Professional Documents

Culture Documents

Ijciet 08 09 109

Ijciet 08 09 109

Uploaded by

Snehal AbhyankarCopyright:

Available Formats

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Meas - Lecture Note Substructure Note 3Document14 pagesMeas - Lecture Note Substructure Note 3LokuliyanaNNo ratings yet

- RCD DRRB LectureDocument3 pagesRCD DRRB Lecturechristian remoquilloNo ratings yet

- Reference 101. Effect of Fibers in Concrete CompositesDocument13 pagesReference 101. Effect of Fibers in Concrete Compositesᜎᜒᜌᜓᜈᜒᜎ᜔ ᜄ᜔ᜏᜇᜒᜈ᜔No ratings yet

- Steel Fiber Reinforced ConcreteDocument26 pagesSteel Fiber Reinforced ConcreteJames Augustine100% (1)

- F INALDocument19 pagesF INALBhushan JadhavNo ratings yet

- Effect of Fibers in Concrete Composites: International Journal of Applied Engineering Research January 2015Document13 pagesEffect of Fibers in Concrete Composites: International Journal of Applied Engineering Research January 2015Aika LorenNo ratings yet

- Fibre Reinforced Concrete FRC Ijariie4483Document7 pagesFibre Reinforced Concrete FRC Ijariie4483Devesh Kumar PandeyNo ratings yet

- Unit6 MCNDocument29 pagesUnit6 MCNPravesh GautamNo ratings yet

- To Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesDocument6 pagesTo Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesIJRASETPublicationsNo ratings yet

- MGK266Document8 pagesMGK266prisak2002No ratings yet

- Benefits of SFRCDocument17 pagesBenefits of SFRCShubhayu_duttaNo ratings yet

- Experimental Study On Steel Fiber Reinforced ConcreteDocument7 pagesExperimental Study On Steel Fiber Reinforced ConcreteIJRASETPublicationsNo ratings yet

- Acknowledgement: M.R. Head of Civil Engineering Department, For Inspiring Take This Project. I Also ExpressedDocument18 pagesAcknowledgement: M.R. Head of Civil Engineering Department, For Inspiring Take This Project. I Also ExpressedRicky RickxNo ratings yet

- FRCFRCDocument11 pagesFRCFRCdhananjay kumarNo ratings yet

- Effect of Steel Fibers On Strength of ConcreteDocument8 pagesEffect of Steel Fibers On Strength of ConcreteBlack KaiserNo ratings yet

- Report On Steel Fiber Reinforced ConcreteDocument44 pagesReport On Steel Fiber Reinforced Concretevishalgore100% (1)

- FM 2 Flooring Journel PDFDocument4 pagesFM 2 Flooring Journel PDFkamaldeep singhNo ratings yet

- TimeeDocument13 pagesTimeeyra.viluan14No ratings yet

- A Review "Experimental Study On Steel Fiber Reinforced Concrete Using Flat Crimped & Round Crimped Type Steel Fiber."Document6 pagesA Review "Experimental Study On Steel Fiber Reinforced Concrete Using Flat Crimped & Round Crimped Type Steel Fiber."IJRASETPublicationsNo ratings yet

- Thesis On Steel Fiber Reinforced ConcreteDocument5 pagesThesis On Steel Fiber Reinforced ConcreteBuyCustomEssayEverett100% (1)

- Rajeev Institute of Technology, Hassan Department of Civil EngineeringDocument4 pagesRajeev Institute of Technology, Hassan Department of Civil EngineeringSamarth NazareNo ratings yet

- FRP NotesDocument11 pagesFRP NotesMohammed ImranNo ratings yet

- Structural Behaviour of Hybrid Fibres Concrete Using Regression AnalysisDocument7 pagesStructural Behaviour of Hybrid Fibres Concrete Using Regression AnalysisIJRASETPublicationsNo ratings yet

- PC Research PaperDocument5 pagesPC Research PaperghNo ratings yet

- Fibre Reinforced Concrete 3858 RrL4YRUDocument29 pagesFibre Reinforced Concrete 3858 RrL4YRUDurvank ShethNo ratings yet

- Thesis On Fibre Reinforced ConcreteDocument4 pagesThesis On Fibre Reinforced Concretefjfsyk5w100% (1)

- Glass Fibre Concrete: Investigation On Strength and Fire Resistant PropertiesDocument5 pagesGlass Fibre Concrete: Investigation On Strength and Fire Resistant Propertiessushma chandrikaNo ratings yet

- Research Paper On Steel Fiber Reinforced ConcreteDocument5 pagesResearch Paper On Steel Fiber Reinforced Concretecaq5kzrg100% (1)

- FibersDocument15 pagesFibersSACHINNo ratings yet

- An Experimental Investigation On StructuralDocument5 pagesAn Experimental Investigation On StructuralAtano RoyNo ratings yet

- High-Performance Fiber-Reinforced Concrete: A ReviewDocument35 pagesHigh-Performance Fiber-Reinforced Concrete: A ReviewAnteneh GeremewNo ratings yet

- CHAPTER 1 FINAL YEAR ProjectDocument5 pagesCHAPTER 1 FINAL YEAR ProjectdejayzNo ratings yet

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Document6 pagesIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationNo ratings yet

- Steel Fibre Concrete Composites For Special ApplicationsDocument213 pagesSteel Fibre Concrete Composites For Special Applicationshamsanram100% (3)

- Study On Strength Parameters On Fibers Using M30 ConcreteDocument13 pagesStudy On Strength Parameters On Fibers Using M30 ConcreteIJRASETPublicationsNo ratings yet

- Chapter 2Document5 pagesChapter 2Mark B. BarrogaNo ratings yet

- Fibre Reinforced Concrete: A Consise ReportDocument5 pagesFibre Reinforced Concrete: A Consise ReportSaleem MohammedNo ratings yet

- SFRCDocument37 pagesSFRCKarthika SNo ratings yet

- Influence of Steel Fiber On Behaviour of Reinforced Concrete Beams: A ReviewDocument7 pagesInfluence of Steel Fiber On Behaviour of Reinforced Concrete Beams: A ReviewAysar AL-KhawajaNo ratings yet

- Report FRCDocument20 pagesReport FRCRahul MadanNo ratings yet

- FRCDocument23 pagesFRCMathur AbhinavNo ratings yet

- Post-Cracking Behaviour of Basalt and Macro Polypropylene Hybrid Fibre Reinforced Concrete With Different Compressive StrengthsDocument13 pagesPost-Cracking Behaviour of Basalt and Macro Polypropylene Hybrid Fibre Reinforced Concrete With Different Compressive StrengthsShruti SharmaNo ratings yet

- FRCDocument144 pagesFRCGyan KumarNo ratings yet

- Ijciet 07 05 037Document8 pagesIjciet 07 05 037kannankannan0539No ratings yet

- Self Compacting Fibre Reinforced Concrete - A Revi PDFDocument4 pagesSelf Compacting Fibre Reinforced Concrete - A Revi PDFNurul'Ain Haniyun Mohamad FodziNo ratings yet

- Fibre Reinforced ConcreteDocument12 pagesFibre Reinforced ConcretePradeepLokhande100% (2)

- Notes On Fibre Reinforced ConcreteDocument9 pagesNotes On Fibre Reinforced ConcreteK.ANISH100% (1)

- A Review On Glass Fibre Reinforced Concrete Used in ConstructionDocument5 pagesA Review On Glass Fibre Reinforced Concrete Used in ConstructionNishan KarkiNo ratings yet

- Keywords: Steel Fiber, Concrete, Properties, Crack, Ductility, TechnologyDocument4 pagesKeywords: Steel Fiber, Concrete, Properties, Crack, Ductility, TechnologySandeep ReddyNo ratings yet

- Increase in Strength of Concrete by Using Bottle CapsDocument6 pagesIncrease in Strength of Concrete by Using Bottle Capsaffan aliNo ratings yet

- Body of The Content Pagenumber Inputed 123Document82 pagesBody of The Content Pagenumber Inputed 123danusri1606No ratings yet

- J Conbuildmat 2019 117043Document10 pagesJ Conbuildmat 2019 117043civilstructure.singhbrothersNo ratings yet

- Strengthening of Structural Concrete Element Using Fiber GlassDocument3 pagesStrengthening of Structural Concrete Element Using Fiber Glassrakshit thapliyalNo ratings yet

- Jurnal SFRCDocument4 pagesJurnal SFRCNabila ValenciaNo ratings yet

- Fibre Reinforced ConcreteDocument50 pagesFibre Reinforced ConcreteAishwarya Madhivanan100% (3)

- Mechanical Properties of Steel Fiber Reinforced Self-Compacting ConcreteDocument8 pagesMechanical Properties of Steel Fiber Reinforced Self-Compacting ConcreteviolettaNo ratings yet

- Polypropylene Fibre Reinforced Concrete Literature ReviewDocument4 pagesPolypropylene Fibre Reinforced Concrete Literature Reviewc5j07dceNo ratings yet

- g 0805025361Document9 pagesg 0805025361Anand KNo ratings yet

- GFRC For SlabsDocument7 pagesGFRC For SlabsJayanth RaviNo ratings yet

- Jute Motar PDFDocument67 pagesJute Motar PDFSøüRãv JãløTrãNo ratings yet

- Performance Assessment of Glass Fiberreinforced Concrete BeamsDocument11 pagesPerformance Assessment of Glass Fiberreinforced Concrete Beamsచిమ్ముల సందీప్ రెడ్డిNo ratings yet

- Statically Indeterminate StructuresDocument7 pagesStatically Indeterminate StructuresSnehal AbhyankarNo ratings yet

- Flyash As A Sustainable Alternate Building Material For Low Cost HousingDocument5 pagesFlyash As A Sustainable Alternate Building Material For Low Cost HousingSnehal AbhyankarNo ratings yet

- Mohh$ HMÑ'MGMR R Ho$Bobr Eò (H $'M Ovbr Ordmda (Ddmhmamyr Damz J - Mdbo Àmu!Document1 pageMohh$ HMÑ'MGMR R Ho$Bobr Eò (H $'M Ovbr Ordmda (Ddmhmamyr Damz J - Mdbo Àmu!Snehal AbhyankarNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Hossein Mola-Abasi, Issa ShooshpashaDocument7 pagesJournal of Rock Mechanics and Geotechnical Engineering: Hossein Mola-Abasi, Issa ShooshpashaSnehal AbhyankarNo ratings yet

- Analytical and Experimental Investigations On Using Waste Marble Powder in ConcreteDocument13 pagesAnalytical and Experimental Investigations On Using Waste Marble Powder in ConcreteSnehal AbhyankarNo ratings yet

- Nternational Ournal of Ngineering Ciences & Esearch EchnologyDocument8 pagesNternational Ournal of Ngineering Ciences & Esearch EchnologySnehal AbhyankarNo ratings yet

- Partial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly AshDocument10 pagesPartial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly AshSnehal AbhyankarNo ratings yet

- Affordable and Climate-Resilient: How Casa Real'S Homes Withstood Cyclone IdaiDocument2 pagesAffordable and Climate-Resilient: How Casa Real'S Homes Withstood Cyclone IdaiSnehal AbhyankarNo ratings yet

- Effects of Concrete Block Pavement On Flow Retardation FactorDocument9 pagesEffects of Concrete Block Pavement On Flow Retardation FactorSnehal AbhyankarNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument7 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologySnehal AbhyankarNo ratings yet

- 109 S. V. Joshi and U. P. WagheDocument1 page109 S. V. Joshi and U. P. WagheSnehal AbhyankarNo ratings yet

- Design of Visible Light Active Photocatalyst For Environmental and Energy ApplicationsDocument73 pagesDesign of Visible Light Active Photocatalyst For Environmental and Energy ApplicationsSnehal AbhyankarNo ratings yet

- PVT Systems-Sustainability - SSSDocument67 pagesPVT Systems-Sustainability - SSSSnehal AbhyankarNo ratings yet

- Sustainable Construction Engineering: Research and PracticesDocument2 pagesSustainable Construction Engineering: Research and PracticesSnehal AbhyankarNo ratings yet

- Research On Different Types of Cracks in Plain and Reinforced ConcreteDocument3 pagesResearch On Different Types of Cracks in Plain and Reinforced ConcreteSnehal AbhyankarNo ratings yet

- Energy Efficiency in Buildings: Anil Kashyap Day 1 Session 2Document28 pagesEnergy Efficiency in Buildings: Anil Kashyap Day 1 Session 2Snehal AbhyankarNo ratings yet

- Report On Building ConstructionDocument38 pagesReport On Building ConstructionOlaifa victorNo ratings yet

- Isolated Footing Design Example and Excel Sheet PDFDocument8 pagesIsolated Footing Design Example and Excel Sheet PDFPrabhakar Reddy33% (3)

- Concrete Bridges in GermanyDocument12 pagesConcrete Bridges in GermanydelujaNo ratings yet

- Earthquake Resistant Masonary BuildingsDocument26 pagesEarthquake Resistant Masonary BuildingsSourabhAdikeNo ratings yet

- Design of PIle Foundation ProjectDocument19 pagesDesign of PIle Foundation ProjectJinendra Bafna100% (2)

- Diaphragm Walls Construction and DesignDocument18 pagesDiaphragm Walls Construction and DesignShirley Munoz100% (1)

- Final Estimation For Rate PreparationDocument5 pagesFinal Estimation For Rate PreparationmanojNo ratings yet

- Concrete Mix ProportioningDocument19 pagesConcrete Mix ProportioningCZ001 Abisha ANo ratings yet

- Steel-Concrete Composite Columns: Prof S R Satish Kumar Dept. of Civil Engineering IIT Madras, Chennai 600036Document37 pagesSteel-Concrete Composite Columns: Prof S R Satish Kumar Dept. of Civil Engineering IIT Madras, Chennai 600036Piyush SinghNo ratings yet

- Smart NotesDocument515 pagesSmart NotesAEMNo ratings yet

- Wind Loading in Steel Joist Design PDFDocument95 pagesWind Loading in Steel Joist Design PDFnitroxx7No ratings yet

- JETIR1903G72Document4 pagesJETIR1903G72Vikas SharmaNo ratings yet

- Fire Rating Requirement For Steel ConstructionDocument2 pagesFire Rating Requirement For Steel ConstructionMamunNo ratings yet

- Road Materials: Asphalt LayerDocument3 pagesRoad Materials: Asphalt LayerMarjorie SalvañaNo ratings yet

- Scope of WorkDocument3 pagesScope of WorkSunday Paul100% (1)

- PCA Concrete Deep Beam DesignDocument12 pagesPCA Concrete Deep Beam DesignjulesjusayanNo ratings yet

- Long Front Wall 25 at 150Document10 pagesLong Front Wall 25 at 150kuttyNo ratings yet

- Pages From Curtain Wall (BD Submission) - 2Document6 pagesPages From Curtain Wall (BD Submission) - 2Con CanNo ratings yet

- Ronan Point Apartment Tower Collapse and Its Effect On Building CDocument7 pagesRonan Point Apartment Tower Collapse and Its Effect On Building CAman 'kebe' KebedeNo ratings yet

- Design of Concrete Structures 15th Edition Ebook PDFDocument61 pagesDesign of Concrete Structures 15th Edition Ebook PDFmario.becker25298% (52)

- 2023-06-09 PICE v05Document53 pages2023-06-09 PICE v05John Michael AngelesNo ratings yet

- JHOELLA Construction Estimate 1,2,3Document13 pagesJHOELLA Construction Estimate 1,2,3jhoella Marie PapasinNo ratings yet

- Truss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionDocument1 pageTruss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionChrysler DuasoNo ratings yet

- Nonlinear Analysis of Reinforced Concrete Slabs at Elevated TemperatureDocument10 pagesNonlinear Analysis of Reinforced Concrete Slabs at Elevated TemperatureHuda JawadNo ratings yet

- C7. SlabsDocument77 pagesC7. SlabsDavid Moreno SanchezNo ratings yet

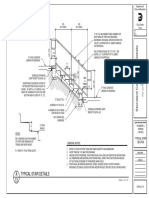

- Typical Stair DetailsDocument1 pageTypical Stair DetailsM IQbalNo ratings yet

- Formwork Is An Ancillary ConstructionDocument25 pagesFormwork Is An Ancillary ConstructionSarinNo ratings yet

- Design Example 9: Cantilevered Monotube Support For A Dynamic Message SignDocument39 pagesDesign Example 9: Cantilevered Monotube Support For A Dynamic Message SignMohamed Zakaria ZaidiNo ratings yet

Ijciet 08 09 109

Ijciet 08 09 109

Uploaded by

Snehal AbhyankarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ijciet 08 09 109

Ijciet 08 09 109

Uploaded by

Snehal AbhyankarCopyright:

Available Formats

International Journal of Civil Engineering and Technology (IJCIET)

Volume 8, Issue 9, September 2017, pp. 983–992, Article ID: IJCIET_08_09_109

Available online at http://http://www.iaeme.com/ijciet/issues.asp?JType=IJCIET&VType=8&IType=9

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

© IAEME Publication Scopus Indexed

EFFECT OF MIXING FIBER COCKTAIL ON

FLEXURAL STRENGTH OF CONCRETE

S. V. Joshi

Research Scholar, Civil Engineering Department, Y.C.C.E, Nagpur, Maharashtra, India

U. P. Waghe

Professor, Civil Engineering Department, Y.C.C.E, Nagpur, Maharashtra, India

ABSTRACT

Steel fibre is used to improve the mechanical properties of concrete, especially the

postcracking tensile resistant. Moreover, it has recently been used as an alternative

engineering material instead of steel bars/steel stirrups in short Steel fibres reinforced

concrete (SFRC) construction is more economical than conventional construction. In

addition to cost reduction, SFRC has other beneficial properties such as higher

stiffness, higher ductility, lightweight, low repair costs, and better post-cracking and

dynamic behavior. An experimental investigation on the behavior of concrete

specimens reinforced with steel fibres and polypropelene fibres subjected to

compressive and flexural loading is presented. Tests were conducted on specimens

with four different fibre volume fractions. With the combinations of varying

percentage of steel and polypropylene fibres various SPFRC mixes with hooked end

fibre and crimped steel fibres were prepared. The results present that flexural and

compressive strength characteristics influenced by steel and polypropylene fibres. Use

steel fibres are found to be more effective for the enhancement of flexural strength

characteristics. The crimped steel fibre is more effective than the hooked end steel

fibre. The workability is also affected by the addition of steel fibres. Workability is

more affected by the crimped steel fibres than hooked steel fibres. It was observed

that SPFRC specimens showed enhanced properties compared to that of normal

specimen.

Keywords: Steel fiber-reinforced concrete (SFRC), steel fibres, polypropelene fibres,

flexural strength, compressive strength

Cite this Article: S. V. Joshi and U. P. Waghe, Effect of Mixing Fiber Cocktail on

Flexural Strength of Concrete, International Journal of Civil Engineering and

Technology, 8(9), 2017, pp. 983–992.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=8&IType=9

http://www.iaeme.com/IJCIET/index.asp 983 editor@iaeme.com

S. V. Joshi and U. P. Waghe

1. INTRODUCTION

Concrete is known to be a brittle material when subjected to tensile stresses and impact loads;

tensile strength of the concrete is approximately one tenth of its compressive strength. As a

result of this, concrete members are unable to withstand such loads and stress that are usually

encountered by concrete structural members. Usually, concrete members are reinforced with

continuous reinforcing bars to withstand tensile stresses and to compensate for the lack of

ductility and strength. The addition of steel reinforcement to concrete significantly increases

its strength, but to produce a concrete with homogenous tensile properties and better micro

cracking behaviour, fibres are advantageous. The introduction of fibres in concrete has

brought a solution to develop a concrete having enhanced flexural and tensile strength, which

are a new form of composite material. At the micro-level, fibres inhibit the initiation and

growth of cracks, and after the micro-cracks coalesce into macro-cracks, fibres provide

mechanisms that abate their unstable propagation, provide effective bridging, and impart

sources of strength gain, toughness and ductility. Fibres are mostly discontinuous, randomly

distributed throughout the cement matrices. The randomly distributed short fibres are

generally introduced into concrete to enhance its control crack system and mechanical

properties such as toughness, impact resistance, ductility (post cracking), tensile strength etc.

of basic matrix. There are many kinds of fibres, such as metallic, synthetic, natural etc which

are being used in normal concrete as shown in Fig 1. The term fibre based concrete (FBC) is

concrete containing fibrous material which increases its structural integrity. It contains short

discrete fibres that are uniformly distributed and randomly oriented. Different type of fibres in

concrete changes the character of fibre based concrete. Further properties of fibre based

concrete changes with varying concrete, fibre materials geometries, distribution, orientation

and densities. When fibre is added to a concrete mix, each and every individual fibre receives

a coating of cement paste. Modification of synthetic fibre geometry includes monofilaments,

fibrillated fibres, fibre mesh, wave cut fibre large end fibres etc. This increases bonding with

cement matrices without increasing in its length and minimized chemical interaction between

fibres and the cement matrices. Fibres also modifies and enhances the mechanical properties

and behaviour of concrete during its application. Fibre can be used with admixture such as

super plasticizer, air entraining, retarding, accelerating etc and all type of cement and concrete

mixtures. These produce a special type of concrete with desired properties in fresh and

hardened concrete. In present study polypropylene and steel fibres have been used.

Polypropylene fibre having low modulus, light density, small monofilament diameter and not

susceptible to corrosion and steel fibre increases its ductility, toughness, and impact

resistance.

The aim of this study is to investigate the change in mechanical properties of concrete

with the addition of steel fiber in high strength concrete. Steel Fibers in Concrete can

improve: Crack, Impact and Fatigue Resistance, Shrinkage Reduction, Toughness- by

preventing/delaying crack propogation from micro-cracks to macro-cracks. SFRC has been

used extensively in construction of industrial floors, bridge deck overlays, airport runways,

highway pavements, tunnel linings, spillways, dams, slope stabilizations, and many precast

products. Nevertheless, relatively little use of SFRC in the building structure is mainly due to

the lack of design provisions in building codes. Steel fibers can improve the characteristics of

hardened concrete, and polypropylene fibers can have significant effects on the fresh

concrete. Polypropylene fibers significantly reduce the slump of the fresh concrete resulting in

an increase in the adhesion and cohesion of the concrete. Polypropylene fibers also reduce the

plastic shrinkage cracks. Polypropylene fibers can increase concrete durability against fire,

freezing, and chemical attacks. Due to its benefits, polypropylene fiber reinforced concrete is

used in pile foundations, piers, highways, industrial floors, bridge decking and others. Fibers

http://www.iaeme.com/IJCIET/index.asp 984 editor@iaeme.com

Effect of Mixing Fiber Cocktail on Flexural Strength of Concrete

are mostly used in concrete to control cracking due to various circumstances. Fibers are also

helpful in concrete to reduce the permeability which may further Impact the bleeding of

water. Some more various types of fibers produces great impact just like abrasion and shatter

resistance in concrete. Some recent researches shows that using fibers in concrete shows

Impact on the impact resistance of the materials but it is only up to a certain limit.

1.1. Importance of Steel Polypropelene fibers in strengthening

The Steel Polypropylene Fibre Reinforced-Pavement Quality Concrete (SPFRC) is composite

of conventional Quality Concrete and uniformly dispersed steel & polypropylene fibre. In this

steel fibre provides the structural improvement whereas polypropylene fibre enhances the

resistance to plastic shrinkage cracking.

Chang et al., 1995, studied the behaviour of fibres-reinforced concrete. They suggested

that with the use of steel fibres; increases in flexural strength and ductility of concrete due to

the ability of the fibres to restrain cracks. All concrete contains flaws which could increase in

size under loads which were less than 50% of the ultimate load. The fatigue failure

mechanism for concrete or mortar develops in three stages:

(i) The first stage, flaw initiation, is an inherent quality of concrete such as the presence

of air voids and weak or debonded regions between aggregate and paste.

(ii) The second stage, the slow growth of flaws to a critical size, is a complex mechanism

in a heterogeneous material such as concrete. The growth of the inherent flaws under

static loading of concrete is called micro cracking. From the previous studies it was

stated that there would be some flaws of a shape, size and orientation in the stress field

that may grow slowly in a stable manner to a critical size and then increase rapidly.

(iii)In this third stage, when a sufficient number of unstable cracks join to form a

continuous crack, failure of the member follows quickly.

The first and third stages of the failure mechanism cannot be prevented, but there is the

possibility of retarding the growth of the flaws in the second stage by using closely spaced

and randomly dispersed steel & polypropylene fibres as reinforcement in the concrete or

mortar.

1.2. Properties of FRC for Study

1.2.1. Workability

Workability is the property of SPFRC which determines the ease and homogeneity with

which it can be mixed, placed, compacted and finished. Major factors affecting the

workability are water content, cement content, aggregate content, fibre type & their content,

air content, temperature, mixing conditions, chemical admixtures etc. After the addition of

fibres significant reduction in fresh properties of concrete (IRC 2013, Yap et al., 2013, Chang

et al., 1995, Kumar et al., 2014, Rokade etal., 2014). The reduction in workability due to

strong fibre matrix bond in the concrete mix. decision makers for appropriate rescue

operations. 3D visualizations are tools for rescue operations during disasters, e.g., cyclone,

tsunami, earthquake, flooding and fire, etc (Patel et al., 2013) [35].

1.2.2. Compressive Strength

The determination of compressive strength for the various grades of concrete has received a

large amount of attention as concrete is primarily meant to withstand compressive stresses.

The addition of fibres enhances the compressive strength of concrete (Parveen et al., 2013,

Qureshi et al., 2013, Rokade etal., 2014). The compressive strength is significantly influenced

by steel fibres and increases by increasing quantity of steel fibre (Chang et al., 1995, Kumar et

http://www.iaeme.com/IJCIET/index.asp 985 editor@iaeme.com

S. V. Joshi and U. P. Waghe

al., 2014, Girish et al., 2012, Li et al., 2010, Soutsos et al., 2012). From the previous studies,

it was concluded that, steel fibre provides the ductility to concrete, as they have high strength

& high modulus of elasticity thus have more ability to arrest the macro cracks.

1.2.3. Tensile Strength

It is well known; concrete is strong in compression but weak in tension. Even a very small

eccentricity of load will induce bending and axial force condition and the concrete fails at

apparent tensile stress other than the tensile strength (Gambhir, 2010). Under an increasing

compression loading, cracks will initiate and advance. When the advancing crack approaches

a fibre, the debonding at the fibre–matrix interface begins due to the tensile stresses

perpendicular to the expected path of the advancing crack. As the advancing crack reaches the

interface, the crack tip stress concentration is reduced, and, thus, the propagation of cracks is

blunted and blocked. This process is the bridging effect or crack arresting ability of fibres in

concrete (Yap et al., 2013, Parveen et al., 2013, Kumar et al., 2014, Girish et al., 2012,

Rokade etal., 2014). The uniformly dispersed fibres create the bridging effect of fibre, hence

tensile strength increases.

1.2.4. Flexural Strength

The flexural tensile strength is important parameter to estimate the load at which the concrete

member may crack. As it is difficult to determine the tensile strength of concrete by

conducting a direct tension test, it is computed by flexural testing. When the concrete has

more flexural strength, it will be more fatigue resistant.

Due to formation of such type of cracks, flexural strength decreases, thus Concrete layer

deteriorated rapidly. The steel fibre has more modulus of rupture than polypropylene fibres,

hence they provide the structural improvement i.e. arrest the macro cracks and undergo the

ductile failure, while polypropylene fibres provide the resistant to plastic shrinkage cracking

and undergo the brittle failure.

1.2.5. Toughness

It is the ability to absorb energy after cracking. This is also defined by area under the stress-

strain curve of SPFRC. Toughness is increase with the addition of fibres. Figure 1.1 presents

typical stress-strain curve for the fibre reinforced concrete.

Figure 1 (Source: The Concrete Institute, 2012)

http://www.iaeme.com/IJCIET/index.asp 986 editor@iaeme.com

Effect of Mixing Fiber Cocktail on Flexural Strength of Concrete

1.3. Effect of Temperature on Behaviour of SPFRC

Concrete is though not a refractory material, is incombustible and has good fire resistant

properties. The effect of temperature on the strength of concrete is not much up to a

temperature of about 250 °C but above 300 °C, considerable loss of strength take place

(Shetty, 2010). It is concluded that incorporating steel fibre remains beneficial to concrete

which has been exposed to high temperatures up to 1200 °C. At high temperature loss in static

modulus of elasticity of concrete. Up to 1000 °C, no effect on poison ratio (Lau et al., 2006).

The results show that the toughness of SFRC under flexural loading increases with a decrease

in temperature. This increase appears to be related to the increase in the strength of the matrix

at low temperatures (because of the freezing of water in the capillary pores), which increases

the energy required for fiber pull-out.

2. EXPERIMENTAL PROGRAMME

2.1. MATERIALS

With the combinations of varying percentage of steel and polypropylene fibres various

SPFRC mixes i.e. SPFRC –A (SF - 0.35% + PPF - 0.15%), SPFRC-B (SF - 0.25% + PPF -

0.25%), SPFRC-C (SF - 0.85% + PPF - 0.15%) and SPFRC-D (SF - 0.75% + PPF - 0.25%)

with hooked end fibre and crimped steel fibres were prepared. The design of mix was done as

per guidelines of Is 10262:2009. Portland Pozzolana Cement make used during the entire

experimental work. Natural coarse aggregates of 20 mm nominal size and natural sand of

confirming to zone –III was used. Further to ease the placing of SPFRC mixes super-

plasticiser was added to enhance the workability requirement of SPFR-PQC mixes. The

dosage of super-plasticiser was identified 0.5% by weight of cement. The total fibre content

for the mix SPFRC-A and SPFRC-B is 0.5% by volume of concrete, whereas for the mix

SPFRC-C and SPFRC-D the total fibre content is 1% by volume of concrete.

To find the suitability of aggregates for the SPFRC mix design the sieve analysis, specific

gravity test, water absorption test, aggregate impact test and loss angles abrasion test are

carried out. During the entire experimental work Portland Pozzolana Cement (PPC) make

Ultra tech cement is used. To find the suitability of PPC cement various test were conducted

like fineness test, consistency test, initial setting and final setting time test and compressive

strength test are carried as per Indian specifications.

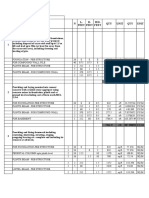

2.2 Experimental Results of SPFRC Mixes

2.2.1 Workability of SPFRC Mixes

In the present experimental work, polypropylene fibre and two types of steel fibre namely

crimped steel fibre and hooked end steel fibre were used and their influence on workability

behaviour is accessed.

http://www.iaeme.com/IJCIET/index.asp 987 editor@iaeme.com

S. V. Joshi and U. P. Waghe

Figure 2 Slump of SPFRC Mixes

The maximum slump loss about 52% was obtained in SPFRC–C Mix made by crimped

steel fibre having higher dose of steel fibre i.e. 0.85%. Whereas in the same mix when

hooked end steel fibres were used the reduction was about 44%. The workability of SPFRC-C

followed by workability of SPFRC-D. In the SPFRC-D, the reduction was 40% observed

when crimped steel fibres were used and 30% reduction was observed when hooked end steel

fibres were used.

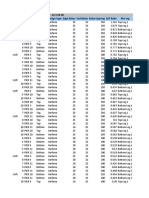

2.2.2 Compressive Strength of SPFRC Specimens

The total fibre contents were 0.5 % and 1%. Various SPFRC Mixes were prepared with

varying percentage of steel and polypropylene fibres to access the compressive strength and

flexure strength characteristics. It presents the variation of compressive strength with

percentage of steel fibre at 7 days. It presents the variation of compressive strength with

percentage of steel fibre at 28 days.

40

SPFRC-C

Compressive Strength (MPa)

SPFRC-A SPFRC-D

33.58

SPFRC-B 29.2 30.6

30 28.5

29.65 30.84

28.16

25.8

20

10

0

0.00 0.20 0.40 0.60 0.80 1.00

% Steel Fibre

Crimped SF Hooked End SF

Figure 3 Variation of Compressive Strength with the % Steel Fibres at 7 Days

http://www.iaeme.com/IJCIET/index.asp 988 editor@iaeme.com

Effect of Mixing Fiber Cocktail on Flexural Strength of Concrete

It is observed that compressive strength of all SPFRC mixes is more than compressive

strength of plain PCC. Compressive Strength is considerably influenced by steel fibre and

increases by increasing the quantity of steel fibre.

70

SPFRC-C

SPFRC-D

Compressive Strength (MPa)

SPFRC-A 57.4

56 51.1 52.2

SPFRC-B

47.38 52.77

49.91

42 47.5

42.63

28

14

0

0.00 0.20 0.40 0.60 0.80 1.00

% Steel Fibre

Crimped SF Hooked End SF

Figure 4 Variation of Compressive Strength with % Steel Fibres at 28 Days

2.3.1 Flexural Strength of SPFRC Specimens

It presents the variation of flexure strength with percentage of steel fibre at 7 days. It presents

the variation of flexure strength with percentage of steel fibre at 28 days. The results indicate

when SPFRC-C includes crimped steel fibres, the flexure strength at 7 days increases by

45.9% than the concrete mix. Similarly for 28 days this value increases by 120% than

concrete mix. On other hand when SPFRC-C comprises the hooked end steel fibres, the

flexure strength at 7 days increased by 21.42 % than the concrete mix. Whereas for 28 days

this value increased by 92% than Concrete mix. The flexural strength of SPFRC-B consists of

either crimped steel fibre or hooked end steel fibres was less as compared to other SPFRC-C

mixes because less steel fibre content was used. For SPFRC-B which consists of crimped

steel fibre the flexural strength at 28 days increased by 63.22% than Concrete mix and when

consist of hooked end steel fibre, flexural strength at 28 days increased by 48.21 %. SPFRC

mixes are more than flexural strength of Concrete Mixes. Flexure Strength is also

considerably influenced by steel fibre and increases by increasing the quantity of steel fibre.

http://www.iaeme.com/IJCIET/index.asp 989 editor@iaeme.com

S. V. Joshi and U. P. Waghe

8

SPFRC-A SPFRC-D SPFRC-C

Flexural Strength (MPa)

6.23 6.51 6.84

SPFRC-B

6

5.27

5.79 5.95

5.57

4 4.86

0

0.00 0.20 0.40 0.60 0.80 1.00

% Steel Fibre

Crimped SF Hooked End SF

3. RESULTS AND DISCUSSION

The workability of SPFRC Mixes is affected with the type of steel fibre and their dosage. It is

observed that as the dosage of steel fibre increases workability reduces.

Maximum slump loss was observed for the SPFRC-C Mix consisting 0.85% crimped end

steel fibre and 0.15% polypropylene fibres. Compressive strength of Concrete Mix increased

by 37% when SPFRC-C mix is prepared. The maximum increase in flexural strength is

observed for the mix SPFRC-C consisting crimped steel fibres.The flexural strength of

Concrete Mix increased by 120% when SPFRC-C mix is prepared.

4. CONCLUSION

In the present study steel and poly-propylene fibres of single aspect ratio are used in PCC.

Studies may be carried out using steel fibres of different aspect ratio and also on different

types of synthetic fibres like nylon, polyethylene, polyamide, acrylic etc.

Also the various other combinations of fibres can be used for the assessment of

workability, flexural strength and compressive strength characteristics of Pavement Quality

Concrete Mixes.

The present study is based on the assessment of flexural strength and compressive

strength characteristics of PQC mixes. Studies may also be carried out on fatigue analysis of

SPFR-PQC.

REFERENCES

[1] Doo-Yeol Yoo, Su- Tea Kang, Joo- Ha Lee, Young- Soo Yoon, Effect of shrinkage

reducing admixture on tensile and flexural behaviours of UHPFRC considering fiber

distribution characteristics, Cement and Concete Research, 54 (2013), pp. 180-190.

[2] X.X. Zhang, A.M. Abd Elazim, G. Ruiz, R. C. Yu, Fracture behavior of steel fibre

reinforced concrete at a wide range Benjamin, J. R., Tsunamis of the Arabian Peninsula A

guide of historic events. Science of Tsunami Hazards, 27(1), 2008, pp. 37.

[3] Brown R., Shukla A., Natarajan K.R., (2002), Fiber Reinforcement of Concrete

Structures, Report No. URITC FY99-02, University of Rhode Island. Accessed 1

September 2014.

http://www.iaeme.com/IJCIET/index.asp 990 editor@iaeme.com

Effect of Mixing Fiber Cocktail on Flexural Strength of Concrete

[4] Buendia A M L., Sanchez M D R., Climent V., Guillem C., (2013) Surface Treated

Polypropylene Fibres for the Reinforced Concrete Cement and Concrete Research 54, pp.

29-35. Accessed 28 August 2014.

[5] Buratti N., Mazzotti C., Savoia M., (2011) Post Cracking Behavior of Steel and Micro

Synthetic Fibre Reinforced Concretes, Construction and Building Material 25, pp 2713 –

2722. Accessed 1 September 2014.

[6] Chang D., Chai W.K., (1995), Flexural Fracture and Fatigue Behavior of Steel-Fiber-

Reinforced Concrete Structures, Nuclear Engineering and Design 156, pp-201-207.

Accessed 28 August 2014.

[7] Gambhir M.L., (2010), Concrete Technology, Tata Mcgraw Hill Publication, pp 154-186.

[8] Girish, M.G., Chandrashekhar A., Ravi Shankar A.U., (2012), Flexural Fatigue Analysis

of Steel Fibre Reinforced Concrete”, International Journal on Earth Science and

Engineering, ISSN 0974-5904, Volume 05, No. 05 (01), pp.1352-1357. Accessed 16

September 2014.

[9] Su Tae Kang , Bang Yeon Lee, Jin-Keun Kim, Yun Yong kim, the Effect of fibre

distribution characteristics on the flexural strength of steel fibres reinforced ultra-high

strength concrete, Construction and building Materials 25 (20111), p.p. 2450-2457.

[10] Adel Kaikea, djamel Achourya, Francois Duplan, Lidia Rizzuti, Effect of mineral

admixtures and steel fibre volume contents on the behaviour of high performance fibre

reinforced concrete, Materials and Design 63(2014), 493-499.

[11] Girish M. G, A Chandrashekhar, A.V. Ravi Shankar, Flexural fatigue analysis of steel

fibre reinforced concrete, International Journal of Earth Sciences and engineering, ISSN-

0974-5904, Volume 5, October 2012, pp. 1352-1357

[12] M.N. Soutos , T.T. Le, A.P. Lampropoulos, Flexural performance of fibre reinforced

concrete made with steel and synthetic fibres, Construction and building materials, 36

(2012), 704-710

[13] Genying Li, Xiaohua Zhao, Chuiqiang Rong, Zhan Wang, Properties of polymer modified

steel fibre Reinforced Cement concrete, 24 (2010), pp. 1201-1206

[14] Standard (1999), “Concrete Admixtures – Specification (amendment 2), IS 9103: 1999,

Bureau of Indian Standards, New Delhi.

[15] Indian Standard (2000), Plain and Reinforced Concrete- Code of Practice, IS 456: 2000,

Bureau of Indian Standards, New Delhi.

[16] India. Bureau of Indian Standards (1997) Indian Standard Methods of Test for

Aggregates. Is: 2386.

[17] Indian Standard (2009), Concrete Mix Proportioning – Guideline (First Revision), IS

10262: 2009, Bureau of Indian Standards, New Delhi.

[18] Indian Standard (1959), Method of Test for Strength of Concrete (Amendments 2),

IS:516-1959, Bureau of Indian Standards, New Delhi.

[19] Indian Standard (1991), Specifications Portland Pozzolana Cement, Part 1 Fly Ash Based

(Amendment 5), IS: 1489-1:1991, Bureau of Indian Standards, New Delhi.

[20] Indian Standard (1991), Specifications for Apparatus for Flexure Testing of Concrete, IS

:9399-1979, Bureau of Indian Standards, New Delhi.

[21] Kaikea A., Achoura D., Duplan F., Rizzuti, L., (2014), Effect of Mineral Admixtures and

Steel Fiber Volume Contents on the Behavior of High Performance Fiber Reinforced

Concrete Material and Design 63, pp.493-499. Accessed 30 August 2014.

[22] Kang, S. T., Lee Y. B., Kim J K., Kim Y Y., (2011), The Effect of Fibre Distribution

Characteristics on the Flexural Strength of Steel Fibre-Reinforced Ultra High Strength

Concrete, Construction and Building Materials 25, pp. 2450-2457. Accessed 8 October

2014.

http://www.iaeme.com/IJCIET/index.asp 991 editor@iaeme.com

S. V. Joshi and U. P. Waghe

[23] Kumar M., Khadwal A., (2014), Strength Evaluation of Steel-Nylon Hybrid Fibre

Reinforced Concrete, International Journal Of Engineering Research And Applications

ISSN: 2248-9622, Vol. 4, Issue 7( Version 6), pp.32-36 Accessed 27 August 2014.

[24] Lau A., Anson M., (2006), Effect of High Temperatures on High Performance Steel Fibre

Reinforced Concrete, Cement and Concrete Research 36, pp 1698 – 1707. Accessed 18

September 2014.

[25] Li G., Zhao X., Rong C., Wang Z., (2010), Properties of Polymer Modified Steel Fibre

Reinforced Cement Concretes, Construction and Building Materials 24, pp 1201 – 1206.

Accessed 4 November 2014.

[26] Narayan N.T., Ramakrishnan S., (2013), Steel Fibre Reinforced Concrete for Ports

Infrastructure, The Masterbuilder, pp. 144-148. Accessed 20 August 2014.

[27] Nataraja M.C., Dhang N., Gupta A.P., (1999), Stress Strain Curves for Steel Fibre

Reinforced Concrete Under Compression, Cement and Concrete Composites 21, pp 383 –

390. Accessed 24 September 2014.

[28] Organization for Economic Co-Operation and Development, (2005), Economic Evaluation

of Long Life Pavement Phase 1, pp. 11-111. Accessed 15 March 2015.

[29] Parveen, Sharma A., (2013), Structural Behaviour of Fibrous Concrete Using

Polypropylene Fibres, International Journal of Modern Engineering Research (Ijmer)

ISSN: 2249-6645 Vol.3, Issue.3, pp-1279-1282. Accessed 18 July 2014.

[30] (http://namidance.ce.metu.edu.tr)

[31] Yalciner, A. C., Karakus, H. and Kuran, U. Modeling of Tsunamis in the Eastern

Mediterranean and Comparison with Caribbean, in Mercado A. and Liu P. L. F eds.,

Caribbean Tsunami Hazard, World Scientific, ISBN 981-256-535-3, 2006a, pp. 326–340

[32] Zlatanova, S., A. Fabbri, A. and Li, J. Geo-information for Disaster Management: Large

scale 3D data needed by Urban Areas. GIM International, 19 (3), 2005, pp. 10–13.

[33] Tayal, T. and Dr. Prema, K. V. An Intelligent Fuzzy-Based Tsunami Warning System.

International Journal of Computer Engineering & Technology, 3(2), 2012, pp. 12–18.

[34] Zlatanova, S., van Oosterom, P. and Verbree, E. Geoinformation supports management of

urban disasters. Open House International, 31(1), 2006, pp. 62–79.

[35] S. Ghouse Basha and P. Polu Raju, Comparative Study on Effect of Steel and Glass Fibers

on Compressive and Flexural Strength of Concrete. International Journal of Civil

Engineering and Technology, 8(4), 2017, pp. 141–155

[36] Suresh Barmavath, Kiran M V, CH Narendra Naik, G Sai Kumar, E Hari Naik, V Amulya

and V Divya. Flexural Strength of Concrete by Replacing Bamboo in RCC Beam.

International Journal of Civil Engineering and Technology, 8(6), 2017, pp. 10–18.

[37] Shehdeh Ghannam, Flexural Strength of Concrete-Filled Steel Tubular Beam with Partial

Replacement of Coarse Aggregate by Granite. International Journal of Civil Engineering

and Technology, 7(5), 2016, pp.161–168.

http://www.iaeme.com/IJCIET/index.asp 992 editor@iaeme.com

You might also like

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Meas - Lecture Note Substructure Note 3Document14 pagesMeas - Lecture Note Substructure Note 3LokuliyanaNNo ratings yet

- RCD DRRB LectureDocument3 pagesRCD DRRB Lecturechristian remoquilloNo ratings yet

- Reference 101. Effect of Fibers in Concrete CompositesDocument13 pagesReference 101. Effect of Fibers in Concrete Compositesᜎᜒᜌᜓᜈᜒᜎ᜔ ᜄ᜔ᜏᜇᜒᜈ᜔No ratings yet

- Steel Fiber Reinforced ConcreteDocument26 pagesSteel Fiber Reinforced ConcreteJames Augustine100% (1)

- F INALDocument19 pagesF INALBhushan JadhavNo ratings yet

- Effect of Fibers in Concrete Composites: International Journal of Applied Engineering Research January 2015Document13 pagesEffect of Fibers in Concrete Composites: International Journal of Applied Engineering Research January 2015Aika LorenNo ratings yet

- Fibre Reinforced Concrete FRC Ijariie4483Document7 pagesFibre Reinforced Concrete FRC Ijariie4483Devesh Kumar PandeyNo ratings yet

- Unit6 MCNDocument29 pagesUnit6 MCNPravesh GautamNo ratings yet

- To Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesDocument6 pagesTo Investigate How Well Industrial Waste Polymer Fibre Performs Physically and Mechanically When Utilised in Concrete MixturesIJRASETPublicationsNo ratings yet

- MGK266Document8 pagesMGK266prisak2002No ratings yet

- Benefits of SFRCDocument17 pagesBenefits of SFRCShubhayu_duttaNo ratings yet

- Experimental Study On Steel Fiber Reinforced ConcreteDocument7 pagesExperimental Study On Steel Fiber Reinforced ConcreteIJRASETPublicationsNo ratings yet

- Acknowledgement: M.R. Head of Civil Engineering Department, For Inspiring Take This Project. I Also ExpressedDocument18 pagesAcknowledgement: M.R. Head of Civil Engineering Department, For Inspiring Take This Project. I Also ExpressedRicky RickxNo ratings yet

- FRCFRCDocument11 pagesFRCFRCdhananjay kumarNo ratings yet

- Effect of Steel Fibers On Strength of ConcreteDocument8 pagesEffect of Steel Fibers On Strength of ConcreteBlack KaiserNo ratings yet

- Report On Steel Fiber Reinforced ConcreteDocument44 pagesReport On Steel Fiber Reinforced Concretevishalgore100% (1)

- FM 2 Flooring Journel PDFDocument4 pagesFM 2 Flooring Journel PDFkamaldeep singhNo ratings yet

- TimeeDocument13 pagesTimeeyra.viluan14No ratings yet

- A Review "Experimental Study On Steel Fiber Reinforced Concrete Using Flat Crimped & Round Crimped Type Steel Fiber."Document6 pagesA Review "Experimental Study On Steel Fiber Reinforced Concrete Using Flat Crimped & Round Crimped Type Steel Fiber."IJRASETPublicationsNo ratings yet

- Thesis On Steel Fiber Reinforced ConcreteDocument5 pagesThesis On Steel Fiber Reinforced ConcreteBuyCustomEssayEverett100% (1)

- Rajeev Institute of Technology, Hassan Department of Civil EngineeringDocument4 pagesRajeev Institute of Technology, Hassan Department of Civil EngineeringSamarth NazareNo ratings yet

- FRP NotesDocument11 pagesFRP NotesMohammed ImranNo ratings yet

- Structural Behaviour of Hybrid Fibres Concrete Using Regression AnalysisDocument7 pagesStructural Behaviour of Hybrid Fibres Concrete Using Regression AnalysisIJRASETPublicationsNo ratings yet

- PC Research PaperDocument5 pagesPC Research PaperghNo ratings yet

- Fibre Reinforced Concrete 3858 RrL4YRUDocument29 pagesFibre Reinforced Concrete 3858 RrL4YRUDurvank ShethNo ratings yet

- Thesis On Fibre Reinforced ConcreteDocument4 pagesThesis On Fibre Reinforced Concretefjfsyk5w100% (1)

- Glass Fibre Concrete: Investigation On Strength and Fire Resistant PropertiesDocument5 pagesGlass Fibre Concrete: Investigation On Strength and Fire Resistant Propertiessushma chandrikaNo ratings yet

- Research Paper On Steel Fiber Reinforced ConcreteDocument5 pagesResearch Paper On Steel Fiber Reinforced Concretecaq5kzrg100% (1)

- FibersDocument15 pagesFibersSACHINNo ratings yet

- An Experimental Investigation On StructuralDocument5 pagesAn Experimental Investigation On StructuralAtano RoyNo ratings yet

- High-Performance Fiber-Reinforced Concrete: A ReviewDocument35 pagesHigh-Performance Fiber-Reinforced Concrete: A ReviewAnteneh GeremewNo ratings yet

- CHAPTER 1 FINAL YEAR ProjectDocument5 pagesCHAPTER 1 FINAL YEAR ProjectdejayzNo ratings yet

- Ijciet: International Journal of Civil Engineering and Technology (Ijciet)Document6 pagesIjciet: International Journal of Civil Engineering and Technology (Ijciet)IAEME PublicationNo ratings yet

- Steel Fibre Concrete Composites For Special ApplicationsDocument213 pagesSteel Fibre Concrete Composites For Special Applicationshamsanram100% (3)

- Study On Strength Parameters On Fibers Using M30 ConcreteDocument13 pagesStudy On Strength Parameters On Fibers Using M30 ConcreteIJRASETPublicationsNo ratings yet

- Chapter 2Document5 pagesChapter 2Mark B. BarrogaNo ratings yet

- Fibre Reinforced Concrete: A Consise ReportDocument5 pagesFibre Reinforced Concrete: A Consise ReportSaleem MohammedNo ratings yet

- SFRCDocument37 pagesSFRCKarthika SNo ratings yet

- Influence of Steel Fiber On Behaviour of Reinforced Concrete Beams: A ReviewDocument7 pagesInfluence of Steel Fiber On Behaviour of Reinforced Concrete Beams: A ReviewAysar AL-KhawajaNo ratings yet

- Report FRCDocument20 pagesReport FRCRahul MadanNo ratings yet

- FRCDocument23 pagesFRCMathur AbhinavNo ratings yet

- Post-Cracking Behaviour of Basalt and Macro Polypropylene Hybrid Fibre Reinforced Concrete With Different Compressive StrengthsDocument13 pagesPost-Cracking Behaviour of Basalt and Macro Polypropylene Hybrid Fibre Reinforced Concrete With Different Compressive StrengthsShruti SharmaNo ratings yet

- FRCDocument144 pagesFRCGyan KumarNo ratings yet

- Ijciet 07 05 037Document8 pagesIjciet 07 05 037kannankannan0539No ratings yet

- Self Compacting Fibre Reinforced Concrete - A Revi PDFDocument4 pagesSelf Compacting Fibre Reinforced Concrete - A Revi PDFNurul'Ain Haniyun Mohamad FodziNo ratings yet

- Fibre Reinforced ConcreteDocument12 pagesFibre Reinforced ConcretePradeepLokhande100% (2)

- Notes On Fibre Reinforced ConcreteDocument9 pagesNotes On Fibre Reinforced ConcreteK.ANISH100% (1)

- A Review On Glass Fibre Reinforced Concrete Used in ConstructionDocument5 pagesA Review On Glass Fibre Reinforced Concrete Used in ConstructionNishan KarkiNo ratings yet

- Keywords: Steel Fiber, Concrete, Properties, Crack, Ductility, TechnologyDocument4 pagesKeywords: Steel Fiber, Concrete, Properties, Crack, Ductility, TechnologySandeep ReddyNo ratings yet

- Increase in Strength of Concrete by Using Bottle CapsDocument6 pagesIncrease in Strength of Concrete by Using Bottle Capsaffan aliNo ratings yet

- Body of The Content Pagenumber Inputed 123Document82 pagesBody of The Content Pagenumber Inputed 123danusri1606No ratings yet

- J Conbuildmat 2019 117043Document10 pagesJ Conbuildmat 2019 117043civilstructure.singhbrothersNo ratings yet

- Strengthening of Structural Concrete Element Using Fiber GlassDocument3 pagesStrengthening of Structural Concrete Element Using Fiber Glassrakshit thapliyalNo ratings yet

- Jurnal SFRCDocument4 pagesJurnal SFRCNabila ValenciaNo ratings yet

- Fibre Reinforced ConcreteDocument50 pagesFibre Reinforced ConcreteAishwarya Madhivanan100% (3)

- Mechanical Properties of Steel Fiber Reinforced Self-Compacting ConcreteDocument8 pagesMechanical Properties of Steel Fiber Reinforced Self-Compacting ConcreteviolettaNo ratings yet

- Polypropylene Fibre Reinforced Concrete Literature ReviewDocument4 pagesPolypropylene Fibre Reinforced Concrete Literature Reviewc5j07dceNo ratings yet

- g 0805025361Document9 pagesg 0805025361Anand KNo ratings yet

- GFRC For SlabsDocument7 pagesGFRC For SlabsJayanth RaviNo ratings yet

- Jute Motar PDFDocument67 pagesJute Motar PDFSøüRãv JãløTrãNo ratings yet

- Performance Assessment of Glass Fiberreinforced Concrete BeamsDocument11 pagesPerformance Assessment of Glass Fiberreinforced Concrete Beamsచిమ్ముల సందీప్ రెడ్డిNo ratings yet

- Statically Indeterminate StructuresDocument7 pagesStatically Indeterminate StructuresSnehal AbhyankarNo ratings yet

- Flyash As A Sustainable Alternate Building Material For Low Cost HousingDocument5 pagesFlyash As A Sustainable Alternate Building Material For Low Cost HousingSnehal AbhyankarNo ratings yet

- Mohh$ HMÑ'MGMR R Ho$Bobr Eò (H $'M Ovbr Ordmda (Ddmhmamyr Damz J - Mdbo Àmu!Document1 pageMohh$ HMÑ'MGMR R Ho$Bobr Eò (H $'M Ovbr Ordmda (Ddmhmamyr Damz J - Mdbo Àmu!Snehal AbhyankarNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Hossein Mola-Abasi, Issa ShooshpashaDocument7 pagesJournal of Rock Mechanics and Geotechnical Engineering: Hossein Mola-Abasi, Issa ShooshpashaSnehal AbhyankarNo ratings yet

- Analytical and Experimental Investigations On Using Waste Marble Powder in ConcreteDocument13 pagesAnalytical and Experimental Investigations On Using Waste Marble Powder in ConcreteSnehal AbhyankarNo ratings yet

- Nternational Ournal of Ngineering Ciences & Esearch EchnologyDocument8 pagesNternational Ournal of Ngineering Ciences & Esearch EchnologySnehal AbhyankarNo ratings yet

- Partial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly AshDocument10 pagesPartial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly AshSnehal AbhyankarNo ratings yet

- Affordable and Climate-Resilient: How Casa Real'S Homes Withstood Cyclone IdaiDocument2 pagesAffordable and Climate-Resilient: How Casa Real'S Homes Withstood Cyclone IdaiSnehal AbhyankarNo ratings yet

- Effects of Concrete Block Pavement On Flow Retardation FactorDocument9 pagesEffects of Concrete Block Pavement On Flow Retardation FactorSnehal AbhyankarNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument7 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologySnehal AbhyankarNo ratings yet

- 109 S. V. Joshi and U. P. WagheDocument1 page109 S. V. Joshi and U. P. WagheSnehal AbhyankarNo ratings yet

- Design of Visible Light Active Photocatalyst For Environmental and Energy ApplicationsDocument73 pagesDesign of Visible Light Active Photocatalyst For Environmental and Energy ApplicationsSnehal AbhyankarNo ratings yet

- PVT Systems-Sustainability - SSSDocument67 pagesPVT Systems-Sustainability - SSSSnehal AbhyankarNo ratings yet

- Sustainable Construction Engineering: Research and PracticesDocument2 pagesSustainable Construction Engineering: Research and PracticesSnehal AbhyankarNo ratings yet

- Research On Different Types of Cracks in Plain and Reinforced ConcreteDocument3 pagesResearch On Different Types of Cracks in Plain and Reinforced ConcreteSnehal AbhyankarNo ratings yet

- Energy Efficiency in Buildings: Anil Kashyap Day 1 Session 2Document28 pagesEnergy Efficiency in Buildings: Anil Kashyap Day 1 Session 2Snehal AbhyankarNo ratings yet

- Report On Building ConstructionDocument38 pagesReport On Building ConstructionOlaifa victorNo ratings yet

- Isolated Footing Design Example and Excel Sheet PDFDocument8 pagesIsolated Footing Design Example and Excel Sheet PDFPrabhakar Reddy33% (3)

- Concrete Bridges in GermanyDocument12 pagesConcrete Bridges in GermanydelujaNo ratings yet

- Earthquake Resistant Masonary BuildingsDocument26 pagesEarthquake Resistant Masonary BuildingsSourabhAdikeNo ratings yet

- Design of PIle Foundation ProjectDocument19 pagesDesign of PIle Foundation ProjectJinendra Bafna100% (2)

- Diaphragm Walls Construction and DesignDocument18 pagesDiaphragm Walls Construction and DesignShirley Munoz100% (1)

- Final Estimation For Rate PreparationDocument5 pagesFinal Estimation For Rate PreparationmanojNo ratings yet

- Concrete Mix ProportioningDocument19 pagesConcrete Mix ProportioningCZ001 Abisha ANo ratings yet

- Steel-Concrete Composite Columns: Prof S R Satish Kumar Dept. of Civil Engineering IIT Madras, Chennai 600036Document37 pagesSteel-Concrete Composite Columns: Prof S R Satish Kumar Dept. of Civil Engineering IIT Madras, Chennai 600036Piyush SinghNo ratings yet

- Smart NotesDocument515 pagesSmart NotesAEMNo ratings yet

- Wind Loading in Steel Joist Design PDFDocument95 pagesWind Loading in Steel Joist Design PDFnitroxx7No ratings yet

- JETIR1903G72Document4 pagesJETIR1903G72Vikas SharmaNo ratings yet

- Fire Rating Requirement For Steel ConstructionDocument2 pagesFire Rating Requirement For Steel ConstructionMamunNo ratings yet

- Road Materials: Asphalt LayerDocument3 pagesRoad Materials: Asphalt LayerMarjorie SalvañaNo ratings yet

- Scope of WorkDocument3 pagesScope of WorkSunday Paul100% (1)

- PCA Concrete Deep Beam DesignDocument12 pagesPCA Concrete Deep Beam DesignjulesjusayanNo ratings yet

- Long Front Wall 25 at 150Document10 pagesLong Front Wall 25 at 150kuttyNo ratings yet

- Pages From Curtain Wall (BD Submission) - 2Document6 pagesPages From Curtain Wall (BD Submission) - 2Con CanNo ratings yet

- Ronan Point Apartment Tower Collapse and Its Effect On Building CDocument7 pagesRonan Point Apartment Tower Collapse and Its Effect On Building CAman 'kebe' KebedeNo ratings yet

- Design of Concrete Structures 15th Edition Ebook PDFDocument61 pagesDesign of Concrete Structures 15th Edition Ebook PDFmario.becker25298% (52)

- 2023-06-09 PICE v05Document53 pages2023-06-09 PICE v05John Michael AngelesNo ratings yet

- JHOELLA Construction Estimate 1,2,3Document13 pagesJHOELLA Construction Estimate 1,2,3jhoella Marie PapasinNo ratings yet

- Truss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionDocument1 pageTruss 01: Mr. & Mrs. Sire Henrik Andersson A Proposed Penthouse ExtensionChrysler DuasoNo ratings yet

- Nonlinear Analysis of Reinforced Concrete Slabs at Elevated TemperatureDocument10 pagesNonlinear Analysis of Reinforced Concrete Slabs at Elevated TemperatureHuda JawadNo ratings yet

- C7. SlabsDocument77 pagesC7. SlabsDavid Moreno SanchezNo ratings yet

- Typical Stair DetailsDocument1 pageTypical Stair DetailsM IQbalNo ratings yet

- Formwork Is An Ancillary ConstructionDocument25 pagesFormwork Is An Ancillary ConstructionSarinNo ratings yet

- Design Example 9: Cantilevered Monotube Support For A Dynamic Message SignDocument39 pagesDesign Example 9: Cantilevered Monotube Support For A Dynamic Message SignMohamed Zakaria ZaidiNo ratings yet