Professional Documents

Culture Documents

JBL Power Amplifier Gts150 112

JBL Power Amplifier Gts150 112

Uploaded by

Montecarlo0 ratings0% found this document useful (0 votes)

28 views17 pagesOriginal Title

Jbl Power Amplifier Gts150 112

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

28 views17 pagesJBL Power Amplifier Gts150 112

JBL Power Amplifier Gts150 112

Uploaded by

MontecarloCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 17

GTS150

2/1 CHANNEL

UBL

AUTOMOTIVE

POWER AMPLIFIER

TECHNICAL MANUAL

=|

TS1 INTENTS

Features ..

Specifications

Disassembly Procedure .....

Exploded View ...

Parts List...

Block Diagram ...

Detail of ICs'Transistors

IC/ Transistor Pin Voltages .

Wiring Diagram...

PC Board Layout ..

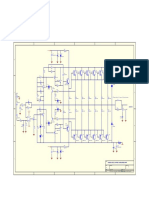

Schematic Diagram.....

Packaging Exploded View

Installation Wiring Diagram ...

MPLIFI ATURI

Minimal Negative Feedback

All amplifiers require some form of negative feedback to minimize distortion and stabilize the

amplifier. Too much feedback, however, increases the Transient intermodulation Distortion (T.I.M.),

‘and reduces its musicality. JBL's Minimal Negative Feedback design provides just enough feedback

to stabilize the amplifer., remove DC offset, and offer excellent Total Harmonic Distortion (T.H.0.)

characteristics,

No Current Limiting

Current Limiting circuitries used in conventional power amplifiers may cause premature clipping and

inferior transient response under demanding conditions. The absence of current limiters in the audio

sections of JBL power amplifiers ensures low Transient Intermodulation Distortion, excellent transient

response, and superb sonic quality.

Quiet Start Circuitry

Special turn on and turn off circuitry have been implemented to prevent amplifier turn on and turn off

Pops.

Pulse Width Modulation (PWM) DC-to-DC Switching Mode Power Supplies

Provides excellent power output throughout the audio bandwidth. Its’ soft clipping characteristics

ensure superb transient response and musicality.

Third Order (1848 per octave) Capacitive/inductive Power Supply Input and Output Filtering

For low radio frequency interference (RFI) and excellent immunity to system noises such as alternator

whine

Fully Complementary, Discrete Output Circuitry

The use of independent output transistors in the audio and power supply section provide excellent

reliability and high current capability for accurate transient response. A fully complementary audio

section offers superb sonic performance.

Full Protection Circuitry

All JBL amplifiers are protected against over-temperature, over-current, over-voltage, input overload,

and DC offset. These special circuitries protect the amplifier from installation errors and unfriendly

environmental conditions. However, none of these protection systems is in the signal path, They

cannot interfere with the sonic performance of the amplifier.

TS150 POWER AMPLIFIER SPECIFICATION:

1, Minimum Power Output into 4 ohms, 2-channel mode, 1% THD

20 Hz: 50 Watts x 2

1 kHz: 50 Watts x2

20 kHz: 50 Watts x 2

2, Minimum Power Output into 2 ohms, 2-channel mode, 1% THD

1kHz: 75 Watts x 2

3. Minimum Power Output into 4 ohms, 1-channel bridged mode, 1% THD:

1 kHz: 150 Watts x 1

4, Maximum THD at 1 watt into 4 ohms, 2-channel mode:

20 H2: 0.5% (30 kHz LPF)

1 kHz: 0.3% (400 Hz HPF, 30 kHz LPF)

20 kHz: 0.5% (400 Hz HPF, 30 kHz LPF)

5. Minimum Signal-to-Noise Ratio into 4 ohms, inputs shorted, Gain Controls at Min., 2-channel

mode

90 dBA

6. Input Sensitivity, Gain Control at maximum:

150 mV +25%

7. Minimum Channel Separation, referenced to 50 watts into 4 ohms, 2-channel mode.

1kHz: 45 dB

8. Gain Control Range, from MIN to MAX, 1 watt, 2-channel mode:

1kHz: 20 dB + 20%

9. Output Level Deviation into 4 ohms, 1 watt, 1 kHz reference, 2-channel mode:

20 Hz: -3 dB or less

1 kHz: 0 dB (reference)

20 kHz: -3 dB or less

10. Current Consumption, 4 ohms, 2-channel mode, 1 kHz signal, 14.4V battery:

50 Watts x 2: 30 A or less

No Input Signal: 1.5 A or less

S150 DISAS

Note: REFER TO EXPLODED VIEW FOR PARTS DESIGNATION.

1. Remove 6 screws (19) securing bottom plate (4),

2. Remove bottom plate to expose main P.C. board assembly.

3. To remove main P.C. board assembly from chassis/heat sink assembly:

a) Remove 1 phillips screw (18) from RCA input jack.

c) Remove 4 T-10 torx screws (17) from opposite end of chassis.

d) Remove 6 screws (16) that secure heat sink brackets (12, 13) to chassis.

e) Main P.C. board will now lift out of chassis. Care should be taken to protect leads of red

L.E.D. that extend beyond P.C. board. During reassembly, align the red L.E.D. to the correct

Position before securing panel.

rev: €”

PART NO.

s-t0-101

110-368

410-201

110-468

310-447

410-301

412-002

4-12-00

a12-110

412133

serene

112-210

12.207

4120522

416-010

4-16-110

416-125

ate?

318-215

418-253

118-207

118-275

418-510

118-322

4-18-335

1-18-367

1218-356

1-18-36

118-368

418-410

at8-u12

118-418

18-422

18-430

418-433

118-407

118-456

418-468

1-18-533

1-18-633

19-190

13-266

1-31-285

420-210

1-20-20

1-20-2380

123-022

sts150

REFERENCE NO.

€34,€35,c40,c41 ,c49

32,033,042

cks,c47,050

9,20

cs2

st

ar

ot

612,06, €12, 13,015,

€28,¢26,25,

7,18, C46

28,c29

€30,c48,c53

65,16

€36,€37,€38,¢39,¢43, cat

3,14, 026

68,17 019

10,011, c2%, c22

R68, R71, R72, RTS

R76,877,

RB, R26, RAZ, RAE

R69, 870,73, R76

Rat Ras

31,9, R10, R17, R19, R27,

28, 29,837, R39, RED

R2, RY2, R20, R30, R64, RES

R40

us

R16, 834, R43, RG, RBS

R81

Ree

RC, R6,RP, R22, RAL, ROS ABB,

Rb, RAB, R78.

R56,R60)

B3,R21

RBS

R57,879

R59, R85

R51, R53, R55, ASB.

R50

5, R23

852,856

RIB, R31, R62, ROS, RO?

1G, R32

R15,R33

R82

866

R61 ROT

RIT, R18, R35, 836

cove.

REVISE DAT

ve

eT. 9

SCRIPTIONS.

1992

WHP.C.8, SECTIONEEY

H.cAP to0ve~10%

‘0ove-10%

‘oove-t0%

‘00ve-10%

s00ve-10%

s00ve-10%,

ECAP

cucaP

Res

Sovs-20%

Sov-20%

s6v+-20%

‘6v-20%

‘6v-20%

‘6¥+-20%

25vs-20%

35ve-20%

sove~10%

sove~10%

s0ve—10%

sees

ive

seve

aes:

ees

1a

ees

yas

1ve-5t

Tyas

rie 5%

1168-5

ies

ye

yas

sae

you

syaue-st

sae

14-53%

raMs-5%

aaNe-5t

hue

ast

nes

aut

5

5

5

5

5

o.tuF

0..068uF

o.o1uF

0.0068uF

0.0047uF

o.ootuF

x11 0.22uF

x11 O.47UF

x11 AOR

x11 BUF

x11 TUF

6x14 t00UF

10x16 470ur

‘1630 2200UF BS

1

1

2

Ps

Ps

*s

Ps

Ps

Ps

Ps

Ps

Ps

Ps

Ps

Ps

Ps

PF

Ps

ne

he

10PF

}00PF

50°F

47 ont

150 oht

330 oft

470 om

750 oh

1K ont

2.2K oh

3.34 ohm

4.7% on

5.6K On

6.2K ont

6.8 nM

10K oF

12K oF

18K oF

22k on

30K on

33K ont

47K ont

56K ont

68K ont

330K oft

3.38 oft

410 onm

TAL FILM 649 oH

TAL FILM 250 OHM

WeeSi METAL FILM 100 OFM

‘we-Si METAL FILM 200 OHM

We-St METAL FILM 300 Ot

Sw+-S% WIRE WOUND 0.22 OHM

ary

Rev: €

PART N0

3-59-0118

41-25-150

127-420

128-002

1-01-4054

1-01-4068

1-28-2024

4-05-007

1-05-008

1-05-9006

105-001

1-05-009

4-06-005

4-07-20

108-009

108-010

1-07-104

407-107

107-109

4-07-108

109-421

109-412

105-561

MODEL: GTS150

REFERENCE NO,

MAIN Pc,

wot

mH su

RELAY

B

n12

%

ois

ou

or

97, 08,09,011

03, 04,05, 06

ot, 02,010

014,015, 016,017

2,09

5,010

1,06

207,011,012

ans

08

ict, 1e2

13

ree

cove

Pee

mH

con.

com.

RECT.

DIO.

ZENER

1

REVISE DATE: SEPT. 9, 1992

DESCRIPTIONS

| SECTIONEA

2033 MAIN P.¢.8.

RED LED HRES1D

‘THERMAL SWITCH

RELAY (OWI-85-22404)

EEG FERRITE CHC, (NKO4S)

‘TOBO-26 IRON POWDER CHOKE

BALUN CHOKE COIL

cru 218

cru 21s

-1w5400)

‘went

Nate

1iew-sx 150

IRFS4O / HTPSONOGE

TIP et

TIP 146

2N 3906

PS 106

PS A56

PS At3

A4560

Th 7317

L494

MECHANICAL PARTS LIST

Rev: € novel: 615150 REVISE DATE: SEPT. 9, 1992

PART No. REFERENCE ho. cove DESCRIPTIONS

3°62-008 1 PANEL 20338-4 TOP COVER HEAT SINK 1

3-62-01 2 20338-1 FRONT PANEL 1

3-62-002 3 20338-2 REAR PANEL 1

3-62-0038 4 20338-3 ROTTON COVER 1

3-61-008 5 20188-8 SUITCH KNOB 1

361-009 6 20188-9 BADGE 1

427-180 7 P.su 2P2T EXT3EQ1S 1

1-26-016 8 F.VR. VeRES, 2OKAX2 (RK1261210) 1

443-012 . JACK BRITA ZRCA JACKCR/Y) GOLD-P, 1

3-61-0054 0 CON SPEAKER TERMINAL ASSEMBLY 1

3-61-0254 " POWER TERMINAL ASSEMBLY 1

yer 2 8KT. PA-T00 TRANSISTOR KT. ‘

167-011 3 ‘1536-11 TRANSISTOR BKT. 1

4-37-930 % StU MB FLAT WASHER ZNC BKT. 6

4-37-230 6 MS SPRING WASHER 2NC BKT. 6

4-38-314 6 ‘3x14 TTB PH INC BKT 6

41-38-307 7 TORK T10 TTB-BTN 3x10 TIN 8

4-35-308 oy THB-PH 3X10 TIN RCA 1

135-305 ” SB 3X6 FOR CovER 6

1-35-381 20 PAN HEAD RACHINE SCREW 3x20 3

4-37-2380 a HS SPRING WASHER 2NC BKT. 3

4-37-030 2 HS NUT FOR TERMINAL 2

433-206 2 PAN HEAD TAPPING SCREW 2x6 4

3-24-08 2% HSXS/NI BH FOR TERMINAL 1

3-24-08 2 HSX9 NI BH FOR TERMINAL 6

PACKING PARTS LIST

Rev: € monet: 6rs150 REVISE DATE: SEPT. 9, 1992

PART No, REFERENCE No. cove DESCRIPTIONS

tf

Gts150-1 26 GTS150 SET 1

e1s150-2 7 GtFT pox 1

2033-1 28 INNER BOX (BIG) 1

2083-72 29,30 INNER BOX (SMALL 2

129-107 30-1 FUSE 20, 1

41-36-120 30-2 PAN HEAD TAPPING SCREW 10x5/8 4

4-37-150 30-3 PLAIN WASHER HS 4

4-37-250 30-4 SPRING WASHER 15 4

4-50-0878 30-5 GTS1S0 F/VIRE SET + 20A F/SET 1

4-50-028 30-6 WIRE, BLACK 610nm (5415) 1

G15150-3 ut (OWNERS: MANUAL 1

re-001 me URARANTY CARD 1

as

arn 48

Ron Oo

vce DD

}———0 o0n~

[0 o0n+

MS OnUSHL

MOOTE OSISLO

ate—nio

si-nid

=

-—

——

—

=

eg |O

£

2

a

z T

roresu,

svoisstirat

-10-

WVYOVIC ONIMIM OSLSLO

GTS150 PC BOARD LAYOUT

EAE

Grs150_

GTS150 WIRING DIAGRAM

Sf

a C

| CD Player

Cassette / Receiver or Changer

0 input

4}

Power oo oo

Antenna

Cassetie/ Receive,

Preamp Output

8

3 2

3 6

af 3

3

T

Romate On7 Orr Seomers [<

a

Ignition Switen

A

Chassis Groura

Vehicle Battery

NK

-

Yellow

Main « 120

Black - Power Ground

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- SURT Service Manual - RMA - Rev3bDocument43 pagesSURT Service Manual - RMA - Rev3bMontecarlo88% (8)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Voltage Test Points 1Document20 pagesVoltage Test Points 1MontecarloNo ratings yet

- Sony Kdl-42w650a Chassis Rb1g Ver.1.0Document29 pagesSony Kdl-42w650a Chassis Rb1g Ver.1.0MontecarloNo ratings yet

- Hfe Denon Pma-860 1060 ServiceDocument35 pagesHfe Denon Pma-860 1060 ServiceMontecarloNo ratings yet

- Marbatell Power Amp 132Document1 pageMarbatell Power Amp 132MontecarloNo ratings yet

- FM Rev EspDocument4 pagesFM Rev EspMontecarloNo ratings yet

- Fuente Pwmdiy Audio Actualizada 137Document1 pageFuente Pwmdiy Audio Actualizada 137MontecarloNo ratings yet

- Protector de Bafles Con Otro Relecomponentes 672Document1 pageProtector de Bafles Con Otro Relecomponentes 672MontecarloNo ratings yet

- Radson 400 Musb-SdDocument1 pageRadson 400 Musb-SdMontecarloNo ratings yet

- Service Manual: HTX29S31SDocument29 pagesService Manual: HTX29S31SMontecarloNo ratings yet

- TP - MS338.TB752 Circuit DiagramDocument11 pagesTP - MS338.TB752 Circuit DiagramMontecarloNo ratings yet