Professional Documents

Culture Documents

Technical Procurement Specification TPS No.: Status: Origination Department: P.O/W.O No.: Project: Location: Client: Pruchaser: Vendor: Item

Technical Procurement Specification TPS No.: Status: Origination Department: P.O/W.O No.: Project: Location: Client: Pruchaser: Vendor: Item

Uploaded by

rafikul123Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Procurement Specification TPS No.: Status: Origination Department: P.O/W.O No.: Project: Location: Client: Pruchaser: Vendor: Item

Technical Procurement Specification TPS No.: Status: Origination Department: P.O/W.O No.: Project: Location: Client: Pruchaser: Vendor: Item

Uploaded by

rafikul123Copyright:

Available Formats

32654‐11‐PS‐001

TECHNICAL PROCUREMENT SPECIFICATION PAGE 1 OF 1 R0

TPS No.: 32654‐11‐PS‐001

Status: Enquiry Commitment

Origination Department: Process Engineering

P.O/W.O No.:

Project: Construction of 350 MT Ammonia Barge Bullets

Location: Ambalamedu, Kochi

Client: M/s. FACT‐CD

Pruchaser: M/.s FEW

Vendor:

Item: 1. Safety Relief Valve (Multiport Type)

0 25/02/2021 Issued For Enquiry AT AT KVR

00FT010/15

Rev Date Details By Chkd. Apprd.

FACT ENGINEERING AND DESIGN ORGANISATION

TECHNICAL 32654-11-PS-001

PROCUREMENT ATTACHMENTS PAGE 1 OF 1 R0

SPECIFICATION

TPS No.: 32654-11-PS-001

Sl. No. of Rev. No. with Issue

Document No. Description

No. Pages 0 1 2 3 4

1. 32654-11-PS-001-IS Equipment/Item to be supplied 1

2. 32654-11-PS-001-SW Scope of Work 1

3. 32654-11-SN-SRV001 Process Datasheet of Safety Relief Valve 1

4. 32654-11-PS-001-INS Scope of Inspection & Tests 2

5. 32654-11-PS-001-SPL Special Requirement of the Project 1

6. 32654-11-PS-001-VDR Vendor Data Requirement 1

7. 00ES001/10 VENDOR Data Submission Procedure3 3

8. 32654-11-PS-001-VDI Vendor Data Index3 1

9. 32654-11-PS-001-CS Compliance Statement3 1

10. 32654-11-PS-001-PF Price Format3 1

Notes:

1. The receipt of all attachments shall be checked and ascertained.

2. All attachments of this TPS shall be retained since only revised sheets, if any, shall be issued.

3. Not enclosed, shall be as per purchaser’s(M/s FEW) tender requirement.

Project: Construction of

350 MT Ammonia Barge

Bullets

0 Issued For Enquiry AT AT KVR 25/02/2021

Client: M/s. FACT-CD

Rev Details By Chkd. Apprd. Date

00FT010/15

FACT ENGINEERING AND DESIGN ORGANISATION

TECHNICAL 32654-11-PS-001-IS

PROCUREMENT EQUIPMENT/ITEMS TO BE SUPPLIED PAGE 1 OF 1 R0

SPECIFICATION

TPS No.: 32654-11-PS-001

Sl.

Eqpt./Item Tag No. Description Quantity Remarks

No.

1. SRV-301/2/3/4 Safety Relief Valve 4 Multiport Type

Notes:

Project: Construction of

350 MT Ammonia Barge

Bullets

0 Issued For Enquiry AT AT KVR 25/02/2021

Client: M/s. FACT-CD

Rev Details By Chkd. Apprd. Date

00FT010/15

FACT ENGINEERING AND DESIGN ORGANISATION

TECHNICAL 32654-11-PS-001-SW

PROCUREMENT SCOPE OF WORK PAGE 1 OF 1 R0

SPECIFICATION

TPS No.: 32654-11-PS-001

Item: Safety Relief Valve (Multiport Type)

Equipment No.: As per 32654-11-PS-001-INS

The scope of the work include the following:

Sl. Inspection Witness

Description Remarks

No. Required Required

Supply of safety relief valves as per the attached

1. Yes

specification for anhydrous ammonia services.

Notes:

Project: Construction of

350 MT Ammonia Barge

Bullets

0 Issued For Enquiry AT AT KVR 25/02/2021

Client: M/s. FACT-CD

Rev Details By Chkd. Apprd. Date

00FT010/15

FACT ENGINEERING AND DESIGN ORGANISATION

PROCESS 32654‐11‐SN‐SRV001

DATA SHEET

SAFETY/RELIEF VALVES PAGE 1 OF 1 R1

1 Tag No. SRV‐301/2/3/41

2 Service Ammonia

GENERAL

3 Quantity Four

4 Nozzle Full / Semi Full / Semi

5 Conventional / Bellows / Pilot Operated C / B / P C / B / P

6 Bonnet Type Open / Close Open / Close

7 Size, Inlet & Outlet 80 NB3 / 100 NB /

CONNEC

TIONS

8 Flange Rating ANSI or Screwed 300# / 150# /

9 Type of Facing RF / …… Groove RF / …… Groove

10 Body A 352 Gr. LCB

11 Seat & Disc SS316

MATERIALS

12 Resilient seat seal Mfr. Std.

13 Guide &Rings SS304

14 Springs SS304

15 Bellows NOT APPLICABLE

16 Cap Screwed or Bolted fr. Std. / Mfr. Std. /

ACCESSORIES

17 Lever Plain or Packed Packed Packed

18 Test Gag Required? Yes / No Yes / No

19 Weather Hood Spring Covers Yes / No Yes / No

20 Code IBR / API /

BASIS

21 Sizing Basis External Fire Scenario

22 Relieves to Atm.

23 Fluid & State (L/G/……) G

24 Required Capacity Per Valve 4.93 Nm3/s

25 Molecular Weight / Sp. Gr. at ...oC 17.0306 / 21.04352 @ 65oC /

26 Operating Pressure, kg/cm2g 1.0

SERVICE CONDITIONS

27 Set Pressure, kg/cm2g 22.84

28 Operating Temperature, oC (‐)33

29 Relieving Temperature, oC 65

30 Back Pressure Constant, kg/cm2g 0

31 Back Pressure Variable, kg/cm2g 0

32 Allowable Over Pressure, % 20%

33 Compressibility / Super Heat Not Applicable / Not Applicable /

34 Viscosity Factor 0.01 cP

35 Max. Valve Capacity VTA

36 Area, Calculated / Selected, cm2 7.27 / 8.30 /

Orifice area

37 Orifice Designation 3J43 1D2

38 Manufacturer’s Model No. VTA

39 Manufacturer

Remarks

VTA – Vendor To Advise

1. Multiport type valve.

2. Density at relieving condition (overpressure)

3. Size & orifice designation indicated are based on conventional relief valve sizing calculation. However vendor to confirm the size of

inlet nozzle & the required orifice designation applicable for multiport type relief valve as mentioned in the special requirements

vide Doc. No. 32654‐11‐PS‐001‐SPL.

Project: Construction of

350 MT Ammonia Barge

Bullets

1 Revised & Issued For Enquiry AT AT KVR 25/02/2021

0 For Comments AT KVR KVR 17/09/2020

Client: M/s. FACT‐CD

Rev Details By Chkd. Apprd. Date

11FT019/15

FACT ENGINEERING AND DESIGN ORGANISATION

TECHNICAL 32654-11-PS-001-INS

PROCUREMENT SCOPE OF INSPECTION AND TESTS PAGE 1 OF 2 R0

SPECIFICATION

TPS No.: 32654-11-PS-001

Item: Safety Relief Valve (Multiport Type)

Equipment No.: SRV-301/2/3/4

The following inspection and tests shall be conducted and records submitted.

Sl. Inspection Witness

Description Remarks

No. Required Required

1. Visual inspection of assembled valves - 100% Yes Yes

Physical inspection for dimensions and construction of

2. Yes Yes

assembled valves - 100%

Inlet/outlet hydrostatic test, set pressure test & seat

3. Yes Yes

tightness test as per procedure enclosed - 100%

For forged valves/components, manufacturer's test

4. certificates for material composition & physical Yes

properties.

For cast valves, the foundry certificate checked &

5. Yes

verified by the supplier.

Notes:

Project: Construction of

350 MT Ammonia Barge

Bullets

0 Issued For Enquiry AT AT KVR 25/02/2021

Client: M/s. FACT-CD

Rev Details By Chkd. Apprd. Date

00FT015/15

FACT ENGINEERING AND DESIGN ORGANISATION

TECHNICAL 32654-11-PS-001-INS

PROCUREMENT SCOPE OF INSPECTION AND TESTS PAGE 2 OF 2 R0

SPECIFICATION

TEST PROCEDURE FOR SAFETY RELIEF VALVES

1. Inlet/Outlet Hydrostatic Test

1.1 All assembled valves covered by this procedure shall have the inlet hydrostatically tested.

1.2 Test media shall be clean water for CS valve. For SS valves either distilled water or water containing less than 30 ppm

of chlorine must be used.

1.3 Testing shall be conducted at room temperature.

1.4 Hydrostatic test pressure shall be one and one half (1½) times the inlet/outlet flange rating. Minimum hydrostatic

test pressure shall be 7.03 kg/cm2(G)

- The nozzle ring shall be set at minus two (-2) notches, by raising the ring to level position and then lowering the

ring two (2) notches.

- The test cap and test rod shall then be installed with the test rod “finger-tight”.

- The hydrostatic test pressure shall then be applied.

- The hydrostatic test pressure shall be maintained for a minimum of three (3) minutes.

- Examination shall be made at the hydrostatic test pressure.

- Acceptance criteria – any visible leakage shall be caused for rejection.

2. Set Pressure Test

2.1 All valves covered by this procedure shall be tested to verify popping point consistency. Test fluid shall be air.

2.2 The nozzle ring shall be set at minus two (-2) notches, by raising the ring to level position and lowering the ring two

(2) notches.

2.3 Adjust the valve to open at the set pressure or cold differential test pressure specified. Set pressure or cold

differential test pressure for valves set on liquids shall be the pressure at which a continuous unbroken stream flows

from the valve.

2.4 Cycle the valve twice to confirm that the popping point is satisfactory and that the popping point is within the

specified tolerance for that set pressure.

2.5 Set Pressure (kg/cm2(G)) : Tolerance

- 4.9 & less : +/- 0.14 kg/cm2

- Above 4.9 : +/- 3% of set pressure

- Fire valves : -0%, +10% of set pressure

3. Seat Tightness Test

Test apparatus and procedure as per API 527.

3.1 All valves covered by this procedure shall be tested for seat tightness, irrespective of the fluid actually handled by

the valve.

3.2 Waiting time before observation of leakage

Inlet Size (Inches) : Waiting Time2

- 2" & smaller : 1 Minute

- 2 ½”, 3” & 4”: 2 Minutes

- 6” to 8” : 5 Minutes

Project: Construction of

350 MT Ammonia Barge

Bullets

0 Issued For Enquiry AT AT KVR 25/02/2021

Client: M/s. FACT-CD

Rev Details By Chkd. Apprd. Date

00FT015/15

FACT ENGINEERING AND DESIGN ORGANISATION

TECHNICAL 32654‐11‐PS‐001‐SPL

PROCUREMENT SPECIAL REQUIREMENTS OF THE PROJECT PAGE 1 OF 1 R0

SPECIFICATION

TPS No.: 32654‐11‐PS‐001

Item: Safety Relief Valve (Multiport Type)

Equipment No.: SRV‐301/2/3/4

SPECIAL REQUIREMENTS

1. Safety relief valves are to be used for the service of anhydrous ammonia, mounted on ammonia barge bullet.

2. Direction of flow, pressure rating and size are to be embossed on the valves.

3. Copper or copper alloys shall not be used.

4. Nameplates as per API 526 must be attached to each valve. In addition, the nameplate must indicate the tag number of

the valve as indicated in the data sheet.

5. Water used for hydro testing of the valves must be either distilled water or water containing less than 30 ppm chlorine.

6. One no. spring and a set of gaskets each are to be supplied as spares for two years operation.

7. Supply of valves shall be in one lot and shall have the completed data sheet dispatched with the valve. All documents

packed inside crates must be protected with polyethylene covers.

8. The safety relief valve shall be “Multiport” type of “REGO” or its equivalent make, provided with atleast one standby

port and suitable isolation mechanism for isolation of each individual port without affecting the normal operation i.e.,

without comprising on required relieving rate.

Project: Construction of

350 MT Ammonia Barge

Bullets

0 Issued for Enquiry AT AT KVR 25/02/2021

Client: M/s. FACT‐CD

00FT021A/15

Rev Details By Chkd. Apprd. Date

FACT ENGINEERING AND DESIGN ORGANISATION

TECHNICAL 32654‐11‐PS‐001‐VDR

PROCUREMENT VENDOR DATA REQUIREMENTS PAGE 1 OF 1 R0

SPECIFICATION

TPS No.: 32654‐11‐PS‐001

Item: Safety Relief valve (Multiport Type)

Equipment No.: SRV‐301/2/3/4

Status: Enquiry Commitment P.O. No.:

Offer After Commitment Final**

Sl. Group

Description Lead Time in Weeks

No. Code Qty. Qty. Qty.

Reqd. Propd.* Agrd.

1. C Valve Catalogue 1S+1P 1S+2P 1 1S +4P

2. B Valve Data Sheet 1S+1P 1S+4P 1 1S +4P

3. B Valve Area Calculation 1S+1P 1S+4P 1 1S +4P

Valve Drawings Within 15 days of TOI/LOI/Order

for Approval Prior to Manufacture or Inspection

indicating, Order No., Valve Tag No., Quantity, End

4. B 1S+4P 3 1S +4P

Connection Details, Set Pressure, Valve

Dimensions, Material of Construction, Wall

Thickness, Hydrostatic Test Pressure etc.,

Place & Address of premises where it is

5. C 1S+1P 3 1S +4P

manufactured

Test Certificates for Chemical Composition &

6. B Mechanical Properties of Valve Material. (Within 3 1S+4P 12 1S +4P

days after Completion of Testing & Inspection)

Pressure Test Certificates as per Scope of

7. B Inspection 32654‐11‐PS‐001‐INS (Within 3 days 1S+4P 12 1S +4P

after Completion of Testing & Inspection)

Legends: Group Code: A – For Review & Detailed Engg. B – For Review C – For Information & Record

Document Type: P – Print S – Editable Soft in AutoCAD / MS Word / ....

Notes: * Vendor shall fill in proposed lead time if different from the required lead time

** Each set of final document shall be submitted in a folder. Two such folders shall be packed & despatched with the equipment

Project: Construction of

350 MT Ammonia Barge

Bullets

0 For Enquiry AT AT KVR 25/02/2021

Client: M/s. FACT‐CD

Rev Details By Chkd. Apprd. Date

00FT010/15

FACT ENGINEERING AND DESIGN ORGANISATION

You might also like

- Fireproofing SpecificationDocument48 pagesFireproofing SpecificationEsteban Castellano100% (12)

- NA-R4B InstructionsDocument8 pagesNA-R4B Instructionsone-eyed fat manNo ratings yet

- Water Hammer ReportDocument16 pagesWater Hammer Reportahemdmohi89% (9)

- Flowserve VOGT 01Document163 pagesFlowserve VOGT 01pratham_72No ratings yet

- TPS 6149Document66 pagesTPS 6149nachiappanNo ratings yet

- SA010-00-1624-FT-0008_P2-C_CODE 1Document4 pagesSA010-00-1624-FT-0008_P2-C_CODE 1Kambam MaheswarareddyNo ratings yet

- 5063-E-EPC-PTR-DE-D-V-001 - Data Sheet Cat A2Document29 pages5063-E-EPC-PTR-DE-D-V-001 - Data Sheet Cat A2SUSOVAN BISWASNo ratings yet

- SA010-00-1624-FT-0002_P2-C_CODE 1Document4 pagesSA010-00-1624-FT-0002_P2-C_CODE 1Kambam MaheswarareddyNo ratings yet

- SA010-00-1624-FT-0007_P2-C_CODE 1Document4 pagesSA010-00-1624-FT-0007_P2-C_CODE 1Kambam MaheswarareddyNo ratings yet

- Tech SpecDocument31 pagesTech SpecakhilNo ratings yet

- SA010-00-1624-FT-0001_P2-C_CODE 1Document4 pagesSA010-00-1624-FT-0001_P2-C_CODE 1Kambam MaheswarareddyNo ratings yet

- Binder Package: Doc. No.: MQ13-02-DS-3510-INSJ004 Rev.: 1Document10 pagesBinder Package: Doc. No.: MQ13-02-DS-3510-INSJ004 Rev.: 1JHONATAN RODRIGUEZ VENTONo ratings yet

- 74821000250SPC0008 - 2 - Support SpecDocument62 pages74821000250SPC0008 - 2 - Support SpecEduardo RateikeNo ratings yet

- SA010-00-0340-SC-0037-00 - TQ0037 Berm MaterialDocument2 pagesSA010-00-0340-SC-0037-00 - TQ0037 Berm MaterialSi ChiniNo ratings yet

- 15Document2 pages15Bruno AbudNo ratings yet

- Technical Specification For Ground Wire OPGWDocument28 pagesTechnical Specification For Ground Wire OPGWtanujaayer100% (1)

- SA010-00-0340-SC-0036-00 - TQ0036 LUP Condition - Closed Drain System (CDS)Document2 pagesSA010-00-0340-SC-0036-00 - TQ0036 LUP Condition - Closed Drain System (CDS)Si ChiniNo ratings yet

- 7650-8550-DS-500-6211 DoneDocument11 pages7650-8550-DS-500-6211 DoneKhan Akhtar HusainNo ratings yet

- L01 MBLC Darh Con TRN 026063Document1 pageL01 MBLC Darh Con TRN 026063Lana krishanNo ratings yet

- OM Manual For Kitchen EquipmentDocument151 pagesOM Manual For Kitchen Equipmentmukilanarul12No ratings yet

- TCN-03 M1275Document275 pagesTCN-03 M1275hardik033No ratings yet

- Manual 0583-PP-7130 A 7132Document261 pagesManual 0583-PP-7130 A 7132gabrielgonzaloverga2No ratings yet

- Technical Specification For Motor Operated ValvesDocument6 pagesTechnical Specification For Motor Operated ValvesĐặng Trung AnhNo ratings yet

- Mechanical Data Sheet For Nitrogen Hold-UP RECEIVER 320-00-V-005ADocument6 pagesMechanical Data Sheet For Nitrogen Hold-UP RECEIVER 320-00-V-005AVittorio FacchettiNo ratings yet

- UntitledDocument2 pagesUntitledBruno AbudNo ratings yet

- Rfi 7022518871-00Document25 pagesRfi 7022518871-00Carlos LiceaNo ratings yet

- N00 C 0005 SP R1 Structure Erection Specification 钢结构Document21 pagesN00 C 0005 SP R1 Structure Erection Specification 钢结构chenghao daiNo ratings yet

- Presentation Gis Cam August 2016Document114 pagesPresentation Gis Cam August 2016anmohieyNo ratings yet

- Daily Report-018 (Su Jinlong)Document8 pagesDaily Report-018 (Su Jinlong)sujinlongNo ratings yet

- 000 SP Pi02 0221Document10 pages000 SP Pi02 0221Samuel ValbuenaNo ratings yet

- MR of HV CableDocument5 pagesMR of HV CableJAY PARIKHNo ratings yet

- Andrew Bannerman - 002 - 001. Previous Comments "LIS Instead of LIT" Has Been AddressedDocument10 pagesAndrew Bannerman - 002 - 001. Previous Comments "LIS Instead of LIT" Has Been Addressedj.serranozavaletaNo ratings yet

- Bop DL 13-5.8 - 5K 2245081-03Document15 pagesBop DL 13-5.8 - 5K 2245081-03a.solvevNo ratings yet

- 37SVT-S080F0312-M-SE-0004-000 Rev CDocument33 pages37SVT-S080F0312-M-SE-0004-000 Rev CsithulibraNo ratings yet

- Submersible PumpDocument105 pagesSubmersible PumpRamKS80100% (1)

- CHW2204-00-EL-DAS-8301 Rev0 Data Sheet For Power Distribution BoardDocument12 pagesCHW2204-00-EL-DAS-8301 Rev0 Data Sheet For Power Distribution BoardThẩm Trần Thanh PhongNo ratings yet

- Petroleum Development Oman L.L.C. (PDO) : Saih Nihayda Condensate Stabilization Plant (SNCP)Document32 pagesPetroleum Development Oman L.L.C. (PDO) : Saih Nihayda Condensate Stabilization Plant (SNCP)sumit kumarNo ratings yet

- 560 000 TS M 296aDocument29 pages560 000 TS M 296awesqui100% (1)

- Supply Specification For Synthetic Lube Oil Plate Cooler ConsoleDocument11 pagesSupply Specification For Synthetic Lube Oil Plate Cooler ConsoleFazliJaafarNo ratings yet

- DIF-0015-ELC-ES-0002 Cathodic Protection - Rev0Document7 pagesDIF-0015-ELC-ES-0002 Cathodic Protection - Rev0wado11No ratings yet

- Gland Seal Water SPOOL 1.5": AREA: 3510Document12 pagesGland Seal Water SPOOL 1.5": AREA: 3510JHONATAN RODRIGUEZ VENTONo ratings yet

- EETT Salas ElectricasDocument22 pagesEETT Salas ElectricasleonardoNo ratings yet

- 12 00 Pi SPC 00022Document12 pages12 00 Pi SPC 00022Erdal CanNo ratings yet

- P5504MEW-SWK-10-T-006 Rev 00 PITDocument61 pagesP5504MEW-SWK-10-T-006 Rev 00 PITvignesh558855No ratings yet

- Master Document ListDocument14 pagesMaster Document ListAry77No ratings yet

- QT1 1 L18 61 Nde 000008Document4 pagesQT1 1 L18 61 Nde 000008Triệu HiếuNo ratings yet

- BZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureDocument25 pagesBZOF-MT-PRO-00035 - 0 DATA Logger Recording ProcedureManik KNo ratings yet

- Scope of Work Technical Condition For Mechanical Works R2-CILDocument33 pagesScope of Work Technical Condition For Mechanical Works R2-CILgullipalli srinivasa raoNo ratings yet

- 6267 Enquirytechnicalspecification - KnifegatevalveDocument17 pages6267 Enquirytechnicalspecification - KnifegatevalveAnonymous XBq5J84No ratings yet

- t3314 1 El SPC 001 Ra1 Low Voltage MccsDocument19 pagest3314 1 El SPC 001 Ra1 Low Voltage MccsPablo Barrios CNo ratings yet

- Method Statement FOR Installation of Electrical Earthing System SP-2Document10 pagesMethod Statement FOR Installation of Electrical Earthing System SP-2Mohammad Fazal KhanNo ratings yet

- P5504MEW-SWK-10-T-008-Rev 00 TITDocument11 pagesP5504MEW-SWK-10-T-008-Rev 00 TITvignesh558855No ratings yet

- Nde Procedures: Star Rafineri, A.Ş. Aegean Refinery Project (Arp)Document52 pagesNde Procedures: Star Rafineri, A.Ş. Aegean Refinery Project (Arp)ONUR100% (1)

- 560 000 TS M 296eDocument8 pages560 000 TS M 296ewesquiNo ratings yet

- BHEL - Technical Specification AC Distribution BoardsDocument63 pagesBHEL - Technical Specification AC Distribution BoardsPrashanth RajuNo ratings yet

- Technical Specification For Oily Water Separation SystemDocument10 pagesTechnical Specification For Oily Water Separation SystemNavneet SinghNo ratings yet

- EHK-IKPP-IS-CAL-002 Pressure Safety Valve Sizing Calculation Rev. 2Document15 pagesEHK-IKPP-IS-CAL-002 Pressure Safety Valve Sizing Calculation Rev. 2nathaNo ratings yet

- IPS-MBD20031-In-512 - Data Sheet of Rotameter - ADocument3 pagesIPS-MBD20031-In-512 - Data Sheet of Rotameter - ANikhil KarkeraNo ratings yet

- CHW2204-00-EL-LSD-7301 Rev2 Lighting System Layout DrawingDocument9 pagesCHW2204-00-EL-LSD-7301 Rev2 Lighting System Layout DrawingphongtttNo ratings yet

- Ivar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3436-00 01EDocument3 pagesIvar Aasen Field Development Project - PDQ: Dn02-S09011-E-Xk-3436-00 01EayemyothantNo ratings yet

- For Construction: Reliance Bangladesh LNG & Power LimitedDocument21 pagesFor Construction: Reliance Bangladesh LNG & Power LimitedCaspian DattaNo ratings yet

- Technical Specifications Pe Ts 421 557 E001 1529735822Document85 pagesTechnical Specifications Pe Ts 421 557 E001 1529735822Charan SinghNo ratings yet

- Tendernotice 1Document7 pagesTendernotice 1rafikul123No ratings yet

- Check List For Commercial Terms: CL-E-R02-07-08-2020Document3 pagesCheck List For Commercial Terms: CL-E-R02-07-08-2020rafikul123No ratings yet

- Tendernotice 1Document3 pagesTendernotice 1rafikul123No ratings yet

- Audit Results For AishagriDocument13 pagesAudit Results For Aishagrirafikul123No ratings yet

- Standard Terms and Conditions of Purchase: 1. DefinitionsDocument4 pagesStandard Terms and Conditions of Purchase: 1. Definitionsrafikul123No ratings yet

- Proforma of Bank Guarantee in Lieu of Security Deposit: (To Be Given On Stamp Paper)Document2 pagesProforma of Bank Guarantee in Lieu of Security Deposit: (To Be Given On Stamp Paper)rafikul123No ratings yet

- Audit Results For EdugritzDocument12 pagesAudit Results For Edugritzrafikul123No ratings yet

- Instructions To Bidders For E-Tenders: Earnest Money Deposit (Emd)Document5 pagesInstructions To Bidders For E-Tenders: Earnest Money Deposit (Emd)rafikul123No ratings yet

- Bid-Security Declaration: 1/we, . . Irrevocably Declare As UnderDocument1 pageBid-Security Declaration: 1/we, . . Irrevocably Declare As Underrafikul123No ratings yet

- 4K Ultra High Definition Laparoscopy Imaging System With ICG Compatibility For The Department of General SurgeryDocument23 pages4K Ultra High Definition Laparoscopy Imaging System With ICG Compatibility For The Department of General Surgeryrafikul123No ratings yet

- Please Enable Macros To View Boq InformationDocument2 pagesPlease Enable Macros To View Boq Informationrafikul123No ratings yet

- NIT For Engagement of Services of A Professional Chartered Accountant Firm For AIIMS NagpurDocument12 pagesNIT For Engagement of Services of A Professional Chartered Accountant Firm For AIIMS Nagpurrafikul123No ratings yet

- NIT For Outsource Laundry Service at IPD of AIIMS NagpurDocument55 pagesNIT For Outsource Laundry Service at IPD of AIIMS Nagpurrafikul123No ratings yet

- Untitled 42Document5 pagesUntitled 42rafikul123No ratings yet

- Hiring of 02 Nos New Mahindra Scorpio S7 BS-VI For Two Years Period by PDHEP, KishtwarDocument13 pagesHiring of 02 Nos New Mahindra Scorpio S7 BS-VI For Two Years Period by PDHEP, Kishtwarrafikul123No ratings yet

- Jewellery Shop in SHADocument65 pagesJewellery Shop in SHArafikul123No ratings yet

- Travel Luggage Shop in SHADocument65 pagesTravel Luggage Shop in SHArafikul123No ratings yet

- Maharashtra Natural Gas LTDDocument113 pagesMaharashtra Natural Gas LTDrafikul123No ratings yet

- Printing of Atr 2020-21Document7 pagesPrinting of Atr 2020-21rafikul123No ratings yet

- Canarbank ManpowerDocument41 pagesCanarbank Manpowerrafikul123No ratings yet

- Airports Authority of IndiaNorthern RegionJAIPURDocument19 pagesAirports Authority of IndiaNorthern RegionJAIPURrafikul123No ratings yet

- Food Corporation of IndiaRegional Office, Gujrat, FCI, MFPDDocument55 pagesFood Corporation of IndiaRegional Office, Gujrat, FCI, MFPDrafikul123No ratings yet

- Delhi Metro Rail Corporation LimitedEDSignalling and TelecommunicationProject-I - DMRCDocument21 pagesDelhi Metro Rail Corporation LimitedEDSignalling and TelecommunicationProject-I - DMRCrafikul123No ratings yet

- Food Corporation of India Regional Office: Haryana PanchkulaDocument8 pagesFood Corporation of India Regional Office: Haryana Panchkularafikul123No ratings yet

- Actuator TorqDocument16 pagesActuator TorqSEPTADONAI TRISNANo ratings yet

- Aerospace Parts 2 Quick Disconnect CouplingsDocument104 pagesAerospace Parts 2 Quick Disconnect CouplingsSohail100% (1)

- Ga132 Comp ListDocument10 pagesGa132 Comp ListMohamed MusaNo ratings yet

- Me Lab 2 Experiment 3Document8 pagesMe Lab 2 Experiment 3John Allen EstillomoNo ratings yet

- LeseprobeDocument118 pagesLeseprobeMatheus da Silva PintoNo ratings yet

- 56-T Series: Temperature Actuated Water Regulating ValveDocument4 pages56-T Series: Temperature Actuated Water Regulating ValveGuatemalan1979No ratings yet

- 2.50 - Vol 2 Part 5 Particular Specifications Marafeq Specifications PDFDocument56 pages2.50 - Vol 2 Part 5 Particular Specifications Marafeq Specifications PDFIntergrity MediaNo ratings yet

- Volume BoostersDocument12 pagesVolume BoosterswindoutNo ratings yet

- System Description S805,815Document14 pagesSystem Description S805,815Luis Fernando Flores FigueirasNo ratings yet

- PDF - Gate Valve OS and YDocument10 pagesPDF - Gate Valve OS and YLENINROMEROH4168No ratings yet

- Choke and Kill Manifold Brochure PDFDocument12 pagesChoke and Kill Manifold Brochure PDFtaloslamomia9417100% (1)

- Catalog enDocument50 pagesCatalog enzoeyNo ratings yet

- HookupDocument161 pagesHookupKumar Kote100% (2)

- VK VKLDocument24 pagesVK VKLrpdicNo ratings yet

- Piping Engineering Interview Questions Part 1Document4 pagesPiping Engineering Interview Questions Part 1smsunil12345No ratings yet

- Request Bestrack Lufor 2Document4 pagesRequest Bestrack Lufor 2Rescos KasarachiNo ratings yet

- 357 Series Control Valves: Bulletin 51.2:357Document10 pages357 Series Control Valves: Bulletin 51.2:357Djebali MouradNo ratings yet

- PRS28Document40 pagesPRS28swaminathangsNo ratings yet

- Diagrama de 426Document2 pagesDiagrama de 426brandonbalmaceda.samuelNo ratings yet

- Untitled PDFDocument238 pagesUntitled PDFSyadila LutfiNo ratings yet

- Application Engineering Bulletin: Automotive Industrial Marine G-Drive Genset KTA19GC Gas Compression Technical PackageDocument10 pagesApplication Engineering Bulletin: Automotive Industrial Marine G-Drive Genset KTA19GC Gas Compression Technical PackageCesar G.100% (1)

- Study & Maintenance of Dyeing MachineDocument8 pagesStudy & Maintenance of Dyeing MachineNaimul Hasan50% (2)

- Dimensions: G A53 A53gDocument2 pagesDimensions: G A53 A53gLuis Miguel Vicente ValentinNo ratings yet

- Section 8 - Control Valve Flow Characteristics PDFDocument6 pagesSection 8 - Control Valve Flow Characteristics PDFMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Indicating Wear Characteristics of Non-Petroleum and Petroleum Hydraulic Fluids in A Constant Volume Vane PumpDocument12 pagesIndicating Wear Characteristics of Non-Petroleum and Petroleum Hydraulic Fluids in A Constant Volume Vane PumpTarlan AllahverdiyevNo ratings yet

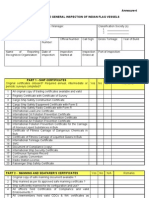

- FSI Checklist (May 2011)Document13 pagesFSI Checklist (May 2011)Arun Mishra67% (3)

- Figure 1. Cleaver-Brooks Boiler ModelDocument9 pagesFigure 1. Cleaver-Brooks Boiler ModelCastillo ZepheusNo ratings yet