Professional Documents

Culture Documents

MT - Area Wall Reheat - Paiton 9 - Rev3

MT - Area Wall Reheat - Paiton 9 - Rev3

Uploaded by

Lexo SitompulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MT - Area Wall Reheat - Paiton 9 - Rev3

MT - Area Wall Reheat - Paiton 9 - Rev3

Uploaded by

Lexo SitompulCopyright:

Available Formats

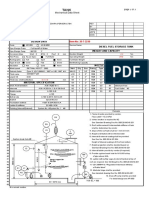

PT PEMBANGKITAN JAWA BALI No. Dok.

:

PJB INTEGRATED MANAGEMENT SYSTEM Tgl. Terbit :

FORM UJI Revisi :

MAGNETIC PARTICLE INSPECTION Halaman : 1 of 3

Site : UBJOM Paiton Manufaktur : Tahun QP No. FU No.

Unit : 9 Inspeksi : ME 2021 OEM Doc. No.

Name of Part : Fin Tube (Area Wall Reheat) - Right Quantity : 1 set

Material : Steel Surface Temp : -

Magnetizing Methode : Yoke Maker : Magnaflux

Magnetic Particles : MAGNAGLO 14-HF Batch No. : -

Classification : Wet MP Application : Aerosol Cans

: Fluorescence

Test Area : Weld Area Procedur No : ASME Sec. V Art.7

Place of Test : Boiler Furnace Acceptance Std. :

Test Result : REPAIR Inspection Date : 10-Feb-21

T63

penomoran tube dari sisi front-rear

T63

Note : Note : Note :

tidak ada indikasi crack tidak ada indikasi crack indikasi crack pada fin tube

note: dibeberapa titik pengujian MT kurang maksimal karena keterbatasan alat untuk melakukan cleaning (kondisi banyak kerak)

RECOMMENDATION ACCEPTED/REWORK/REPAIR

(by Quality Control) dilakukan repair dengan menghilangkan crack terlebih dahulu

Measuring Tool: Magnaflux MPI, UV Lamp, Yoke

Description Tested/measured by Coordinator QualityControl Witness

Name Mufid Ali B. Wedha Adji L. Andy Wahyu Arianto

Signature

Date 10-Feb-21 10-Feb-21

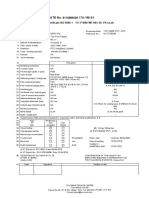

PT PEMBANGKITAN JAWA BALI No. Dok. :

PJB INTEGRATED MANAGEMENT SYSTEM Tgl. Terbit :

FORM UJI Revisi :

MAGNETIC PARTICLE INSPECTION Halaman : 2 of 3

Site : UBJOM Paiton Manufaktur : Tahun QP No. FU No.

Unit : 9 Inspeksi : ME 2021 OEM Doc. No.

Name of Part : Fin Tube (Area Wall Reheat) - Right Quantity : 1 set

Material : Steel Surface Temp : -

Magnetizing Methode : Yoke Maker : Magnaflux

Magnetic Particles : MAGNAGLO 14-HF Batch No. : -

Classification : Wet MP Application : Aerosol Cans

: Fluorescence

Test Area : Weld Area Procedur No : ASME Sec. V Art.7

Place of Test : Boiler Furnace Acceptance Std. :

Test Result : REPAIR Inspection Date : 12-Feb-21

T119

T117

indikasi crack pada fin tube no. T117, T119, T129

penomoran tube dari sisi front-rear

T117

Note : Note : Note :

tidak ada indikasi crack tidak ada indikasi crack indikasi crack pada fin tube

note: dibeberapa titik pengujian MT kurang maksimal karena keterbatasan alat untuk melakukan cleaning (kondisi banyak kerak)

RECOMMENDATION ACCEPTED/REWORK/REPAIR

(by Quality Control) dilakukan repair dengan menghilangkan crack terlebih dahulu

Measuring Tool: Magnaflux MPI, UV Lamp, Yoke

Description Tested/measured by Coordinator QualityControl Witness

Name Mufid Ali B. Wedha Adji L. Andy Wahyu Arianto

Signature

Date 12-Feb-21 12-Feb-21

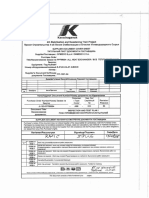

PT PEMBANGKITAN JAWA BALI No. Dok. :

PJB INTEGRATED MANAGEMENT SYSTEM Tgl. Terbit :

FORM UJI Revisi :

MAGNETIC PARTICLE INSPECTION Halaman : 3 of 3

Site : UBJOM Paiton Manufaktur : Tahun QP No. FU No.

Unit : 9 Inspeksi : ME 2021 OEM Doc. No.

Name of Part : Fin Tube (Area Wall Reheat) - Left Quantity : 1 set

Material : Steel Surface Temp : -

Magnetizing Methode : Yoke Maker : Magnaflux

Magnetic Particles : MAGNAGLO 14-HF Batch No. : -

Classification : Wet MP Application : Aerosol Cans

: Fluorescence

Test Area : Weld Area Procedur No : ASME Sec. V Art.7

Place of Test : Boiler Furnace Acceptance Std. :

Test Result : REPAIR Inspection Date : 14-Feb-21

T51

penomoran tube sesuai wall reheat dari rear ke front

T107 T51

Note : Note : Note :

tidak ada indikasi crack indikasi crack pada fin tube indikasi crack pada fin tube

note: dibeberapa titik pengujian MT kurang maksimal karena keterbatasan alat untuk melakukan cleaning (kondisi banyak kerak)

RECOMMENDATION ACCEPTED/REWORK/REPAIR repair welding pada fintube tube T107

dilakukan retubing (tube pernah dilakukan overlay karena riwayat indikasi overheat T51)

Measuring Tool: Magnaflux MPI, UV Lamp, Yoke

Description Tested/measured by Coordinator QualityControl Witness

Name Mufid Ali B. Wedha Adji L. Andy Wahyu Arianto

Signature

Date 10-Feb-21 14-Feb-21

You might also like

- Painting Inspection Report Final CoatDocument3 pagesPainting Inspection Report Final Coatabdulgafoor54100% (1)

- Itr Steel StruktureDocument8 pagesItr Steel StruktureIjoel PutraNo ratings yet

- Exportlayers DWG ISO13567Document6 pagesExportlayers DWG ISO13567Naassom VazNo ratings yet

- Elbow 0,5-3000 NPT - OKDocument1 pageElbow 0,5-3000 NPT - OKJovianto PrisilaNo ratings yet

- Int-Aim-231887 PT 06-15-23Document2 pagesInt-Aim-231887 PT 06-15-23Joshua ClaytonNo ratings yet

- PT PLN Nusantara Power Integrated Management System Form Uji Visual InspectionDocument4 pagesPT PLN Nusantara Power Integrated Management System Form Uji Visual InspectionDidit Gencar LaksanaNo ratings yet

- Procedure No.: Liquid Penetrant TestDocument4 pagesProcedure No.: Liquid Penetrant Testคุณพ่อน้อง บิ๊กบอสNo ratings yet

- PT UT Journal Bearing Turbine 1 Ropa #2Document9 pagesPT UT Journal Bearing Turbine 1 Ropa #2Adjie Aza100% (1)

- Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairDocument3 pagesNon Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairAkhmad RamdaniNo ratings yet

- 10-03-2020 C1 Gland Steam Superheater - MTDocument6 pages10-03-2020 C1 Gland Steam Superheater - MTDave CheungNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Data Sheet For Magnetic Type Level GaugeDocument5 pagesData Sheet For Magnetic Type Level GaugeJaya RamNo ratings yet

- 51Q-BU-0010 - Rev.1 Plaster Works ChecklistDocument1 page51Q-BU-0010 - Rev.1 Plaster Works Checklistnazim7No ratings yet

- COC 2nd LotDocument3 pagesCOC 2nd LotVinay YadavNo ratings yet

- Test Sheet: PT Pembangkitan Jawa Bali Services Siap Integrated Management SystemDocument4 pagesTest Sheet: PT Pembangkitan Jawa Bali Services Siap Integrated Management SystemAdjie AzaNo ratings yet

- Elbow 3 S80 180D SRDocument1 pageElbow 3 S80 180D SRJovianto PrisilaNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- Int Aim 231787 PT 14 1302&03Document1 pageInt Aim 231787 PT 14 1302&03Joshua ClaytonNo ratings yet

- Mir Pipe NewDocument11 pagesMir Pipe NewDimas agungNo ratings yet

- Project Final Vendor Dossier Summary - 15.10.2015Document39 pagesProject Final Vendor Dossier Summary - 15.10.2015rajuNo ratings yet

- Pad Eye ACS 10Document10 pagesPad Eye ACS 10irnaldi yoza wijayaNo ratings yet

- Constrologix Engineering & Research Services Pvt. LTD.: Test ReportDocument1 pageConstrologix Engineering & Research Services Pvt. LTD.: Test ReportBharat KoraleNo ratings yet

- BH MT 199 2022 T&aDocument1 pageBH MT 199 2022 T&aDeanz KmcNo ratings yet

- CNT230022-5 C3 HRSG LP Drum - MTreportDocument6 pagesCNT230022-5 C3 HRSG LP Drum - MTreportDave CheungNo ratings yet

- Daily Painting Report System P 01ndDocument49 pagesDaily Painting Report System P 01ndArung IdNo ratings yet

- C6 Turbine LP Cylinder Casing (Bottom Half) - MPIDocument7 pagesC6 Turbine LP Cylinder Casing (Bottom Half) - MPIDave CheungNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- 51Q-BU-0002 - Rev.1 Protected Membrane Roofing Roof Water Proofing ChecklistDocument1 page51Q-BU-0002 - Rev.1 Protected Membrane Roofing Roof Water Proofing Checklistnazim7No ratings yet

- Isulation GasketDocument1 pageIsulation GasketKhánh TrầnNo ratings yet

- VT - Furnace Sootblower 15 - Paiton 9Document2 pagesVT - Furnace Sootblower 15 - Paiton 9Lexo SitompulNo ratings yet

- Bao Cao PT Ba Ria-04Document4 pagesBao Cao PT Ba Ria-04Sang Nguyen QuangNo ratings yet

- Hex Bushing 0,75 X 0,5Document1 pageHex Bushing 0,75 X 0,5Jovianto PrisilaNo ratings yet

- 107.8182.MPI - Pre.Unit.730395.Fuel TankDocument2 pages107.8182.MPI - Pre.Unit.730395.Fuel TankHerr DdimanNo ratings yet

- Position Actual Dimension Remark Drawing / Sketch:: Pt. DffiDocument1 pagePosition Actual Dimension Remark Drawing / Sketch:: Pt. DffiJovianto PrisilaNo ratings yet

- Inspection Report and Leak Test FormatDocument2 pagesInspection Report and Leak Test Formatmujahed_muhammedNo ratings yet

- Atch Igt SPK DSDocument1 pageAtch Igt SPK DSSudar MyshaNo ratings yet

- IMIR - 107 of Rectangle Hollow Section For Group IIDocument1 pageIMIR - 107 of Rectangle Hollow Section For Group IIFredin FrancisNo ratings yet

- 17-03-2020 C1 Turbine HP Stop Valve Cover Bolt, Nut - FMPIDocument7 pages17-03-2020 C1 Turbine HP Stop Valve Cover Bolt, Nut - FMPIDave CheungNo ratings yet

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Document4 pagesENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronNo ratings yet

- 17-03-2020 C1 Turbine HP Stop Valve - Cover Bolt - FMPIDocument4 pages17-03-2020 C1 Turbine HP Stop Valve - Cover Bolt - FMPIDave CheungNo ratings yet

- NDT Report - Old.Turbine BearingsDocument3 pagesNDT Report - Old.Turbine BearingsOm Ar TanNo ratings yet

- Compressive Strength of Concrete Cylinders: PTJ-SGCP-CIV-39737-39728-39765-39768 CST RFI REF:PTJ-SGCP-CIV-40802Document30 pagesCompressive Strength of Concrete Cylinders: PTJ-SGCP-CIV-39737-39728-39765-39768 CST RFI REF:PTJ-SGCP-CIV-40802Mohamed RamadanNo ratings yet

- Ecs 18.012 Pompa BFP Ip LabuanDocument1 pageEcs 18.012 Pompa BFP Ip LabuanAdeImanudinNo ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- Magnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Document5 pagesMagnetic Particle Inspection Reference: Goodrich NDT Manual Chapter: 32-40-75Dinesh Gupta100% (1)

- Certificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDocument1 pageCertificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDeepak Das100% (1)

- M22 TC Bolts - Material Sampling RecordDocument1 pageM22 TC Bolts - Material Sampling RecordmameniqNo ratings yet

- Packaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorDocument6 pagesPackaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorNuzul FurqonyNo ratings yet

- Request For Inspection: Tripatra-Samsung ConsortiumDocument12 pagesRequest For Inspection: Tripatra-Samsung Consortiumcrys suryo pNo ratings yet

- A05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFDocument14 pagesA05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFfdfazfzNo ratings yet

- LTJ-PGAS-GTLT-EN-DS-001 Buffer Tank Data SheetDocument15 pagesLTJ-PGAS-GTLT-EN-DS-001 Buffer Tank Data SheetsswahyudiNo ratings yet

- LNG Booster Pump DatasheetDocument7 pagesLNG Booster Pump DatasheetsswahyudiNo ratings yet

- 5 MAY Kaser TubesDocument3 pages5 MAY Kaser Tubesmini p shende100% (1)

- U2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1ADocument14 pagesU2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1ATommy ArjanggiNo ratings yet

- Mpi CB, LBDocument7 pagesMpi CB, LBSuhari AriNo ratings yet

- 23-01-24. Comp MTA 6 Plant SignDocument4 pages23-01-24. Comp MTA 6 Plant Signwahyudi140417No ratings yet

- AHMSW 8 Fiche de PhaseDocument12 pagesAHMSW 8 Fiche de PhaseBOUBAKER LOGBINo ratings yet

- NTPC DPTDocument495 pagesNTPC DPTKuppan Srinivasan100% (1)

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantFrom EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryRating: 4 out of 5 stars4/5 (5)

- HRC Din Fuses - 3naDocument20 pagesHRC Din Fuses - 3naDilip VemulaNo ratings yet

- PT Gunanusa Utama Fabricators PT Gunanusa Utama Fabricators PT Gunanusa Utama FabricatorsDocument2 pagesPT Gunanusa Utama Fabricators PT Gunanusa Utama Fabricators PT Gunanusa Utama FabricatorsRiandi HartartoNo ratings yet

- Diederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During TunnelingDocument28 pagesDiederichs Et Al. 2004 Damage Initiation and Propagation in Hard Rock During Tunnelingfatihkaya_16No ratings yet

- Continuous T BeamDocument27 pagesContinuous T BeamMar Martillano100% (1)

- Pumping Station Design CalculationDocument67 pagesPumping Station Design CalculationAmit PatelNo ratings yet

- MultiCore - ClassD - ThickWall IS19642Document1 pageMultiCore - ClassD - ThickWall IS19642Tumbin DilseNo ratings yet

- 107 ConcreteDocument44 pages107 Concretenoadspls2029No ratings yet

- Company Profile - EskayDocument4 pagesCompany Profile - EskayNarasimha PrasadNo ratings yet

- IS 13920 - 1993vs2016Document14 pagesIS 13920 - 1993vs2016RonakShahNo ratings yet

- Thermodynamics DnotesDocument122 pagesThermodynamics DnotesatcrooksNo ratings yet

- CFD Analysis of Electronic Cabinet With High Power Devices and Fin Heat SinkDocument7 pagesCFD Analysis of Electronic Cabinet With High Power Devices and Fin Heat SinkPrateek thakurNo ratings yet

- Failure Analysis of A Gas Turbine BladeDocument10 pagesFailure Analysis of A Gas Turbine BladeJoao Vitor de Almeida Soares100% (1)

- Kerto Manual LVL Mechanical PropertiesDocument6 pagesKerto Manual LVL Mechanical PropertiesTiago GonçalvesNo ratings yet

- ETA 11 0030 RB Screws 2019Document68 pagesETA 11 0030 RB Screws 2019Frits BouwknechtNo ratings yet

- Patent LeatherDocument10 pagesPatent LeathervinothjohnnashNo ratings yet

- Tds 1323203 enDocument2 pagesTds 1323203 enMartín BaezaNo ratings yet

- MEP SpecsDocument737 pagesMEP Specsmahadeva1No ratings yet

- Presentation On Industrial Training at Thermal Power Plan, GandhinagarDocument21 pagesPresentation On Industrial Training at Thermal Power Plan, GandhinagarChauhan Sudhir100% (1)

- Introduction To Eurocodes: The Eurocode FamilyDocument8 pagesIntroduction To Eurocodes: The Eurocode FamilySewGuanNo ratings yet

- PK VALVE Catalogue PDFDocument148 pagesPK VALVE Catalogue PDFMayur PatelNo ratings yet

- Factored Reaction (W) Factored Tensile Force On The Plate W/2Document9 pagesFactored Reaction (W) Factored Tensile Force On The Plate W/2Sudhanshu Shekhar SinglaNo ratings yet

- Investigation of The Gelatinization and Extrusion Processes of Corn StarchDocument8 pagesInvestigation of The Gelatinization and Extrusion Processes of Corn StarchRobertaSouzaNo ratings yet

- Soni's BunglowDocument10 pagesSoni's Bunglowkukadiya127_48673372No ratings yet

- Amana Ref S S 16021484r1 PDFDocument65 pagesAmana Ref S S 16021484r1 PDFaderlochNo ratings yet

- Combination Air Valve For Wastewater: DescriptionDocument4 pagesCombination Air Valve For Wastewater: DescriptionVanderson LimaNo ratings yet

- Phase Transformation in SteelDocument5 pagesPhase Transformation in SteelBobby Yusuf HakaNo ratings yet

- ACB10 Technical Data April10Document12 pagesACB10 Technical Data April10RK TekNo ratings yet

- Lecture 1.2 Features of DamDocument15 pagesLecture 1.2 Features of DamChanako DaneNo ratings yet

- Fin Cat S17 Sheet Products PDFDocument14 pagesFin Cat S17 Sheet Products PDFMurray TurnerNo ratings yet