Professional Documents

Culture Documents

A Study On Energy Audit of A Cold Storage

A Study On Energy Audit of A Cold Storage

Uploaded by

Ashfaq Ali KhanCopyright:

Available Formats

You might also like

- Camel Intro 2Document34 pagesCamel Intro 2Inventor SolidworksNo ratings yet

- MECH4880-Assignment1 S2 2017 v1 - 01Document25 pagesMECH4880-Assignment1 S2 2017 v1 - 01charitha RanwalaNo ratings yet

- Words That Look Alike: Pass The TOEIC TestDocument2 pagesWords That Look Alike: Pass The TOEIC TestLành CaNo ratings yet

- AirConditioning & Ventilation TCX Methodology Rev# 1.1Document12 pagesAirConditioning & Ventilation TCX Methodology Rev# 1.1Non Etabas GadnatamNo ratings yet

- Tube Wire Vs Wall Condenser PDFDocument15 pagesTube Wire Vs Wall Condenser PDFHimanshu100% (1)

- MR2207 Atd1 Q&aDocument33 pagesMR2207 Atd1 Q&ajeffreysingh jdNo ratings yet

- Understanding Chiller EfficiencyDocument14 pagesUnderstanding Chiller EfficiencyOmair Farooq100% (2)

- Year Book2008Document790 pagesYear Book2008Patricia GomesNo ratings yet

- I Ching Acupuncture The Balance MethodDocument14 pagesI Ching Acupuncture The Balance MethodMaria Agustina Flores de Seguela100% (2)

- Thermal Insulation Calculation Guide - AMARINEDocument5 pagesThermal Insulation Calculation Guide - AMARINEEddie FongNo ratings yet

- DBA CalculationDocument4 pagesDBA CalculationKevin J. MillsNo ratings yet

- Moist Air PropertiesDocument12 pagesMoist Air PropertiesLily DianaNo ratings yet

- R&AC Lecture 30Document17 pagesR&AC Lecture 30Denise Koh Chin HuiNo ratings yet

- IRR Calculation Sheet For Auto LoansDocument8 pagesIRR Calculation Sheet For Auto LoansmskharadeNo ratings yet

- Newton's Law of Cooling Math Assignment Winston BoonDocument27 pagesNewton's Law of Cooling Math Assignment Winston BoonWinston BoonNo ratings yet

- Literature Study On Literature Study On Building Services Building ServicesDocument41 pagesLiterature Study On Literature Study On Building Services Building ServicesAmey DeshmukhNo ratings yet

- Psychrometric Chart (Altitude 0, 750, 1500, 2250, 3000 M)Document5 pagesPsychrometric Chart (Altitude 0, 750, 1500, 2250, 3000 M)Kam Wai CheongNo ratings yet

- HVACPow Den InstructionsDocument5 pagesHVACPow Den InstructionsadamyzcNo ratings yet

- Fcu Selection For Vitamin RoomDocument2 pagesFcu Selection For Vitamin RoomArjay SalgadoNo ratings yet

- Air Conditioner: The BasicsDocument14 pagesAir Conditioner: The BasicsNikki AmuraoNo ratings yet

- Waste Heat Recovery (Mech-31)Document18 pagesWaste Heat Recovery (Mech-31)shammiNo ratings yet

- Quotation Cold Room An NAM Group - 17 Aug 2010Document12 pagesQuotation Cold Room An NAM Group - 17 Aug 2010huyly34No ratings yet

- Hvac Cep ReportDocument66 pagesHvac Cep ReportMuhammad KashifNo ratings yet

- Acoustic Calculation of Ventilation SystemsDocument4 pagesAcoustic Calculation of Ventilation SystemsSandeep BhatiaNo ratings yet

- Tsi Panda 341 User ManualDocument37 pagesTsi Panda 341 User Manuala k bNo ratings yet

- Lokring I Single Ring 01.07.2013Document58 pagesLokring I Single Ring 01.07.2013Sandra Mabel Leguizamon100% (1)

- Dr. Fixit Newcoat 105 1 PDFDocument3 pagesDr. Fixit Newcoat 105 1 PDFmohdrashidNo ratings yet

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenDocument9 pagesNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenrakamechNo ratings yet

- As 2254-1988 Acoustics - Recommended Noise Levels For Various Areas of Occupancy in Vessels and OffshoreDocument5 pagesAs 2254-1988 Acoustics - Recommended Noise Levels For Various Areas of Occupancy in Vessels and OffshoreSAI Global - APACNo ratings yet

- Arctic Evaporative Cooler CatalogDocument3 pagesArctic Evaporative Cooler Catalogसारंग बेलसरेNo ratings yet

- Coils Selection FormulasDocument3 pagesCoils Selection FormulasalbrgmailNo ratings yet

- Cooling Load Casa AzulDocument40 pagesCooling Load Casa AzulHenry San PedroNo ratings yet

- Engineering: Energy RecoveryDocument4 pagesEngineering: Energy RecoverySuchitKNo ratings yet

- ICE Factory Balance SheetDocument2 pagesICE Factory Balance SheetAhmad FarhatNo ratings yet

- Spitler McQuiston Lindsey 93 2Document11 pagesSpitler McQuiston Lindsey 93 2Shafawati ShahneelNo ratings yet

- Cooling Load Calculation DetailDocument2 pagesCooling Load Calculation DetailNikita SinhaNo ratings yet

- MECH3429Air Conditioning and Refrigeration Engineering3Document84 pagesMECH3429Air Conditioning and Refrigeration Engineering3Umair Khan MarwatNo ratings yet

- AC V For Fast Food RestaurantsDocument4 pagesAC V For Fast Food Restaurantselijah namomoNo ratings yet

- Zeus Acds Series BrochureDocument40 pagesZeus Acds Series BrochureAntonio Osante LeyvaNo ratings yet

- Information Bulletin 3 Building Def Rev3Document1 pageInformation Bulletin 3 Building Def Rev3Alan TanNo ratings yet

- Waste Heat Recovery System For RefrigeratorDocument10 pagesWaste Heat Recovery System For RefrigeratorlalkrishnaNo ratings yet

- COOLING LOAD CAPACITY GONZALESxNOLASCODocument70 pagesCOOLING LOAD CAPACITY GONZALESxNOLASCOJohn Robert GonzalesNo ratings yet

- Training Materials CatalogDocument32 pagesTraining Materials CatalogFELIXDEJNo ratings yet

- MULTI V 5 Catalog PDFDocument34 pagesMULTI V 5 Catalog PDFquangNo ratings yet

- AT4 HumidifierDocument64 pagesAT4 Humidifiermdalt9180No ratings yet

- Dynair Ecology UnitDocument12 pagesDynair Ecology Unitrid100% (1)

- AHU Friction Loss CalculationsDocument4 pagesAHU Friction Loss CalculationsAdnan AttishNo ratings yet

- Materaial For Question 3. - Cooling Load CLTD Example Ashrae PDFDocument5 pagesMateraial For Question 3. - Cooling Load CLTD Example Ashrae PDFkumarNo ratings yet

- Hvac Design CalculationsDocument1 pageHvac Design CalculationsAnonymous oUoJ4A8xNo ratings yet

- Energy Performance Assessment of Hvac SystemsDocument4 pagesEnergy Performance Assessment of Hvac SystemsBudihardjo Sarwo SastrosudiroNo ratings yet

- Non Circular Pipe FrictionDocument3 pagesNon Circular Pipe Frictionravi_radanNo ratings yet

- Cooling Loads Calculation: Cooling Load Temperature Difference (CLTD) MethodDocument8 pagesCooling Loads Calculation: Cooling Load Temperature Difference (CLTD) MethodChristopher LloydNo ratings yet

- BCA Energy Performance Points CalculatorDocument96 pagesBCA Energy Performance Points CalculatorRidwan ArifinNo ratings yet

- Sealant - 1st Acrylic A-700 MSDSDocument6 pagesSealant - 1st Acrylic A-700 MSDSBozow BongNo ratings yet

- Carriage Bolts and Nuts DIN 603 (Bolt) DIN 934 (Nut)Document1 pageCarriage Bolts and Nuts DIN 603 (Bolt) DIN 934 (Nut)Srinivasa TemkarNo ratings yet

- By Chandana Dalugoda: Air Conditioning Load CalculationsDocument7 pagesBy Chandana Dalugoda: Air Conditioning Load CalculationsWASO IBDNo ratings yet

- Serbia Cleanrooms Seminar 1Document46 pagesSerbia Cleanrooms Seminar 1Иван ШимчукNo ratings yet

- Cibse Heat Loss & Heat Gain (Apachecalc) Calculation MethodsDocument9 pagesCibse Heat Loss & Heat Gain (Apachecalc) Calculation Methodsวรศิษฐ์ อ๋องNo ratings yet

- Cooling Load1111 PDFDocument43 pagesCooling Load1111 PDFJason PaquibulanNo ratings yet

- Cooling Load EstimationDocument4 pagesCooling Load Estimationk.vikasNo ratings yet

- NAVY Health Center - Indoor Firing RangeDocument58 pagesNAVY Health Center - Indoor Firing Rangekumar123rajuNo ratings yet

- Reverse Cornot, Vapor Compression Cycles Part IDocument14 pagesReverse Cornot, Vapor Compression Cycles Part ISumran ShahidNo ratings yet

- Efficiency of Compact Organic Rankine Cycle System With Rotary-Vane-Type Expander For Low-Temperature Waste Heat RecoveryDocument6 pagesEfficiency of Compact Organic Rankine Cycle System With Rotary-Vane-Type Expander For Low-Temperature Waste Heat Recoverythanhtbk2000No ratings yet

- Stellar Ammonia Safety ChecklistDocument1 pageStellar Ammonia Safety ChecklistAshfaq Ali KhanNo ratings yet

- Cold Front - Vol. 10 No. 2, 2010 NewsletterDocument8 pagesCold Front - Vol. 10 No. 2, 2010 NewsletterAshfaq Ali KhanNo ratings yet

- Cold Front - Vol. 1 No. 1, 2001 NewsletterDocument5 pagesCold Front - Vol. 1 No. 1, 2001 NewsletterAshfaq Ali KhanNo ratings yet

- Cold Front - Vol. 10 No. 3, 2010 NewsletterDocument8 pagesCold Front - Vol. 10 No. 3, 2010 NewsletterAshfaq Ali KhanNo ratings yet

- Commissioning - A Process To Achieve Sustainable Refrigerated FacilitiesDocument7 pagesCommissioning - A Process To Achieve Sustainable Refrigerated FacilitiesAshfaq Ali KhanNo ratings yet

- Safe Handling of Ammonia As Refrigerant: Anders Lindborg Ammonia Partnership AB SwedenDocument53 pagesSafe Handling of Ammonia As Refrigerant: Anders Lindborg Ammonia Partnership AB SwedenAshfaq Ali KhanNo ratings yet

- Cold Front - Vol. 15 No. 4, 2015 NewsletterDocument8 pagesCold Front - Vol. 15 No. 4, 2015 NewsletterAshfaq Ali KhanNo ratings yet

- I D A R S: IRC StaffDocument7 pagesI D A R S: IRC StaffAshfaq Ali KhanNo ratings yet

- IRC Staff: in This IssueDocument7 pagesIRC Staff: in This IssueAshfaq Ali KhanNo ratings yet

- B B: C R P: in This Issue IRC StaffDocument7 pagesB B: C R P: in This Issue IRC StaffAshfaq Ali KhanNo ratings yet

- Reducing Energy Consumption in Cold Stores Using A Freely Available Mathematical ModelDocument30 pagesReducing Energy Consumption in Cold Stores Using A Freely Available Mathematical ModelAshfaq Ali KhanNo ratings yet

- Refrigeration FormulasDocument8 pagesRefrigeration FormulasAshfaq Ali KhanNo ratings yet

- Example 10B - 1 - Ideal Ammonia Vapor-Compression RefrigeratorDocument22 pagesExample 10B - 1 - Ideal Ammonia Vapor-Compression RefrigeratorAshfaq Ali KhanNo ratings yet

- Energy Modeling Guideline For Cold Storage and Refrigerated Warehouse FacilitiesDocument12 pagesEnergy Modeling Guideline For Cold Storage and Refrigerated Warehouse FacilitiesAshfaq Ali KhanNo ratings yet

- Using Ammonia As A RefrigerantDocument3 pagesUsing Ammonia As A RefrigerantAshfaq Ali KhanNo ratings yet

- Overview of Ammonia Refrigeration SystemsDocument4 pagesOverview of Ammonia Refrigeration SystemsAshfaq Ali KhanNo ratings yet

- 1 NergyGuidelines 2013-12-19Document12 pages1 NergyGuidelines 2013-12-19Ashfaq Ali KhanNo ratings yet

- 14 Factors To Keep Your Refrigeration Compressor Package in Check - Stellar Food For ThoughtDocument2 pages14 Factors To Keep Your Refrigeration Compressor Package in Check - Stellar Food For ThoughtAshfaq Ali KhanNo ratings yet

- 3 Ways To Determine The Fitness of Your Refrigeration Compressor - Stellar Food For ThoughtDocument2 pages3 Ways To Determine The Fitness of Your Refrigeration Compressor - Stellar Food For ThoughtAshfaq Ali KhanNo ratings yet

- S - T - S C ?: Ingle OR WO Tage OmpressionDocument9 pagesS - T - S C ?: Ingle OR WO Tage OmpressionAshfaq Ali KhanNo ratings yet

- 3.cold Chain Assessment Apr 3 2013Document37 pages3.cold Chain Assessment Apr 3 2013Ashfaq Ali KhanNo ratings yet

- HVAC - 10 Cooler Ideas For Refrigeration System Efficiency - Plant ServicesDocument5 pagesHVAC - 10 Cooler Ideas For Refrigeration System Efficiency - Plant ServicesAshfaq Ali KhanNo ratings yet

- Calculate Size of SolarDocument2 pagesCalculate Size of SolarMuhammad SalmanNo ratings yet

- Britannica Childrens Encyclopedia 2007Document1 pageBritannica Childrens Encyclopedia 2007Marius AndreiNo ratings yet

- CLPWPost War Literary WorksDocument4 pagesCLPWPost War Literary WorksRohann Ban0% (1)

- Accomplishment Report On 2019 SchoolDocument10 pagesAccomplishment Report On 2019 SchoolJuliet AlanNo ratings yet

- IDC POS Lab Project Plan 2 2Document471 pagesIDC POS Lab Project Plan 2 2shiramkkNo ratings yet

- Dissertation Topic MailDocument57 pagesDissertation Topic MailANUPNo ratings yet

- Rural - India Oct 10 EDELWEISSDocument89 pagesRural - India Oct 10 EDELWEISSpkn04100% (1)

- Status of Led Lighting World Market 2020 Final Rev 2Document82 pagesStatus of Led Lighting World Market 2020 Final Rev 2javadeveloper lokeshNo ratings yet

- Sep. Gravimetrica - CromitaDocument13 pagesSep. Gravimetrica - Cromitaemerson sennaNo ratings yet

- Bunk Bed Plans SampleDocument4 pagesBunk Bed Plans SampleCedrickNo ratings yet

- 1.publications All BranchesDocument25 pages1.publications All BranchesNaresh GollapalliNo ratings yet

- SpencerDocument34 pagesSpencervenkatteja75No ratings yet

- CMRL.12.18 : Section A: New Business, Regulatory and Sales-Related RequirementsDocument2 pagesCMRL.12.18 : Section A: New Business, Regulatory and Sales-Related RequirementsJovelyn ArgeteNo ratings yet

- Ca17 Activity 1Document2 pagesCa17 Activity 1Mark Kenneth CeballosNo ratings yet

- Corporate Tax - UAEDocument48 pagesCorporate Tax - UAEUmair BaigNo ratings yet

- Transportation Engineering - I: Introduction To Bridge EngineeringDocument33 pagesTransportation Engineering - I: Introduction To Bridge Engineeringmit rami0% (1)

- Investigative Skills 3Document75 pagesInvestigative Skills 3Keling HanNo ratings yet

- Essay On Corruption in in IndiaDocument1 pageEssay On Corruption in in IndiaGaurav ThakurNo ratings yet

- Sexy Book 121Document252 pagesSexy Book 121Irepan Ponce50% (2)

- F R N W: Rench Evolutionary Apoleonic ArsDocument7 pagesF R N W: Rench Evolutionary Apoleonic ArsevansauroNo ratings yet

- Shark ClassificationDocument44 pagesShark ClassificationSheeka TareyamaNo ratings yet

- CodaDocument15 pagesCodaShashi KartikyaNo ratings yet

- Fotip ResumeDocument3 pagesFotip Resumeapi-529088054No ratings yet

- PHD Thesis Library Science DownloadDocument8 pagesPHD Thesis Library Science Downloadyvrpugvcf100% (2)

- How Can Apologetics Help Me Defend My Faith?Document16 pagesHow Can Apologetics Help Me Defend My Faith?Regina D. RogersNo ratings yet

- Weather Forecast: by Vass Tunde Juen, 1 Verbal and Non-Verbal CommunicationDocument5 pagesWeather Forecast: by Vass Tunde Juen, 1 Verbal and Non-Verbal CommunicationAlina-Cristina CotoiNo ratings yet

- HLLQP QuickFact FormulaSheet 2016Document2 pagesHLLQP QuickFact FormulaSheet 2016nandhinigrmNo ratings yet

A Study On Energy Audit of A Cold Storage

A Study On Energy Audit of A Cold Storage

Uploaded by

Ashfaq Ali KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Study On Energy Audit of A Cold Storage

A Study On Energy Audit of A Cold Storage

Uploaded by

Ashfaq Ali KhanCopyright:

Available Formats

Dr. N. Mukhopadhyay Int. Journal of Engineering Research and Applications www.ijera.

com

ISSN : 2248-9622, Vol. 5, Issue 4, ( Part -7) April 2015, pp.06-10

RESEARCH ARTICLE OPEN ACCESS

A Study on Energy Audit of a Cold Storage

1

Dr. N. Mukhopadhyay, 2Raj Gopal Nanda

1

Assistant professor, Department of Mechanical Engineering, Jalpaiguri Govt.Engg. College,

2

M.Tech. Scholar, Department of Mechanical Engineering, Jalpaiguri Govt.Engg. College,

ABSTRACT

Energy consumption of a cold storage was measured for different storage temperatures. Suction temperature and

pressure temperature of the compressor and working time of the compressor were determined to reach

evaporator set up temperatures. An axial fan located back of the evaporator was used to distribute the cooled air

into the cold store. An electrical heater was used to defrost.

The compressor suction temperatures and discharge temperatures varied between 1.80 C - 070 C and 270 C - 350

C respectively. Condenser output temperature is varies 40 C - 100 C. Compressor suction pressure (p1) = 3.5

Kg/cm2 and discharge pressure (p2) = 10.5 Kg/cm2.

Key words: Energy, Cold Storage, Refrigeration

I. INTRODUCTION important costly raw materials like dry fruits,

Energy auditing in a integral part of energy chemicals, essences and processed foods like fruit

conservation and energy management is also part and juice/pulp, concentrate dairy products, frozen meat,

parallel of conservation. Damage and supply gap is fish and eggs are being stored in cold storages to

large energy to lead to similar natural defects, Energy regulate marketing channels of these products.

disaster such as Tsunami and earth quake. The next Energy consumption of an experimental cold

generation generating yet to come will be completely storage was measured for different storage

light blind. It is because power never be available temperatures. Suction temperature and pressure

after this disaster and not ever rehabilitate the temperature of the compressor and working time of

reconstruction of buildings. To avoid the energy the compressor were determined to reach evaporator

calamity proposed auditing report use the innovative set up temperatures. Capacity of compressor,

energy utilization schemes through which the condenser, and evaporator were 10460 kJ/h, 12552

ferocious of situation might blindness can be kJ/h , and 10460 kJ/h, respectively. An axial fan

eradicated. located back of the evaporator was used to distribute

Cold Storage is a special kind of room, the the cooled air into the cold store. An electrical heater

temperature of, which is kept very low with the help was used to defrost. Refrigerant was R22.

of machines and precision instruments. India is Energy use in a cold storage facility is affected

having a unique geographical position and a wide by the amount of heat the refrigeration equipment

range of soil thus producing variety of fruits and must remove and the efficiency of the equipment.

vegetables like apples, grapes, oranges, potatoes, The main sources of heat in a facility for long-term

chillies, ginger, etc. Marine products are also being storage are transmission through walls, evaporator

produced in large quantities due to large coastal coil fans, lights, air leakage, and respiration of the

areas. The present production level of fruits and stored commodity.

vegetables is more than 100 million MT and keeping The electric energy consumption of existing cold

in view the growth rate of population and demand, stores ranges between 30 and 50kWh/m3/year for

the production of perishable commodities is storage. It is depends on the quality of the building,

increasing every year. The cold storage facilities are on the activities (chilled or frozen storage), room

the prime infrastructural component for such size, stock turnover, temperature of the incoming

perishable commodities. Besides the role of produce, outside temperatures, etc. The total cost of

stabilizing market prices and evenly distributing both electric energy is about 10 to 15% of the total

on demand basis and time basis, the cold storage running costs of a store. Improving Energy

industry renders other advantages and benefits to Efficiency (EE) has two goals: cost reduction and

both the farmers and the consumers. The farmers get environmental protection.

opportunity of producing cash crops to get Objective of this research is to determine energy

remunerative prices. The consumers get the supply of consumption of a cold storage for different storage

perishable commodities with lower fluctuation of temperatures. Energy consumption of the system

prices. Commercially apples, potatoes, oranges are elements such as compressor, condenser and fan of

stored on large scale in the cold storages. Other the evaporator were measured and evaluated. In

www.ijera.com 6|P age

Dr. N. Mukhopadhyay Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 5, Issue 4, ( Part -7) April 2015, pp.06-10

addition, suction and pressure temperatures of the the positive mismatch cannot be compensated either

compressor, condenser output temperature and by organic way or it might be difficult task.

required time to reach to the each set up temperature This paper deals with different aspects of design

were determined and evaluated. of cold storage and includes all standard refrigeration

Energy auditing is one tool through which principles and heat load factors which are normally

balancing of demand and supply is determined and considered in a cold storage design and various

energy audits.

II. MODEL ANALYSIS

(a) Technical analysis –

I visit a cold storage at West Bengal , INDIA and collect the data which is given below :-

T1 = 2.5 0 C , T2 = 30 0 C

T3 = 4.5 0 C , T4 = 1 0 C

P1 = 3.5 kg/cm 2 , P2 = 10.5 kg/cm 2

Calculation for Actual energy : -

At first I take the data of actual energy by a compressor (KC 2) for one chamber from reading, this is equal

to = 55 KW per hour.

Now also I got this actual energy by the electricity bill for that cold storage --

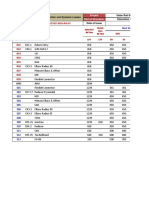

Month Electricity bill

July , 2014 73,890 KWH

August , 2014 86,135 KWH

September , 2014 60,295 KWH

So, the average of this three months electricity bill is

73890 + 86135 + 60295 220320

= = = 𝟕𝟑𝟒𝟒𝟎 KWH

3 3

This unit is for one month and for 2 chambers only.

The running time for a month is 540 Hours.

Now, Total unit consumption for one hour and for one chamber

73440

= = 𝟔𝟖 𝑲𝑾 𝒑𝒆𝒓 𝒉𝒐𝒖𝒓

540 × 2

[ One compressor is running for one chamber ]

Now , there is also a pump, 336 pieces of fan & 800 lights are running .

www.ijera.com 7|P age

Dr. N. Mukhopadhyay Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 5, Issue 4, ( Part -7) April 2015, pp.06-10

Unit consumed by the pump = 11.19 KW

Unit consumed by the fan = 0.06 KW

Unit consumed by the light = 0.018 KW

So, the total unit consumed by this three

= [ 11.19 + 0.06 + 0.018 ] KW

= 11.27 KW

So, unit consumed by a compressor is = [ 68 - 11.27 ] KW

= 56.73 KW

This value is approximately similar to the actual energy by a compressor from reading. So, I take 55 KW/h

So,

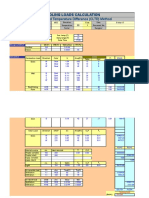

Calculation for Theoretical energy : - p 2 = 10.5 kg/cm2 = 105000 kg/m2

I have done this theoretical energy calculation with = 105000/101.972 KPa = 1029.69 KPa

1.4

three process :- Etheoritical = 343.23 x 0.00221 x

1.4−1

(i) The power of compressor = V . I . CosØ 1.4−1

10.5 1.4

{ − 1}

3.5

Here , V = 415 volt

= 2.665 x [ 1.375 - 1]

I = 125 Amp.

Etheoritical = 0.996 Joule

CosØ = 0.8

Here the speed of motor for compressor is = 1440

So, Etheoritical = V . I . CosØ

rpm and number of cylinder is = 2, then

= 415 X 125 X 0.85 0.996 × 2 ×1440

= 44093.75 Watt Etheoritical =

60

Etheoritical = 44.09 KW per hour Etheoritical = 47.8 KW per hour

(ii) Also we know, (iii) Now,

Etheoritical = work done by a compressor Heat grade energy output ( KWH)

𝒏−𝟏

𝒏 𝒑𝟐 𝒏

Co-efficient of performance (COP) = -------------------

Etheoritical = 𝐩𝟏 𝐯𝟏 { − 𝟏} -----------------------------------

𝒏−𝟏 𝒑𝟏

Where, Electrical/Mechanical energy input (KWH)

𝑸

n = 1.4 COP =

𝑾

p 1 = 3.5 kg/cm2 = 35000 kg/m2 𝒅𝒕𝟏

Also, COP =

= 35000/101. 972 KPa 𝒅𝒕𝟏 −𝒅𝒕𝟐

= 343.23 KPa Where, dt1 = Condensing temperature difference

dt2 = Evaporating temperature difference

𝜋 𝑸 𝒅𝒕𝟏

v1 = 𝐷2 𝐿 where D = Bore = 160 mm So, =

4 𝑾 𝒅𝒕𝟏 −𝒅𝒕𝟐

L = Stroke = 110 mm 𝑸(𝒅𝒕𝟏 − 𝒅𝒕𝟐 )

𝜋

0.16 2 × 0.11 𝑾 =

=

4 𝒅𝒕𝟏

= 0.00221 m3

www.ijera.com 8|P age

Dr. N. Mukhopadhyay Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 5, Issue 4, ( Part -7) April 2015, pp.06-10

Here Q = 55 KW per hour. [ It is calculated from a August 2014 86135 KWH Rs. 5,42,071 /-

journal paper]

𝟓𝟓 𝑻𝟐 −𝑻𝟑 − 𝑻𝟏 −𝑻𝟒 September 60295 KWH Rs. 4,66,395 /-

Then, 𝑾 =

𝑻𝟐 −𝑻𝟑 2014

𝟓𝟓 𝟑𝟎𝟑 − 𝟐𝟕𝟕. 𝟓 – 𝟐𝟕𝟓. 𝟓 − 𝟐𝟕𝟒

𝑾 =

𝟑𝟎𝟑 − 𝟐𝟕𝟕. 𝟓 So, the average

cost of one month =

538972 + 542071 +466395

𝟓𝟓 𝟐𝟓. 𝟓 − 𝟏. 𝟓 = Rs. 5,15,813 /-

𝑾 = 3

𝟐𝟓. 𝟓 Now the excess energy for a month is equal to 2700

𝑾 = 𝟓𝟏. 𝟕𝟔 𝑲𝑾 𝒑𝒆𝒓 𝒉𝒐𝒖𝒓 KWH and for a year is equal to 32400 KWH.

Etheoritical = 51.76 KW per hour So the saving money is = 2700 x 7.5 = Rs. 20,250 /-

Now , the average of this three in a month.

44.09 + 47.8 + 51.76

Etheoritical = = 32400 x 7.5 = Rs. 2,43,000 /- in a year.

3

= 47.88 KW per hour

So, when I take mechanical/electrical energy loss of III. RESULT & DISCUSSION

the compressor then this energy is equal to At first I make a programming for the equation

𝒏−𝟏

𝒏 𝒑𝟐 𝒏

Etheoritical = × 𝟐 × 𝟐𝟒 × 𝐩𝟏 𝐯𝟏 { − 𝟏}

Etheoritical = 50 KW per hour. 𝒏−𝟏 𝒑𝟏

in KW

Where n = 1.4

(b) Energy Gap Analysis – The program is -

There is a huge gap when I calculating the #include<iostream.h>

energy difference. #include<conio.h>

Gap energy = Eactual - Etheoritical #include<math.h>

= 55 − 50 KW per hour = 5 KW per int main( ) {

hour double p1 , p2 , v1 = 0.00221, e , x ;

If I take per month then it becomes :- cout<< “give the value of p1 , p2 / n”;

Gap energy = 5 × 540 KW per hour cin>> p1 >> p2

= 2700 KW per hour x = pow (p2 / p1 , 0.29);

If I take per year it becomes :- e = 3.5 * 2 * 24 *(p1 * v1 * x – p1 * v1);

Gap energy = 2700 × 12 KW per hour cout << e ;

= 32400 KW per hour return 0 ;

(c) Cost Analysis – }

This data is collected from total electricity bill of that This programming is done for the twenty values of p 1

cold storage – , p2 and E which is used for making the graph plotting

Month Unit Cost –

(i) p1 vs E and (ii) p2 vs E (iii) T1 vs E

July 2014 73890 KWH Rs. 5,38,972 /- Where p1 = suction pressure, p2 = discharge pressure,

E = energy and T1 = suction tempera ture.

(i) Graph of compressor suction pressure vs compressor energy :-

The graph indicates that energy increases with increase in suction pressure

(ii) Graph of compressor discharge pressure vs compressor energy :-

www.ijera.com 9|P age

Dr. N. Mukhopadhyay Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 5, Issue 4, ( Part -7) April 2015, pp.06-10

The graph indicates that energy increases with increase in discharge pressure

(iii) Graph of compressor suction temperature vs compressor energy :-

The graph indicates that energy increases with increase in discharge pressure

IV. CONCLUSION REFERANCES

It has been observed that the actual energy [1] www.google.com

consumption of a cold storage by a compressor for [2] http://en.wikipedia.org

one chamber is 55 KW per hour and theoretical [3] Engineering Thermodynamics, P. K. Nag

energy consumption is 50 KW per hour. So, a gap of (Book)

5 KW per hour is found between the theoretical and [4] Willis croft PMP, NZ Rural Press Limited,

actual energy consumption by a compressor. If this Auckland, 2007

gap is fulfilled then a savings of Rs 20,250 /- per [5] ISHRAE Publications, Air conditioning and

month will be obtained which will amount to Rs Refrigeration

2,43,000 /- per year.

To save energy the following practices must be

implemented:-

1. Reducing Heat Loads

2. Uses of latest energy saving equipments

3. Proper Insulation

4. Efficient maintenance practices

5. Automation & Integration

There are other factor which contributes to the

total energy consumption, which are (i) lights (total

800 pcs) , (ii) fans (total 336 pcs). To increase the

efficiency, conventional lights will replaced by

energy efficient devices that is LED, CFL etc.

If we replace three compressors for three

chambers with a single equivalent compressor which

will deliver the same amount of load, then maximum

energy will be saved.

www.ijera.com 10 | P a g e

You might also like

- Camel Intro 2Document34 pagesCamel Intro 2Inventor SolidworksNo ratings yet

- MECH4880-Assignment1 S2 2017 v1 - 01Document25 pagesMECH4880-Assignment1 S2 2017 v1 - 01charitha RanwalaNo ratings yet

- Words That Look Alike: Pass The TOEIC TestDocument2 pagesWords That Look Alike: Pass The TOEIC TestLành CaNo ratings yet

- AirConditioning & Ventilation TCX Methodology Rev# 1.1Document12 pagesAirConditioning & Ventilation TCX Methodology Rev# 1.1Non Etabas GadnatamNo ratings yet

- Tube Wire Vs Wall Condenser PDFDocument15 pagesTube Wire Vs Wall Condenser PDFHimanshu100% (1)

- MR2207 Atd1 Q&aDocument33 pagesMR2207 Atd1 Q&ajeffreysingh jdNo ratings yet

- Understanding Chiller EfficiencyDocument14 pagesUnderstanding Chiller EfficiencyOmair Farooq100% (2)

- Year Book2008Document790 pagesYear Book2008Patricia GomesNo ratings yet

- I Ching Acupuncture The Balance MethodDocument14 pagesI Ching Acupuncture The Balance MethodMaria Agustina Flores de Seguela100% (2)

- Thermal Insulation Calculation Guide - AMARINEDocument5 pagesThermal Insulation Calculation Guide - AMARINEEddie FongNo ratings yet

- DBA CalculationDocument4 pagesDBA CalculationKevin J. MillsNo ratings yet

- Moist Air PropertiesDocument12 pagesMoist Air PropertiesLily DianaNo ratings yet

- R&AC Lecture 30Document17 pagesR&AC Lecture 30Denise Koh Chin HuiNo ratings yet

- IRR Calculation Sheet For Auto LoansDocument8 pagesIRR Calculation Sheet For Auto LoansmskharadeNo ratings yet

- Newton's Law of Cooling Math Assignment Winston BoonDocument27 pagesNewton's Law of Cooling Math Assignment Winston BoonWinston BoonNo ratings yet

- Literature Study On Literature Study On Building Services Building ServicesDocument41 pagesLiterature Study On Literature Study On Building Services Building ServicesAmey DeshmukhNo ratings yet

- Psychrometric Chart (Altitude 0, 750, 1500, 2250, 3000 M)Document5 pagesPsychrometric Chart (Altitude 0, 750, 1500, 2250, 3000 M)Kam Wai CheongNo ratings yet

- HVACPow Den InstructionsDocument5 pagesHVACPow Den InstructionsadamyzcNo ratings yet

- Fcu Selection For Vitamin RoomDocument2 pagesFcu Selection For Vitamin RoomArjay SalgadoNo ratings yet

- Air Conditioner: The BasicsDocument14 pagesAir Conditioner: The BasicsNikki AmuraoNo ratings yet

- Waste Heat Recovery (Mech-31)Document18 pagesWaste Heat Recovery (Mech-31)shammiNo ratings yet

- Quotation Cold Room An NAM Group - 17 Aug 2010Document12 pagesQuotation Cold Room An NAM Group - 17 Aug 2010huyly34No ratings yet

- Hvac Cep ReportDocument66 pagesHvac Cep ReportMuhammad KashifNo ratings yet

- Acoustic Calculation of Ventilation SystemsDocument4 pagesAcoustic Calculation of Ventilation SystemsSandeep BhatiaNo ratings yet

- Tsi Panda 341 User ManualDocument37 pagesTsi Panda 341 User Manuala k bNo ratings yet

- Lokring I Single Ring 01.07.2013Document58 pagesLokring I Single Ring 01.07.2013Sandra Mabel Leguizamon100% (1)

- Dr. Fixit Newcoat 105 1 PDFDocument3 pagesDr. Fixit Newcoat 105 1 PDFmohdrashidNo ratings yet

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenDocument9 pagesNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenrakamechNo ratings yet

- As 2254-1988 Acoustics - Recommended Noise Levels For Various Areas of Occupancy in Vessels and OffshoreDocument5 pagesAs 2254-1988 Acoustics - Recommended Noise Levels For Various Areas of Occupancy in Vessels and OffshoreSAI Global - APACNo ratings yet

- Arctic Evaporative Cooler CatalogDocument3 pagesArctic Evaporative Cooler Catalogसारंग बेलसरेNo ratings yet

- Coils Selection FormulasDocument3 pagesCoils Selection FormulasalbrgmailNo ratings yet

- Cooling Load Casa AzulDocument40 pagesCooling Load Casa AzulHenry San PedroNo ratings yet

- Engineering: Energy RecoveryDocument4 pagesEngineering: Energy RecoverySuchitKNo ratings yet

- ICE Factory Balance SheetDocument2 pagesICE Factory Balance SheetAhmad FarhatNo ratings yet

- Spitler McQuiston Lindsey 93 2Document11 pagesSpitler McQuiston Lindsey 93 2Shafawati ShahneelNo ratings yet

- Cooling Load Calculation DetailDocument2 pagesCooling Load Calculation DetailNikita SinhaNo ratings yet

- MECH3429Air Conditioning and Refrigeration Engineering3Document84 pagesMECH3429Air Conditioning and Refrigeration Engineering3Umair Khan MarwatNo ratings yet

- AC V For Fast Food RestaurantsDocument4 pagesAC V For Fast Food Restaurantselijah namomoNo ratings yet

- Zeus Acds Series BrochureDocument40 pagesZeus Acds Series BrochureAntonio Osante LeyvaNo ratings yet

- Information Bulletin 3 Building Def Rev3Document1 pageInformation Bulletin 3 Building Def Rev3Alan TanNo ratings yet

- Waste Heat Recovery System For RefrigeratorDocument10 pagesWaste Heat Recovery System For RefrigeratorlalkrishnaNo ratings yet

- COOLING LOAD CAPACITY GONZALESxNOLASCODocument70 pagesCOOLING LOAD CAPACITY GONZALESxNOLASCOJohn Robert GonzalesNo ratings yet

- Training Materials CatalogDocument32 pagesTraining Materials CatalogFELIXDEJNo ratings yet

- MULTI V 5 Catalog PDFDocument34 pagesMULTI V 5 Catalog PDFquangNo ratings yet

- AT4 HumidifierDocument64 pagesAT4 Humidifiermdalt9180No ratings yet

- Dynair Ecology UnitDocument12 pagesDynair Ecology Unitrid100% (1)

- AHU Friction Loss CalculationsDocument4 pagesAHU Friction Loss CalculationsAdnan AttishNo ratings yet

- Materaial For Question 3. - Cooling Load CLTD Example Ashrae PDFDocument5 pagesMateraial For Question 3. - Cooling Load CLTD Example Ashrae PDFkumarNo ratings yet

- Hvac Design CalculationsDocument1 pageHvac Design CalculationsAnonymous oUoJ4A8xNo ratings yet

- Energy Performance Assessment of Hvac SystemsDocument4 pagesEnergy Performance Assessment of Hvac SystemsBudihardjo Sarwo SastrosudiroNo ratings yet

- Non Circular Pipe FrictionDocument3 pagesNon Circular Pipe Frictionravi_radanNo ratings yet

- Cooling Loads Calculation: Cooling Load Temperature Difference (CLTD) MethodDocument8 pagesCooling Loads Calculation: Cooling Load Temperature Difference (CLTD) MethodChristopher LloydNo ratings yet

- BCA Energy Performance Points CalculatorDocument96 pagesBCA Energy Performance Points CalculatorRidwan ArifinNo ratings yet

- Sealant - 1st Acrylic A-700 MSDSDocument6 pagesSealant - 1st Acrylic A-700 MSDSBozow BongNo ratings yet

- Carriage Bolts and Nuts DIN 603 (Bolt) DIN 934 (Nut)Document1 pageCarriage Bolts and Nuts DIN 603 (Bolt) DIN 934 (Nut)Srinivasa TemkarNo ratings yet

- By Chandana Dalugoda: Air Conditioning Load CalculationsDocument7 pagesBy Chandana Dalugoda: Air Conditioning Load CalculationsWASO IBDNo ratings yet

- Serbia Cleanrooms Seminar 1Document46 pagesSerbia Cleanrooms Seminar 1Иван ШимчукNo ratings yet

- Cibse Heat Loss & Heat Gain (Apachecalc) Calculation MethodsDocument9 pagesCibse Heat Loss & Heat Gain (Apachecalc) Calculation Methodsวรศิษฐ์ อ๋องNo ratings yet

- Cooling Load1111 PDFDocument43 pagesCooling Load1111 PDFJason PaquibulanNo ratings yet

- Cooling Load EstimationDocument4 pagesCooling Load Estimationk.vikasNo ratings yet

- NAVY Health Center - Indoor Firing RangeDocument58 pagesNAVY Health Center - Indoor Firing Rangekumar123rajuNo ratings yet

- Reverse Cornot, Vapor Compression Cycles Part IDocument14 pagesReverse Cornot, Vapor Compression Cycles Part ISumran ShahidNo ratings yet

- Efficiency of Compact Organic Rankine Cycle System With Rotary-Vane-Type Expander For Low-Temperature Waste Heat RecoveryDocument6 pagesEfficiency of Compact Organic Rankine Cycle System With Rotary-Vane-Type Expander For Low-Temperature Waste Heat Recoverythanhtbk2000No ratings yet

- Stellar Ammonia Safety ChecklistDocument1 pageStellar Ammonia Safety ChecklistAshfaq Ali KhanNo ratings yet

- Cold Front - Vol. 10 No. 2, 2010 NewsletterDocument8 pagesCold Front - Vol. 10 No. 2, 2010 NewsletterAshfaq Ali KhanNo ratings yet

- Cold Front - Vol. 1 No. 1, 2001 NewsletterDocument5 pagesCold Front - Vol. 1 No. 1, 2001 NewsletterAshfaq Ali KhanNo ratings yet

- Cold Front - Vol. 10 No. 3, 2010 NewsletterDocument8 pagesCold Front - Vol. 10 No. 3, 2010 NewsletterAshfaq Ali KhanNo ratings yet

- Commissioning - A Process To Achieve Sustainable Refrigerated FacilitiesDocument7 pagesCommissioning - A Process To Achieve Sustainable Refrigerated FacilitiesAshfaq Ali KhanNo ratings yet

- Safe Handling of Ammonia As Refrigerant: Anders Lindborg Ammonia Partnership AB SwedenDocument53 pagesSafe Handling of Ammonia As Refrigerant: Anders Lindborg Ammonia Partnership AB SwedenAshfaq Ali KhanNo ratings yet

- Cold Front - Vol. 15 No. 4, 2015 NewsletterDocument8 pagesCold Front - Vol. 15 No. 4, 2015 NewsletterAshfaq Ali KhanNo ratings yet

- I D A R S: IRC StaffDocument7 pagesI D A R S: IRC StaffAshfaq Ali KhanNo ratings yet

- IRC Staff: in This IssueDocument7 pagesIRC Staff: in This IssueAshfaq Ali KhanNo ratings yet

- B B: C R P: in This Issue IRC StaffDocument7 pagesB B: C R P: in This Issue IRC StaffAshfaq Ali KhanNo ratings yet

- Reducing Energy Consumption in Cold Stores Using A Freely Available Mathematical ModelDocument30 pagesReducing Energy Consumption in Cold Stores Using A Freely Available Mathematical ModelAshfaq Ali KhanNo ratings yet

- Refrigeration FormulasDocument8 pagesRefrigeration FormulasAshfaq Ali KhanNo ratings yet

- Example 10B - 1 - Ideal Ammonia Vapor-Compression RefrigeratorDocument22 pagesExample 10B - 1 - Ideal Ammonia Vapor-Compression RefrigeratorAshfaq Ali KhanNo ratings yet

- Energy Modeling Guideline For Cold Storage and Refrigerated Warehouse FacilitiesDocument12 pagesEnergy Modeling Guideline For Cold Storage and Refrigerated Warehouse FacilitiesAshfaq Ali KhanNo ratings yet

- Using Ammonia As A RefrigerantDocument3 pagesUsing Ammonia As A RefrigerantAshfaq Ali KhanNo ratings yet

- Overview of Ammonia Refrigeration SystemsDocument4 pagesOverview of Ammonia Refrigeration SystemsAshfaq Ali KhanNo ratings yet

- 1 NergyGuidelines 2013-12-19Document12 pages1 NergyGuidelines 2013-12-19Ashfaq Ali KhanNo ratings yet

- 14 Factors To Keep Your Refrigeration Compressor Package in Check - Stellar Food For ThoughtDocument2 pages14 Factors To Keep Your Refrigeration Compressor Package in Check - Stellar Food For ThoughtAshfaq Ali KhanNo ratings yet

- 3 Ways To Determine The Fitness of Your Refrigeration Compressor - Stellar Food For ThoughtDocument2 pages3 Ways To Determine The Fitness of Your Refrigeration Compressor - Stellar Food For ThoughtAshfaq Ali KhanNo ratings yet

- S - T - S C ?: Ingle OR WO Tage OmpressionDocument9 pagesS - T - S C ?: Ingle OR WO Tage OmpressionAshfaq Ali KhanNo ratings yet

- 3.cold Chain Assessment Apr 3 2013Document37 pages3.cold Chain Assessment Apr 3 2013Ashfaq Ali KhanNo ratings yet

- HVAC - 10 Cooler Ideas For Refrigeration System Efficiency - Plant ServicesDocument5 pagesHVAC - 10 Cooler Ideas For Refrigeration System Efficiency - Plant ServicesAshfaq Ali KhanNo ratings yet

- Calculate Size of SolarDocument2 pagesCalculate Size of SolarMuhammad SalmanNo ratings yet

- Britannica Childrens Encyclopedia 2007Document1 pageBritannica Childrens Encyclopedia 2007Marius AndreiNo ratings yet

- CLPWPost War Literary WorksDocument4 pagesCLPWPost War Literary WorksRohann Ban0% (1)

- Accomplishment Report On 2019 SchoolDocument10 pagesAccomplishment Report On 2019 SchoolJuliet AlanNo ratings yet

- IDC POS Lab Project Plan 2 2Document471 pagesIDC POS Lab Project Plan 2 2shiramkkNo ratings yet

- Dissertation Topic MailDocument57 pagesDissertation Topic MailANUPNo ratings yet

- Rural - India Oct 10 EDELWEISSDocument89 pagesRural - India Oct 10 EDELWEISSpkn04100% (1)

- Status of Led Lighting World Market 2020 Final Rev 2Document82 pagesStatus of Led Lighting World Market 2020 Final Rev 2javadeveloper lokeshNo ratings yet

- Sep. Gravimetrica - CromitaDocument13 pagesSep. Gravimetrica - Cromitaemerson sennaNo ratings yet

- Bunk Bed Plans SampleDocument4 pagesBunk Bed Plans SampleCedrickNo ratings yet

- 1.publications All BranchesDocument25 pages1.publications All BranchesNaresh GollapalliNo ratings yet

- SpencerDocument34 pagesSpencervenkatteja75No ratings yet

- CMRL.12.18 : Section A: New Business, Regulatory and Sales-Related RequirementsDocument2 pagesCMRL.12.18 : Section A: New Business, Regulatory and Sales-Related RequirementsJovelyn ArgeteNo ratings yet

- Ca17 Activity 1Document2 pagesCa17 Activity 1Mark Kenneth CeballosNo ratings yet

- Corporate Tax - UAEDocument48 pagesCorporate Tax - UAEUmair BaigNo ratings yet

- Transportation Engineering - I: Introduction To Bridge EngineeringDocument33 pagesTransportation Engineering - I: Introduction To Bridge Engineeringmit rami0% (1)

- Investigative Skills 3Document75 pagesInvestigative Skills 3Keling HanNo ratings yet

- Essay On Corruption in in IndiaDocument1 pageEssay On Corruption in in IndiaGaurav ThakurNo ratings yet

- Sexy Book 121Document252 pagesSexy Book 121Irepan Ponce50% (2)

- F R N W: Rench Evolutionary Apoleonic ArsDocument7 pagesF R N W: Rench Evolutionary Apoleonic ArsevansauroNo ratings yet

- Shark ClassificationDocument44 pagesShark ClassificationSheeka TareyamaNo ratings yet

- CodaDocument15 pagesCodaShashi KartikyaNo ratings yet

- Fotip ResumeDocument3 pagesFotip Resumeapi-529088054No ratings yet

- PHD Thesis Library Science DownloadDocument8 pagesPHD Thesis Library Science Downloadyvrpugvcf100% (2)

- How Can Apologetics Help Me Defend My Faith?Document16 pagesHow Can Apologetics Help Me Defend My Faith?Regina D. RogersNo ratings yet

- Weather Forecast: by Vass Tunde Juen, 1 Verbal and Non-Verbal CommunicationDocument5 pagesWeather Forecast: by Vass Tunde Juen, 1 Verbal and Non-Verbal CommunicationAlina-Cristina CotoiNo ratings yet

- HLLQP QuickFact FormulaSheet 2016Document2 pagesHLLQP QuickFact FormulaSheet 2016nandhinigrmNo ratings yet