Professional Documents

Culture Documents

Technical Specifications For Carbon Steel Plates /sheets Conforming To Sa-516M Gr. 485

Technical Specifications For Carbon Steel Plates /sheets Conforming To Sa-516M Gr. 485

Uploaded by

Kingston RivingtonCopyright:

Available Formats

You might also like

- Sample ASME QC Manual For U, U2, S&PPDocument53 pagesSample ASME QC Manual For U, U2, S&PPKingston RivingtonNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- MOTS-08 Squirrel Cage Induction Motors - Rev 4.0Document17 pagesMOTS-08 Squirrel Cage Induction Motors - Rev 4.0Kingston RivingtonNo ratings yet

- Men Are From Mars SummaryDocument7 pagesMen Are From Mars SummaryDeepak Rao Rao100% (2)

- Charles Stanley - Let Go and Let GODDocument50 pagesCharles Stanley - Let Go and Let GODTheAgapeIncNo ratings yet

- Millipore AcademicDocument93 pagesMillipore Academickron541No ratings yet

- Purchase Spec. For Flange-Nickel Alloy Forgings (SB564 Uns N08825)Document5 pagesPurchase Spec. For Flange-Nickel Alloy Forgings (SB564 Uns N08825)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Document4 pagesPURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- Purchase Spec. For Plates (Sa36)Document5 pagesPurchase Spec. For Plates (Sa36)Daison PaulNo ratings yet

- Purchase Spec. For Fittings (Sa403 WP321)Document4 pagesPurchase Spec. For Fittings (Sa403 WP321)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + S31803)Document7 pagesPurchase Spec. For Plates-Weld Overlay (CS + S31803)Daison PaulNo ratings yet

- Purchase Spec. For Pipes (Sa790)Document5 pagesPurchase Spec. For Pipes (Sa790)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + 304L)Document3 pagesPurchase Spec. For Plates-Weld Overlay (CS + 304L)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa789 S31803)Document6 pagesPurchase Spec. For Tubes (Sa789 S31803)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa179)Document5 pagesPurchase Spec. For Tubes (Sa179)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR BOLTS&NUTS (SA320M Gr.L7 & SA194M Gr.4)Document4 pagesPURCHASE SPEC. FOR BOLTS&NUTS (SA320M Gr.L7 & SA194M Gr.4)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PIPES (SA106 GR.B)Document4 pagesPURCHASE SPEC. FOR PIPES (SA106 GR.B)Daison PaulNo ratings yet

- Purchase Spec. For Bar (SB425)Document4 pagesPurchase Spec. For Bar (SB425)Daison PaulNo ratings yet

- Purchase Spec. For Tubes-Nonferrous (SB111 H55 C1200)Document6 pagesPurchase Spec. For Tubes-Nonferrous (SB111 H55 C1200)Daison PaulNo ratings yet

- Purchase Spec. For Tubes-Nonferrous (SB111 Uns C71500)Document6 pagesPurchase Spec. For Tubes-Nonferrous (SB111 Uns C71500)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa213 TP321)Document5 pagesPurchase Spec. For Tubes (Sa213 TP321)Daison PaulNo ratings yet

- Purchase Spec. For Plugs-Forging (Sa105)Document4 pagesPurchase Spec. For Plugs-Forging (Sa105)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Copper Alloy (SB171 Uns C46400)Document4 pagesPurchase Spec. For Plates-Copper Alloy (SB171 Uns C46400)Daison PaulNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Purchase Spec. For Flanges (Sa182 F304&F304L)Document4 pagesPurchase Spec. For Flanges (Sa182 F304&F304L)Daison PaulNo ratings yet

- Microsoft Word - 2028B - Rev - 0Document10 pagesMicrosoft Word - 2028B - Rev - 0Padmanabhan VenkateshNo ratings yet

- Purchase Spec. For Plates (Sa240 304L)Document3 pagesPurchase Spec. For Plates (Sa240 304L)Daison PaulNo ratings yet

- Materials System SpecificationDocument12 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- Purchase Spec. For Tubes-Cu-Ni Seamless Condenser TubesDocument4 pagesPurchase Spec. For Tubes-Cu-Ni Seamless Condenser TubesDaison PaulNo ratings yet

- B2020-TDC-FIT-013 Coupling Plug R1Document2 pagesB2020-TDC-FIT-013 Coupling Plug R1Ramalingam PrabhakaranNo ratings yet

- Materials System Specification: 04-SAMSS-001 21 December 2008 Gate Valves Valves Standards Committee MembersDocument10 pagesMaterials System Specification: 04-SAMSS-001 21 December 2008 Gate Valves Valves Standards Committee MembersAkilesh Aravindakshan100% (1)

- Purchase Spec. For Pipes (Sa928 Uns S31803)Document8 pagesPurchase Spec. For Pipes (Sa928 Uns S31803)Daison PaulNo ratings yet

- 01 Samss 010 PDFDocument11 pages01 Samss 010 PDFAnonymous ZxJZoU0% (1)

- 01 Samss 010Document12 pages01 Samss 010Fortunato SegubanNo ratings yet

- Purchase Spec. For Fittings (Sa815 Uns S31803)Document5 pagesPurchase Spec. For Fittings (Sa815 Uns S31803)Daison PaulNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010biplabpal2009No ratings yet

- Purchase Spec. For Pipes (Sa312 TP316L)Document5 pagesPurchase Spec. For Pipes (Sa312 TP316L)Daison PaulNo ratings yet

- Purchase Request (PR) : Procurement SupervisorDocument2 pagesPurchase Request (PR) : Procurement SupervisorKingston RivingtonNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA516 Gr.70N + SA 240 GR 316L)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA516 Gr.70N + SA 240 GR 316L)Daison Paul100% (1)

- 01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentDocument13 pages01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentAbdul HannanNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010doyenofcastleNo ratings yet

- Koc MP 016Document18 pagesKoc MP 016Ravi MahetoNo ratings yet

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Document23 pagesES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsNo ratings yet

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010이진영No ratings yet

- Materials System SpecificationDocument14 pagesMaterials System SpecificationSyed Zain Ali100% (1)

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Document3 pagesPURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- WCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSDocument9 pagesWCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSsingaravelan narayanasamyNo ratings yet

- Complete - Catalogue 2021 05 16 07 - 58 - 36Document22 pagesComplete - Catalogue 2021 05 16 07 - 58 - 36CésarNo ratings yet

- Project: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Document14 pagesProject: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Mohamed Wasim ShaikhNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- BBK 10146630Document1 pageBBK 10146630asarwar83No ratings yet

- Oriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesDocument18 pagesOriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesTejas ShahNo ratings yet

- 04-SAMSS-002 Globe Valves PDFDocument11 pages04-SAMSS-002 Globe Valves PDFSaeed KazemiNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- OPSS 1210 Nov08Document8 pagesOPSS 1210 Nov08Muhammad UmarNo ratings yet

- Spec 1Document11 pagesSpec 1velan73No ratings yet

- EGP3-03.00 Piping Specifications For Valves, Material and Service ClassesDocument162 pagesEGP3-03.00 Piping Specifications For Valves, Material and Service ClassesMathias Onosemuode100% (1)

- 02 SAMSS 011 FlangesDocument30 pages02 SAMSS 011 FlangesALINo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Ut Level Spec QB 5 (49L)Document14 pagesUt Level Spec QB 5 (49L)Kingston RivingtonNo ratings yet

- Inspection Report: Karachaganak Petroleum Oper. B.V ProjectDocument4 pagesInspection Report: Karachaganak Petroleum Oper. B.V ProjectKingston RivingtonNo ratings yet

- Purchase Request (PR) : Procurement SupervisorDocument2 pagesPurchase Request (PR) : Procurement SupervisorKingston RivingtonNo ratings yet

- Quality Assurance Plan (Qap)Document3 pagesQuality Assurance Plan (Qap)Kingston RivingtonNo ratings yet

- 8-1 Din R0Document2 pages8-1 Din R0Kingston RivingtonNo ratings yet

- MOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsDocument20 pagesMOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsKingston RivingtonNo ratings yet

- Inspection Report: Karachaganak Petroleum Oper. B.V ProjectDocument5 pagesInspection Report: Karachaganak Petroleum Oper. B.V ProjectKingston RivingtonNo ratings yet

- Inspection Report: D A DonovanDocument5 pagesInspection Report: D A DonovanKingston RivingtonNo ratings yet

- MOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationDocument27 pagesMOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationKingston RivingtonNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsKingston RivingtonNo ratings yet

- MOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseDocument25 pagesMOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseKingston RivingtonNo ratings yet

- MOTS-10 - Rev. 4.0 - MOG-FP-ELE-STD-0010 Electrical InstallationsDocument45 pagesMOTS-10 - Rev. 4.0 - MOG-FP-ELE-STD-0010 Electrical InstallationsKingston RivingtonNo ratings yet

- Sample CalculationsDocument10 pagesSample CalculationsKingston RivingtonNo ratings yet

- Supplement 10 TS Calibration ECSPP ECBSDocument16 pagesSupplement 10 TS Calibration ECSPP ECBSKingston Rivington100% (1)

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- 2nd Ed Critical Care Pharmacy Handbook Revised 19th Jan 2021 Final 5.5.21Document186 pages2nd Ed Critical Care Pharmacy Handbook Revised 19th Jan 2021 Final 5.5.21SAUMOJIT MAJUMDERNo ratings yet

- Prenatal Care Case PresentationDocument32 pagesPrenatal Care Case PresentationMary Grace Mas100% (1)

- HCDPDocument92 pagesHCDPMuddassar SultanNo ratings yet

- SoR - 2019-20 (1) Andhra PradeshDocument526 pagesSoR - 2019-20 (1) Andhra Pradeshsudhakar170588% (8)

- Relative Density and Absorption Lab RepoDocument13 pagesRelative Density and Absorption Lab RepoKristine SuguitanNo ratings yet

- In This Issue : Summer Photo ContestDocument4 pagesIn This Issue : Summer Photo ContestCarrie Aldrich MaliszewskiNo ratings yet

- CP120-4 Catalog Page SHUTTLEDocument1 pageCP120-4 Catalog Page SHUTTLEfrancis_15inNo ratings yet

- Devesh Mishra Patho NotesDocument17 pagesDevesh Mishra Patho Notesmilli6No ratings yet

- Walmart Discrimination CaseDocument10 pagesWalmart Discrimination Casepemnad100% (2)

- E290 Procedure Feb 2024Document3 pagesE290 Procedure Feb 2024I weld with hot glueNo ratings yet

- Benzene: Product and Technical InformationDocument24 pagesBenzene: Product and Technical InformationLaila FaeizahNo ratings yet

- Heizka Catalogue Cat6 24awg Utp 2Document2 pagesHeizka Catalogue Cat6 24awg Utp 2votinh20687No ratings yet

- Venture Lighting Lamp Catalog 1991 - 1992Document52 pagesVenture Lighting Lamp Catalog 1991 - 1992Alan MastersNo ratings yet

- CHN Ratio Test 2022Document12 pagesCHN Ratio Test 2022Arvinjohn GacutanNo ratings yet

- Jurnal AnemiaDocument4 pagesJurnal AnemiaAchmad Aidil TazakkaNo ratings yet

- Developmental Victimology - The Comprehensive Study of Childhood Victimizations PDFDocument26 pagesDevelopmental Victimology - The Comprehensive Study of Childhood Victimizations PDFatjoerossNo ratings yet

- Upper Airway DisordersDocument25 pagesUpper Airway DisordersIliana EsquivelNo ratings yet

- Tutorial 6 (Alcohols, Aldehydes, Haloalkanes, Carboxylic Acids)Document5 pagesTutorial 6 (Alcohols, Aldehydes, Haloalkanes, Carboxylic Acids)dasani93No ratings yet

- 6es7288 2de08 0aa0Document2 pages6es7288 2de08 0aa0Ngọc TrầnNo ratings yet

- Skandalakis Surgical Anatomy The EmbryolDocument2 pagesSkandalakis Surgical Anatomy The EmbryolArvin Aditya PrakosoNo ratings yet

- 2021 Annual StatementDocument12 pages2021 Annual Statementbkadariya6288No ratings yet

- L MesitranDocument0 pagesL MesitranCesar Alcides Pezo BorreroNo ratings yet

- Fire Pump Sizing and SelectionDocument5 pagesFire Pump Sizing and SelectionEshref AlemdarNo ratings yet

- 4.1 - Cell Cycle Part 1Document5 pages4.1 - Cell Cycle Part 1Deomar Joseph ParadoNo ratings yet

- MHA - HAMP Supplemental Directive 09-01Document38 pagesMHA - HAMP Supplemental Directive 09-01SoCal ForeclosuresNo ratings yet

- Mars T1000 User ManualDocument24 pagesMars T1000 User ManualesclavoatuspiesNo ratings yet

- P Task GRASPS Q4 FNL Week 5Document3 pagesP Task GRASPS Q4 FNL Week 5Louise Andy V. ValidorNo ratings yet

Technical Specifications For Carbon Steel Plates /sheets Conforming To Sa-516M Gr. 485

Technical Specifications For Carbon Steel Plates /sheets Conforming To Sa-516M Gr. 485

Uploaded by

Kingston RivingtonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specifications For Carbon Steel Plates /sheets Conforming To Sa-516M Gr. 485

Technical Specifications For Carbon Steel Plates /sheets Conforming To Sa-516M Gr. 485

Uploaded by

Kingston RivingtonCopyright:

Available Formats

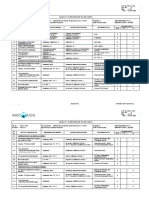

TS NO.: U101 / TS-01 Rev No .

: 0

Page : 1 of 1

Date of Issue : 06 April 2007

TECHNICAL SPECIFICATIONS FOR CARBON STEEL PLATES /SHEETS

CONFORMING TO SA-516M GR. 485

1.0 Scope : This specification deals with technical requirements for delivery condition for

carbon steel plates/sheets required for pressure parts.

2.0 Material Specification : SA-516M GR. 485 of ASME Section II, Part A Edition 2004, Addenda 2006

& Grade

3.0 References : ASME Section II, Part A, Edition 2004, Addenda 2006

SA-516M

SA-20M

SA-370

4.0 Size and Quantity : As Per Purchase order

5.0 Dimensional Tolerances : As per SA-20M

6.0 Delivery Conditions : As Rolled / Normalised

7.0 Chemical & Mechanical :

As per SA-516M GR. 485 and SA-20M

Properties

8.0 Supplementary : Nil

Requirements (If any)

9.0 Marking Requirements : Required as per SA-20M, Clause 13

10.0 Material Test Reports : Required as per SA-20M, Clause 19

11.0 Special Remarks : Repair by Welding is not permitted

12.0 Inspection : By KIOS QC Inspector at KIOS Shop.

Prepared By Approved By

Sign and

Date

Designation Design Engineer Engineering Supervisior

Exhibit Sr.No.8-3, Rev.0

TS NO.: U101 / TS-02 Rev No .: 0

Page : 1 of 1

Date of Issue : 06 April 2007

TECHNICAL SPECIFICATIONS FOR CARBON STEEL PIPES

CONFORMING TO SA - 106 GRADE B

1.0 Scope : This specification deals with technical requirements for delivery condition

for Seamless carbon steel pipes required for pressure parts.

2.0 Material Specification : SA-106 Grade B of ASME Section II, Part A Edition 2004, Addenda 2006

& Grade

3.0 References : ASME Section II, Part A Edition 2004, Addenda 2006

SA-106

SA-530M

SA-370

ASME B36 10M Edition 2000

4.0 Size and Quantity : As Per Purchase Order

5.0 Dimensions : As per ASME B36.10M Edition 2000

6.0 Dimensional Tolerances : As per SA-530M

7.0 Delivery Conditions : Hot -Finished

8.0 Chemical & Mechanical : As per SA-106 Grade B and SA-530M

Properties

9.0 Supplementary : Nil

Requirements (If any)

10.0 Marking Requirements : Required as per SA-106 Clause 24 and SA-530M Clause 24

11.0 Material Test Reports : Required as per SA-106 Clause 23 and SA-530M Clause 21

12.0 Special Remarks : a) Hydrostatic test shall be carried out as per SA530M.

b) Repair by Welding is not permitted

13.0 Inspection : By KIOS QC Inspector at KIOS Shop.

Prepared By Approved By

Sign and

Date

Designation Design Engineer Engineering Supervisior

Exhibit 8-3, Rev.0

TS NO.: U101 / TS-03 Rev No .: 0

Page : 1 of 1

Date of Issue : 06 April 2007

TECHNICAL SPECIFICATIONS FOR CARBON STEEL FLANGES

CONFORMING TO SA - 105M

1.0 Scope : This specification deals with technical requirements for delivery condition for

carbon steel flanges required for pressure parts.

2.0 Material Specification : SA-105M of ASME Section II, Part A Edition 2004, Addenda 2006

& Grade

3.0 References : ASME Section II, Part A, Edition 2004, Addenda 2006

SA 105M

SA-370

SA-788

SA-961

ASME B16.5 Edition 2003

4.0 Size and Quantity : As Per Purchase Order

5.0 Dimensions & Tolerances : As per ASME B16.5 Edition 2003, Class 150

6.0 Delivery Conditions : As Forged / Normalised

7.0 Chemical & Mechanical :

As per SA-105M

Properties

8.0 Supplementary : Nil

Requirements (If any)

9.0 Marking Requirements : Required as Per SA-105M Clause 13, SA-961 Clause 20 and ASME B16.5 Edition 2003

10.0 Material Test Reports : Required as per SA-105M Clause 12 and SA-961 Clause 19

11.0 Special Remarks : Repair by Welding is not permitted

12.0 Inspection : By KIOS QC Inspector at KIOS Shop.

Prepared By Approved By

Sign and

Date

Designation Design Engineer Engineering Supervisior

Exhibit 8-3, Rev.0

TS NO.: U101 / TS-04 Rev No .: 0

Page : 1 of 1

Date of Issue : 06 April 2007

TECHNICAL SPECIFICATIONS FOR ALLOY STEEL STUDS

CONFORMING TO SA - 193

1.0 Scope : This specification deals with technical requirements for delivery condition for

alloy steel full threaded studs required for pressure parts.

2.0 Material Specification : SA-193 Grade B7 of ASME Section II, Part A Edition 2004, Addenda 2006

& Grade

3.0 References : ASME Section II, Part A, Edition 2004, Addenda 2006

SA-370

SA-788

ASME B1.1 Edition 2003

4.0 Size and Quantity : As Per Purchase order

5.0 Threading : As per ASME B1.1 Edition 2003, Class 2A fit, 8-pitch thread series

6.0 Delivery Conditions : Quenched and Tempered as per SA193 Grade B7

7.0 Chemical & Mechanical : As per SA193 Grade B7

Properties

8.0 Supplementary : Nil

Requirements (If any)

9.0 Marking Requirements : Required as per SA-193, Clause 19

10.0 Material Test Reports : Required as per SA-194, Clause 18

11.0 Special Remarks : Nil

12.0 Inspection : By KIOS QC Inspector at KIOS Shop.

Prepared By Approved By

Sign and

Date

Designation Design Engineer Engineering Supervisior

Exhibit 8-3, Rev.0

TS NO.: U101 / TS-05 Rev No .: 0

Page : 1 of 1

Date of Issue : 06 April 2007

TECHNICAL SPECIFICATIONS FOR CARBON STEEL NUTS

CONFORMING TO SA - 194

1.0 Scope : This specification deals with technical requirements for delivery condition for

alloy steel hexagonal bolts required for pressure parts.

2.0 Material Specification : SA-194 Grade 2H of ASME Section II, Part A Edition 2004, Addenda 2006

& Grade

3.0 References : ASME Section II, Part A, Edition 2004, Addenda 2006

SA-370

SA-788

ASME B18.2.2 - 1987 (R1999)

ASME B1.1 Edition 2003

4.0 Size and Quantity : As Per Purchase order

5.0 Dimensions & Tolerances : As per ASME B18.2.2 - 1987 (R1999) Heavy Hex Series

Threading : As per ASME B1.1 Edition 2003, Class 2B fit, 8 UN series

6.0 Delivery Conditions : Quenched and Tempered as per SA194 Grade 2H

7.0 Chemical & Mechanical : As per SA194 Grade 2H

Properties

8.0 Supplementary : Nil

Requirements (If any)

9.0 Marking Requirements : Required as per SA-194, Clause 12

10.0 Material Test Reports : Required as per SA-194, Clause 11

11.0 Special Remarks : Nil

12.0 Inspection : By KIOS QC Inspector at KIOS Shop.

Prepared By Approved By

Sign and

Date

Designation Design Engineer Engineering Supervisior

Exhibit 8-3, Rev.0

TS NO.: U101 / TS-06 Rev No .: 0

Page : 1 of 1

Date of Issue : 06 April 2007

TECHNICAL SPECIFICATIONS FOR FORMED DISHED END

1.0 Scope : This specification deals with technical requirements for forming of carbon steel

dished ends.

2.0 Material Specification : SA-516M GR. 485 of ASME Section II Part A, Edition 2004 Addenda 2006

and Grade and KIOS Technical Specification No. U101 / TS-01 R0

3.0 Size, Quantity & Dimension : As per Part no. 10103 of KIOS drawing no. U101- 90100-1 R0

4.0 Tolerances : As per UG-81 of ASME Section VIII Division-1, Edition 2004 + A06 and KIOS drawing

5.0 Method of Forming : Cold

5.0 Heat Treatment after : Not Required

Forming

6.0 Supplementary : Nil

Requirements (If any)

7.0 Marking Requirements : Markings as per Material Specification is required to be maintained.

In addition, dished end manufacturer's name or trademark is to be marked.

8.0 Certification : As built dimensions including minimum thickness after forming, method of forming and

heat treatment (if any) shall be certified by dished end manufacturer in addition to

Material test reports as per KIOS TS No. U101 / TS-01 Rev.0

9.0 Special Remarks : No welding or tacking shall be done by the dished end manufacturer.

10.0 Inspection : By KIOS QC Inspector at KIOS Shop.

-

Prepared By Approved By

Sign and

Date

Designation Design Engineer Engineering Supervisior

Exhibit No. 8-3, Rev.0

TS NO.: U101 / TS-07 Rev No .: 0

Page : 1 of 1

Date of Issue : 06 April 2007

TECHNICAL SPECIFICATIONS FOR COMPRESSED

NON ASBESTOS FIBRE (CNAF) GASKET

1.0 Scope : This specification deals with technical requirements for delivery condition for

compressed non-asbestos fibre gasket for nozzles.

2.0 Material Specification : Compressed Non-asbestos Fibre (CNAF)

3.0 References : ASME B16.21 - 1992

4.0 Size and Quantity : As Per Purchase order

5.0 Dimensions & Tolerances : As per ASME B16.21 - 1992

6.0 Supplementary : Nil

Requirements (If any)

7.0 Marking Requirements : Required as per ASME B16.21 - 1992

10.0 Material Test Reports : Certificate of Compliance is required as per ASME B16.21 - 1992

11.0 Special Remarks : Nil

12.0 Inspection : By KIOS QC Inspector at KIOS Shop.

Prepared By Approved By

Sign and

Date

Designation Design Engineer Engineering Supervisior

Exhibit 8-3, Rev.0

TS NO.: U101 / TS-08 Rev No .: 0

Page : 1 of 1

Date of Issue : 06 April 2007

TECHNICAL SPECIFICATIONS FOR ROLLING OF SHELL AND MANHOLE NECK

1.0 Scope : This specification deals with technical requirements for rolling of shell sections and

nozzle necks.

2.0 Material : Material with identification markings shall be supplied by KIOS.

The identification markings shall be maintained during rolling.

3.0 Size, Quantity & Dimension : As per Part no. 10101 and 10105 of KIOS drawing no. U101- 90100-2 R0

4.0 Tolerances : As per KIOS drawing

5.0 Method of Forming : Cold

5.0 Heat Treatment after : Not Required

Forming

6.0 Supplementary : Nil

Requirements (If any)

7.0 Marking Requirements : The identification markings shall be maintained on outside surface during rolling.

8.0 Certification : Method of forming and heat treatment (if any) shall be certified sub-contractor.

9.0 Special Remarks : No welding or tacking shall be done by the sub-contractor.

10.0 Inspection : By KIOS QC Inspector at KIOS Shop.

-

Prepared By Approved By

Sign and

Date

Designation Design Engineer Engineering Supervisior

Exhibit No. 8-3, Rev.0

You might also like

- Sample ASME QC Manual For U, U2, S&PPDocument53 pagesSample ASME QC Manual For U, U2, S&PPKingston RivingtonNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- MOTS-08 Squirrel Cage Induction Motors - Rev 4.0Document17 pagesMOTS-08 Squirrel Cage Induction Motors - Rev 4.0Kingston RivingtonNo ratings yet

- Men Are From Mars SummaryDocument7 pagesMen Are From Mars SummaryDeepak Rao Rao100% (2)

- Charles Stanley - Let Go and Let GODDocument50 pagesCharles Stanley - Let Go and Let GODTheAgapeIncNo ratings yet

- Millipore AcademicDocument93 pagesMillipore Academickron541No ratings yet

- Purchase Spec. For Flange-Nickel Alloy Forgings (SB564 Uns N08825)Document5 pagesPurchase Spec. For Flange-Nickel Alloy Forgings (SB564 Uns N08825)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Document4 pagesPURCHASE SPEC. FOR PLATES-WELD OVERLAY (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- Purchase Spec. For Plates (Sa36)Document5 pagesPurchase Spec. For Plates (Sa36)Daison PaulNo ratings yet

- Purchase Spec. For Fittings (Sa403 WP321)Document4 pagesPurchase Spec. For Fittings (Sa403 WP321)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + S31803)Document7 pagesPurchase Spec. For Plates-Weld Overlay (CS + S31803)Daison PaulNo ratings yet

- Purchase Spec. For Pipes (Sa790)Document5 pagesPurchase Spec. For Pipes (Sa790)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Weld Overlay (CS + 304L)Document3 pagesPurchase Spec. For Plates-Weld Overlay (CS + 304L)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa789 S31803)Document6 pagesPurchase Spec. For Tubes (Sa789 S31803)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa179)Document5 pagesPurchase Spec. For Tubes (Sa179)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR BOLTS&NUTS (SA320M Gr.L7 & SA194M Gr.4)Document4 pagesPURCHASE SPEC. FOR BOLTS&NUTS (SA320M Gr.L7 & SA194M Gr.4)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PIPES (SA106 GR.B)Document4 pagesPURCHASE SPEC. FOR PIPES (SA106 GR.B)Daison PaulNo ratings yet

- Purchase Spec. For Bar (SB425)Document4 pagesPurchase Spec. For Bar (SB425)Daison PaulNo ratings yet

- Purchase Spec. For Tubes-Nonferrous (SB111 H55 C1200)Document6 pagesPurchase Spec. For Tubes-Nonferrous (SB111 H55 C1200)Daison PaulNo ratings yet

- Purchase Spec. For Tubes-Nonferrous (SB111 Uns C71500)Document6 pagesPurchase Spec. For Tubes-Nonferrous (SB111 Uns C71500)Daison PaulNo ratings yet

- Purchase Spec. For Tubes (Sa213 TP321)Document5 pagesPurchase Spec. For Tubes (Sa213 TP321)Daison PaulNo ratings yet

- Purchase Spec. For Plugs-Forging (Sa105)Document4 pagesPurchase Spec. For Plugs-Forging (Sa105)Daison PaulNo ratings yet

- Purchase Spec. For Plates-Copper Alloy (SB171 Uns C46400)Document4 pagesPurchase Spec. For Plates-Copper Alloy (SB171 Uns C46400)Daison PaulNo ratings yet

- TDC 004 CS Fittings r0Document1 pageTDC 004 CS Fittings r0samkarthik47No ratings yet

- Purchase Spec. For Flanges (Sa182 F304&F304L)Document4 pagesPurchase Spec. For Flanges (Sa182 F304&F304L)Daison PaulNo ratings yet

- Microsoft Word - 2028B - Rev - 0Document10 pagesMicrosoft Word - 2028B - Rev - 0Padmanabhan VenkateshNo ratings yet

- Purchase Spec. For Plates (Sa240 304L)Document3 pagesPurchase Spec. For Plates (Sa240 304L)Daison PaulNo ratings yet

- Materials System SpecificationDocument12 pagesMaterials System SpecificationJeck MaquitedNo ratings yet

- Purchase Spec. For Tubes-Cu-Ni Seamless Condenser TubesDocument4 pagesPurchase Spec. For Tubes-Cu-Ni Seamless Condenser TubesDaison PaulNo ratings yet

- B2020-TDC-FIT-013 Coupling Plug R1Document2 pagesB2020-TDC-FIT-013 Coupling Plug R1Ramalingam PrabhakaranNo ratings yet

- Materials System Specification: 04-SAMSS-001 21 December 2008 Gate Valves Valves Standards Committee MembersDocument10 pagesMaterials System Specification: 04-SAMSS-001 21 December 2008 Gate Valves Valves Standards Committee MembersAkilesh Aravindakshan100% (1)

- Purchase Spec. For Pipes (Sa928 Uns S31803)Document8 pagesPurchase Spec. For Pipes (Sa928 Uns S31803)Daison PaulNo ratings yet

- 01 Samss 010 PDFDocument11 pages01 Samss 010 PDFAnonymous ZxJZoU0% (1)

- 01 Samss 010Document12 pages01 Samss 010Fortunato SegubanNo ratings yet

- Purchase Spec. For Fittings (Sa815 Uns S31803)Document5 pagesPurchase Spec. For Fittings (Sa815 Uns S31803)Daison PaulNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010biplabpal2009No ratings yet

- Purchase Spec. For Pipes (Sa312 TP316L)Document5 pagesPurchase Spec. For Pipes (Sa312 TP316L)Daison PaulNo ratings yet

- Purchase Request (PR) : Procurement SupervisorDocument2 pagesPurchase Request (PR) : Procurement SupervisorKingston RivingtonNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA516 Gr.70N + SA 240 GR 316L)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA516 Gr.70N + SA 240 GR 316L)Daison Paul100% (1)

- 01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentDocument13 pages01-SAMSS-017 Auxiliary Piping For Mechanical EquipmentAbdul HannanNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010Ahmed Shaban KotbNo ratings yet

- 01 Samss 010Document11 pages01 Samss 010doyenofcastleNo ratings yet

- Koc MP 016Document18 pagesKoc MP 016Ravi MahetoNo ratings yet

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Document23 pagesES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsNo ratings yet

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 pagesEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarNo ratings yet

- 01 Samss 010Document12 pages01 Samss 010이진영No ratings yet

- Materials System SpecificationDocument14 pagesMaterials System SpecificationSyed Zain Ali100% (1)

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Document3 pagesPURCHASE SPEC. FOR PLATES-CLADDED&FORMING (SA516 Gr.70 + SA240 316L)Daison PaulNo ratings yet

- WCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSDocument9 pagesWCS 15 - Rev 4 Updations-15.02.2016 - Final Uploaded To DMSsingaravelan narayanasamyNo ratings yet

- Complete - Catalogue 2021 05 16 07 - 58 - 36Document22 pagesComplete - Catalogue 2021 05 16 07 - 58 - 36CésarNo ratings yet

- Project: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Document14 pagesProject: Engineering, Procurement & Construction For Upgrade Uthmaniyah-Abqaiq Pipelines Systems Bi# 10-01196 CONTRACT# 6600049184Mohamed Wasim ShaikhNo ratings yet

- Materials System SpecificationDocument8 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- BBK 10146630Document1 pageBBK 10146630asarwar83No ratings yet

- Oriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesDocument18 pagesOriental Manufacturers: Title: Purchase Order Specification For Carbon Steel PlatesTejas ShahNo ratings yet

- 04-SAMSS-002 Globe Valves PDFDocument11 pages04-SAMSS-002 Globe Valves PDFSaeed KazemiNo ratings yet

- PURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Document6 pagesPURCHASE SPEC. FOR PLATES-CLADDED (SA266 Gr.2 + S31803)Daison PaulNo ratings yet

- OPSS 1210 Nov08Document8 pagesOPSS 1210 Nov08Muhammad UmarNo ratings yet

- Spec 1Document11 pagesSpec 1velan73No ratings yet

- EGP3-03.00 Piping Specifications For Valves, Material and Service ClassesDocument162 pagesEGP3-03.00 Piping Specifications For Valves, Material and Service ClassesMathias Onosemuode100% (1)

- 02 SAMSS 011 FlangesDocument30 pages02 SAMSS 011 FlangesALINo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Ut Level Spec QB 5 (49L)Document14 pagesUt Level Spec QB 5 (49L)Kingston RivingtonNo ratings yet

- Inspection Report: Karachaganak Petroleum Oper. B.V ProjectDocument4 pagesInspection Report: Karachaganak Petroleum Oper. B.V ProjectKingston RivingtonNo ratings yet

- Purchase Request (PR) : Procurement SupervisorDocument2 pagesPurchase Request (PR) : Procurement SupervisorKingston RivingtonNo ratings yet

- Quality Assurance Plan (Qap)Document3 pagesQuality Assurance Plan (Qap)Kingston RivingtonNo ratings yet

- 8-1 Din R0Document2 pages8-1 Din R0Kingston RivingtonNo ratings yet

- MOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsDocument20 pagesMOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsKingston RivingtonNo ratings yet

- Inspection Report: Karachaganak Petroleum Oper. B.V ProjectDocument5 pagesInspection Report: Karachaganak Petroleum Oper. B.V ProjectKingston RivingtonNo ratings yet

- Inspection Report: D A DonovanDocument5 pagesInspection Report: D A DonovanKingston RivingtonNo ratings yet

- MOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationDocument27 pagesMOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationKingston RivingtonNo ratings yet

- British Steel Sections DatasheetsDocument18 pagesBritish Steel Sections DatasheetsKingston RivingtonNo ratings yet

- MOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseDocument25 pagesMOTS-17 - Rev 2.0 - MOG-EP-WEN-STD-0017 NoiseKingston RivingtonNo ratings yet

- MOTS-10 - Rev. 4.0 - MOG-FP-ELE-STD-0010 Electrical InstallationsDocument45 pagesMOTS-10 - Rev. 4.0 - MOG-FP-ELE-STD-0010 Electrical InstallationsKingston RivingtonNo ratings yet

- Sample CalculationsDocument10 pagesSample CalculationsKingston RivingtonNo ratings yet

- Supplement 10 TS Calibration ECSPP ECBSDocument16 pagesSupplement 10 TS Calibration ECSPP ECBSKingston Rivington100% (1)

- Tech SpecDocument16 pagesTech SpecKingston RivingtonNo ratings yet

- 2nd Ed Critical Care Pharmacy Handbook Revised 19th Jan 2021 Final 5.5.21Document186 pages2nd Ed Critical Care Pharmacy Handbook Revised 19th Jan 2021 Final 5.5.21SAUMOJIT MAJUMDERNo ratings yet

- Prenatal Care Case PresentationDocument32 pagesPrenatal Care Case PresentationMary Grace Mas100% (1)

- HCDPDocument92 pagesHCDPMuddassar SultanNo ratings yet

- SoR - 2019-20 (1) Andhra PradeshDocument526 pagesSoR - 2019-20 (1) Andhra Pradeshsudhakar170588% (8)

- Relative Density and Absorption Lab RepoDocument13 pagesRelative Density and Absorption Lab RepoKristine SuguitanNo ratings yet

- In This Issue : Summer Photo ContestDocument4 pagesIn This Issue : Summer Photo ContestCarrie Aldrich MaliszewskiNo ratings yet

- CP120-4 Catalog Page SHUTTLEDocument1 pageCP120-4 Catalog Page SHUTTLEfrancis_15inNo ratings yet

- Devesh Mishra Patho NotesDocument17 pagesDevesh Mishra Patho Notesmilli6No ratings yet

- Walmart Discrimination CaseDocument10 pagesWalmart Discrimination Casepemnad100% (2)

- E290 Procedure Feb 2024Document3 pagesE290 Procedure Feb 2024I weld with hot glueNo ratings yet

- Benzene: Product and Technical InformationDocument24 pagesBenzene: Product and Technical InformationLaila FaeizahNo ratings yet

- Heizka Catalogue Cat6 24awg Utp 2Document2 pagesHeizka Catalogue Cat6 24awg Utp 2votinh20687No ratings yet

- Venture Lighting Lamp Catalog 1991 - 1992Document52 pagesVenture Lighting Lamp Catalog 1991 - 1992Alan MastersNo ratings yet

- CHN Ratio Test 2022Document12 pagesCHN Ratio Test 2022Arvinjohn GacutanNo ratings yet

- Jurnal AnemiaDocument4 pagesJurnal AnemiaAchmad Aidil TazakkaNo ratings yet

- Developmental Victimology - The Comprehensive Study of Childhood Victimizations PDFDocument26 pagesDevelopmental Victimology - The Comprehensive Study of Childhood Victimizations PDFatjoerossNo ratings yet

- Upper Airway DisordersDocument25 pagesUpper Airway DisordersIliana EsquivelNo ratings yet

- Tutorial 6 (Alcohols, Aldehydes, Haloalkanes, Carboxylic Acids)Document5 pagesTutorial 6 (Alcohols, Aldehydes, Haloalkanes, Carboxylic Acids)dasani93No ratings yet

- 6es7288 2de08 0aa0Document2 pages6es7288 2de08 0aa0Ngọc TrầnNo ratings yet

- Skandalakis Surgical Anatomy The EmbryolDocument2 pagesSkandalakis Surgical Anatomy The EmbryolArvin Aditya PrakosoNo ratings yet

- 2021 Annual StatementDocument12 pages2021 Annual Statementbkadariya6288No ratings yet

- L MesitranDocument0 pagesL MesitranCesar Alcides Pezo BorreroNo ratings yet

- Fire Pump Sizing and SelectionDocument5 pagesFire Pump Sizing and SelectionEshref AlemdarNo ratings yet

- 4.1 - Cell Cycle Part 1Document5 pages4.1 - Cell Cycle Part 1Deomar Joseph ParadoNo ratings yet

- MHA - HAMP Supplemental Directive 09-01Document38 pagesMHA - HAMP Supplemental Directive 09-01SoCal ForeclosuresNo ratings yet

- Mars T1000 User ManualDocument24 pagesMars T1000 User ManualesclavoatuspiesNo ratings yet

- P Task GRASPS Q4 FNL Week 5Document3 pagesP Task GRASPS Q4 FNL Week 5Louise Andy V. ValidorNo ratings yet