Professional Documents

Culture Documents

Series 5200: Materials of Construction

Series 5200: Materials of Construction

Uploaded by

Gỗ MộcCopyright:

Available Formats

You might also like

- (4.2) HM ManualDocument28 pages(4.2) HM ManualGỗ Mộc0% (1)

- Mounting and Operating Instructions Electrical Position ControllerDocument44 pagesMounting and Operating Instructions Electrical Position ControllerGỗ Mộc100% (1)

- SMM1 & SMM 2Document30 pagesSMM1 & SMM 2Hafizan Hanafiah100% (3)

- SmartSlope C 110 Installation Manual PDFDocument5 pagesSmartSlope C 110 Installation Manual PDFAivan Dredd PunzalanNo ratings yet

- 1.concentric Butterfly Valve in Various ApplicationDocument10 pages1.concentric Butterfly Valve in Various ApplicationMaciekNo ratings yet

- VLATB110-Rack & Pinion & Scotch Yoke Actuators TBDocument18 pagesVLATB110-Rack & Pinion & Scotch Yoke Actuators TBBoy AlfredoNo ratings yet

- Advanced V-Control Ball ValvesDocument8 pagesAdvanced V-Control Ball ValvesNGUYEN VAN TUAN EPPNo ratings yet

- Model 590 Control Valves: Technical Sales BulletinDocument12 pagesModel 590 Control Valves: Technical Sales BulletinRyan DuhonNo ratings yet

- ISIC Heavy Duty Pneumatic ActuatorDocument14 pagesISIC Heavy Duty Pneumatic Actuatoraizat91.acisNo ratings yet

- Series 2200 TechBro 041812Document8 pagesSeries 2200 TechBro 041812GianniNo ratings yet

- Pneumatische-Schwenkantriebe enDocument20 pagesPneumatische-Schwenkantriebe enSasawahyu WahyukuNo ratings yet

- Product BrochuresDocument6 pagesProduct BrochuresTanjong Minyak Car Wash Sdn BhdNo ratings yet

- Roos ValveDocument6 pagesRoos ValveSubhi MahmoudNo ratings yet

- Yarway Series 7100Document12 pagesYarway Series 7100Cecep AtmegaNo ratings yet

- CSM - Modular ValvesDocument2 pagesCSM - Modular Valvesramon slepickaNo ratings yet

- Bermad: Level Control ValveDocument4 pagesBermad: Level Control ValveSupolNo ratings yet

- Power & Severe ServiceDocument220 pagesPower & Severe ServiceJeremiah CayondongNo ratings yet

- Check Valve - Type CK4ADocument4 pagesCheck Valve - Type CK4AHuong QuangNo ratings yet

- DelVal Series 56 - 57 (PC - BFV.016.00 - 00)Document8 pagesDelVal Series 56 - 57 (PC - BFV.016.00 - 00)Prathamesh Pradeep MashilkarNo ratings yet

- Ezy Torque Pan IndustriesDocument1 pageEzy Torque Pan IndustriesRakefsNo ratings yet

- Performance: Palfinger Advanced Package As Standard!Document4 pagesPerformance: Palfinger Advanced Package As Standard!Joel VillalbaNo ratings yet

- TT OpEXL Eccentric Plug Rotary Valve BrochureDocument16 pagesTT OpEXL Eccentric Plug Rotary Valve BrochureSergio Gana GonzalezNo ratings yet

- E A - Style I Complete - SectionDocument16 pagesE A - Style I Complete - SectionWilliam VazquezNo ratings yet

- New G 2016Document5 pagesNew G 2016Andrs AlvearNo ratings yet

- Bray Controls - Manual OperatorsDocument2 pagesBray Controls - Manual OperatorsChandravadanNo ratings yet

- Válvula DireccionalDocument30 pagesVálvula DireccionalDiego DuranNo ratings yet

- Subsea Actuation: Valves and ActuatorsDocument20 pagesSubsea Actuation: Valves and ActuatorsSeymur AkbarovNo ratings yet

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- Series 2200 Butterfly Valve Product BrochureDocument18 pagesSeries 2200 Butterfly Valve Product BrochureSandesh KambleNo ratings yet

- System Valves v411 v431 AlcDocument5 pagesSystem Valves v411 v431 Alcmohamed mansourNo ratings yet

- Eclips Orfice ValveDocument4 pagesEclips Orfice Valveاحمد الجزار2007No ratings yet

- E4036Document2 pagesE4036Pablo Cardenas SandovalNo ratings yet

- Automan Series 20Document8 pagesAutoman Series 20kumaraguruNo ratings yet

- Lfgproducts Brochure WebDocument10 pagesLfgproducts Brochure WebAldo Germán Pavez MoraNo ratings yet

- PK 72002 Ficha TecnicaDocument4 pagesPK 72002 Ficha Tecnicamaquinariayequipos.andreyNo ratings yet

- Valvula YarwayDocument12 pagesValvula YarwayRobert VillavicencioNo ratings yet

- Pneumatic Actuators f257 Suedmo Brochure enDocument6 pagesPneumatic Actuators f257 Suedmo Brochure enSincro AutomatizacionesNo ratings yet

- Nutech ControlsDocument5 pagesNutech ControlsmuralisunNo ratings yet

- Renmc 0218 UsDocument4 pagesRenmc 0218 UsRioga RiogaNo ratings yet

- Bellofram T10Document4 pagesBellofram T10adNo ratings yet

- Valv - Nugget 500Document22 pagesValv - Nugget 500FRANK PRUDENCIO OBREGONNo ratings yet

- Gflo - Globe ValveDocument20 pagesGflo - Globe ValveVarun PatelNo ratings yet

- 17 - Ace Valves - Butterfly ValveDocument9 pages17 - Ace Valves - Butterfly ValveRuan FreitasNo ratings yet

- Catalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Document2 pagesCatalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Joshua Garcia CarrilloNo ratings yet

- Large Vertical Circulating Water Pumps 12182013Document8 pagesLarge Vertical Circulating Water Pumps 12182013yogeshNo ratings yet

- Fast Vessels: ZWVS 440 - 930 - 350 - 3,082 KWDocument6 pagesFast Vessels: ZWVS 440 - 930 - 350 - 3,082 KWĐại DươngNo ratings yet

- Valvulas Mariposa EclipseDocument12 pagesValvulas Mariposa EclipseFernando GiadansNo ratings yet

- Actuador Lineal ValtekDocument16 pagesActuador Lineal ValtekEduardo Landa GonzalezNo ratings yet

- 2017 Price List PDFDocument40 pages2017 Price List PDFJOHNNY CALERONo ratings yet

- Valtech BQS-1 T D-SCBV TDocument1 pageValtech BQS-1 T D-SCBV TSony CNo ratings yet

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- Piper DC Diverter Bro 0313 O PDFDocument4 pagesPiper DC Diverter Bro 0313 O PDFjoebrazNo ratings yet

- Aceco PV3 & PV4 BrochureDocument16 pagesAceco PV3 & PV4 BrochureLynn AlgerNo ratings yet

- Nova 10 B PsDocument2 pagesNova 10 B PsJonathan AvilaNo ratings yet

- Air Filter + Regulator + LubricatorDocument12 pagesAir Filter + Regulator + LubricatorSunil ChandrawanshiNo ratings yet

- Brochure Catalog Throttle Trip ValvesDocument4 pagesBrochure Catalog Throttle Trip ValvesdrgNo ratings yet

- Highćcapacity Rotary Valves For General or Fibrous Slurry ServiceDocument20 pagesHighćcapacity Rotary Valves For General or Fibrous Slurry ServiceMohamed RashidNo ratings yet

- 7000 Series UHP Control Valve: Bulletin 86.1:7000Document8 pages7000 Series UHP Control Valve: Bulletin 86.1:7000Datt NguyenNo ratings yet

- Foam System - V.0 - WS PDFDocument82 pagesFoam System - V.0 - WS PDFSajjadNo ratings yet

- AVK Check Valve BrochureDocument12 pagesAVK Check Valve BrochureDunia AnakNo ratings yet

- Series BDV ValvesDocument20 pagesSeries BDV ValvesMuhammad NaeemNo ratings yet

- Experience High Performance Across A Broad Range of ApplicationsDocument12 pagesExperience High Performance Across A Broad Range of ApplicationsOlegario PalmaNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Concentric AB - HistoryDocument16 pagesConcentric AB - HistoryGỗ MộcNo ratings yet

- Atwood & Morrill Catalogue 2Document5 pagesAtwood & Morrill Catalogue 2Gỗ MộcNo ratings yet

- iRSVP 3100 Data Sheet.Document2 pagesiRSVP 3100 Data Sheet.Gỗ MộcNo ratings yet

- R/F - Pn16 Rating Cast Compact 'Y'-Type Strainer: Sdd/Ycp/Pn16/StlDocument1 pageR/F - Pn16 Rating Cast Compact 'Y'-Type Strainer: Sdd/Ycp/Pn16/StlGỗ MộcNo ratings yet

- The Largest Bore Size (280 To 400mm) in General Cylinders. The Piston and Rod Seal Used On U Seals That Has Durable SpecificationDocument8 pagesThe Largest Bore Size (280 To 400mm) in General Cylinders. The Piston and Rod Seal Used On U Seals That Has Durable SpecificationGỗ MộcNo ratings yet

- BHCN 3500 123 EBV TS 20253D 0720 EnglishDocument38 pagesBHCN 3500 123 EBV TS 20253D 0720 EnglishGỗ MộcNo ratings yet

- Ó Chi PDFDocument16 pagesÓ Chi PDFGỗ MộcNo ratings yet

- Product Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerDocument8 pagesProduct Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerGỗ MộcNo ratings yet

- Euro Power BrochureDocument24 pagesEuro Power BrochureGỗ MộcNo ratings yet

- Product Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Document21 pagesProduct Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Gỗ MộcNo ratings yet

- Furnace Wall SootblowerDocument5 pagesFurnace Wall SootblowerGỗ MộcNo ratings yet

- Part Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialDocument5 pagesPart Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialGỗ MộcNo ratings yet

- PS 30 Model 700 ActuatorDocument19 pagesPS 30 Model 700 ActuatorGỗ MộcNo ratings yet

- Diamond Power IR-3Z: Furnace Wall SootblowerDocument4 pagesDiamond Power IR-3Z: Furnace Wall SootblowerGỗ MộcNo ratings yet

- AUMA Electric Actuator (DALIAN DV Valve)Document74 pagesAUMA Electric Actuator (DALIAN DV Valve)Gỗ Mộc100% (1)

- Over 10 Million GMP Cutlass Bearings Sold WorldwideDocument4 pagesOver 10 Million GMP Cutlass Bearings Sold WorldwideGỗ MộcNo ratings yet

- List of Part-3Document2,000 pagesList of Part-3Gỗ Mộc100% (1)

- Valve Drawing VSG2 PDFDocument1 pageValve Drawing VSG2 PDFGỗ MộcNo ratings yet

- Minfm67141 Astm A182 Grade F6a 1 PDFDocument4 pagesMinfm67141 Astm A182 Grade F6a 1 PDFGỗ MộcNo ratings yet

- 3841Document10 pages3841Gỗ MộcNo ratings yet

- F-PMD-001 - Rev2 - Concrete Pouring RequestDocument1 pageF-PMD-001 - Rev2 - Concrete Pouring RequestAlexander RaposasNo ratings yet

- Estimate ManualDocument94 pagesEstimate ManualRamilArtatesNo ratings yet

- Form For Upgradation of FirmsDocument18 pagesForm For Upgradation of FirmsOwaisAhmedNo ratings yet

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

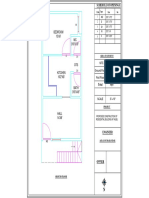

- Bedroom 13'x8' WC 3'6"X3'6": Schedule of OpeningsDocument1 pageBedroom 13'x8' WC 3'6"X3'6": Schedule of OpeningsAslamMakandarNo ratings yet

- Mount Guide CircularDocument8 pagesMount Guide CircularOla BaruwaNo ratings yet

- City Lifter CL25 Brochure DIGITALDocument4 pagesCity Lifter CL25 Brochure DIGITALdamindaNo ratings yet

- Masteremaco S 433 - TdsDocument3 pagesMasteremaco S 433 - TdsMudassir AliNo ratings yet

- Readyplast M Super Ready Mix Plastering MortarDocument2 pagesReadyplast M Super Ready Mix Plastering MortarPritpal SinghNo ratings yet

- Heavi-Wate Drill Pipe Tables: in LB/FT in BBL/FT BBL/FTDocument6 pagesHeavi-Wate Drill Pipe Tables: in LB/FT in BBL/FT BBL/FTMohamad TayeaNo ratings yet

- BCA Circular On GlassDocument6 pagesBCA Circular On GlassSiYing LaiNo ratings yet

- 12 Unit2Document24 pages12 Unit2ezedinNo ratings yet

- Roof Truss Analysis Example: CE 331, Summer 2016 1Document3 pagesRoof Truss Analysis Example: CE 331, Summer 2016 1Joshua CastilloNo ratings yet

- The Government of The Hong Kong Special Administrative RegionDocument11 pagesThe Government of The Hong Kong Special Administrative RegionSky LiNo ratings yet

- Floortech: Made in ItalyDocument2 pagesFloortech: Made in ItalyVaibhav DafaleNo ratings yet

- Inventario Consumibles LaboratorioDocument8 pagesInventario Consumibles Laboratoriocamilo molanoNo ratings yet

- 0409 - JCB Attachments BHL Product Guide Issue 3 30.10.14Document19 pages0409 - JCB Attachments BHL Product Guide Issue 3 30.10.14Darryl CareyNo ratings yet

- Ecoply Bracing EP2 Specification Tech Note April 2016Document2 pagesEcoply Bracing EP2 Specification Tech Note April 2016郭骥No ratings yet

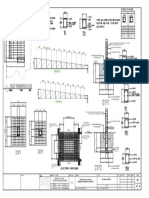

- Roof Framing Plan: B1 B2 TB1Document1 pageRoof Framing Plan: B1 B2 TB1Fred GervacioNo ratings yet

- LEEA-Reference LibraryDocument23 pagesLEEA-Reference LibraryMohamed FathyNo ratings yet

- WUHAN DICT TECH Sodium LignosulfonateDocument3 pagesWUHAN DICT TECH Sodium LignosulfonatejimmyNo ratings yet

- Call 800-DIESELS (343-7357) : 3163652 ICON Kit Contents Sheet 3396587Document4 pagesCall 800-DIESELS (343-7357) : 3163652 ICON Kit Contents Sheet 3396587reycoeleNo ratings yet

- Bid Tabs For Asphalt Milling ProjectDocument1 pageBid Tabs For Asphalt Milling Projectpezcado123No ratings yet

- Ijazullah Ibadullah CVDocument1 pageIjazullah Ibadullah CVIjazullah sahebzadaNo ratings yet

- Renderoc CS: Constructive SolutionsDocument2 pagesRenderoc CS: Constructive SolutionsjitendraNo ratings yet

- Sec 05100 - Structural SteelDocument10 pagesSec 05100 - Structural Steeltiju2005hereNo ratings yet

- Ufgs 01 32 17.00 20Document15 pagesUfgs 01 32 17.00 20jackcan501No ratings yet

- Work Instruction - Mold LoftingDocument2 pagesWork Instruction - Mold LoftingAaron PerezNo ratings yet

Series 5200: Materials of Construction

Series 5200: Materials of Construction

Uploaded by

Gỗ MộcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 5200: Materials of Construction

Series 5200: Materials of Construction

Uploaded by

Gỗ MộcCopyright:

Available Formats

MỤC 11

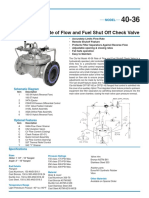

Series 5200

P High cycle life, repeatable control The Red Valve Series 5200 Control Valve design

P Sleeve is the only component in contact with offers maximum durability with precise control and

the media, eliminating the need for expensive bodies virtually eliminates maintenance. The Series 5200 is

available in sizes up to four inches. A heavy-duty,

P Versatile choice of sleeve trim to meet exact rugged pinch mechanism positions the sleeve for

flow requirements accurate flow control. The valve has no packing to

P External stroke adjustment maintain or seats to wear, eliminating fugitive

emissions and the need for expensive body alloys.

P Bi-directional, drop-tight shutoff

The standard Series 5200 Control Pinch Valve is

designed with a stroke adjustment that is located

inside the valve yoke. The stroke adjustment allows

customers to easily make small control changes in the

field and simplifies actuator maintenance by creating

a removal point in the valve stem. Particularly in

slurry applications, the stroke adjustment allows for

fine-tuned flow control as the sleeve wears.

Cone sleeves can be specified to further enhance

control performance and match the exact CV level

desired. True feedback positioning is accomplished

through the direct linkage of the positioner to the

6 valve stem shaft. There is no splitting of the

positioner output. The benefits of true feedback

positioning on Red Valve’s Series 5200 valves are

accurate small-change response signals to the posi-

Materials of Construction tioner, causing similar changes in true valve position,

greatly enhancing control accuracy.

P Ductile iron body

P ATO/ATC, ATO/Fail Close and

ATC/Fail Open actuators

P Sleeves available in Pure Gum Rubber,

Neoprene, Hypalon®, Chlorobutyl, H1

Buna-N, EPDM and Viton®

P Drilled and tapped to mate with

ANSI B16.5 Class 150 flanges

H

Closing Action W L

Dimensions Series 5200 Control Valve

HEIGHT WORKING WEIGHT

VALVE LENGTH WIDTH ATO/ATC PRESSURE ATO/ATC

SIZE L W H H1 * psi** lbs*

1" 7-1/4" 6" 2-7/16" 19" 150 50

1-1/2" 8-3/4" 8" 2-3/4" 19" 150 95

2" 10" 8" 3-1/2" 22" 150 125

2-1/2" 10-7/8" 9" 4" 24" 150 150

3" 11-3/4" 11-1/2" 4-1/4" 26" 150 185

4" 13-7/8" 13-1/2" 6-5/8" 29" 150 225

*Consult factory for specific heights and weights of Fail-Close or Fail-Open valves.

**Higher working pressures available.

You might also like

- (4.2) HM ManualDocument28 pages(4.2) HM ManualGỗ Mộc0% (1)

- Mounting and Operating Instructions Electrical Position ControllerDocument44 pagesMounting and Operating Instructions Electrical Position ControllerGỗ Mộc100% (1)

- SMM1 & SMM 2Document30 pagesSMM1 & SMM 2Hafizan Hanafiah100% (3)

- SmartSlope C 110 Installation Manual PDFDocument5 pagesSmartSlope C 110 Installation Manual PDFAivan Dredd PunzalanNo ratings yet

- 1.concentric Butterfly Valve in Various ApplicationDocument10 pages1.concentric Butterfly Valve in Various ApplicationMaciekNo ratings yet

- VLATB110-Rack & Pinion & Scotch Yoke Actuators TBDocument18 pagesVLATB110-Rack & Pinion & Scotch Yoke Actuators TBBoy AlfredoNo ratings yet

- Advanced V-Control Ball ValvesDocument8 pagesAdvanced V-Control Ball ValvesNGUYEN VAN TUAN EPPNo ratings yet

- Model 590 Control Valves: Technical Sales BulletinDocument12 pagesModel 590 Control Valves: Technical Sales BulletinRyan DuhonNo ratings yet

- ISIC Heavy Duty Pneumatic ActuatorDocument14 pagesISIC Heavy Duty Pneumatic Actuatoraizat91.acisNo ratings yet

- Series 2200 TechBro 041812Document8 pagesSeries 2200 TechBro 041812GianniNo ratings yet

- Pneumatische-Schwenkantriebe enDocument20 pagesPneumatische-Schwenkantriebe enSasawahyu WahyukuNo ratings yet

- Product BrochuresDocument6 pagesProduct BrochuresTanjong Minyak Car Wash Sdn BhdNo ratings yet

- Roos ValveDocument6 pagesRoos ValveSubhi MahmoudNo ratings yet

- Yarway Series 7100Document12 pagesYarway Series 7100Cecep AtmegaNo ratings yet

- CSM - Modular ValvesDocument2 pagesCSM - Modular Valvesramon slepickaNo ratings yet

- Bermad: Level Control ValveDocument4 pagesBermad: Level Control ValveSupolNo ratings yet

- Power & Severe ServiceDocument220 pagesPower & Severe ServiceJeremiah CayondongNo ratings yet

- Check Valve - Type CK4ADocument4 pagesCheck Valve - Type CK4AHuong QuangNo ratings yet

- DelVal Series 56 - 57 (PC - BFV.016.00 - 00)Document8 pagesDelVal Series 56 - 57 (PC - BFV.016.00 - 00)Prathamesh Pradeep MashilkarNo ratings yet

- Ezy Torque Pan IndustriesDocument1 pageEzy Torque Pan IndustriesRakefsNo ratings yet

- Performance: Palfinger Advanced Package As Standard!Document4 pagesPerformance: Palfinger Advanced Package As Standard!Joel VillalbaNo ratings yet

- TT OpEXL Eccentric Plug Rotary Valve BrochureDocument16 pagesTT OpEXL Eccentric Plug Rotary Valve BrochureSergio Gana GonzalezNo ratings yet

- E A - Style I Complete - SectionDocument16 pagesE A - Style I Complete - SectionWilliam VazquezNo ratings yet

- New G 2016Document5 pagesNew G 2016Andrs AlvearNo ratings yet

- Bray Controls - Manual OperatorsDocument2 pagesBray Controls - Manual OperatorsChandravadanNo ratings yet

- Válvula DireccionalDocument30 pagesVálvula DireccionalDiego DuranNo ratings yet

- Subsea Actuation: Valves and ActuatorsDocument20 pagesSubsea Actuation: Valves and ActuatorsSeymur AkbarovNo ratings yet

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- Series 2200 Butterfly Valve Product BrochureDocument18 pagesSeries 2200 Butterfly Valve Product BrochureSandesh KambleNo ratings yet

- System Valves v411 v431 AlcDocument5 pagesSystem Valves v411 v431 Alcmohamed mansourNo ratings yet

- Eclips Orfice ValveDocument4 pagesEclips Orfice Valveاحمد الجزار2007No ratings yet

- E4036Document2 pagesE4036Pablo Cardenas SandovalNo ratings yet

- Automan Series 20Document8 pagesAutoman Series 20kumaraguruNo ratings yet

- Lfgproducts Brochure WebDocument10 pagesLfgproducts Brochure WebAldo Germán Pavez MoraNo ratings yet

- PK 72002 Ficha TecnicaDocument4 pagesPK 72002 Ficha Tecnicamaquinariayequipos.andreyNo ratings yet

- Valvula YarwayDocument12 pagesValvula YarwayRobert VillavicencioNo ratings yet

- Pneumatic Actuators f257 Suedmo Brochure enDocument6 pagesPneumatic Actuators f257 Suedmo Brochure enSincro AutomatizacionesNo ratings yet

- Nutech ControlsDocument5 pagesNutech ControlsmuralisunNo ratings yet

- Renmc 0218 UsDocument4 pagesRenmc 0218 UsRioga RiogaNo ratings yet

- Bellofram T10Document4 pagesBellofram T10adNo ratings yet

- Valv - Nugget 500Document22 pagesValv - Nugget 500FRANK PRUDENCIO OBREGONNo ratings yet

- Gflo - Globe ValveDocument20 pagesGflo - Globe ValveVarun PatelNo ratings yet

- 17 - Ace Valves - Butterfly ValveDocument9 pages17 - Ace Valves - Butterfly ValveRuan FreitasNo ratings yet

- Catalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Document2 pagesCatalog Ultra High Purity Regulator Compact Panel Tescom en 5386990Joshua Garcia CarrilloNo ratings yet

- Large Vertical Circulating Water Pumps 12182013Document8 pagesLarge Vertical Circulating Water Pumps 12182013yogeshNo ratings yet

- Fast Vessels: ZWVS 440 - 930 - 350 - 3,082 KWDocument6 pagesFast Vessels: ZWVS 440 - 930 - 350 - 3,082 KWĐại DươngNo ratings yet

- Valvulas Mariposa EclipseDocument12 pagesValvulas Mariposa EclipseFernando GiadansNo ratings yet

- Actuador Lineal ValtekDocument16 pagesActuador Lineal ValtekEduardo Landa GonzalezNo ratings yet

- 2017 Price List PDFDocument40 pages2017 Price List PDFJOHNNY CALERONo ratings yet

- Valtech BQS-1 T D-SCBV TDocument1 pageValtech BQS-1 T D-SCBV TSony CNo ratings yet

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- Piper DC Diverter Bro 0313 O PDFDocument4 pagesPiper DC Diverter Bro 0313 O PDFjoebrazNo ratings yet

- Aceco PV3 & PV4 BrochureDocument16 pagesAceco PV3 & PV4 BrochureLynn AlgerNo ratings yet

- Nova 10 B PsDocument2 pagesNova 10 B PsJonathan AvilaNo ratings yet

- Air Filter + Regulator + LubricatorDocument12 pagesAir Filter + Regulator + LubricatorSunil ChandrawanshiNo ratings yet

- Brochure Catalog Throttle Trip ValvesDocument4 pagesBrochure Catalog Throttle Trip ValvesdrgNo ratings yet

- Highćcapacity Rotary Valves For General or Fibrous Slurry ServiceDocument20 pagesHighćcapacity Rotary Valves For General or Fibrous Slurry ServiceMohamed RashidNo ratings yet

- 7000 Series UHP Control Valve: Bulletin 86.1:7000Document8 pages7000 Series UHP Control Valve: Bulletin 86.1:7000Datt NguyenNo ratings yet

- Foam System - V.0 - WS PDFDocument82 pagesFoam System - V.0 - WS PDFSajjadNo ratings yet

- AVK Check Valve BrochureDocument12 pagesAVK Check Valve BrochureDunia AnakNo ratings yet

- Series BDV ValvesDocument20 pagesSeries BDV ValvesMuhammad NaeemNo ratings yet

- Experience High Performance Across A Broad Range of ApplicationsDocument12 pagesExperience High Performance Across A Broad Range of ApplicationsOlegario PalmaNo ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Concentric AB - HistoryDocument16 pagesConcentric AB - HistoryGỗ MộcNo ratings yet

- Atwood & Morrill Catalogue 2Document5 pagesAtwood & Morrill Catalogue 2Gỗ MộcNo ratings yet

- iRSVP 3100 Data Sheet.Document2 pagesiRSVP 3100 Data Sheet.Gỗ MộcNo ratings yet

- R/F - Pn16 Rating Cast Compact 'Y'-Type Strainer: Sdd/Ycp/Pn16/StlDocument1 pageR/F - Pn16 Rating Cast Compact 'Y'-Type Strainer: Sdd/Ycp/Pn16/StlGỗ MộcNo ratings yet

- The Largest Bore Size (280 To 400mm) in General Cylinders. The Piston and Rod Seal Used On U Seals That Has Durable SpecificationDocument8 pagesThe Largest Bore Size (280 To 400mm) in General Cylinders. The Piston and Rod Seal Used On U Seals That Has Durable SpecificationGỗ MộcNo ratings yet

- BHCN 3500 123 EBV TS 20253D 0720 EnglishDocument38 pagesBHCN 3500 123 EBV TS 20253D 0720 EnglishGỗ MộcNo ratings yet

- Ó Chi PDFDocument16 pagesÓ Chi PDFGỗ MộcNo ratings yet

- Product Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerDocument8 pagesProduct Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerGỗ MộcNo ratings yet

- Euro Power BrochureDocument24 pagesEuro Power BrochureGỗ MộcNo ratings yet

- Product Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Document21 pagesProduct Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Gỗ MộcNo ratings yet

- Furnace Wall SootblowerDocument5 pagesFurnace Wall SootblowerGỗ MộcNo ratings yet

- Part Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialDocument5 pagesPart Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialGỗ MộcNo ratings yet

- PS 30 Model 700 ActuatorDocument19 pagesPS 30 Model 700 ActuatorGỗ MộcNo ratings yet

- Diamond Power IR-3Z: Furnace Wall SootblowerDocument4 pagesDiamond Power IR-3Z: Furnace Wall SootblowerGỗ MộcNo ratings yet

- AUMA Electric Actuator (DALIAN DV Valve)Document74 pagesAUMA Electric Actuator (DALIAN DV Valve)Gỗ Mộc100% (1)

- Over 10 Million GMP Cutlass Bearings Sold WorldwideDocument4 pagesOver 10 Million GMP Cutlass Bearings Sold WorldwideGỗ MộcNo ratings yet

- List of Part-3Document2,000 pagesList of Part-3Gỗ Mộc100% (1)

- Valve Drawing VSG2 PDFDocument1 pageValve Drawing VSG2 PDFGỗ MộcNo ratings yet

- Minfm67141 Astm A182 Grade F6a 1 PDFDocument4 pagesMinfm67141 Astm A182 Grade F6a 1 PDFGỗ MộcNo ratings yet

- 3841Document10 pages3841Gỗ MộcNo ratings yet

- F-PMD-001 - Rev2 - Concrete Pouring RequestDocument1 pageF-PMD-001 - Rev2 - Concrete Pouring RequestAlexander RaposasNo ratings yet

- Estimate ManualDocument94 pagesEstimate ManualRamilArtatesNo ratings yet

- Form For Upgradation of FirmsDocument18 pagesForm For Upgradation of FirmsOwaisAhmedNo ratings yet

- 7-12-0026 Rev6 (Earthing Lug)Document1 page7-12-0026 Rev6 (Earthing Lug)sumit kumarNo ratings yet

- Bedroom 13'x8' WC 3'6"X3'6": Schedule of OpeningsDocument1 pageBedroom 13'x8' WC 3'6"X3'6": Schedule of OpeningsAslamMakandarNo ratings yet

- Mount Guide CircularDocument8 pagesMount Guide CircularOla BaruwaNo ratings yet

- City Lifter CL25 Brochure DIGITALDocument4 pagesCity Lifter CL25 Brochure DIGITALdamindaNo ratings yet

- Masteremaco S 433 - TdsDocument3 pagesMasteremaco S 433 - TdsMudassir AliNo ratings yet

- Readyplast M Super Ready Mix Plastering MortarDocument2 pagesReadyplast M Super Ready Mix Plastering MortarPritpal SinghNo ratings yet

- Heavi-Wate Drill Pipe Tables: in LB/FT in BBL/FT BBL/FTDocument6 pagesHeavi-Wate Drill Pipe Tables: in LB/FT in BBL/FT BBL/FTMohamad TayeaNo ratings yet

- BCA Circular On GlassDocument6 pagesBCA Circular On GlassSiYing LaiNo ratings yet

- 12 Unit2Document24 pages12 Unit2ezedinNo ratings yet

- Roof Truss Analysis Example: CE 331, Summer 2016 1Document3 pagesRoof Truss Analysis Example: CE 331, Summer 2016 1Joshua CastilloNo ratings yet

- The Government of The Hong Kong Special Administrative RegionDocument11 pagesThe Government of The Hong Kong Special Administrative RegionSky LiNo ratings yet

- Floortech: Made in ItalyDocument2 pagesFloortech: Made in ItalyVaibhav DafaleNo ratings yet

- Inventario Consumibles LaboratorioDocument8 pagesInventario Consumibles Laboratoriocamilo molanoNo ratings yet

- 0409 - JCB Attachments BHL Product Guide Issue 3 30.10.14Document19 pages0409 - JCB Attachments BHL Product Guide Issue 3 30.10.14Darryl CareyNo ratings yet

- Ecoply Bracing EP2 Specification Tech Note April 2016Document2 pagesEcoply Bracing EP2 Specification Tech Note April 2016郭骥No ratings yet

- Roof Framing Plan: B1 B2 TB1Document1 pageRoof Framing Plan: B1 B2 TB1Fred GervacioNo ratings yet

- LEEA-Reference LibraryDocument23 pagesLEEA-Reference LibraryMohamed FathyNo ratings yet

- WUHAN DICT TECH Sodium LignosulfonateDocument3 pagesWUHAN DICT TECH Sodium LignosulfonatejimmyNo ratings yet

- Call 800-DIESELS (343-7357) : 3163652 ICON Kit Contents Sheet 3396587Document4 pagesCall 800-DIESELS (343-7357) : 3163652 ICON Kit Contents Sheet 3396587reycoeleNo ratings yet

- Bid Tabs For Asphalt Milling ProjectDocument1 pageBid Tabs For Asphalt Milling Projectpezcado123No ratings yet

- Ijazullah Ibadullah CVDocument1 pageIjazullah Ibadullah CVIjazullah sahebzadaNo ratings yet

- Renderoc CS: Constructive SolutionsDocument2 pagesRenderoc CS: Constructive SolutionsjitendraNo ratings yet

- Sec 05100 - Structural SteelDocument10 pagesSec 05100 - Structural Steeltiju2005hereNo ratings yet

- Ufgs 01 32 17.00 20Document15 pagesUfgs 01 32 17.00 20jackcan501No ratings yet

- Work Instruction - Mold LoftingDocument2 pagesWork Instruction - Mold LoftingAaron PerezNo ratings yet