Professional Documents

Culture Documents

Jesco Corp Brochure

Jesco Corp Brochure

Uploaded by

Ghani KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jesco Corp Brochure

Jesco Corp Brochure

Uploaded by

Ghani KhanCopyright:

Available Formats

S PERFOR

E S M

L A

M N

A

C

S

E

E FIRST SEAM

TH LE

S

S

PIP

EM

ILL IN MID

DLE

EA

ST

Affiliate of Industrialization & Energy Services Co.

Jubail Energy Services Company

is exclusive exporter to international market.

For domestic sales: sales@jesco.com.sa; For international sales: jesco.sales@duferco.com

Industrialization & Energy Services Company

Our Vision

“To be the leading manufacturer of high-quality

seamless pipes”

Our Mission

To provide the best quality products & services to our

customers at competitive conditions, create value for

Corporate Profile our shareholders, transfer technology and create

The Industrialization & Energy Services Company (TAQA) is a Saudi Joint Stock Company established by

employment opportunities while committed to

Ministerial Decree in May 2003. It has been endorsed by the Ministry of Petroleum & Mineral Resources since its

inception and during its formative stages. TAQA is owned 45% by the Saudi Government, while the remaining

quality, safety, social responsibility and environmental

55% is owned collectively by Joint Stock Companies and several private and industrial investors representing a

cross section of the Saudi industrial community.

protection.

The Government’s share through the Public Investment Fund (PIF) was contributed in kind by transferring from

Petromin to TAQA the Government’s 51% ownership in the Arabian Drilling Company (ADC) and the Arabian

Geophysical and Surveying Company (ARGAS). The balance of TAQA’s share capital was contributed in cash by

the other Saudi investors. TAQA’s share capital

was increased in May 2006 from SR 533 million to SAR 2,000 million.

The company’s main objectives are to localize industry,

transfer technologies, increase local content and

create employment opportunities for Saudi

Nationals. TAQA serves as a project development

and investment platform to attract equity

partners and to form strategic alliances. Its

broad charter allows the company to

participate in a spectrum of activities in the

energy and energy related sectors.

<0 1> Jubail Energy Services Company JESCO 2010

Introduction

Jubail Energy Services Company (JESCO) was established to build a state-of-the art manufacturing facility to

produce Seamless Pipe products.

The Company was sponsored and developed through initiatives from the Industrialization and Energy Services

Company (TAQA), which owns 51% of JESCO’s paid-in capital of the SR. 750 millions. The balance of JESCO’s

capital is owned by 9 other prominent business houses in the Kingdom of Saudi Arabia as well as Duferco Saudi

Ltd, a subsidiary of a global leader in the metals trading sector. TAQA itself is a joint stock company owned by

public institutions like Public Investment Fund, General Organization of Social Insurance, a number of Saudi

Arabian joint stock companies, and, prominent individual investors.

The FQM manufacturing and control process is based on equipment designed and produced by Danieli & C.

Officine Meccaniche SpA of Italy.

JESCO produces casing and pipeline seamless pipes from 5-1/2” to 16”, including intermediate sizes, to the

specifications of API Standards; and its proprietary steel grades cover critical features such as sour service, high

Our Shareholders

collapse and high compression.

Being the first Seamless Pipes manufacturing company in the Middle East and with its latest applied

manufacturing technology and highest quality standards, JESCO is confident of getting a sizeable market share

within the Kingdom of Saudi Arabia and the entire Middle East region. From our ideal location at the sea port

of Al-Jubail, JESCO will offer minimal delivery times by both sea and land transportation, thus catering to the TAQA, with its own inherent strengths in the business of oil field and

ever changing and demanding market needs. Our “value added customer supply chain” will meet or exceed

customers’ expectations at all times and will help them choose JESCO as their preferred supplier.

energy services sector lends its solid backing to JESCO, along with the

added support of other shareholders, in establishing a most modern

Our aim is to work closely with our customers offering ex-mill “just in time/short deliveries” aiming to reduce

some costly inventory burdens currently faced by the customers.

manufacturing facility to produce highest quality Seamless Pipes in the

Middle East.

Our foreign partner, Duferco lends its expertise to JESCO through an uninterrupted supply of

the required raw materials and marketing of the finished products in world markets.

These strong alliances will lead JESCO to acquire the reputation it aspires for as a world class producer with the

necessary financial strength for any and all long term commitments it makes.

<2 3> Jubail Energy Services Company JESCO 2010

Technology

JESCO has state-of-the-art FQM Technology provided by Danieli & C. Officine Meccaniche SpA of Italy.

FQM technology allows JESCO to produce high quality pipes, with a high degree of production flexibility,

versatility and efficiency. The FQM 3-roll retained Mandrel Mill has pronounced advantages over other seamless

pipes manufacturing technologies, some of which are:

• Improved wall thickness tolerances.

• Improved pipe surface quality

• Improved pipe outer diameter accuracy

• Higher diameter to wall thickness ratios can be rolled

• Allows efficient use of larger range of sophisticated steel grades

• High and low tonnages can be rolled, allowing order size flexibility and versatility

Through the latest heat treatment technology we are able to achieve API grades and tailored steel grades.

Our proprietary steel grades cover critical features such as sour service, high collapse, high compression or a

combination of them all.

Our Products

We produce Seamless Steel Pipes of various dimensions ranging from 5-1/2” to 16”. These Seamless Steel Pipes

are mainly used in the Oil and Gas sector. Our slated annual production rate is 400,000 Metric Tons (MT) of

Seamless Pipes and OCTG products.

Financing

Apart from paid-in capital, JESCO project financing was obtained from the following prominent financial

institutions:

• The Public Investment Fund (PIF)

• The Saudi Industrial Development Fund (SIDF), and

• Commercial Banks

Infrastructure

JESCO manufacturing facility is located in Jubail Industrial City utilizing a 720,000 square meters of land

allocated by the Royal Commission.

Utilities

JESCO is assured of uninterrupted supply of required utilities provided by the Royal Commission, Saudi Aramco,

Saudi Electric Company and MARAFIQ.

<4 5> Jubail Energy Services Company JESCO 2010

Sales & Marketing Quality

The finished products will be extensively marketed in Saudi Arabia, GCC and other MENA countries. JESCO and

Duferco will cover all these regions and further expand to serve customers in Europe and the Unites States.

Our quality policy is an integral part of the company’s

From our location in Jubail Industrial City with proximity to modern sea port facilities and a network of roads, we

have the ability to deliver our finished products within the shortest possible time.

overall policies and strategies. This Quality Policy guides

Following is our local sales and marketing contact:

the organization towards continuous improvement to

1)

2)

fulfill its mission.

Overseas customers are served by Duferco. Duferco has following marketing offices:

1)

2) JESCO recognizes that continual improvement is key to

sustainable success.

JESCO is committed to ensure consistent compliance

with its Quality Management System requirements

which is continually reviewed and updated to improve

its effectiveness.

JESCO pursues policies which enhance its employee’s

quality of life and preserve the business relationship

with its suppliers.

JESCO maintains and makes every effort to improve the

health and safety of employees and protect the

environment.

JESCO is committed to continuously evaluate, motivate,

train and develop its human resources with particular

emphasis to provide training to its young Saudi Arabian

employees.

<6 7> Jubail Energy Services Company JESCO 2010

Certifications

After following and practicing every word of our Quality Policy and with the commitment at all levels of our

organization to follow the same, we are very proud to have secured the following API and ISO Certifications

during the last quarter of 2009 which is an important milestone in our business.

<8 9> Jubail Energy Services Company JESCO 2010

Our Clients Technical Data OCTG

Our prospective clients are :

• Oil and Gas exploration and production companies

• Refineries

• Petrochemical Companies

•

OCTG CASING AND COUPLINGS (API 5CT)

By utilizing its state of the art, Danieli manufactured, FQM rolling mill, JESCO will produce seamless casing pipe

from 5 ½” to 16” (as well as intermediate sizes), to a minimum of API specifications and standards.

JESCO intends to produce connections, as per API standards and is currently developing its own interchangeable

premium connection. Finishing line capacities are 400,000mt per annum.

Through the very latest heat treatment technology, JESCO will be able to achieve API and tailored steel grades.

JESCO’s proprietary steel grades will cover critical features such as sour service, high collapse, high compression

or a combination of them all. (200,000mt per annum)

A dedicated process control system will ensure that our manufacturing process follows the designed production

plan.

Critical operations shall be actively monitored through specially designed and produced devices, which will

ensure an accurate and continuous process control.

Our Level 3 automation system will integrate all control and traceability data for our products all the way

through to our customer’s receipt at the final destination.

JESCO will provide after sales technical services for all its customers.

The following pages indicate the size and grade ranges which JESCO will produce.

<10 11> Jubail Energy Services Company JESCO 2010

Technical Data OCTG

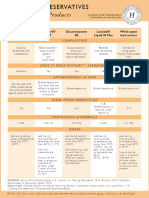

SIZE DESIGNATION PIPE BODY YIELD STRENGTH SIZE DESIGNATION PIPE BODY YIELD STRENGTH

OD Nominal Wall OD Nominal Wall

in. mm Weight Thickness H 40 J 55 M 65 N/L 80 C 90 C/T 95 P 110 Q 25 in. mm Weight Thickness H 40 J 55 M 65 N/L 80 C 90 C/T 95 P 110 Q 25

in. mm lb/ft in. mm x 1000 kg in. mm lb/ft in. mm x 1000 kg

5 1/2 139.70 14.00 0.244 6.20 73 101 119 146 165 174 201 229 7 3/4 196.85 46.10 0.595 15.11 243 334 395 486 546 577 668 759

15.50 0.275 6.99 82 113 133 164 184 195 225 256 8 5/8 219.08 24.00 0.26 46.71 126 173 205 252 283 299 346 394

17.00 0.304 7.72 90 124 146 180 203 214 248 282 28.00 0.30 47.72 144 198 235 289 325 343 397 451

20.00 0.361 9.17 106 146 172 212 238 251 291 331 32.00 0.35 28.94 166 228 270 332 374 395 457 519

23.00 0.415 10.54 120 166 196 241 271 286 331 376 36.00 0.400 10.16 188 258 305 375 422 446 516 587

26.80 0.500 12.70 143 196 232 285 321 339 392 446 40.00 0.450 11.43 210 289 341 420 472 498 577 656

29.70 0.562 14.27 158 218 257 317 356 376 435 495 44.00 0.500 12.70 232 319 377 464 521 550 637 724

32.60 0.625 15.88 174 239 282 348 391 413 478 543 49.00 0.557 14.15 256 353 417 513 577 609 705 801

35.30 0.687 17.45 189 259 307 377 424 448 519 590 9 5/82 44.48 32.30 0.312 7.92 166 228 269 332 373 394 456 518

38.00 0.750 19.05 203 279 330 406 457 483 559 635 36.00 0.352 8.94 186 256 303 372 419 442 512 582

40.50 0.812 20.62 217 299 353 434 489 516 597 679 40.00 0.395 10.03 208 286 338 416 468 494 572 650

43.10 0.875 22.23 231 317 375 462 519 548 635 721 43.5 0.435 11.05 228 314 371 456 513 542 627 713

6 5/8 168.28 20.00 0.288 7.32 104 143 169 208 234 247 286 325 47.00 0.472 11.99 246 339 401 493 555 585 678 770

24.00 0.352 8.94 126 173 205 252 283 299 346 394 53.50 0.545 13.84 282 388 459 565 635 671 776 882

28.00 0.417 10.59 148 203 240 295 332 351 406 462 58.40 0.595 15.11 307 421 498 613 690 728 843 958

32.00 0.475 12.07 167 229 271 333 375 396 458 521 59.40 0.609 15.47 313 431 509 627 705 744 861 979

7 177.80 17.00 0.231 5.87 89 123 145 178 201 212 245 279 64.90 0.672 17.07 343 472 558 686 772 815 944 1073

20.00 0.272 6.91 104 144 170 209 235 248 287 326 70.30 0.734 18.64 372 512 605 745 838 884 1024 1163

23.00 0.317 8.05 121 166 196 242 272 287 332 378 75.60 0.797 20.24 401 552 652 803 903 953 1104 1254

26.00 0.362 9.19 137 189 223 274 308 326 377 428 10 3/42 73.05 32.75 0.279 7.09 167 229 271 333 375 396 458 521

29.00 0.408 10.36 153 211 249 307 345 364 422 480 40.50 0.350 8.89 208 286 337 415 467 493 571 649

32.00 0.453 11.51 169 233 275 338 381 402 465 529 45.50 0.400 10.16 236 325 384 472 531 561 650 738

35.00 0.498 12.65 185 254 300 369 416 439 508 577 51.0 0.450 11.43 264 364 430 529 595 628 727 826

38.00 0.540 13.72 199 274 323 398 448 473 547 622 55.50 0.495 12.57 290 398 471 579 652 688 796 905

42.70 0.625 15.88 227 313 369 455 511 540 625 710 60.70 0.545 13.84 317 436 516 635 714 754 873 992

46.40 0.687 17.45 247 340 402 495 557 588 680 773 65.70 0.595 15.11 345 474 560 689 776 819 948 1077

50.10 0.750 19.05 267 368 435 535 602 635 735 836 73.20 0.672 17.07 386 531 628 773 869 918 1063 1207

53.60 0.812 20.62 287 394 466 573 645 681 788 896 79.20 0.734 18.64 419 577 682 839 944 996 1153 1311

57.10 0.875 22.23 306 420 497 612 688 726 841 955 85.30 0.797 20.24 453 622 735 905 1018 1075 1245 1414

7 5/8 193.68 24.00 0.300 7.62 125 172 204 251 282 298 345 392 11 3/42 98.45 42.00 0.333 8.46 217 298 352 434 488 515 596 678

26.20 0.328 8.33 137 188 222 273 307 324 376 427 47.00 0.37 59.53 243 335 395 487 548 578 669 760

29.70 0.375 9.53 155 213 252 310 349 368 427 485 54.00 0.435 11.05 281 386 456 562 632 667 772 878

33.70 0.430 10.92 177 243 287 353 397 419 485 552 60.0 0.489 12.42 314 432 511 628 707 746 864 982

39.00 0.500 12.70 203 279 330 406 457 483 559 635 65.00 0.534 13.56 342 470 555 683 769 812 940 1068

42.80 0.562 14.27 226 311 368 453 510 538 623 708 71.00 0.582 14.78 371 510 603 742 834 881 1020 1159

45.30 0.595 15.11 239 328 388 477 537 567 656 746 13 3/83 39.73 48.00 0.330 8.38 246 338 399 491 553 583 675 767

47.10 0.625 15.88 250 343 406 499 562 593 686 780 54.50 0.380 9.65 282 387 458 563 634 669 775 880

51.20 0.687 17.45 272 374 442 544 612 646 748 850 61.00 0.430 10.92 318 437 516 635 715 754 873 992

55.30 0.750 19.05 294 404 478 588 662 699 809 919 68.0 0.480 12.19 353 486 574 706 795 839 971 1104

72.00 0.514 13.06 377 519 613 754 849 896 1037 1179

<12 13> Jubail Energy Services Company JESCO 2010

Technical Data OCTG

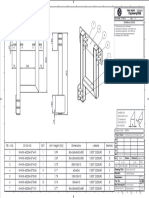

JESCO will produce carbon steel grades as per API standards TYPE GRADE COUPLING PIPE END TYPE GRADE COUPLING PIPE END

API GRADES MANUFACTURED BY JESCO J55 JEP80S

JESCO Severe

Yield strength (ksi) 40 55 65 80 90 95 110 125

Sour Service

K55

JEP90S

Group 1 H 40 J 55 N 80

K 55

M65

Group 2 M 65 L 80 C 90 C 95

T 95

JEP95S

Group 3 P 110 N80-1

Group 4 Q 125 JEP110S

N80-Q

Every oil and gas field has its own specific features. JESCO’s research and development department will develop

tailored solutions for its customers, in order to overcome such constraints and to maximize the performance and L80 JEP55L

Temperature Service

behavior of its seamless pipes inside the well.

API Steel Grades

C90-1

JESCO Low

PROPRIETARY GRADES MANUFACTURED BY JESCO JEP80L

Yield strength (ksi) 55 80 90 95 110 125 C90-2

JEP90L

Sour Service JEP80S JEP90S JEP95S JEP110S

T95-1

High Collapse Service JEP55HC JEP80HC JEP90HC JEP95HC JEP110HC

Low Temperature Service JEP55L JEP80L JEP90L JEP95L JEP110L JEP125L JEP95L

T95-2

High Collapse & Sour Service JEP55HS JEP80HS JEP90HS JEP95HS JEP110HS

Severe Sour Service JEP90SS JEP95SS

C95 JEP110L

JESCO’s laboratories will house high collapse and sour service testing equipment. All proprietary steel grades will P110

be certified internally. JEP80HC

JESCO High

Q125-1

JESCO aims to improve and develop new steel grades in order to overcome a higher level of sophisticated

Collapse

constraints. JEP90HC

Q125-1

JESCO’s threaded and coupled (T&C) manufacturing program will include short thread cut (STC), long thread cut

(LTC) and buttress thread cut (BTC) connections in accordance with API 5CT & API 5B, along with JESCO’s self

branded proprietary connections for use in more demanding environments. JEP95HC

Q125-1

Technical support for string design will be available from JESCO’s research and development team. Through a

dedicated premium supply chain service, JESCO intends to supply all tubular needs for field operations, including

Q125-1 JEP110HC

pup-joints, interconnecting cross-overs and loose couplings. JESCO also intends to provide a dedicated repair

network for its main regional markets. JESCO will develop pipe management solutions for long term customers

as part of a supply agreement for a premium supply chain service.

JESCO’s proprietary steel grade color identification system is user friendly allowing our products to be easily identified.

Special clearance couplings will be painted with a grey band adjacent to the color identification band on the coupling.

<14 15> Jubail Energy Services Company JESCO 2010

Technical Data OCTG

The design of the JESCO mill, means that following the pipe rolling and / or heat treatment process all pipes will

be subject to in-line Non Destructive Testing (NDT) consisting of 100% electromagnetic inspection (EMI) tests for

longitudinal, transversal, internal and external defects, as well as ultrasonic testing (UT).

The wall thickness (WT) of each pipe will be inspected along its full length.

In-line steel grade monitoring will be conducted on each pipe through an eddy current (EC) device.

Finishing Lines will include wet magnetic powder inspection (WMPI) for pipe ends as well as pin phosphating

units.

Hydrostatic tests will be performed with a made-up coupling at the box end. The pin end will be threaded

following this test. Alternative pressure hydrostatic tests will be available on request.

Standard and tailored tests will be performed by JESCO on their products.

Critical tests for casing - NACE and high collapse will be conducted in JESCO’s laboratories.

Tensile Test ISO 6892 and/or ASTM A 370

PHYSICAL

TESTS

Hardness Test

Impact Test

Grain Size determination McQuaid-Ehn Test or others as specified in ISO 643 and/or ASTM E 112

METALOGRAPHIC

CHEMICAL TEST

Hardenability - grades C 90 and T 95

AND

Metalographic Evaluation

Chemical Analyses

Hydrostatic Test (including alternative test pressure)

Dimensional Measurements (OD, Wt, Length, Thread)

INSPECTION AND

TESTING ONLINE

Weight Determination

Straightness

Non-Destructive Examination (NDE) - EMI,UT, MT

Visual inspection

SPECIAL

Sulfide stress cracking-test; grades C 90 and T 95 ANSI-NACE Test Method TM 0177-96

TESTS

Collapse Test

<16 17> Jubail Energy Services Company JESCO 2010

Technical Data LINE PIPE

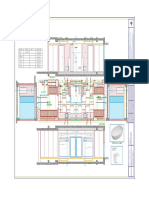

SIZE DESIGNATION PIPE BODY YIELD STRENGTH

NPS OD Nominal Wall

in. mm Weight Thickness A B X 42 X 46 X 52 X 56 X 60 X 65 X 70 X 80

in. mm kg/m in. mm x 1000 kg

5 9/16 141.3 21.92 0.258 6.6 59 68 82 90 102 109 117 127 137 156

23.50 0.281 7.1 64 74 89 97 110 119 127 138 148 169

25.99 0.312 7.9 70 82 98 107 121 131 140 152 164 187

28.45 0.344 8.7 77 90 108 118 133 143 154 166 179 205

30.88 0.375 9.5 83 97 117 128 144 155 166 180 194 222

40.28 0.500 12.7 108 126 152 166 188 202 217 235 253 289

49.17 0.625 15.9 132 154 185 202 229 246 264 286 308 352

57.56 0.750 19.1 154 180 216 237 268 288 309 335 360 412

6 5/8 168.3 25.55 0.250 6.4 68 80 95 105 118 127 136 148 159 182

LINE PIPES (API 5L PSL1, PSL2) 28.23

31.25

0.280

0.312

7.1

7.9

76

84

89

98

106

118

117

129

132

146

142

157

152

169

165

183

177

197

203

225

34.24 0.344 8.7 92 108 129 142 160 173 185 200 216 247

37.20 0.375 9.5 100 117 140 154 174 187 201 217 234 267

By utilizing its State of the Art - Danieli FQM rolling mill, JESCO will produce seamless Line Pipe from 5.563” to

42.67 0.432 11.0 114 134 160 176 198 214 229 248 267 305

16” (as well as intermediate sizes), to the most restricted API Specifications and Standards.

48.73 0.500 12.7 131 153 183 201 227 245 262 284 306 349

54.31 0.562 14.3 146 170 204 224 253 272 292 316 340 389

Through the very latest heat treatment technology, JESCO will be able to achieve API and tailored steel grades.

59.76 0.625 15.9 160 187 225 246 278 300 321 348 374 428

JESCO’s proprietary steel grades will cover critical features such as sour service.

67.70 0.719 18.3 182 212 254 279 315 339 363 394 424 485

70.28 0.750 19.1 189 220 264 289 327 352 377 408 440 503

A dedicated process control system will ensure that our manufacturing process follows the designed production

79.07 0.864 21.9 213 248 298 327 369 398 426 461 497 568

plan.

79.99 0.875 22.2 215 251 301 330 373 402 431 466 502 574

8 5/8 219.1 33.57 0.250 6.4 90 105 125 137 155 167 179 194 209 239

Critical operations shall be actively monitored through specially designed and produced devices, which will

36.61 0.277 7.0 99 115 139 152 172 185 198 214 231 264

ensure an accurate and continuous process control.

41.15 0.312 7.9 111 129 155 170 192 207 222 240 259 296

42.65 0.322 8.2 114 133 160 175 198 214 229 248 267 305

Our level 3 automation system will integrate all control and traceability data for our products all the way through

45.14 0.344 8.7 122 142 171 187 211 228 244 264 284 325

to our customer’s receipt at the final destination.

49.11 0.375 9.5 132 154 185 203 229 247 265 287 309 353

56.94 0.438 11.1 153 179 215 235 266 286 307 332 358 409

JESCO will provide after sales technical services for all its customers.

64.64 0.500 12.7 174 203 243 267 301 324 348 377 406 464

72.22 0.562 14.3 194 226 271 297 336 362 388 420 452 517

The following pages indicate the size and grade ranges which

79.68 0.625 15.9 214 250 300 328 371 399 428 464 499 571

JESCO will produce.

90.62 0.719 18.3 243 284 341 373 422 454 486 527 568 649

94.21 0.750 19.1 253 295 354 388 438 472 505 548 590 674

100.84 0.812 20.6 271 317 380 416 471 507 543 588 633 724

107.80 0.875 22.2 290 339 406 445 503 542 580 629 677 774

121.33 1.000 25.4 326 381 457 500 566 609 653 707 761 870

10 3/4 273.1 42.09 0.250 6.4 112 131 157 172 195 210 225 243 262 300

46.58 0.279 7.1 125 146 175 192 217 233 250 271 292 333

51.03 0.307 7.8 137 160 192 210 238 256 274 297 320 366

56.73 0.344 8.7 153 179 214 235 265 286 306 332 357 408

60.50 0.365 9.3 162 189 227 249 281 303 324 351 378 433

71.72 0.438 11.1 193 225 271 296 335 361 387 419 451 515

81.56 0.500 12.7 219 256 307 336 380 409 439 475 512 585

91.27 0.562 14.3 245 286 343 376 425 457 490 531 572 653

100.85 0.625 15.9 271 316 379 415 469 505 542 587 632 722

114.99 0.719 18.3 309 360 432 473 535 576 617 669 720 823

128.28 0.812 20.6 345 403 483 529 598 645 691 748 806 921

137.36 0.875 22.2 370 431 518 567 641 690 739 801 863 986

146.33 0.938 23.8 394 459 551 604 683 735 788 853 919 1050

155.16 1.000 25.4 417 487 584 640 723 779 834 904 973 1113

<18 19> Jubail Energy Services Company JESCO 2010

Technical Data LINE PIPE Line Pipes can be ordered in single length range (SRL) or Double range length (DRL).

SIZE DESIGNATION PIPE BODY YIELD STRENGTH

NPS OD Nominal Wall

Tailored fixed lengths as well are possible to be cut in line, subject of previous agreement prior to order placing.

in. mm Weight Thickness A B X 42 X 46 X 52 X 56 X 60 X 65 X 70 X 80 OD wallthicknessin

In 0.250 0.258 0.281 0.312 0.344 0.375 0.406 0.438 0.469 0.500 0.562 0.625 0.688 0.719 0.750 0.812 0.864 0.875 0.938 1.000 1.062 1.125

mm 6.4 6.6 7.1 7.9 8.7 9.5 10.3 11.1 11.9 12.7 14.3 15.9 17.5 18.3 19.1 20.6 21.9 22.2 23.8 25.4 27 28.6

in. mm kg/m in. mm x 1000 kg

5 9/16 141.3

6 5/8 168.3

12 3/43 23.9 50.11 0.250 6.4 134 156 187 205 232 250 267 290 312 357

8 5/8 219.1

55.47 0.281 7.1 150 175 210 230 260 280 300 325 350 400 10 3/4 273.1

61.56 0.312 7.9 166 194 232 255 288 310 332 360 387 443 12 3/4 323.9

14 355.6

65.36 0.330 8.4 175 205 246 269 304 327 351 380 409 468

16 406.4

67.63 0.344 8.7 183 213 256 280 317 341 365 396 426 487

JESCO range

73.66 0.375 9.5 199 232 278 304 344 371 397 380 463 530

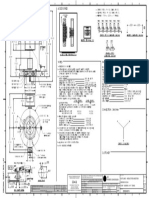

79.66 0.406 10.3 214 250 300 329 372 400 429 465 500 572 A P I S P E C I F I C AT I O N

85.63 0.438 11.1 231 269 323 354 400 431 461 500 538 615 CHEMICAL REQUIREMENTS, % TENSILE REQUIREMENTS

97.47 0.500 12.7 262 306 367 402 454 489 524 568 612 699 Yield Strength, min Tensile Strength, min

Product

109.18 0.562 14.3 293 342 410 449 508 547 586 635 684 782 Specification Grade Cª MNª P S Ti Other

psi Mpa psi Mpa

120.77 0.625 15.9 324 378 454 497 562 605 649 703 757 865

max. max. max. max. max. max. min. max. min. max. min. max. min. max.

132.23 0.688 17.5 355 414 497 544 615 663 710 769 829 947

143.57 0.750 19.1 385 449 539 590 668 719 770 834 899 1027 A 0.22 0.9 0.03 0.03 - - 30,000 207 48,000 331

154.08 0.812 20.6 415 484 581 636 719 774 830 899 968 1106

165.18 0.875 22.2 445 519 622 682 771 830 889 963 1037 1186 B 1.2 b,c,d 35,000 241

176.14 0.938 23.8 474 553 664 727 822 885 948 1027 1106 1264 60,000 414

X 42 1.3 42,000 290

186.98 1.000 25.4 503 587 704 771 871 938 1006 1089 1173 1341

208.28 1.125 28.6 560 653 783 858 970 1045 1119 1212 1306 1492 X 46 46,000 317 63,000 434

14 355.6 55.12 0.250 6.4 147 172 206 226 255 275 294 319 343 392 0.04

61.02 0.281 7.1 165 192 231 253 286 308 330 357 385 440 PSL 1 X 52 52,000 - 359 - 66,000 - 455

67.74 0.312 7.9 183 213 256 280 317 341 365 396 426 487 0.28 0.03 0.03

74.43 0.344 8.7 201 235 281 308 348 375 402 436 469 536 X 56 c,d 56,000 386 71,000 490

1.4

81.09 0.375 9.5 219 255 306 335 379 408 437 474 510 583

X 60 60,000 414 75,000 517

87.71 0.406 10.3 236 276 331 362 409 441 472 512 551 630

0.06

94.30 0.438 11.1 254 297 356 390 441 474 508 551 593 678 X 65 65,000 448 77,000 531

100.87 0.469 11.9 272 317 380 416 471 507 543 588 634 724

107.40 0.500 12.7 289 337 404 443 501 539 578 626 674 770 X 70 70,000 483 82,000 565

120.36 0.562 14.3 323 377 452 495 560 603 646 700 754 862

B 1.2 d,e 35,000 65,000 241 448

133.20 0.625 15.9 35 8417 501 548 620 668 715 775 835 954

60,000 414

145.92 0.688 17.5 392 457 549 601 679 732 784 849 914 1045 X 42 1.3 42,000 72,000 290 496

158.50 0.750 19.1 425 496 595 652 737 794 850 921 992 1134 0.04

170.19 0.812 20.6 458 535 641 703 794 855 916 993 1069 1222 X 46 46,000 76,000 317 524 63,000 434

182.53 0.875 22.2 491 573 688 753 852 917 983 1065 1147 1310 110,000 758

194.75 0.938 23.8 524 612 734 804 909 979 1049 1136 1223 1398 X 52 52,000 77,000 359 531 66,000 455

206.84 1.000 25.4 556 649 779 853 964 1038 111312051298 1483 c,d

218.80 1.062 27.0 588 686 823 901 1019 1097 1176 1274 1372 1568 PSL 2 X 56 0.24 0.03 0.02 56,000 79,000 386 544 71,000 490

230.64 1.125 28.6 620 723 868 950 1074 1157 1240 1343 1446 1653 X 60 1.4 60,000 82,000 414 565 75,000 517

16 406.4 100.61 0.41 10.3 271 316 379 415 470 506 542 587 632 722

108.21 0.44 11.1 292 340 408 447 506 544 583 632 681 778 X 65 65,000 87,000 448 600 77,000 531

115.77 0.47 11.9 312 364 436 478 540 582 623 675 727 831

123.31 0.50 12.7 332 387 464 508 575 619 663 718 774 884 X 70 0.06 70,000 90,000 483 621 82,000 565

138.28 0.56 14.3 371 433 520 569 643 693 742 804 866 990

X 80 80,000 100,000 552 690 90,000 120,000 621 827

153.12 0.63 15.9 411 480 576 630 713 768 822 891 959 1096

167.84 0.69 17.5 451 526 631 691 781 841 902 977 1052 1202 a For each reduction of 0.01% below the specified maximum Carbon content, an increase of 0.05% above thespecified maximum Manganese content is

permissible up to a maximum of 1.50% for grades X 42 through X 52up to a maximum of 1.65% for grades higher than X 52 but less than X 70, and up to

182.43 0.75 19.1 489 571 685 750 848 914 979 1060 1142 1305

2.00% for grades X 70 and higher

196.00 0.81 20.6 528 616 739 809 915 985 1055 1143 1231 1407 b The sum of Columbium (Niobium) and Vanadium content shall not exceed 0.03%, except that, by agreement betweenpurchaser and manufacturer, an

210.34 0.88 22.2 566 661 793 868 982 1057 1133 1227 1321 1510 alternative maximum may be established

c Columbium (Niobium), Vanadium, Titanium or combination thereof may be used at the discretion of the manufacturer

224.56 0.94 23.8 605 705 846 927 1048 1128 1209 1310 1411 1612 d The sum of Columbium (Niobium) ,Vanadium and Titanium content shall not exceed 0.15%

238.66 1.000 25.4 642 749 899 984 1113 1198 1284 1391 1498 1712 e The sum of Columbium (Niobium) and Vanadium content shall not exceed 0.06%, except that, by agreement betweenpurchaser and manufacturer, an

alternative maximum may be established

<20 21> Jubail Energy Services Company JESCO 2010

Technical Data LINE PIPE

ISO 3183-3(1999) SPECIFICATION

Steel Name C Si Mna P S V Nb Ti otherb CEVc Pcmde Steel Name C Si Mna P S V Nb Ti otherb CEVc Pcmde

L245NC 0.14 0.40 1.35 0.02 0.01 0.36 0.19 L245NCS 0.14 0.40 1.35 0.02 0.03 0.36 0.19

f

L290NC 0.14 0.40 1.35 0.02 0.01 0.05 0.05 0.04 0.36 0.19 L290NCS 0.14 0.40 1.35 0.02 0.03 0.05 0.05 0.04 0.36 0.19

f g

L360NC 0.16 0.45 1.65 0.02 0.01 0.10 0.05 0.04 0.43 0.22 L360NCS 0.16 0.45 1.65 0.02 0.03 0.10 0.05 0.04 0.43 0.22

gh

L290QC 0.14 0.40 1.35 0.02 0.01 0.04 0.04 0.04 0.34 0.19 L290QCS 0.14 0.40 1.35 0.02 0.03 0.04 0.04 0.04 0.34 0.19

f g

L360QC 0.16 0.45 1.65 0.02 0.01 0.07 0.05 0.04 0.39 0.20 L360QCS 0.16 0.45 1.65 0.02 0.03 0.07 0.05 0.04 0.39 0.20

gh gl

L415QC 0.16 0.45 1.65 0.02 0.01 0.08 0.05 0.04 0.41 0.22 L415QCS 0.16 0.45 1.65 0.02 0.03 0.08 0.05 0.04 0.41 0.22

gh gl

L450QC 0.16 0.45 1.65 0.02 0.01 0.09 0.05 0.06 0.42 0.22 L450QCS 0.16 0.45 1.65 0.02 0.03 0.09 0.05 0.06 0.42 0.22

gh

L485QC 0.17 0.45 1.75 0.02 0.01 0.10 0.05 0.06 0.42 0.23 L290MCS 0.10 0.40 1.25 0.02 0.02 0.04 0.04 0.04 0.34 0.19

L555QC 0.17 0.45 1.85 0.02 0.01 0.10 0.06 0.06 by agreement L360MCS 0.10 0.45 1.45 0.02 0.02 0.05 0.05 0.04 0.37 0.20

f g

L290MC 0.12 0.40 1.35 0.02 0.01 0.04 0.04 0.04 0.34 0.19 L415MCS 0.10 0.45 1.45 0.02 0.02 0.08 0.06 0.06 0.38 0.21

h gl

L360MC 0.12 0.45 1.65 0.02 0.01 0.05 0.05 0.04 0.37 0.20 L450MCS 0.10 0.45 1.45 0.02 0.02 0.10 0.06 0.06 0.39 0.22

gh gl

L415MC 0.12 0.45 1.65 0.02 0.01 0.08 0.06 0.06 0.38 0.21 L485MCS 0.10 0.45 1.55 0.02 0.02 0.10 0.06 0.06 0.41 0.23

gh

L450MC 0.12 0.45 1.65 0.02 0.01 0.10 0.06 0.06 0.39 0.22

gh

L485MC 0.12 0.45 1.75 0.02 0.01 0.10 0.06 0.06 0.41 0.23

L555MC 0.14 0.45 1.85 0.02 0.01 0.10 0.06 0.06 by agreement

Pipe bodym Charpy V-notch impact energy Pipe bodym Charpy V-notch impact energy

q q

Yield Tensile Ratio Elongation Average of Min Yield Tensile Ratio Elongation Average of Min

Steel Name Strength Strength Strength L0=5.65 S0 Test Temperature thickness (t) mm three test individual Steel Name Strength Strength Strength L0=5.65 S0 Test Temperature thickness (t) mm three test individual

R10.5 Rm R10.5/R10.5 max pieces value R10.5 Rm R10.5/R10.5 max pieces value

N/mm2 N/mm2mmin max t 20 20 t 30 t>30 J J N/mm2 N/mm2mmin max t 20 20 t 30 t>30 J J

L245NC 245 to 440 415 0.90 22 TD-10ºC TD-20ºC TD-30ºC 27 22 L245NCS 245 to 440 415 0.90 22 TD-10ºC TD-20ºC TD-30ºC 27 22

L290NC 290 to 440 415 0.90 21 TD-10ºC TD-20ºC TD-30ºC 30 24 L290NCS 290 to 440 415 0.90 21 TD-10ºC TD-20ºC TD-30ºC 30 24

L360NC 360 to 510 460 0.90 20 TD-10ºC TD-20ºC TD-30ºC 36 30 L360NCS 360 to 510 460 0.90 20 TD-10ºC TD-20ºC TD-30ºC 36 30

L290QC 290 to 440 415 0.90 21 TD-10ºC TD-20ºC TD-30ºC 30 24 L290QCS 290 to 440 415 0.90 21 TD-10ºC TD-20ºC TD-30ºC 30 24

L360QC 360 to 510 460 0.90 20 TD-10ºC TD-20ºC TD-30ºC 36 30 L360QCS 360 to 510 460 0.90 20 TD-10ºC TD-20ºC TD-30ºC 36 30

L415QC 415 to 565 520 0.92 18 TD-10ºC TD-20ºC TD-30ºC 42 35 L415QCS 415 to 565 520 0.92 18 TD-10ºC TD-20ºC TD-30ºC 42 35

L450QC 450 to 570 535 0.92 18 TD-10ºC TD-20ºC TD-30ºC 45 38 L450QCS 450 to 570 535 0.92 18 TD-10ºC TD-20ºC TD-30ºC 45 38

L485QC 485 to 605 570 0.92 18 TD-10ºC TD-20ºC TD-30ºC 50 40 L290MCS 290 to 440 415 0.90 21 TD-10ºC TD-20ºC TD-30ºC 30 24

L555QC 555 to 675 625 0.92 18 TD-10ºC TD-20ºC TD-30ºC 56 45 L360MCS 360 to 510 460 0.90 20 TD-10ºC TD-20ºC TD-30ºC 36 30

L290MC 290 to 440 415 0.90 21 TD-10ºC TD-20ºC TD-30ºC 30 24 L415MCS 415 to 565 520 0.92 18 TD-10ºC TD-20ºC TD-30ºC 42 35

L360MC 360 to 510 460 0.90 20 TD-10ºC TD-20ºC TD-30ºC 36 30 L450MCS 450 to 570 535 0.92 18 TD-10ºC TD-20ºC TD-30ºC 45 38

L415MC 415 to 565 520 0.92 18 TD-10ºC TD-20ºC TD-30ºC 42 35 L485MSC 485 to 605 570 0.92 18 TD-10ºC TD-20ºC TD-30ºC 50 40

L450MC 450 to 570 535 0.92 18 TD-10ºC TD-20ºC TD-30ºC 45 38

L485MC 485 to 605 570 0.92 18 TD-10ºC TD-20ºC TD-30ºC 50 40

L555MC 555 to 675 625 0.92 18 TD-10ºC TD-20ºC TD-30ºC 56 45

Note

a For each reduction of 0.01% below the maximum carbon content an increase of 0.05% manganese above the specified maximum value it is permitted, i For seamless pipe, sulphur content up to 0.08% is permitted

with a maximum increase of 0.2% j Al total <0.006; N 0.012; Al:N 2:1 (not available to titanium killed steels);Cu 0.35 (by agreement 0.10); Ni 0.30;

b Al total <0.006; N 0.012; Al:N 2:1 (not available to titanium killed steels) k Cr 0.30; Mo 0.10;B 0.0005 Ca shall be restricted to 0.006%

c Ceq=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15 l For these steel grades, a molybdenium content up to 0.035% may be agreed

d Pcm=C+V/10+Mo/15+(Cr+Mn+Cu)/20+Si/30+Ni/60+5B n The value for the yield strength ratio apply to the product "pipe".They can not be required for the starting material. For grades L415MCS, L450MCS and

e For seamless pipe Pcm values 0.03 higher than tabulated value are permitted, up to maximum of 0.25 L485MCS the ratio may be increased by agreement to 0.93. For seamless pipe manufatured by a process of quenching and tempering, R10.5/Rm ratio

f Cu 0.35; Ni 0.30; Mo 0.10; B 0.0005 greater than the tabulated values may be agreed

g The sum of V, Nb, Ti shall not exceed 0.15% p The R10.5/Rm ratio for M grades applies to transversal test pieces only

h Cu 0.50; Ni 0.50; Cr 0.50; Mo 0.50;B 0.0005 q These values apply to transverse test pieces taken from the pipe body. If longitudinal test pieces are tested, the values of elongation shall be 2 units higher.

<22 23> Jubail Energy Services Company JESCO 2010

Technical Data LINE PIPE

Product Yield Strength Ultimate tensile Strength

Specification Grade Color Grade Source

min kPSI max kPSI min kPSI max kPSI

A25 25 45 API

A 30 48 API

B 35 60 API

X42 42 60 API

X46 46 63 API

X52 52 66 API

PSL 1

X56 56 71 API

X60 60 75 API

X65 65 77 API

X70 70 82 API

B 35 65 60 110 API

X42 42 72 60 110 API

X46 46 76 63 110 API

X52 52 77 66 110 API

PSL 2

X56 56 79 71 110 API

X60 60 82 75 110 API

X65 65 87 77 110 API

X70 70 90 82 110 API

X80 80 100 90 120 API

JESCO’s proprietary steel grade color identification system is user friendly allowing our products to be easily identified.

Correlation between API ang other International Standards

ISO 3183 NFA 49-211

API 5L EN 10 208 NFA 49-411 BS 3602 ASTM A 53 ASTM A 333 ASTM A 106

Grade A Steel 360 Grade A Grade 1 Grade A

TUE 220

Grade 3 Grade B

Grade B L245NB TUE 250 Grade B

Grade 6

TUE 275 Steel 430 Grade C

X 42 L290NB TUE 290

X 46 TUE 320

L360NB

X 52 TUE 360

L360QB

X 56

X 60 L415QB TUE 415

X 65 L450QB TUE 450

X 70 L485QB

X 80 L555QB

<24 25> Jubail Energy Services Company

You might also like

- Harrier Posner (2016) Marketing de La Moda 2da Edicion GGModaDocument225 pagesHarrier Posner (2016) Marketing de La Moda 2da Edicion GGModaPola Vanesa100% (1)

- Project Report PDFDocument41 pagesProject Report PDFAKRAMA HASANNo ratings yet

- BS 8110Document9 pagesBS 8110Priyadarshini Sahoo100% (1)

- Mama Don't Take My Kodachrome AwayDocument1 pageMama Don't Take My Kodachrome AwayTinto RajNo ratings yet

- 0 Natural PreservativesDocument1 page0 Natural PreservativesAytekin GaribliNo ratings yet

- Management Services Division Management Services DivisionDocument130 pagesManagement Services Division Management Services DivisionVictor Viceor100% (6)

- Amico-As-Air-And-Vacuum-Systems-BrochureDocument20 pagesAmico-As-Air-And-Vacuum-Systems-BrochureLuis PalaciosNo ratings yet

- Brown Beige Simple Thank You Poster A3 Portrait 1Document1 pageBrown Beige Simple Thank You Poster A3 Portrait 1RonMiguel SalazarrNo ratings yet

- Creating Videos With Confidence WorkbookDocument29 pagesCreating Videos With Confidence Workbookvero baudensNo ratings yet

- AFL Substation SolutionsDocument12 pagesAFL Substation SolutionsManali PrajapatiNo ratings yet

- 08-Swipe FIle Ideation WorksheetDocument1 page08-Swipe FIle Ideation WorksheetDuc TranNo ratings yet

- Vishleshan Varun HansrajDocument2 pagesVishleshan Varun Hansrajvarunvalecha2005No ratings yet

- Leadership Development GuideDocument17 pagesLeadership Development GuideAlan SantiagoNo ratings yet

- Onix Renewable Profile-2023Document17 pagesOnix Renewable Profile-2023ozaankit1992No ratings yet

- ADAPTOGENS For The New Year PDFDocument1 pageADAPTOGENS For The New Year PDFRaluca ScrieciuNo ratings yet

- FP029-CAEMR-Esp ActPracticas Material2Document12 pagesFP029-CAEMR-Esp ActPracticas Material2Margarita Cruz RiveraNo ratings yet

- SustainabilityDocument9 pagesSustainabilityMeezan Bank LimitedNo ratings yet

- RETROACTIVO 2021 Incerpaz Playas REVISADO AdmDocument9 pagesRETROACTIVO 2021 Incerpaz Playas REVISADO AdmGersy paul Rodriguez AraujoNo ratings yet

- Teclado Paradox 639 PDFDocument17 pagesTeclado Paradox 639 PDFjovensnosec218889No ratings yet

- Balanced Scorecard: A Case Study On Clothing Retail Business, Ambala CityDocument6 pagesBalanced Scorecard: A Case Study On Clothing Retail Business, Ambala CityAnmol GulatiNo ratings yet

- B15 GB Environmental and Municipal TechnologyDocument24 pagesB15 GB Environmental and Municipal TechnologyThinker OctansNo ratings yet

- Best SalespeopleDocument2 pagesBest SalespeopleScott Chen ChuangxinNo ratings yet

- Master Batroom-Master ToiletDocument1 pageMaster Batroom-Master ToiletMohamed OwaisNo ratings yet

- Medicinal MushroomsDocument3 pagesMedicinal MushroomsEllice O. MonizNo ratings yet

- Diagrama de ProcesosDocument2 pagesDiagrama de Procesosdiego rojas avellanedaNo ratings yet

- BP Fragrance Journal PagesDocument1 pageBP Fragrance Journal PagesConstance FenskeNo ratings yet

- BP Fragrance Families TableDocument1 pageBP Fragrance Families TableConstance FenskeNo ratings yet

- Planta Estructuras y Elevaciones - Sede Social Color PDFDocument1 pagePlanta Estructuras y Elevaciones - Sede Social Color PDFNikolas CaroNo ratings yet

- UK Is A Maritime Nation: The Components of RN Ethos AreDocument2 pagesUK Is A Maritime Nation: The Components of RN Ethos Arejoethompson007No ratings yet

- Conveyor 3700 3600 1000Document11 pagesConveyor 3700 3600 1000andre rahmat suardiNo ratings yet

- G74 KSK 60236Document1 pageG74 KSK 60236Ashkan AsefiNo ratings yet

- 6500 Adjustable Liquid Level Gauges General InformationDocument2 pages6500 Adjustable Liquid Level Gauges General InformationCesar VasquezNo ratings yet

- G71 KSK 60236Document1 pageG71 KSK 60236Ashkan AsefiNo ratings yet

- Bulacan State University Sarmiento: Business DescriptionDocument4 pagesBulacan State University Sarmiento: Business DescriptionClea CapiliNo ratings yet

- DodoDocument1 pageDodokhaingacademylcNo ratings yet

- 30 M. Wide Road (Saket Road)Document1 page30 M. Wide Road (Saket Road)hanif sayedNo ratings yet

- 17041aa108 DWG PDF-modeldDocument1 page17041aa108 DWG PDF-modeldVishnu ThipparthiNo ratings yet

- Harpers Ferry National Historical Park: MarylandDocument1 pageHarpers Ferry National Historical Park: Marylandapi-27451723No ratings yet

- Rompa International 2023Document220 pagesRompa International 2023AnAs Al ArjanNo ratings yet

- 02a Progress Basic Common CoreDocument12 pages02a Progress Basic Common CoreAlain AlotsipeNo ratings yet

- Electric Potters WhelDocument1 pageElectric Potters WhelGajsNo ratings yet

- Nuydeup - 1: STR STR CON CON DEX DEX INT INT WIS WIS CHA CHADocument9 pagesNuydeup - 1: STR STR CON CON DEX DEX INT INT WIS WIS CHA CHADylan VeraartNo ratings yet

- Detail A-A: SKALA 1:50Document1 pageDetail A-A: SKALA 1:50Hajie OmenNo ratings yet

- Leger Nilai 2016Document4 pagesLeger Nilai 2016smknsolor timurNo ratings yet

- GE Power Conversion: KVAF - 8339P30 - 4P - TEAACDocument1 pageGE Power Conversion: KVAF - 8339P30 - 4P - TEAACLuis CaballeroNo ratings yet

- Town of Philipstown Land Use and Development Overlay District Zoning MapDocument1 pageTown of Philipstown Land Use and Development Overlay District Zoning MapPCNRNo ratings yet

- FILIPO CompressedDocument1 pageFILIPO CompressedCarolina CarrascoNo ratings yet

- IMvula Quality Protection ProfileDocument33 pagesIMvula Quality Protection ProfileAnonymous fSKAwNCNo ratings yet

- 10-082-01 NEC Brochure ENG MyCalls LRDocument12 pages10-082-01 NEC Brochure ENG MyCalls LRRavneel Kant SharmaNo ratings yet

- Cover p4Document1 pageCover p4Muhammad FikriNo ratings yet

- Due Date 1.31.34Document1 pageDue Date 1.31.341919gmajNo ratings yet

- Bloodrager, BarbarianDocument7 pagesBloodrager, BarbarianJoão EstrellaNo ratings yet

- Pathfinder RPGDocument307 pagesPathfinder RPGmatthew677No ratings yet

- STR STR DEX DEX CON CON INT INT WIS WIS CHA CHA: CharacterDocument8 pagesSTR STR DEX DEX CON CON INT INT WIS WIS CHA CHA: CharacterJosé Antonio Rodríguez PascualNo ratings yet

- STR STR DEX DEX CON CON INT INT WIS WIS CHA CHA: CharacterDocument7 pagesSTR STR DEX DEX CON CON INT INT WIS WIS CHA CHA: CharacterZachary HeussNo ratings yet

- STR STR DEX DEX CON CON INT INT WIS WIS CHA CHA: CharacterDocument7 pagesSTR STR DEX DEX CON CON INT INT WIS WIS CHA CHA: CharacterZachary HeussNo ratings yet

- STR STR DEX DEX CON CON INT INT WIS WIS CHA CHA: CharacterDocument7 pagesSTR STR DEX DEX CON CON INT INT WIS WIS CHA CHA: CharacterZachary HeussNo ratings yet

- PaladinDocument5 pagesPaladinmrmonkeymetalNo ratings yet

- Magus Slayer Fighter (Melee) ClericDocument9 pagesMagus Slayer Fighter (Melee) ClericaleriyaNo ratings yet

- Wizard Pathfinder SheetDocument8 pagesWizard Pathfinder SheetWinterwarlordNo ratings yet

- 55219-07160 MSDSDocument13 pages55219-07160 MSDSGhani KhanNo ratings yet

- Hitachi Fittings CatalogueDocument8 pagesHitachi Fittings CatalogueGhani KhanNo ratings yet

- Ulma-Fittings Data SheetDocument11 pagesUlma-Fittings Data SheetGhani KhanNo ratings yet

- Benken Fittings Data Sheet..Document4 pagesBenken Fittings Data Sheet..Ghani KhanNo ratings yet

- Lesson 2 Discrete Probability DistributionsDocument11 pagesLesson 2 Discrete Probability DistributionsReign SaplacoNo ratings yet

- Introduction To Sports: Sports Benefits of Playing SportDocument7 pagesIntroduction To Sports: Sports Benefits of Playing SportMa. Karyl Ashrivelle CarreonNo ratings yet

- Pre Loading Condition SurveyDocument16 pagesPre Loading Condition Surveymax.pitchiah100% (1)

- CM YSM Air Handling Unit Catalogue Part4Document1 pageCM YSM Air Handling Unit Catalogue Part4JosephRusselVizmanosNo ratings yet

- Structural Clay Loadbearing Wall Tile: Standard Specification ForDocument4 pagesStructural Clay Loadbearing Wall Tile: Standard Specification ForM RattanasakNo ratings yet

- QUINTA DE PACOS PresentationDocument2 pagesQUINTA DE PACOS PresentationBeatrice ŞtefaniaNo ratings yet

- Ketu in Jaimini-4Document8 pagesKetu in Jaimini-4Ramesh DoddaNo ratings yet

- Get Art Sex Music Cosey Fanni Tutti pdf full chapterDocument24 pagesGet Art Sex Music Cosey Fanni Tutti pdf full chapterrajaifrenk100% (5)

- Mizoram 2Document66 pagesMizoram 2lalthansangaNo ratings yet

- Badminton 1Document32 pagesBadminton 1MaroLynn Natalia RominaNo ratings yet

- Net Ionic Equations-ProblemsDocument3 pagesNet Ionic Equations-ProblemsChikuta ShingaliliNo ratings yet

- DSTV PDFDocument4 pagesDSTV PDFEddy TangaNo ratings yet

- Chromosome Mapping by Conjugation ExperimentsDocument26 pagesChromosome Mapping by Conjugation ExperimentskittyngameNo ratings yet

- Kings Meadows Public ToiletDocument16 pagesKings Meadows Public ToiletThe ExaminerNo ratings yet

- Ultimate Goals of LifeDocument11 pagesUltimate Goals of LifeDaniel C. DequiñaNo ratings yet

- Module Week 9Document3 pagesModule Week 9Hanz Kirby Reyes FranciaNo ratings yet

- Kong Long Huat Borax Decahydrate, BI GHSDocument14 pagesKong Long Huat Borax Decahydrate, BI GHSOsh 0717No ratings yet

- B1900d LimitationsDocument3 pagesB1900d LimitationsMikeParsonsNo ratings yet

- Iso Iec - 14443 1Document8 pagesIso Iec - 14443 1Adel A. AbdelazizNo ratings yet

- Signals and Systems: BITS PilaniDocument21 pagesSignals and Systems: BITS Pilanirajeevdutt_1215No ratings yet

- Machiavelli'S Critique of Christianity: Paul-Erik KorvelaDocument31 pagesMachiavelli'S Critique of Christianity: Paul-Erik KorvelaMichael MungaiNo ratings yet

- SLG Chem2 LG 4.9 BuffersDocument6 pagesSLG Chem2 LG 4.9 BuffersIman SontousidadNo ratings yet

- Practical Stress Analysis For Design... by Flabel, Jean-ClaudeDocument1 pagePractical Stress Analysis For Design... by Flabel, Jean-ClaudeDAVID GRACEYNo ratings yet

- CHALLENGES IN IMPLEMENTING A NEW SIGNALLING SYSTEM TO REPLACE AN EXISTING SIGNALLING SYSTEM WHILE MAINTAINING NORMAL TRAIN SERVICE-good ReferenceDocument47 pagesCHALLENGES IN IMPLEMENTING A NEW SIGNALLING SYSTEM TO REPLACE AN EXISTING SIGNALLING SYSTEM WHILE MAINTAINING NORMAL TRAIN SERVICE-good ReferencePulin ChaudhariNo ratings yet

- Denon AVR-770SD Use ManualDocument83 pagesDenon AVR-770SD Use ManualMuhammad Naveed ShahNo ratings yet

- Surprises From Celiac Disease Scientific American August 2009Document8 pagesSurprises From Celiac Disease Scientific American August 2009Mihaly KovacsNo ratings yet

- Can CommunicationDocument139 pagesCan CommunicationMirceaNo ratings yet

- American Values and Assumptions SDocument22 pagesAmerican Values and Assumptions Ssushan ghajuNo ratings yet