ratings yet

- Pragyan 08-01Document104 pagesPragyan 08-01PRAGYAN,Tinsukia CollegeNo ratings yet

- A Project Report On: Systematic Investment Plan in Security Investment Platform Mutual FundsDocument4 pagesA Project Report On: Systematic Investment Plan in Security Investment Platform Mutual FundsDibyaranjan SahooNo ratings yet

- Activity Proposal FormDocument3 pagesActivity Proposal FormFitz MagbanuaNo ratings yet

- Strategies For Improving Students' Enrollment Into Technical College Programmes in Ebonyi StateDocument7 pagesStrategies For Improving Students' Enrollment Into Technical College Programmes in Ebonyi StateEMERSON REXNo ratings yet

- IIBFDocument8 pagesIIBFSonia ChauhanNo ratings yet

- MAUD 151 Staffing PatternDocument2 pagesMAUD 151 Staffing PatternSNRajeevNo ratings yet

- Lab Report Form-1Document1 pageLab Report Form-1Operator Sergey IvanovNo ratings yet

The Qualifications and Requirements Required For Being Part of The Service Crew Management

The Qualifications and Requirements Required For Being Part of The Service Crew Management

Uploaded by

Franchesca Valerio0 ratings0% found this document useful (0 votes)

24 views3 pagesThe document discusses the 6 Ms of operation management - Money, Manpower, Machinery, Materials, Methods, and Management. It provides details on each:

1) Money - A street food business earns $183,250 per month.

2) Manpower - Skilled workers are needed for complex manufacturing processes. Training helps increase productivity.

3) Machinery - Precise, reliable, and durable machines create lean processes and reduce waste.

4) Materials - Quality materials prevent defects and improve performance while clean materials eliminate waste.

5) Methods - Establishing effective processes avoids wasted time and labor.

6) Management - Proper management keeps a business running efficiently with minimal

Original Description:

Original Title

6 Ms of Operation

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the 6 Ms of operation management - Money, Manpower, Machinery, Materials, Methods, and Management. It provides details on each:

1) Money - A street food business earns $183,250 per month.

2) Manpower - Skilled workers are needed for complex manufacturing processes. Training helps increase productivity.

3) Machinery - Precise, reliable, and durable machines create lean processes and reduce waste.

4) Materials - Quality materials prevent defects and improve performance while clean materials eliminate waste.

5) Methods - Establishing effective processes avoids wasted time and labor.

6) Management - Proper management keeps a business running efficiently with minimal

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

24 views3 pagesThe Qualifications and Requirements Required For Being Part of The Service Crew Management

The Qualifications and Requirements Required For Being Part of The Service Crew Management

Uploaded by

Franchesca ValerioThe document discusses the 6 Ms of operation management - Money, Manpower, Machinery, Materials, Methods, and Management. It provides details on each:

1) Money - A street food business earns $183,250 per month.

2) Manpower - Skilled workers are needed for complex manufacturing processes. Training helps increase productivity.

3) Machinery - Precise, reliable, and durable machines create lean processes and reduce waste.

4) Materials - Quality materials prevent defects and improve performance while clean materials eliminate waste.

5) Methods - Establishing effective processes avoids wasted time and labor.

6) Management - Proper management keeps a business running efficiently with minimal

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

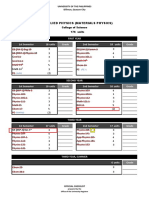

6 Ms of Operation

MONEY Samgyeop Street food earns Php 183,250/month.

MANAGEMENT Management is the art of accomplishing tasks with

and through the help of others. It is critical for an

entrepreneur to understand how to keep the firm

going with the least amount of work. The first step

toward successful operations management is to hire

the proper people.

THE QUALIFICATIONS and REQUIREMENTS REQUIRED

FOR BEING PART OF THE SERVICE CREW

MANAGEMENT

NBI Clearance

Medical & Health Permit

Work Permit

Qualifications:

At least High School Graduate

18 years old & above

Male or Female

Single/Married

With or Without Experience

Full time position only

Can start immediately with SSS, Pag-Ibig, Phil-

Health

Duties and Responsibilities:

Maintain a fast speed of service especially

during rush hours.

Take orders from customers and input their

selection into the cashier.

Assemble orders depending on the type of

orders.

Count down your till at the end of each shift

and deposit money in the safe.

Clean your station thoroughly before, during,

and after the shift.

Respond to guest question concerns and

complaints and make sure they leave

satisfied.

Follow all the company’s safety and security

procedures.

MANPOWER As far as manufacturing automation has come, we’ll

never eliminate the need for skilled workers in the

manufacturing process. In fact, many manufacturers

are finding a shortage of highly-skilled workers with

enough experience to perform today’s complex

production procedures. In order to overcome this

challenge, companies must focus on maintaining the

efficiency of their workforce if they hope to increase

productivity. Workers need focused, timely, and

frequent training in an environment where efficiency

and productivity is a common goal.

MACHINERY Design, installation, and maintenance of durable

precise machines reduces waste, saves money, creates

more precise products. Each machine in a

manufacturing process must be precisely designed,

built, and programmed to perform its function with

precision, reliability, and durability. Machines that are

reliable, durable, and efficient create a truly lean

manufacturing process.

MATERIALS Careful material selection and monitoring lead to

significant increase in efficiency over your entire

process.

Quality - Sound material choices make

effective products. You will prevent defective

work pieces, improve performance of the

final product by selecting materials with the

proper strength, weight, and endurance.

Carbonfiber composites and other commonly

used hard-to-machine materials are in high-

demand because of their strength and

flexibility. New technologies, like Cryogenic

Machining, make even hard-to-machine

materials accessible for nearly any process

Cleanliness - Eliminating Waste = Eliminating

Expense. Between wasted raw materials,

worn-out tooling, and coating parts in

contaminated, oily coolant, traditional

metalworking methods are far from efficient.

By leveraging state-of-the-art materials like

cryogenic cooling and efficient manufacturing

systems, you can prevent contamination of

work pieces and reduce the use of

consumables like specialty cutting tools.

Performance - Superior tooling leads to

better precision. Lean Manufacturing cannot

be achieved with inferior tooling. The quality,

availability, flexibility of your tool assets

relates directly to how adaptive your business

can be. By taking control of your tooling

supply, you’ll gain precise control of your

materials and work pieces.

Environmental-Efficiency - Increase the

efficiency of your manufacturing operation by

maintaining a clean and healthy environment

both outside and inside your organization.

Environmentally friendly materials are

characterized by:

Reduced Waste

Less Scrap Material

Decreased Contamination

Time Savings

Energy Efficiency

Increased Health & Safety

METHODS Wrong methods to conduct jobs might be costly

because you may not be able to achieve the desired

results. The Manager will establish the most effective

way to complete each step of the process in order to

avoid product damage and to remove areas where

time and labor are wasted. Waste management is

essential for efficient and profitable production.

You might also like

- IMO Manual On Oil Pollution - Section II Contingency PlanningDocument81 pagesIMO Manual On Oil Pollution - Section II Contingency PlanningSatria 'igin' Girindra Nugraha100% (2)

- Architecture and SportDocument44 pagesArchitecture and SportNeitherboth73% (11)

- Annotated BibliographyDocument6 pagesAnnotated Bibliographyapi-581682791No ratings yet

- Lean and Agile Manufacturing: Prepared By: Pallavi JoshiDocument25 pagesLean and Agile Manufacturing: Prepared By: Pallavi Joshipallaveejoshi100% (1)

- E-Games (Valorant)Document10 pagesE-Games (Valorant)Franchesca ValerioNo ratings yet

- IMRAD - Black HolesDocument8 pagesIMRAD - Black HolesFranchesca ValerioNo ratings yet

- Letter To PostmasterDocument2 pagesLetter To Postmastermary100% (2)

- Productivity Tool EssayDocument1 pageProductivity Tool EssayJohnelyn Porlucas MacaraegNo ratings yet

- Fairview Program PDFDocument36 pagesFairview Program PDFMargo Crawford50% (2)

- 4 MsDocument3 pages4 MsFranchesca Valerio0% (1)

- 5M For PlanningDocument7 pages5M For PlanningalaminNo ratings yet

- TPM BookletDocument26 pagesTPM Bookletamishraioc100% (5)

- Self Notes Pom Unit 1Document17 pagesSelf Notes Pom Unit 1Darshna ChaudharyNo ratings yet

- Lect 1 2010Document20 pagesLect 1 2010Mona FatimaNo ratings yet

- Chapter 4Document16 pagesChapter 4Mary Neilene PerezNo ratings yet

- Lean Manufacturing: College of Engineering, BBSRDocument24 pagesLean Manufacturing: College of Engineering, BBSRSmileyNo ratings yet

- Coatings and Construction Components (EU)Document20 pagesCoatings and Construction Components (EU)Shahid MirzaNo ratings yet

- JD Maintenance Engineer InstrumentationDocument2 pagesJD Maintenance Engineer InstrumentationsamcruiseatcNo ratings yet

- Chapter 4Document15 pagesChapter 4Bea Dela PeniaNo ratings yet

- Four Process StrategyDocument10 pagesFour Process StrategyChandria FordNo ratings yet

- Total Productive Maintenance (TPM) : Prevent Inefficiencies and Enhance Safety Through The Power of The TPM SystemDocument16 pagesTotal Productive Maintenance (TPM) : Prevent Inefficiencies and Enhance Safety Through The Power of The TPM SystemjjfmedNo ratings yet

- Production Notes (Summary)Document2 pagesProduction Notes (Summary)NeenaNo ratings yet

- OM Chapter 4Document14 pagesOM Chapter 4abdulwahab kemalNo ratings yet

- Factory JDDocument16 pagesFactory JDSatyam DixitNo ratings yet

- Operations Esterline Case Report Bog1 04 Feb 2012 PDF FreeDocument4 pagesOperations Esterline Case Report Bog1 04 Feb 2012 PDF FreeJonathan OngNo ratings yet

- Graduate School: BA 235: Production Operations Management Assignment Number 1Document8 pagesGraduate School: BA 235: Production Operations Management Assignment Number 1neilbryan bolañoNo ratings yet

- The Seven Questions You Should Ask Before Selecting Your Manufacturing PartnerDocument30 pagesThe Seven Questions You Should Ask Before Selecting Your Manufacturing PartnersrujanodayNo ratings yet

- 7 Lean Manufacturing 1 1 Five S and Visual ControlDocument44 pages7 Lean Manufacturing 1 1 Five S and Visual Controlmax hopus100% (1)

- LEAN SystemDocument29 pagesLEAN SystemАлексей БеломестныйNo ratings yet

- Print PDFDocument10 pagesPrint PDFsoniNo ratings yet

- Operation ManagementDocument18 pagesOperation Managementjeonlei02No ratings yet

- Apply Quality StandardsDocument41 pagesApply Quality StandardsMher RiveroNo ratings yet

- LeanDocument23 pagesLeanfatim1987No ratings yet

- LeanDocument23 pagesLeanfatim1987No ratings yet

- Production and Operation ManagementDocument8 pagesProduction and Operation ManagementMerari ValenciaNo ratings yet

- A Product of Jaivin SurfactantsDocument12 pagesA Product of Jaivin SurfactantsRupesh NaiduNo ratings yet

- Reviewer OmDocument8 pagesReviewer Omピヤ メイNo ratings yet

- Operation Management - I (MFT4CCOQ01) Individual Assignment - IDocument9 pagesOperation Management - I (MFT4CCOQ01) Individual Assignment - IComplete AramNo ratings yet

- Saswat Kumar Mohapatra: Profile SummaryDocument3 pagesSaswat Kumar Mohapatra: Profile SummarySAMSON GLOBALNo ratings yet

- Group 1Document25 pagesGroup 1romalyn purificacionNo ratings yet

- Production AssistantDocument1 pageProduction AssistantMjay Chris BangNo ratings yet

- Wa0000.Document9 pagesWa0000.manikdarshanNo ratings yet

- Industrial Production: Is - The Industrial Sector Includes,, andDocument6 pagesIndustrial Production: Is - The Industrial Sector Includes,, andDoãn VyNo ratings yet

- Nilesh Panchal ResumeDocument3 pagesNilesh Panchal ResumeShanaNo ratings yet

- The Ugly Truth About Paper-Based QMS - Making The Switch To eQMSDocument19 pagesThe Ugly Truth About Paper-Based QMS - Making The Switch To eQMScivicbladeNo ratings yet

- CI CloudDocument2 pagesCI CloudAnurag BahugunaNo ratings yet

- POM Midterm ReviewerDocument8 pagesPOM Midterm ReviewerDaniel HunksNo ratings yet

- SALIHU Ibrahim RESUMEA - 001Document5 pagesSALIHU Ibrahim RESUMEA - 001favowritesNo ratings yet

- Product Quality Management 101:: A Guide For Non-Tech FoundersDocument9 pagesProduct Quality Management 101:: A Guide For Non-Tech FoundersDon RodrigueNo ratings yet

- Product Quality Management 101:: A Guide For Non-Tech FoundersDocument9 pagesProduct Quality Management 101:: A Guide For Non-Tech FoundersDon RodrigueNo ratings yet

- Group 5 - Chapter 6Document137 pagesGroup 5 - Chapter 6Jessa IlaoNo ratings yet

- Production Management New Unit 1Document47 pagesProduction Management New Unit 1Saif Ali KhanNo ratings yet

- Production of Goods & ServicesDocument35 pagesProduction of Goods & ServicesShahannah DOOKHAN100% (1)

- Operator Milling Machine - NOV CareersDocument5 pagesOperator Milling Machine - NOV CareersMFNo ratings yet

- Asset 1Document7 pagesAsset 1sarahmdqNo ratings yet

- Lean Vs TraditionalDocument3 pagesLean Vs TraditionalmuhammadajkhanNo ratings yet

- Indian Oil Corporation LTD Guwahati RefineryDocument27 pagesIndian Oil Corporation LTD Guwahati Refineryelectram67% (6)

- TPM-Presentation ModifiedDocument33 pagesTPM-Presentation Modifiedmathan.kNo ratings yet

- Operations ManagementDocument48 pagesOperations Managementfrancine olilaNo ratings yet

- Set 10-12 @12Document20 pagesSet 10-12 @12Cj EllazarNo ratings yet

- Introduction To Operations Management: Dr. Erlita C. Guerra, Mba, MpaDocument30 pagesIntroduction To Operations Management: Dr. Erlita C. Guerra, Mba, MpaJessa BasadreNo ratings yet

- TQM LessonDocument23 pagesTQM LessonJastine HularNo ratings yet

- Production ProcessDocument3 pagesProduction Processpenelope plushNo ratings yet

- Introduction To Our in House Manufacturing ShopDocument8 pagesIntroduction To Our in House Manufacturing ShopsalmansharifNo ratings yet

- (New) Industrial Manufacuring ProcessesDocument74 pages(New) Industrial Manufacuring ProcessesEnigma YTNo ratings yet

- Job BriefDocument2 pagesJob BriefCOLLINS OCHIENGNo ratings yet

- Manufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1From EverandManufacturing Secret : Product Development and Intelligent Manufacturing For Flexible Automation With Odoo 17: odoo consultations, #1.1No ratings yet

- Pasay City West High SchoolDocument33 pagesPasay City West High SchoolFranchesca ValerioNo ratings yet

- Learning Task: Matrix Completion: Name: Pedroso, Roane Joy Q. Section: OBTEC I-24Document4 pagesLearning Task: Matrix Completion: Name: Pedroso, Roane Joy Q. Section: OBTEC I-24Franchesca ValerioNo ratings yet

- I-24 Group7 Chapter Review Chapter6Document5 pagesI-24 Group7 Chapter Review Chapter6Franchesca ValerioNo ratings yet

- Tasking No.2 - Rizal'S Life, Works and Writings: Reflective Essay On "Ganito Kami Nuon, Paano Kayo Ngayon?"Document3 pagesTasking No.2 - Rizal'S Life, Works and Writings: Reflective Essay On "Ganito Kami Nuon, Paano Kayo Ngayon?"Franchesca Valerio100% (1)

- Analysis A and BDocument4 pagesAnalysis A and BFranchesca ValerioNo ratings yet

- Historical Foundations of Education: Education During The Ancient TimesDocument5 pagesHistorical Foundations of Education: Education During The Ancient TimesFranchesca ValerioNo ratings yet

- Pasay City West High School: Executive SummaryDocument30 pagesPasay City West High School: Executive SummaryFranchesca ValerioNo ratings yet

- The Math Behind The Virus' Dangerous Spread - Inquirer BusinessDocument6 pagesThe Math Behind The Virus' Dangerous Spread - Inquirer BusinessFranchesca ValerioNo ratings yet

- Wekullo 2018Document32 pagesWekullo 2018Franchesca ValerioNo ratings yet

- Analyzing Katipunan DocumentsDocument16 pagesAnalyzing Katipunan DocumentsFranchesca ValerioNo ratings yet

- To Bomb, or Not To BombDocument3 pagesTo Bomb, or Not To BombFranchesca ValerioNo ratings yet

- Wiring A Web For A Global Good: Reaction PaperDocument3 pagesWiring A Web For A Global Good: Reaction PaperFranchesca Valerio100% (1)

- TangledDocument3 pagesTangledFranchesca ValerioNo ratings yet

- Types of Medical Imaging Procedures and Effectiveness of Radiation DosesDocument9 pagesTypes of Medical Imaging Procedures and Effectiveness of Radiation DosesFranchesca ValerioNo ratings yet

- Globalization and How It Affected My Daily LifeDocument4 pagesGlobalization and How It Affected My Daily LifeFranchesca ValerioNo ratings yet

- Background of The Research ProblemDocument2 pagesBackground of The Research ProblemFranchesca ValerioNo ratings yet

- Normal Distribution Application in The Pandemic by Aiyesha Dela PeñaDocument2 pagesNormal Distribution Application in The Pandemic by Aiyesha Dela PeñaFranchesca ValerioNo ratings yet

- Purposive Communication Listening Reading Writing March 2021Document15 pagesPurposive Communication Listening Reading Writing March 2021Franchesca ValerioNo ratings yet

- 1 5 Chapter Complete Na YesDocument59 pages1 5 Chapter Complete Na YesFranchesca ValerioNo ratings yet

- Winsem2018 19 Course Allocation 10 Nov 2018Document239 pagesWinsem2018 19 Course Allocation 10 Nov 2018ayushi singhNo ratings yet

- Project Proposal LahamanDocument8 pagesProject Proposal LahamanNuraina NasirNo ratings yet

- Artificial Intelligence Research CenterDocument20 pagesArtificial Intelligence Research Centerpatmos666No ratings yet

- Understanding Learner - Sissy EntrekinDocument2 pagesUnderstanding Learner - Sissy Entrekinapi-404363060No ratings yet

- Reviewer in RWS 11Document4 pagesReviewer in RWS 11Arch GarciaNo ratings yet

- APJ Abdul KalamDocument15 pagesAPJ Abdul KalamAtharv Jaiswal100% (1)

- FINAL Parent Handbook AitchisonDocument68 pagesFINAL Parent Handbook AitchisonSaeed AhmedNo ratings yet

- What Is Evidence-Based Reading Instruction and How Do You Know It When You See ItDocument13 pagesWhat Is Evidence-Based Reading Instruction and How Do You Know It When You See ItTaranisaNo ratings yet

- Usha MTTDocument4 pagesUsha MTTUsha.R Primary ACONo ratings yet

- Protecting InnonationDocument16 pagesProtecting Innonationalessandro genoveseNo ratings yet

- Maharashtra University of Health Sciences, Nashik: II Year Post Basic B.SC NursingDocument25 pagesMaharashtra University of Health Sciences, Nashik: II Year Post Basic B.SC NursingshivaNo ratings yet

- BS Applied Physics (Materials Physics)Document2 pagesBS Applied Physics (Materials Physics)Jenny SagisiNo ratings yet

- Presentation On Marketing MixDocument11 pagesPresentation On Marketing MixTriciaGay DaleyNo ratings yet

- Clean Up Drive: Narrative ReportDocument5 pagesClean Up Drive: Narrative ReportNorie Jose100% (1)

- The Adult Probation LawDocument3 pagesThe Adult Probation LawAngel Urbano100% (1)

- Individualized Education Program (Iep)Document20 pagesIndividualized Education Program (Iep)api-302050301No ratings yet

- Internal Audit PolicyDocument7 pagesInternal Audit PolicyRUBELNo ratings yet

- Pragyan 08-01Document104 pagesPragyan 08-01PRAGYAN,Tinsukia CollegeNo ratings yet

- A Project Report On: Systematic Investment Plan in Security Investment Platform Mutual FundsDocument4 pagesA Project Report On: Systematic Investment Plan in Security Investment Platform Mutual FundsDibyaranjan SahooNo ratings yet

- Activity Proposal FormDocument3 pagesActivity Proposal FormFitz MagbanuaNo ratings yet

- Strategies For Improving Students' Enrollment Into Technical College Programmes in Ebonyi StateDocument7 pagesStrategies For Improving Students' Enrollment Into Technical College Programmes in Ebonyi StateEMERSON REXNo ratings yet

- IIBFDocument8 pagesIIBFSonia ChauhanNo ratings yet

- MAUD 151 Staffing PatternDocument2 pagesMAUD 151 Staffing PatternSNRajeevNo ratings yet

- Lab Report Form-1Document1 pageLab Report Form-1Operator Sergey IvanovNo ratings yet