Professional Documents

Culture Documents

Cambridge Assessment International Education: Design and Technology 6043/01 October/November 2017

Cambridge Assessment International Education: Design and Technology 6043/01 October/November 2017

Uploaded by

Anotidaishe NyakudyaCopyright:

Available Formats

You might also like

- 3126 01 MS 4RP AFP tcm142-665777Document10 pages3126 01 MS 4RP AFP tcm142-665777Kenzy Maher100% (3)

- Cambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationDocument10 pagesCambridge Secondary 1 Checkpoint: Cambridge Assessment International Educationahmed saad100% (3)

- Essentials PDF 2021Document8 pagesEssentials PDF 2021Ngô Tuấn KiệtNo ratings yet

- Singapore Secondary 1 End Year Examination For MathDocument10 pagesSingapore Secondary 1 End Year Examination For Mathshandlysoo50% (2)

- BOUNDS-Analysis of Properties of Fiber Composites With Anisotropic Constituents PDFDocument8 pagesBOUNDS-Analysis of Properties of Fiber Composites With Anisotropic Constituents PDFRaghavendra PrasadNo ratings yet

- Cambridge O Level: Design & Technology 6043/32 October/November 2021Document10 pagesCambridge O Level: Design & Technology 6043/32 October/November 2021Ozan EffendiNo ratings yet

- MATHEMATICS Compulsory Part Paper 1: Question-Answer BookDocument5 pagesMATHEMATICS Compulsory Part Paper 1: Question-Answer Book20/21-5B-(05) HoMeiYi/何美誼No ratings yet

- 5070 w17 Ms 42 PDFDocument9 pages5070 w17 Ms 42 PDFdR SHAMMIR AHMEDNo ratings yet

- 3123 01 MS 4RP AFP tcm142-699263Document10 pages3123 01 MS 4RP AFP tcm142-699263Nigar RasulzadaNo ratings yet

- Cambridge Assessment International Education: Chemistry 0620/62 October/November 2017Document4 pagesCambridge Assessment International Education: Chemistry 0620/62 October/November 2017Asmaa El SawyNo ratings yet

- June 2017 QP - Paper 1 OCR (A) Chemistry A-LevelDocument26 pagesJune 2017 QP - Paper 1 OCR (A) Chemistry A-LevelRisha SelvaNo ratings yet

- End of Year Examination Paper 1 - Sec 1 Math 1BDocument8 pagesEnd of Year Examination Paper 1 - Sec 1 Math 1Btiaachan14No ratings yet

- Edexcel Foundation PredictedDocument17 pagesEdexcel Foundation PredictedSara DuaNo ratings yet

- Cambridge Assessment International Education: English As A Second Language 0510/32 October/November 2017Document3 pagesCambridge Assessment International Education: English As A Second Language 0510/32 October/November 2017Alag MohammedNo ratings yet

- Edexcel Chemistry Unit 1 June 2010 GceDocument28 pagesEdexcel Chemistry Unit 1 June 2010 Gceaym3nNo ratings yet

- Chemistry 2022Document24 pagesChemistry 202220sirohiuNo ratings yet

- Year 9 Baseline Test - CalculatorDocument5 pagesYear 9 Baseline Test - CalculatornellytusiimeNo ratings yet

- GCSE Higher Maths Practice Paper 2 (Calculator)Document13 pagesGCSE Higher Maths Practice Paper 2 (Calculator)Polaroid educationNo ratings yet

- October 2022 MsDocument10 pagesOctober 2022 Msesraagalal3100% (1)

- Adobe Scan Mar 06, 2024Document7 pagesAdobe Scan Mar 06, 2024Simbai MuganoNo ratings yet

- Cambridge Assessment International Education: Chemistry 9701/41 October/November 2017Document13 pagesCambridge Assessment International Education: Chemistry 9701/41 October/November 2017Tony KassangaNo ratings yet

- JSSC JE General Engg. & GK Official Paper-I (Held On - 03 July, 2022)Document25 pagesJSSC JE General Engg. & GK Official Paper-I (Held On - 03 July, 2022)kumar swatantraNo ratings yet

- In Unit2 Higher Nov2010Document16 pagesIn Unit2 Higher Nov2010Heavenly SinNo ratings yet

- Solution Report For: Home My Test My ProfileDocument6 pagesSolution Report For: Home My Test My ProfilerajuNo ratings yet

- Cambridge IGCSE ™: English As A Second Language 0511/22Document11 pagesCambridge IGCSE ™: English As A Second Language 0511/22Wayne WeiNo ratings yet

- Cambridge International Examinations: This Document Consists of 6 Printed PagesDocument6 pagesCambridge International Examinations: This Document Consists of 6 Printed PagesBara' HammadehNo ratings yet

- Chemistry: Edexcel GCEDocument24 pagesChemistry: Edexcel GCEOmar HashemNo ratings yet

- Cambridge International Examinations: Chemistry 0620/61 May/June 2017Document4 pagesCambridge International Examinations: Chemistry 0620/61 May/June 2017Layal GhaddarNo ratings yet

- Chemistry: Pearson EdexcelDocument24 pagesChemistry: Pearson EdexcelApollo WongNo ratings yet

- Ieb gr9 Maths 2016Document13 pagesIeb gr9 Maths 2016sharonmangundu036No ratings yet

- Cambridge International Examinations: Chemistry 0620/61 May/June 2017Document4 pagesCambridge International Examinations: Chemistry 0620/61 May/June 2017...No ratings yet

- Cambridge Assessment International Education: Chemistry 0620/63 October/November 2017Document5 pagesCambridge Assessment International Education: Chemistry 0620/63 October/November 2017jadenjedidiahNo ratings yet

- IGCSE - Listening-Mark Scheme-May 20thDocument4 pagesIGCSE - Listening-Mark Scheme-May 20thAshley WilsonNo ratings yet

- Ial WCH05 01 Nov19 PDFDocument28 pagesIal WCH05 01 Nov19 PDFsammam mahdi samiNo ratings yet

- June 2019 QPDocument32 pagesJune 2019 QPkreoalt123No ratings yet

- Mathematics IDocument21 pagesMathematics IMohamed MubarakNo ratings yet

- Wednesday 9 January 2019: ChemistryDocument24 pagesWednesday 9 January 2019: ChemistryAhmad MohdNo ratings yet

- Specialist Mathematics: Written Examination 1Document16 pagesSpecialist Mathematics: Written Examination 1Eden ChanNo ratings yet

- Mark Scheme 3, English and Science PDFDocument36 pagesMark Scheme 3, English and Science PDFPonytailNo ratings yet

- English Paper 1 - 2023Document10 pagesEnglish Paper 1 - 2023suganya deviNo ratings yet

- Stage - 3 - English - Paper - 1 - Progression Test, 2023, Past Paper - MSDocument10 pagesStage - 3 - English - Paper - 1 - Progression Test, 2023, Past Paper - MSTr AstellaNo ratings yet

- Cambridge IGCSE ™: English As A Second Language 0510/12Document9 pagesCambridge IGCSE ™: English As A Second Language 0510/12sanctus.madhuranivashiniNo ratings yet

- 2001 P1 PDFDocument16 pages2001 P1 PDFErwin CahanapNo ratings yet

- Paper 5 November 2016 Mark SchemeDocument7 pagesPaper 5 November 2016 Mark SchememahahajNo ratings yet

- WBPSC Je Me 2018 Question PaperDocument12 pagesWBPSC Je Me 2018 Question Paperonlinebiz0032No ratings yet

- Cambridge Assessment International Education: Biology 0610/33 October/November 2017Document11 pagesCambridge Assessment International Education: Biology 0610/33 October/November 2017123 456No ratings yet

- Chemistry: Pearson EdexcelDocument24 pagesChemistry: Pearson EdexcelShopneel MHNo ratings yet

- F1 Math 2014 1stexam Paper1 Question BookDocument2 pagesF1 Math 2014 1stexam Paper1 Question BookyujuuumjiNo ratings yet

- Cambridge Secondary 1 CheckpointDocument12 pagesCambridge Secondary 1 CheckpointDương Ngọc Cường50% (4)

- 9260 92602E International Gcse Mathematics Specimen Paper 2016 v1Document26 pages9260 92602E International Gcse Mathematics Specimen Paper 2016 v1amr.taman41No ratings yet

- Cambridge Secondary 1 CheckpointDocument12 pagesCambridge Secondary 1 CheckpointDương Ngọc Cường50% (2)

- End of Year Examination Paper 2 - Sec 1 Math 1BDocument8 pagesEnd of Year Examination Paper 2 - Sec 1 Math 1Btiaachan14No ratings yet

- 0625 s17 Ms 63 PDFDocument5 pages0625 s17 Ms 63 PDFpriyaNo ratings yet

- Quick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesFrom EverandQuick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesRating: 3 out of 5 stars3/5 (2)

- Integration of One-forms on P-adic Analytic Spaces. (AM-162)From EverandIntegration of One-forms on P-adic Analytic Spaces. (AM-162)No ratings yet

- NYAKUDYA SecurityDocument5 pagesNYAKUDYA SecurityAnotidaishe NyakudyaNo ratings yet

- NYAKUDYA Grading SystemDocument10 pagesNYAKUDYA Grading SystemAnotidaishe NyakudyaNo ratings yet

- BS Notes Bones 2017Document332 pagesBS Notes Bones 2017Anotidaishe NyakudyaNo ratings yet

- Trade Regulations OverviewDocument4 pagesTrade Regulations OverviewAnotidaishe NyakudyaNo ratings yet

- 2020 Fee Schedule: Hillcrest Christian CollegeDocument1 page2020 Fee Schedule: Hillcrest Christian CollegeAnotidaishe NyakudyaNo ratings yet

- Cala SecurityDocument5 pagesCala SecurityAnotidaishe NyakudyaNo ratings yet

- Holdings in The Crop Science LibraryDocument27 pagesHoldings in The Crop Science LibraryAnotidaishe NyakudyaNo ratings yet

- Samson Gym Booking System: Candidatename: Anotidaishe NyakudyaDocument33 pagesSamson Gym Booking System: Candidatename: Anotidaishe NyakudyaAnotidaishe NyakudyaNo ratings yet

- Shalom Freight ManagementDocument37 pagesShalom Freight ManagementAnotidaishe NyakudyaNo ratings yet

- Zimbabwe School Examinations CouncilDocument16 pagesZimbabwe School Examinations CouncilAnotidaishe NyakudyaNo ratings yet

- Secondary Catalogue ZimbabweDocument23 pagesSecondary Catalogue ZimbabweAnotidaishe Nyakudya0% (1)

- AttachmentDocument308 pagesAttachmentAnotidaishe NyakudyaNo ratings yet

- Crop Science Progress and ProspectsDocument33 pagesCrop Science Progress and ProspectsAnotidaishe NyakudyaNo ratings yet

- Building Technology and Design Syllabus: Forms 1 - 4Document52 pagesBuilding Technology and Design Syllabus: Forms 1 - 4Anotidaishe Nyakudya100% (1)

- Technical Data Sheet: Polyethylene Terephthalate FlakesDocument2 pagesTechnical Data Sheet: Polyethylene Terephthalate Flakesdorra snoussiNo ratings yet

- 01 - En1999 - IntroductionDocument51 pages01 - En1999 - Introductionnebojsadj6411No ratings yet

- Acid-Base Behaviour of The Period 3 OxidesDocument13 pagesAcid-Base Behaviour of The Period 3 OxidesAdam KhairulNo ratings yet

- Paper ChromatographyDocument7 pagesPaper ChromatographySEHAR KHAN100% (1)

- Military Stallna N KCMSL: DD, FW 672-1 J - M-"."Document3 pagesMilitary Stallna N KCMSL: DD, FW 672-1 J - M-"."Bryan MartinezNo ratings yet

- Nichrome60 Wire Data SheetDocument2 pagesNichrome60 Wire Data SheetvvingtsabtaNo ratings yet

- The Effect of Process Parameters On Electrocoagulation For Paint Effluent Treatment, by Oliyad LenchoDocument80 pagesThe Effect of Process Parameters On Electrocoagulation For Paint Effluent Treatment, by Oliyad LenchoOliyad LenchoNo ratings yet

- D2 Tool SteelDocument1 pageD2 Tool SteelMarwan ShehataNo ratings yet

- Physcial Chemistry 2021 - HW#1Document2 pagesPhyscial Chemistry 2021 - HW#1盧郁禎No ratings yet

- Tutorial 2 NMJ10103 Answer SchemeDocument5 pagesTutorial 2 NMJ10103 Answer SchemeWendy LohNo ratings yet

- DCM EnggDocument30 pagesDCM EnggManil KumarNo ratings yet

- DR Lal Pathlabs: LPL - Lpl-Rohini (National Reference Lab) Sector - 18, Block - E Rohini Delhi 110085Document2 pagesDR Lal Pathlabs: LPL - Lpl-Rohini (National Reference Lab) Sector - 18, Block - E Rohini Delhi 110085Nehul PatilNo ratings yet

- Development of A Validated RP HPLC DAD MDocument8 pagesDevelopment of A Validated RP HPLC DAD Medlyntonic2No ratings yet

- Boiling House EfficiencyDocument14 pagesBoiling House EfficiencyManoj KageNo ratings yet

- Ds210-0-Eng (Fix)Document4 pagesDs210-0-Eng (Fix)Mostafa EidNo ratings yet

- How To Run SIESTADocument35 pagesHow To Run SIESTAVíctor SerranoNo ratings yet

- Well Completion IntroductionDocument21 pagesWell Completion IntroductionJonathan ShimNo ratings yet

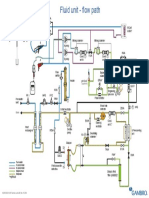

- Ak 96 Fluid Unit - Flow Path: (Upgrade Kit)Document1 pageAk 96 Fluid Unit - Flow Path: (Upgrade Kit)Mounir AngadNo ratings yet

- List of ReferencesDocument17 pagesList of ReferencesYash SankrityayanNo ratings yet

- Exp 4Document6 pagesExp 4RiazNo ratings yet

- 52 BMA Question Solution by DESIGN INTEGRITYDocument5 pages52 BMA Question Solution by DESIGN INTEGRITYMd.Towhidul IslamNo ratings yet

- Manual ElectrodoDocument19 pagesManual Electrodoandrea garciaNo ratings yet

- 1516-Advanced Paper-2 Set-A PDFDocument21 pages1516-Advanced Paper-2 Set-A PDFGame CrashNo ratings yet

- QuotationsDocument7 pagesQuotationsIan PalenNo ratings yet

- Pipe Friction For Laminar...Document6 pagesPipe Friction For Laminar...charanNo ratings yet

- Naming Inorganic CompoundsDocument18 pagesNaming Inorganic Compoundsaika smithNo ratings yet

- Streamer 11Document13 pagesStreamer 11Firas_karboujNo ratings yet

- 2004 GPAT PaperDocument15 pages2004 GPAT PaperRajat GoelNo ratings yet

Cambridge Assessment International Education: Design and Technology 6043/01 October/November 2017

Cambridge Assessment International Education: Design and Technology 6043/01 October/November 2017

Uploaded by

Anotidaishe NyakudyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cambridge Assessment International Education: Design and Technology 6043/01 October/November 2017

Cambridge Assessment International Education: Design and Technology 6043/01 October/November 2017

Uploaded by

Anotidaishe NyakudyaCopyright:

Available Formats

Cambridge Assessment International Education

Cambridge Ordinary Level

DESIGN AND TECHNOLOGY 6043/01

Paper 1 October/November 2017

MARK SCHEME

Maximum Mark: 100

Published

This mark scheme is published as an aid to teachers and candidates, to indicate the requirements of the

examination. It shows the basis on which Examiners were instructed to award marks. It does not indicate the

details of the discussions that took place at an Examiners’ meeting before marking began, which would have

considered the acceptability of alternative answers.

Mark schemes should be read in conjunction with the question paper and the Principal Examiner Report for

Teachers.

Cambridge International will not enter into discussions about these mark schemes.

Cambridge International is publishing the mark schemes for the October/November 2017 series for most

Cambridge IGCSE®, Cambridge International A and AS Level components and some Cambridge O Level

components.

® IGCSE is a registered trademark.

This document consists of 8 printed pages.

© UCLES 2017 [Turn over

6043/01 Cambridge O Level – Mark Scheme October/November

PUBLISHED 2017

Part A

Attempt all questions.

Question Answer Marks

1(a) forstner bit, flat bit,drill, hole saw 1

1(b) coping saw. Jigsaw, reciprocating saw 1

1(c) dividers, compass 1

1(d) centre punch, (masking tape) 1

1(e) template 1

1(f) marker pen, chinagraph pencil 1

Question Answer Marks

2(a) bench hook 1

2(b) holding work still to saw accurately 1

Question Answer Marks

3(a) clear sketch of sash cramp up to 2 2

3(b) clear sketch of bradawl up to 2 2

Question Answer Marks

4 beech does not splinter easily, takes a smooth finish, tough, takes knocks 2

1×2

Question Answer Marks

5 tempering – heat treatment process 1 to increase toughness 1 (reduces 2

hardness)

Question Answer Marks

6(a) Glass Reinforced Plastic (Polyester) 1

6(b) vehicle body, kayak 1

© UCLES 2017 Page 2 of 8

6043/01 Cambridge O Level – Mark Scheme October/November

PUBLISHED 2017

Question Answer Marks

7 micrometer, Vernier calliper, (calliper and rule) 1×2 2

Question Answer Marks

8 plastic cup – expanded polystyrene 1 3

garden bench – teak, iroko, cedar, any other appropriate 1

saucepan – aluminium alloy, stainless steel (copper) 1

Question Answer Marks

9 tie hair back, wear goggles , secure work, any other appropriate 1×2 2

Question Answer Marks

10 brass 1 copper 1 zinc 1 3

bronze 1 copper 1 tin 1

steel, 1 iron 1 carbon 1

© UCLES 2017 Page 3 of 8

6043/01 Cambridge O Level – Mark Scheme October/November

PUBLISHED 2017

Part B

Attempt four questions, two from Section 1 and two from Section 2.

Section 1 – Tools and Materials

Question Answer Marks

11(a) Three tools identified and use stated 6

A – Jack plane (accept smoothing or plane) – preparing flat surface on

wood

B – spokeshave – preparing curved shapes in wood

C – rasp – shaping wood or foamed/expanded plastic 2×3

11(b)(i) vertical adjustment by hand nut, lateral adjustment by lever, good 6

description 2

11(b)(ii) blade depth set by two adjusting screws 1 adjust each screw to ensure

even depth 1

11(b)(iii) slicing, single cut action, good finish in A 1– multiple ‘teeth’ cuts C, not as

good a finish with C 1

11(c)(i) sketch of countersink bit – cutting csk for screw-heads up to 3 6

11(c)(ii) sketch of tap wrench, purpose – turning tap to cut a thread up to 3

© UCLES 2017 Page 4 of 8

6043/01 Cambridge O Level – Mark Scheme October/November

PUBLISHED 2017

Question Answer Marks

12 Material Application Properties 18

Large surfaces available,

Medium Large furniture –

smooth finish, dimensionally

Density wardrobes, table

stable,

Fibreboard tops

Can be veneered, painted

Electrical fittings, Heat resistant, usually dark

Phenol

door handles, irons, products, stiff, hard material,

formaldehyde

saucepan handle can be used in laminates

Aircraft and vehicle Ductile, malleable, corrosion

Duralumin

parts resistant, lightweight

Shop signs, baths,

Good optical qualities, variety

rear light units on

of colours, better impact

Acrylic cars

resistance than glass but

(school based

scratches easily

projects)

Large surfaces available,

Thin ply used for cross grain effect very strong

Plywood laminated shapes, dimensionally stable,

flooring, construction with water resistant adhesive

can be used outdoors

Malleable, ductile, very good

Water pipes, electric

Copper conductivity, heat and

cable, car radiators

electrical

1 for application, 2 for property/ function with link to application

(1 × 6 + 2 × 6)

Question Answer Marks

13(a)(i) Hardwoods Softwoods both for 1 3

Ferrous Non-ferrous both for 1

Thermoplastic thermosetting plastic both for 1

13(a)(ii) appropriate hardwood and softwood 2 6

appropriate Ferrous and non-ferrous 2

appropriate Thermoplastic and thermosetting plastic 2

13(b) explanation should include: 3

Material example e.g. specific hardwood , MDF, acrylic, specific metal 1,

Hazard – dust inhalation , sharp edge , 1 Accept any other specific safety

risks

Precaution – masks, extractors, remove sharp edges, use gloves 1

13(c)(i) explanation should include: 3

product 1

Availability, recyclability, obtaining/processing materials up to 2

© UCLES 2017 Page 5 of 8

6043/01 Cambridge O Level – Mark Scheme October/November

PUBLISHED 2017

Question Answer Marks

13(c)(ii) explanation should include: 3

product 1

function, safety, appearance, market appeal up to 2

Question Answer Marks

14(a)(i) die (die holder) 1

14(a)(ii) forstner bit, (flat bit, small point) 1

14(a)(iii) coping saw, (abrafile), hegner saw 1

14(b)(i) guillotine, shears/tinsnips, fine blade hack saw 12

14(b)(ii) fine tooth saw, dovetail/tenon with guide, (fine blade coping saw with

guide), band saw

14(b)(iii) tenon saw with guide. Jigsaw, band saw

Good communication 1, details of tools, holding work whilst cutting up to 3

3×4

14(c) explanation could include: sharpness, quality finish, speed / ease of use, 3

safety implications – up to 3

© UCLES 2017 Page 6 of 8

6043/01 Cambridge O Level – Mark Scheme October/November

PUBLISHED 2017

Section 2 – Processes

Question Answer Marks

15(a) Material could be – nylon, aluminium, brass, appropriate hardwood 3

(birch/beech)

1

Reasons could be, easy to turn, takes a good finish, aesthetically

pleasing.

1×2

15(b)(i) appropriate turning process including details of tools up to 5 15

15(b)(ii) appropriate application of quality control/measurement up to 5

15(b)(iii) appropriate method of achieving smooth finish up to 5

Question Answer Marks

16 any two processes 18

16(a) hollowing – cutting disc – tinsnips

– annealing –

– bossing mallet/hammer – leather sand bag

– hammer – hollow wooden block, blocking

hammer

– final planishing/finish most stages 9

16(b) injection moulding – split mould prepared

– plastic granules fall from hopper into heating

chamber

– archimedes screw injects into mould

– remove and trim most stages 9

16(c) steam bending – prepare bending jig

– steam strips in chamber until pliable

– hold in bending jig

– remove and trim to shape most stages 9

2×9

© UCLES 2017 Page 7 of 8

6043/01 Cambridge O Level – Mark Scheme October/November

PUBLISHED 2017

Question Answer Marks

17(a) suitable materials

handle – aluminium, stainless steel, brass, (acrylic) nylon rod

base – named hardwood, aluminium, copper acrylic,

polystyrene

17(a)(i) processes could be –vacuum formed, pressed, turned 5

Material 1 process 4

17(a)(ii) processes could be – shaping using heat/jig 5

Material 1 process 4

17(a)(iii) joining process could be – riveting, , using threads, drilling and cementing 5

Material 1 process 4

17(b) appropriate modification 3

Question Answer Marks

18(a)(i) mark out using sliding bevel, engineers blue engineers square, scriber 12

Saw/file to shape

Flux and braze

Clean up most stages 6

18(a)(ii) prepare former

Cut veneer/thin ply to shape

Glue and alternate grain

Clamp up/vacuum bag

Remove trim to shape/finish most stages 6

18(a)(iii) cut length of rectangular section nylon

Mill (saw and file) shoulders

File rounded shape

Finish

Or injection moulded

Create two part mould

Heat plastic granules, preheat mould

Inject plastic

Water cool mould

Eject part/remove sprue most stages 6

Accept other appropriate processes

2×6

18(b) appropriate method of securely attaching the seat most stages 6 6

© UCLES 2017 Page 8 of 8

You might also like

- 3126 01 MS 4RP AFP tcm142-665777Document10 pages3126 01 MS 4RP AFP tcm142-665777Kenzy Maher100% (3)

- Cambridge Secondary 1 Checkpoint: Cambridge Assessment International EducationDocument10 pagesCambridge Secondary 1 Checkpoint: Cambridge Assessment International Educationahmed saad100% (3)

- Essentials PDF 2021Document8 pagesEssentials PDF 2021Ngô Tuấn KiệtNo ratings yet

- Singapore Secondary 1 End Year Examination For MathDocument10 pagesSingapore Secondary 1 End Year Examination For Mathshandlysoo50% (2)

- BOUNDS-Analysis of Properties of Fiber Composites With Anisotropic Constituents PDFDocument8 pagesBOUNDS-Analysis of Properties of Fiber Composites With Anisotropic Constituents PDFRaghavendra PrasadNo ratings yet

- Cambridge O Level: Design & Technology 6043/32 October/November 2021Document10 pagesCambridge O Level: Design & Technology 6043/32 October/November 2021Ozan EffendiNo ratings yet

- MATHEMATICS Compulsory Part Paper 1: Question-Answer BookDocument5 pagesMATHEMATICS Compulsory Part Paper 1: Question-Answer Book20/21-5B-(05) HoMeiYi/何美誼No ratings yet

- 5070 w17 Ms 42 PDFDocument9 pages5070 w17 Ms 42 PDFdR SHAMMIR AHMEDNo ratings yet

- 3123 01 MS 4RP AFP tcm142-699263Document10 pages3123 01 MS 4RP AFP tcm142-699263Nigar RasulzadaNo ratings yet

- Cambridge Assessment International Education: Chemistry 0620/62 October/November 2017Document4 pagesCambridge Assessment International Education: Chemistry 0620/62 October/November 2017Asmaa El SawyNo ratings yet

- June 2017 QP - Paper 1 OCR (A) Chemistry A-LevelDocument26 pagesJune 2017 QP - Paper 1 OCR (A) Chemistry A-LevelRisha SelvaNo ratings yet

- End of Year Examination Paper 1 - Sec 1 Math 1BDocument8 pagesEnd of Year Examination Paper 1 - Sec 1 Math 1Btiaachan14No ratings yet

- Edexcel Foundation PredictedDocument17 pagesEdexcel Foundation PredictedSara DuaNo ratings yet

- Cambridge Assessment International Education: English As A Second Language 0510/32 October/November 2017Document3 pagesCambridge Assessment International Education: English As A Second Language 0510/32 October/November 2017Alag MohammedNo ratings yet

- Edexcel Chemistry Unit 1 June 2010 GceDocument28 pagesEdexcel Chemistry Unit 1 June 2010 Gceaym3nNo ratings yet

- Chemistry 2022Document24 pagesChemistry 202220sirohiuNo ratings yet

- Year 9 Baseline Test - CalculatorDocument5 pagesYear 9 Baseline Test - CalculatornellytusiimeNo ratings yet

- GCSE Higher Maths Practice Paper 2 (Calculator)Document13 pagesGCSE Higher Maths Practice Paper 2 (Calculator)Polaroid educationNo ratings yet

- October 2022 MsDocument10 pagesOctober 2022 Msesraagalal3100% (1)

- Adobe Scan Mar 06, 2024Document7 pagesAdobe Scan Mar 06, 2024Simbai MuganoNo ratings yet

- Cambridge Assessment International Education: Chemistry 9701/41 October/November 2017Document13 pagesCambridge Assessment International Education: Chemistry 9701/41 October/November 2017Tony KassangaNo ratings yet

- JSSC JE General Engg. & GK Official Paper-I (Held On - 03 July, 2022)Document25 pagesJSSC JE General Engg. & GK Official Paper-I (Held On - 03 July, 2022)kumar swatantraNo ratings yet

- In Unit2 Higher Nov2010Document16 pagesIn Unit2 Higher Nov2010Heavenly SinNo ratings yet

- Solution Report For: Home My Test My ProfileDocument6 pagesSolution Report For: Home My Test My ProfilerajuNo ratings yet

- Cambridge IGCSE ™: English As A Second Language 0511/22Document11 pagesCambridge IGCSE ™: English As A Second Language 0511/22Wayne WeiNo ratings yet

- Cambridge International Examinations: This Document Consists of 6 Printed PagesDocument6 pagesCambridge International Examinations: This Document Consists of 6 Printed PagesBara' HammadehNo ratings yet

- Chemistry: Edexcel GCEDocument24 pagesChemistry: Edexcel GCEOmar HashemNo ratings yet

- Cambridge International Examinations: Chemistry 0620/61 May/June 2017Document4 pagesCambridge International Examinations: Chemistry 0620/61 May/June 2017Layal GhaddarNo ratings yet

- Chemistry: Pearson EdexcelDocument24 pagesChemistry: Pearson EdexcelApollo WongNo ratings yet

- Ieb gr9 Maths 2016Document13 pagesIeb gr9 Maths 2016sharonmangundu036No ratings yet

- Cambridge International Examinations: Chemistry 0620/61 May/June 2017Document4 pagesCambridge International Examinations: Chemistry 0620/61 May/June 2017...No ratings yet

- Cambridge Assessment International Education: Chemistry 0620/63 October/November 2017Document5 pagesCambridge Assessment International Education: Chemistry 0620/63 October/November 2017jadenjedidiahNo ratings yet

- IGCSE - Listening-Mark Scheme-May 20thDocument4 pagesIGCSE - Listening-Mark Scheme-May 20thAshley WilsonNo ratings yet

- Ial WCH05 01 Nov19 PDFDocument28 pagesIal WCH05 01 Nov19 PDFsammam mahdi samiNo ratings yet

- June 2019 QPDocument32 pagesJune 2019 QPkreoalt123No ratings yet

- Mathematics IDocument21 pagesMathematics IMohamed MubarakNo ratings yet

- Wednesday 9 January 2019: ChemistryDocument24 pagesWednesday 9 January 2019: ChemistryAhmad MohdNo ratings yet

- Specialist Mathematics: Written Examination 1Document16 pagesSpecialist Mathematics: Written Examination 1Eden ChanNo ratings yet

- Mark Scheme 3, English and Science PDFDocument36 pagesMark Scheme 3, English and Science PDFPonytailNo ratings yet

- English Paper 1 - 2023Document10 pagesEnglish Paper 1 - 2023suganya deviNo ratings yet

- Stage - 3 - English - Paper - 1 - Progression Test, 2023, Past Paper - MSDocument10 pagesStage - 3 - English - Paper - 1 - Progression Test, 2023, Past Paper - MSTr AstellaNo ratings yet

- Cambridge IGCSE ™: English As A Second Language 0510/12Document9 pagesCambridge IGCSE ™: English As A Second Language 0510/12sanctus.madhuranivashiniNo ratings yet

- 2001 P1 PDFDocument16 pages2001 P1 PDFErwin CahanapNo ratings yet

- Paper 5 November 2016 Mark SchemeDocument7 pagesPaper 5 November 2016 Mark SchememahahajNo ratings yet

- WBPSC Je Me 2018 Question PaperDocument12 pagesWBPSC Je Me 2018 Question Paperonlinebiz0032No ratings yet

- Cambridge Assessment International Education: Biology 0610/33 October/November 2017Document11 pagesCambridge Assessment International Education: Biology 0610/33 October/November 2017123 456No ratings yet

- Chemistry: Pearson EdexcelDocument24 pagesChemistry: Pearson EdexcelShopneel MHNo ratings yet

- F1 Math 2014 1stexam Paper1 Question BookDocument2 pagesF1 Math 2014 1stexam Paper1 Question BookyujuuumjiNo ratings yet

- Cambridge Secondary 1 CheckpointDocument12 pagesCambridge Secondary 1 CheckpointDương Ngọc Cường50% (4)

- 9260 92602E International Gcse Mathematics Specimen Paper 2016 v1Document26 pages9260 92602E International Gcse Mathematics Specimen Paper 2016 v1amr.taman41No ratings yet

- Cambridge Secondary 1 CheckpointDocument12 pagesCambridge Secondary 1 CheckpointDương Ngọc Cường50% (2)

- End of Year Examination Paper 2 - Sec 1 Math 1BDocument8 pagesEnd of Year Examination Paper 2 - Sec 1 Math 1Btiaachan14No ratings yet

- 0625 s17 Ms 63 PDFDocument5 pages0625 s17 Ms 63 PDFpriyaNo ratings yet

- Quick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesFrom EverandQuick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesRating: 3 out of 5 stars3/5 (2)

- Integration of One-forms on P-adic Analytic Spaces. (AM-162)From EverandIntegration of One-forms on P-adic Analytic Spaces. (AM-162)No ratings yet

- NYAKUDYA SecurityDocument5 pagesNYAKUDYA SecurityAnotidaishe NyakudyaNo ratings yet

- NYAKUDYA Grading SystemDocument10 pagesNYAKUDYA Grading SystemAnotidaishe NyakudyaNo ratings yet

- BS Notes Bones 2017Document332 pagesBS Notes Bones 2017Anotidaishe NyakudyaNo ratings yet

- Trade Regulations OverviewDocument4 pagesTrade Regulations OverviewAnotidaishe NyakudyaNo ratings yet

- 2020 Fee Schedule: Hillcrest Christian CollegeDocument1 page2020 Fee Schedule: Hillcrest Christian CollegeAnotidaishe NyakudyaNo ratings yet

- Cala SecurityDocument5 pagesCala SecurityAnotidaishe NyakudyaNo ratings yet

- Holdings in The Crop Science LibraryDocument27 pagesHoldings in The Crop Science LibraryAnotidaishe NyakudyaNo ratings yet

- Samson Gym Booking System: Candidatename: Anotidaishe NyakudyaDocument33 pagesSamson Gym Booking System: Candidatename: Anotidaishe NyakudyaAnotidaishe NyakudyaNo ratings yet

- Shalom Freight ManagementDocument37 pagesShalom Freight ManagementAnotidaishe NyakudyaNo ratings yet

- Zimbabwe School Examinations CouncilDocument16 pagesZimbabwe School Examinations CouncilAnotidaishe NyakudyaNo ratings yet

- Secondary Catalogue ZimbabweDocument23 pagesSecondary Catalogue ZimbabweAnotidaishe Nyakudya0% (1)

- AttachmentDocument308 pagesAttachmentAnotidaishe NyakudyaNo ratings yet

- Crop Science Progress and ProspectsDocument33 pagesCrop Science Progress and ProspectsAnotidaishe NyakudyaNo ratings yet

- Building Technology and Design Syllabus: Forms 1 - 4Document52 pagesBuilding Technology and Design Syllabus: Forms 1 - 4Anotidaishe Nyakudya100% (1)

- Technical Data Sheet: Polyethylene Terephthalate FlakesDocument2 pagesTechnical Data Sheet: Polyethylene Terephthalate Flakesdorra snoussiNo ratings yet

- 01 - En1999 - IntroductionDocument51 pages01 - En1999 - Introductionnebojsadj6411No ratings yet

- Acid-Base Behaviour of The Period 3 OxidesDocument13 pagesAcid-Base Behaviour of The Period 3 OxidesAdam KhairulNo ratings yet

- Paper ChromatographyDocument7 pagesPaper ChromatographySEHAR KHAN100% (1)

- Military Stallna N KCMSL: DD, FW 672-1 J - M-"."Document3 pagesMilitary Stallna N KCMSL: DD, FW 672-1 J - M-"."Bryan MartinezNo ratings yet

- Nichrome60 Wire Data SheetDocument2 pagesNichrome60 Wire Data SheetvvingtsabtaNo ratings yet

- The Effect of Process Parameters On Electrocoagulation For Paint Effluent Treatment, by Oliyad LenchoDocument80 pagesThe Effect of Process Parameters On Electrocoagulation For Paint Effluent Treatment, by Oliyad LenchoOliyad LenchoNo ratings yet

- D2 Tool SteelDocument1 pageD2 Tool SteelMarwan ShehataNo ratings yet

- Physcial Chemistry 2021 - HW#1Document2 pagesPhyscial Chemistry 2021 - HW#1盧郁禎No ratings yet

- Tutorial 2 NMJ10103 Answer SchemeDocument5 pagesTutorial 2 NMJ10103 Answer SchemeWendy LohNo ratings yet

- DCM EnggDocument30 pagesDCM EnggManil KumarNo ratings yet

- DR Lal Pathlabs: LPL - Lpl-Rohini (National Reference Lab) Sector - 18, Block - E Rohini Delhi 110085Document2 pagesDR Lal Pathlabs: LPL - Lpl-Rohini (National Reference Lab) Sector - 18, Block - E Rohini Delhi 110085Nehul PatilNo ratings yet

- Development of A Validated RP HPLC DAD MDocument8 pagesDevelopment of A Validated RP HPLC DAD Medlyntonic2No ratings yet

- Boiling House EfficiencyDocument14 pagesBoiling House EfficiencyManoj KageNo ratings yet

- Ds210-0-Eng (Fix)Document4 pagesDs210-0-Eng (Fix)Mostafa EidNo ratings yet

- How To Run SIESTADocument35 pagesHow To Run SIESTAVíctor SerranoNo ratings yet

- Well Completion IntroductionDocument21 pagesWell Completion IntroductionJonathan ShimNo ratings yet

- Ak 96 Fluid Unit - Flow Path: (Upgrade Kit)Document1 pageAk 96 Fluid Unit - Flow Path: (Upgrade Kit)Mounir AngadNo ratings yet

- List of ReferencesDocument17 pagesList of ReferencesYash SankrityayanNo ratings yet

- Exp 4Document6 pagesExp 4RiazNo ratings yet

- 52 BMA Question Solution by DESIGN INTEGRITYDocument5 pages52 BMA Question Solution by DESIGN INTEGRITYMd.Towhidul IslamNo ratings yet

- Manual ElectrodoDocument19 pagesManual Electrodoandrea garciaNo ratings yet

- 1516-Advanced Paper-2 Set-A PDFDocument21 pages1516-Advanced Paper-2 Set-A PDFGame CrashNo ratings yet

- QuotationsDocument7 pagesQuotationsIan PalenNo ratings yet

- Pipe Friction For Laminar...Document6 pagesPipe Friction For Laminar...charanNo ratings yet

- Naming Inorganic CompoundsDocument18 pagesNaming Inorganic Compoundsaika smithNo ratings yet

- Streamer 11Document13 pagesStreamer 11Firas_karboujNo ratings yet

- 2004 GPAT PaperDocument15 pages2004 GPAT PaperRajat GoelNo ratings yet