Professional Documents

Culture Documents

Shell Cariphalte Spray Grade PG 76: Product Specification Sheet

Shell Cariphalte Spray Grade PG 76: Product Specification Sheet

Uploaded by

Yogie TbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell Cariphalte Spray Grade PG 76: Product Specification Sheet

Shell Cariphalte Spray Grade PG 76: Product Specification Sheet

Uploaded by

Yogie TbCopyright:

Available Formats

Shell Cariphalte Spray Grade PG 76

Product Specification Sheet

Shell CariphalteTM Spray Grade PG 76 is a premium grade of Polymer Modified Bitumen (PMB) used for

spray applications for Stress Absorbing Membrane/ Interlayer (SAM/SAMI), tack coat, chip sealing, and

other spray sealing applications. CariphalteTM Spray Grade PG 76 is a Styrene Butadiene Styrene (SBS)

modified bitumen utilizing the technical and operational expertise of Shell Bitumen. The CariphalteTM

technology ensures the formation of a 3-dimensional network within the PMB resulting in a spray able PMB

for high stress applications.

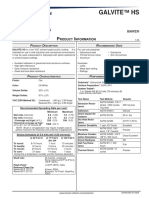

Typical Binder Properties

Test Property Method Unit Specification

Original Binder

Softening Point, min ASTM D36 ⁰C >80

Viscosity at135⁰C, max. ASTM D4402 Pa.s <3

Viscosity at 180⁰C, max. ASTM D4402 Pa.s <0.4

Penetration at 25 ⁰C, min. ASTM D5 1/10 mm >25

Flash Point, ⁰C, min. ASTM D92 ⁰C >230

Dynamic Shear, G*/ sinδ, min 1.00kPa, test ASTM D7175 ⁰C 76

temperature @ 10 rad/s, ⁰C

Elastic recovery on fresh binder, 25 ⁰C, 10cm ASTM D6084 % >75

elongation, %

Rolling Thin Film Oven Residue

Mass Loss, max. ASTM D2872 % <1

Dynamic Shear, G*/ sinδ, min 2.20kPa, test ASTM D7175 ⁰C 76

temperature @ 10 rad/s, ⁰C

Softening Point, min ASTM D36 ⁰C >80

Elastic recovery on RTFO aged binder, 25 ⁰C, 10cm ASTM D6084 % >75

elongation, %

After storage, 48h @ 163⁰C

Difference in softening point, max ASTM D5892 ⁰C REPORT ONLY

Application Temperatures

The following temperatures are recommended for Shell Cariphalte Spray Grade PG 76:

At the point of spraying : 180⁰C - 190⁰C

You might also like

- Performance Grade 76 (PG 76) : Aspal Yang Digunakan Adalah Aspal Modifikasi Polimer (Polymer Modified Bitumen) SetaraDocument1 pagePerformance Grade 76 (PG 76) : Aspal Yang Digunakan Adalah Aspal Modifikasi Polimer (Polymer Modified Bitumen) SetaraPT. Nur Straits EngineeringNo ratings yet

- MyPDF 3Document2 pagesMyPDF 3nikenNo ratings yet

- Certificate of Quality: Results Min Max Properties Test Methods Unit Specification RequirementDocument1 pageCertificate of Quality: Results Min Max Properties Test Methods Unit Specification RequirementMUHAMMAD ASHRAF BIN ABDUL AZIZ STUDENTNo ratings yet

- Castrol Magna 150 Ep - TDSDocument2 pagesCastrol Magna 150 Ep - TDSHector Martin BarajasNo ratings yet

- QBC CRMB TDS Rev 0Document2 pagesQBC CRMB TDS Rev 0nainaNo ratings yet

- Certificate of Quality: Results Min Max Properties Test Methods Unit Specification RequirementDocument1 pageCertificate of Quality: Results Min Max Properties Test Methods Unit Specification RequirementMUHAMMAD ASHRAF BIN ABDUL AZIZ STUDENTNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBassam AljiffryNo ratings yet

- Equate EMDA 6200Document2 pagesEquate EMDA 6200HichamSalamaNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- SpirdaneD60S COADocument1 pageSpirdaneD60S COAvivek dakavarapuNo ratings yet

- Product: Penetration Grade Bitumen 60/70 Packing: New Steel Drum 180 5Kgs / BulkDocument2 pagesProduct: Penetration Grade Bitumen 60/70 Packing: New Steel Drum 180 5Kgs / BulkvinayaiyappaNo ratings yet

- GR180 EN Timken Spec SheetDocument2 pagesGR180 EN Timken Spec SheetThe WorshipperNo ratings yet

- Mobilgrease 28Document2 pagesMobilgrease 28Jeef100% (1)

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 pagesVISCOWRAP-HT Product Data Sheet EnglishJA BustosNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Crystic Gelcoat 76 PA FRDocument3 pagesCrystic Gelcoat 76 PA FRmohamed rafiNo ratings yet

- Dew Heat Transfer OilDocument1 pageDew Heat Transfer OilednsmnNo ratings yet

- Repsol Merak VDL PDFDocument1 pageRepsol Merak VDL PDFrandiNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Repsol Maker Hydroflux EP 32,46,68Document1 pageRepsol Maker Hydroflux EP 32,46,68ibrahim maulanaNo ratings yet

- Din/ Iso Astm RangeDocument2 pagesDin/ Iso Astm RangeSumitBhaumikNo ratings yet

- (Ems) (TDS) Grilamid TR 90 LXDocument4 pages(Ems) (TDS) Grilamid TR 90 LXMarcos KodairaNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBudi SetiawanNo ratings yet

- (Grade 1.5) GR181-EN-Timken-Spec-SheetDocument2 pages(Grade 1.5) GR181-EN-Timken-Spec-SheetnacerNo ratings yet

- Aircol SR 68Document2 pagesAircol SR 68nauta007No ratings yet

- Repsol Tauro PDFDocument1 pageRepsol Tauro PDFrandiNo ratings yet

- Nyco Grease GN 22 Air4222Document1 pageNyco Grease GN 22 Air4222muhammad_andinovaNo ratings yet

- Yours' Maintenance Solution: HD Lithium Complex GreaseDocument1 pageYours' Maintenance Solution: HD Lithium Complex GreaseSiong Wu SiewNo ratings yet

- BP Energrease LSDocument2 pagesBP Energrease LSsaddamNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- TDS Nycolube NL3525-9E2 PDFDocument1 pageTDS Nycolube NL3525-9E2 PDFRoman GrantNo ratings yet

- Premium Gasoline 91 RONDocument1 pagePremium Gasoline 91 RONbohdanturgenevNo ratings yet

- 2017716154112bitumen 6070Document1 page2017716154112bitumen 6070lab copriNo ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

- Daphne Alpha Screw 32: Lubricant Product InformationDocument2 pagesDaphne Alpha Screw 32: Lubricant Product InformationSadid ShahzadNo ratings yet

- Arcanol MULTITOP: FAG Rolling Bearing GreaseDocument1 pageArcanol MULTITOP: FAG Rolling Bearing GreasejuniorNo ratings yet

- Globalene ST031: Technical Data Sheet / 技術資料表Document1 pageGlobalene ST031: Technical Data Sheet / 技術資料表Ale AriasNo ratings yet

- Bitoner Resin C5 BT-2104 TDSDocument2 pagesBitoner Resin C5 BT-2104 TDSdamiendamNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- TDS Castrol Perfecto XPG - Power VersionDocument2 pagesTDS Castrol Perfecto XPG - Power VersionTeguh SNo ratings yet

- HDPE Blow Ineos-G50-100Document2 pagesHDPE Blow Ineos-G50-100luisalbertolvNo ratings yet

- PDS - ETRO 6plus - 2022.01Document1 pagePDS - ETRO 6plus - 2022.01Sawan TaylorNo ratings yet

- Propriedades ABSDocument1 pagePropriedades ABSengmecanica07022013No ratings yet

- Bitumen 80-100 Pen EcDocument1 pageBitumen 80-100 Pen EcsamirNo ratings yet

- Repsol Hydroflux Ep PDFDocument1 pageRepsol Hydroflux Ep PDFrandiNo ratings yet

- Super Gasoline 95 RONDocument1 pageSuper Gasoline 95 RONxtrooz abiNo ratings yet

- 4 - Epoksi Boya Technical Data Sheet PDFDocument2 pages4 - Epoksi Boya Technical Data Sheet PDFVasaNo ratings yet

- Castrol Tribol Cs 890Document3 pagesCastrol Tribol Cs 890carlos pachecoNo ratings yet

- Gulf Therm Aug12 - 20120903171744Document1 pageGulf Therm Aug12 - 20120903171744Nashrul HakimNo ratings yet

- Rotoroil 8000F2 Technical DataDocument1 pageRotoroil 8000F2 Technical DataSerwis SprężarekNo ratings yet

- 7354 Hydra Power 46 PDSDocument1 page7354 Hydra Power 46 PDSMartín BaezaNo ratings yet

- Royco 756/756A Hydraulic Fluid, Aircraft, Missile, and Ordinance Petroleum BaseDocument4 pagesRoyco 756/756A Hydraulic Fluid, Aircraft, Missile, and Ordinance Petroleum Baseroger gonzales hoyosNo ratings yet

- 29f44e12-20dc ZA Sasolwax C80 en-ZADocument1 page29f44e12-20dc ZA Sasolwax C80 en-ZAchinmaydabkeNo ratings yet

- Turbo Oil 2380Document2 pagesTurbo Oil 2380barcaza_13No ratings yet

- 4376 Industrial Gear Oil CLP 320Document1 page4376 Industrial Gear Oil CLP 320ralish12No ratings yet

- Repsol Circulation 220Document1 pageRepsol Circulation 220ibrahim maulanaNo ratings yet