Professional Documents

Culture Documents

2020.12.29 CTW320-CGD-AIC-000659-E01-Subm.-MAR Steel Pipe Painting (Red Oxide Primer & Gloss Top Coat (let-AIC-002289)

2020.12.29 CTW320-CGD-AIC-000659-E01-Subm.-MAR Steel Pipe Painting (Red Oxide Primer & Gloss Top Coat (let-AIC-002289)

Uploaded by

Jafffar MahasnehCopyright:

Available Formats

You might also like

- Masterseal DR1: Geotextile Drainage Fleece For Use With MASTERSEAL 340/345 Spray Applied Waterproofing MembranesDocument2 pagesMasterseal DR1: Geotextile Drainage Fleece For Use With MASTERSEAL 340/345 Spray Applied Waterproofing MembranesFrancois-No ratings yet

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- Tds-Al-Jazeera Zinc Phosphate Primer QDDocument2 pagesTds-Al-Jazeera Zinc Phosphate Primer QDferoz khanNo ratings yet

- Jazeera Tetra Zinc l1Document3 pagesJazeera Tetra Zinc l1salam nazarNo ratings yet

- Jazeera Epo MasticDocument3 pagesJazeera Epo Masticm.deghadyNo ratings yet

- Polypropylene 4820WZ: DescriptionDocument1 pagePolypropylene 4820WZ: DescriptionChivuAlexandruNo ratings yet

- RF TransmitterDocument7 pagesRF Transmitterchandra sekharNo ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- Polypropylene 4720WZ: DescriptionDocument1 pagePolypropylene 4720WZ: DescriptionChivuAlexandruNo ratings yet

- Ds - INTERDRAIN GMG 620 - enDocument1 pageDs - INTERDRAIN GMG 620 - enThameem SharaafNo ratings yet

- Data Sheet C25.30 4D 8060 PDFDocument1 pageData Sheet C25.30 4D 8060 PDFNavneet NarayanNo ratings yet

- Neenah Gessner Air FiltrationDocument19 pagesNeenah Gessner Air FiltrationSurajPandeyNo ratings yet

- Astmproperty Astmproperty: Grade ResintypeDocument2 pagesAstmproperty Astmproperty: Grade Resintypejulius hasan33No ratings yet

- Dow Integraflux™ Ultrafiltration Modules: Product Data SheetDocument3 pagesDow Integraflux™ Ultrafiltration Modules: Product Data SheetArunkumar ChandaranNo ratings yet

- Line Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKDocument3 pagesLine Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKSadiqNo ratings yet

- Nya 8896 PDFDocument1 pageNya 8896 PDFSaor PakpahanNo ratings yet

- Vor inkGravureFall2009Document1 pageVor inkGravureFall2009don-carli-6370No ratings yet

- Waterman Filter PapersDocument34 pagesWaterman Filter PapersDAve QINNo ratings yet

- Abs sr101 DatasheetDocument2 pagesAbs sr101 Datasheetphanplastic299No ratings yet

- Stepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)Document4 pagesStepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)s0n1907No ratings yet

- UF IntegraFlux SFP 2860XP SFD 2860XP SFP 2880XP SFD 2880XP PDS 45 D01048 enDocument4 pagesUF IntegraFlux SFP 2860XP SFD 2860XP SFP 2880XP SFD 2880XP PDS 45 D01048 enOsama AhmedNo ratings yet

- MSDS Denso-LT-TapeDocument2 pagesMSDS Denso-LT-TapeEMPATI LUWU TIMURNo ratings yet

- FLR2X11Y CablesDocument1 pageFLR2X11Y CablesKristaNo ratings yet

- LFTD Panel MSDS (Updated)Document5 pagesLFTD Panel MSDS (Updated)Ernane RitaNo ratings yet

- FLR2X11Y CablesDocument1 pageFLR2X11Y CablesVijay KarthikeyanNo ratings yet

- Ega CatalogueDocument13 pagesEga CatalogueaaquilNo ratings yet

- Premier Coatings Premcote 500Document2 pagesPremier Coatings Premcote 500Im ChinithNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous zBSE9MNo ratings yet

- Ductmate Lag ItDocument2 pagesDuctmate Lag ItAbdykapar BatyrovNo ratings yet

- Denso Densopol 60 TapeDocument2 pagesDenso Densopol 60 TapeDwi SutiknoNo ratings yet

- FLR4G11Y-FL4G11Y CablesDocument1 pageFLR4G11Y-FL4G11Y CablesVijay KarthikeyanNo ratings yet

- Sika Fiber T48 - DoP SIKA Eng PDFDocument4 pagesSika Fiber T48 - DoP SIKA Eng PDFMarko StojanovicNo ratings yet

- A6M LTCC SystemDocument2 pagesA6M LTCC SystemkaleemafridiNo ratings yet

- RT-duroid 5870 - 5880 Data SheetDocument2 pagesRT-duroid 5870 - 5880 Data SheetDenis CarlosNo ratings yet

- D139FKDocument1 pageD139FKsonhungdoanNo ratings yet

- Premier Coatings Premtape TropicalDocument2 pagesPremier Coatings Premtape TropicalIm ChinithNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- Catologue Mang MBR LG-KOReD 03.2021Document16 pagesCatologue Mang MBR LG-KOReD 03.2021shjnbe18No ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Ohmnews 180Document2 pagesOhmnews 180motorciNo ratings yet

- TDS Fastflex - Eng - Rev.14 23 07 19 1Document5 pagesTDS Fastflex - Eng - Rev.14 23 07 19 1Swapnil JadhavNo ratings yet

- Technical Performance Certificate: Technical Compliance of ProductDocument1 pageTechnical Performance Certificate: Technical Compliance of ProductashishvaidNo ratings yet

- Linear Low Density Polyethylene: LL 22402 (Basell Grade: 22402)Document1 pageLinear Low Density Polyethylene: LL 22402 (Basell Grade: 22402)Jaime222No ratings yet

- 8 LD Mesh Ribbon AnodesDocument2 pages8 LD Mesh Ribbon AnodesFareed KhanNo ratings yet

- Sigma 36Document2 pagesSigma 36EngTamerNo ratings yet

- Alfdrain SHP10-D255Document1 pageAlfdrain SHP10-D255Aladin AbrashNo ratings yet

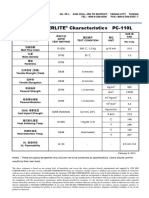

- Sae PC Wonderlite Characteristics PC-110L: February 6, 2014Document1 pageSae PC Wonderlite Characteristics PC-110L: February 6, 2014Ilton EduardoNo ratings yet

- Impactos Ingles 7600Document2 pagesImpactos Ingles 7600casillasfigjcNo ratings yet

- RO4835IND LoPro Laminate Data SheetDocument2 pagesRO4835IND LoPro Laminate Data SheetChar OuzoNo ratings yet

- 10-6000MHz Wideband Transformer TCM1-63AXDocument1 page10-6000MHz Wideband Transformer TCM1-63AXMichael Dave MyersNo ratings yet

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocument1 pageMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiAchraf BoudayaNo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- Denso Densyl TapeDocument2 pagesDenso Densyl TapeDianWidodoNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Carboguard 890 GF PDSDocument2 pagesCarboguard 890 GF PDSfazeel mohammedNo ratings yet

- Rma 223Document2 pagesRma 223Sergio ChicNo ratings yet

- JKR Presentation (15-3-2017) PDFDocument288 pagesJKR Presentation (15-3-2017) PDFWall Panel100% (2)

- Ds - TECHDRAIN GTG 720 - enDocument1 pageDs - TECHDRAIN GTG 720 - enThameem SharaafNo ratings yet

- 02 622320 0000100120 Dah Des Sow 000001 - ADocument84 pages02 622320 0000100120 Dah Des Sow 000001 - AJafffar Mahasneh100% (2)

- Selection TablesDocument6 pagesSelection TablesJafffar MahasnehNo ratings yet

- 10 603174 1100001334 Aac Civ MST 000013 - 01Document35 pages10 603174 1100001334 Aac Civ MST 000013 - 01Jafffar MahasnehNo ratings yet

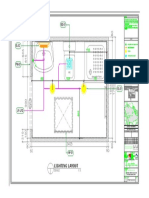

- Updated Drawings OrthoPhoto Road LayoutDocument1 pageUpdated Drawings OrthoPhoto Road LayoutJafffar MahasnehNo ratings yet

- Updated Drawings Road LayoutDocument1 pageUpdated Drawings Road LayoutJafffar MahasnehNo ratings yet

- CTW320 Msy 03 El Abd 5002 01Document1 pageCTW320 Msy 03 El Abd 5002 01Jafffar MahasnehNo ratings yet

- CTW320 Msy 00 El Abd 5002 04Document1 pageCTW320 Msy 00 El Abd 5002 04Jafffar MahasnehNo ratings yet

- CTW320 Msy 00 El Abd 5002 03Document1 pageCTW320 Msy 00 El Abd 5002 03Jafffar MahasnehNo ratings yet

- CTW320 Msy 00 El Abd 5002 05Document1 pageCTW320 Msy 00 El Abd 5002 05Jafffar MahasnehNo ratings yet

- 2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Document3 pages2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Jafffar MahasnehNo ratings yet

- CTW320 Msy 00 El Abd 5002 01Document1 pageCTW320 Msy 00 El Abd 5002 01Jafffar MahasnehNo ratings yet

- Epilux 200 Polyamide Cured Coaltar EpoxyDocument3 pagesEpilux 200 Polyamide Cured Coaltar EpoxyIqra AngelsNo ratings yet

- NIOZ 1 (In Organic Zinc Silicate)Document3 pagesNIOZ 1 (In Organic Zinc Silicate)abdulhadiNo ratings yet

- Por 15 CatalogDocument56 pagesPor 15 CatalogPOR 1567% (3)

- Hempel WB Primer 28830Document3 pagesHempel WB Primer 28830Noman AhmedNo ratings yet

- IMO RequirementsDocument23 pagesIMO Requirementsshahid khanNo ratings yet

- Mechanical Building Services Specification 2007Document167 pagesMechanical Building Services Specification 2007Son Cao ThanhNo ratings yet

- 604 Dr. Fixit PrimesealDocument2 pages604 Dr. Fixit Primesealkkundan52No ratings yet

- EPC ScheduleDocument81 pagesEPC ScheduleSatyajit MondalNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- BS 04147 1980 1999 PDFDocument16 pagesBS 04147 1980 1999 PDFvivim109No ratings yet

- Dulux GuideDocument24 pagesDulux GuideReedwan GaniyuNo ratings yet

- Painting 1-35 Scale Figures in AcrylicsDocument5 pagesPainting 1-35 Scale Figures in AcrylicsErisieNo ratings yet

- Royale Play DuneDocument2 pagesRoyale Play Dunevenkat26740% (1)

- Test Methods For The Evaluation of Protective Organic CoatingsDocument10 pagesTest Methods For The Evaluation of Protective Organic Coatingsnikopigni2100% (1)

- EURO INOX - Colouring Stainless SteelDocument24 pagesEURO INOX - Colouring Stainless SteelFernando Casanova RicaldoniNo ratings yet

- DR Fixit Raincoat NeoDocument3 pagesDR Fixit Raincoat Neoprakash iyerNo ratings yet

- LCP LYCORRIB 35 SpecificationDocument2 pagesLCP LYCORRIB 35 SpecificationGarfieldNo ratings yet

- Work Method Statement For Painting WorkDocument3 pagesWork Method Statement For Painting WorkMicheal B Haizen67% (9)

- Mastertop 1270 AsDocument3 pagesMastertop 1270 AsDoby YuniardiNo ratings yet

- CHAPTER 15 and 16Document21 pagesCHAPTER 15 and 16Johnro LebasteNo ratings yet

- Luxepoxy T: Tintable Two Pack Epoxy FinishDocument2 pagesLuxepoxy T: Tintable Two Pack Epoxy FinishlivefreakNo ratings yet

- BS 8204-5-1994-Screeds, Bases and in Situ Floorings-Code ofDocument24 pagesBS 8204-5-1994-Screeds, Bases and in Situ Floorings-Code ofgops1963No ratings yet

- Bus Body Regulations PDFDocument106 pagesBus Body Regulations PDFUsha Kiran KumarNo ratings yet

- Drying and Curing Time: Technical Data Sheet Hardtop AlfaDocument1 pageDrying and Curing Time: Technical Data Sheet Hardtop AlfaTamerTamerNo ratings yet

- Solventbased SS7Document2 pagesSolventbased SS7Arun StarlightNo ratings yet

- Technical Data Sheet Priomat® Pore Filler 3311: Substrate Application Recoating StorageDocument4 pagesTechnical Data Sheet Priomat® Pore Filler 3311: Substrate Application Recoating StorageАртем ШевчукNo ratings yet

- Understanding Paint: HAT S AintDocument9 pagesUnderstanding Paint: HAT S AintMohan MalavNo ratings yet

- Luna and The Lie - Zapata MarianaDocument793 pagesLuna and The Lie - Zapata MarianaKassandraNo ratings yet

- Plastiseal : Rubber-Bitumen Cold Applied Joint SealantDocument4 pagesPlastiseal : Rubber-Bitumen Cold Applied Joint SealantzeroicesnowNo ratings yet

- Examination of Alternative Pretreatments To Hexavalent Chromium-Based DOD-P-15328D Wash Primer For MIL-A-46100D High Hard Steel ArmorDocument52 pagesExamination of Alternative Pretreatments To Hexavalent Chromium-Based DOD-P-15328D Wash Primer For MIL-A-46100D High Hard Steel ArmorCordova RaphaelNo ratings yet

2020.12.29 CTW320-CGD-AIC-000659-E01-Subm.-MAR Steel Pipe Painting (Red Oxide Primer & Gloss Top Coat (let-AIC-002289)

2020.12.29 CTW320-CGD-AIC-000659-E01-Subm.-MAR Steel Pipe Painting (Red Oxide Primer & Gloss Top Coat (let-AIC-002289)

Uploaded by

Jafffar MahasnehOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2020.12.29 CTW320-CGD-AIC-000659-E01-Subm.-MAR Steel Pipe Painting (Red Oxide Primer & Gloss Top Coat (let-AIC-002289)

2020.12.29 CTW320-CGD-AIC-000659-E01-Subm.-MAR Steel Pipe Painting (Red Oxide Primer & Gloss Top Coat (let-AIC-002289)

Uploaded by

Jafffar MahasnehCopyright:

Available Formats

Technical Data Sheet

AL-JAZEERA RED OXIDE PRIMER JI-71001

One Component , Red Oxide Alkyd Primer

DESCRIPTION: Paint System

A high quality primer based on modified alkyd resin and iron Primers: Itself.

oxide pigment. It has good anti-corrosive property on steel Topcoats:Can be over coated with all kinds of alkyd. For

surfaces. other suitable topcoats, consult Al-Jazeera TSD.

RECOMMENDED USE: Film Thickness and Spreading Rate:

Recommended to use as primer for exterior and interior applica-

tions in wide range of industerial structures, on steel works Minimum Maximum Recommended

such as: warehouses, steel structures, doors, and fire fighting

(µm) mil (µm) mil (µm) mil

systems.

Dry Film

CHARACTERISTICS: Thickness (DFT) 25 1 75 3 40 1.6

-Good resistance to corrosion. Wet Film

-Very good adhesion. Thickness (WFT) 46 1.85 136 5.5 73 2.9

-Resistant to weather conditions.

m /l

2

ft /USgal

2

m /l

2

ft /USgal

2

m /l

2

ft /US gal

2

Physical Constants: Theoretical

Finish: Flat Spreading Rate 22 882 7.33 294 13.75 551

Colour: Red

Volume Solid: 55% , ASTM D2697 Application Condition

Viscosity: 87 KU @25°C, ASTM D562

Specific Gravity: 1.58, ASTM D1475 Temperature:

VOC Values: 376 g/ ltr. 1) surface: at least (3°C) above dew point.

Surface Preparation: 2) ambient: minimum10°C & maximum 43°C.

Remove all visible surface deposits such as grease, oils with

suitable detergent per (SSPC-SP1). Remove salt and other Relative humidity: maximum 85%.

contaminants by washing using high pressure fresh water.

Any fabrication defects such as weld spatter, delamination, Drying Time and Recoating

sharp edges and weld slag should be repaired prior to

surface preparation. Drying times are generally related to air circulation, tempera-

ture, film thickness and number of coats, and will be affected

Steel Surfaces: correspondingly.

The surface must be prepared according to Sa 2½ (ISO Temperature 25°C/77°F

8501-1)- (NACE No.2/SSPC-SP10), or Sa2 (NACE

No.3/SSPC-SP6) or hand and power tool cleaning according Relative Humidity 50%

to St3(SSPC-SP3). Surface Dry 1 hour

Application Method and Thinning: Hard Dry 8 hours

Dry to recoat, minimum 4.5 hours @ 45°C

THINNER: Recommended thinner is “Al-Jazeera Thinner 504”. Dry to recoat, maximum* -------

Application Full Cured: 24 hours

Method Airless Spray Air Spray Brush/Roller**

Thinning

(by volume)* (0-5)% (20-25) % (10-15)% Note: All records given in the table are typical at: recom-

Nozzle Orifice 0.015-0.021" 1.5- 1.8 mm N/A mended film thickness, good ventilation and one coat

system.

*The surface should be dry and clean prior to application.

Nozzle Pressure 15 MPa The best time to recoat is before previous coat is cured. If

( 2100psi) 29.0-43.5psi N/A this time is exceeded, the surface may need to be

Spray Angle 40-80 0

50-80 0

N/A roughened slightly.

* Depends on the weather condition at work place.

** Recommended for stripe coat and small areas.

Disclaimer Issued 2017

To the best of our knowledge the technical data listed herein is true and accurate up to publication date and is subject to change without prior notice. User must contact Al-Jazeera

Paints Company to verify of any modifications before specifying or ordering the product. Thus, information given in this sheet is not intended to be exhaustive and any person using

the product other than the recommendations in this sheet or without reverting to our Al-Jazeera TSD, he should take his accountability in this connection.

As we are not capable to control the quality and the substrate's conditions as well as the factors that affect on using, or applying the product, so we never give any written or implied

guarantee in these documents, but we guarantee our products to conform to Al-Jazeera quality while we assume no responsibility for coverage, performance or injuries resulting

from application. Liability "if any" is limited to replace the products mentioned above.

Technical Data Sheet

AL-JAZEERA RED OXIDE PRIMER JI-71001

One Component , Red Oxide Alkyd Primer

PACKING:

Packed in: US Gallon Drum 18 Ltr

SHELF LIFE & STORAGE:

Shelf life : 24 months @ 25 °C.

Storage: The container should be kept in sealed, dry, cool,

well ventilated place and stored in accordance with

national regulations.

SAFETY PRECAUTIONS:

Clean up: Use "Al-Jazeera Thinner 504" for tools

cleaning and in case of spillage, absorb and

dispose.

Handling: Handle with care. Stir very well before use.

Health

and safety: Please read and follow the precautionary

notices displayed on the container, and all

caution statements on the MSDS of this

product. During application of paint, contact

of liquid paint with eyes, skin, inhalation of

paint mist and paint vapor should be strongly

avoided. For spray application systems;

applicator should wear protective clothing,

gloves, also eye, skin and respiratory

protection are always recommended. Keep

away from reach of children.

Ventilation: When used in enclosed areas, thorough

air circulation must be used during and after

application until the coating is cured. In

addition, respirators must be used by all

applicator.

Caution: This product contains flammable solvents,

keep away from sparks and open flame.

For information on LEL and TLV, please

read the MSDS.

Environmental

safety: Please donate the leftover paint and

packaging to your local authorized institution

for usage or recycling purpose.

Note: Wastes and empty containers should be

disposed of in accordance with local

regulations made under the Control of

Pollution Act and the Env i r o n m e n t a l

Protection Act.

Disclaimer Issued 2017

To the best of our knowledge the technical data listed herein is true and accurate up to publication date and is subject to change without prior notice. User must contact Al-Jazeera

Paints Company to verify of any modifications before specifying or ordering the product. Thus, information given in this sheet is not intended to be exhaustive and any person using

the product other than the recommendations in this sheet or without reverting to our Al-Jazeera TSD, he should take his accountability in this connection.

As we are not capable to control the quality and the substrate's conditions as well as the factors that affect on using, or applying the product, so we never give any written or implied

guarantee in these documents, but we guarantee our products to conform to Al-Jazeera quality while we assume no responsibility for coverage, performance or injuries resulting

from application. Liability "if any" is limited to replace the products mentioned above.

Technical Data Sheet

JAZETAL GLOSS JA-38001

4. A suitable quantity of “Al-Jazeera Thinner 504” can be

DESCRIPTION: added to get reasonable viscosity for application.

A high quality gloss finish enamel paint based on modified

5.Do not apply on wet and moistened surfaces until

acrylic resin. It has a very good gloss retention and leveling

completely dry.

properties.

6.Do not apply the next coat unless the previous one is fully

RECOMMENDED USE: dry. Minimum recoating interval time should be

Recommended to use as for interior and exterior applications on followed.

steel, concrete, cement, wood and gypsum surfaces. 7. Adequate ventilation should be provided during application.

CHARACTERISTICS: APPLICATION TOOLS :

- Very good weather resistance property. •Airless spray:

- Washable with water and soap. Nozzle orifice : 0.015-0.019"

- Very good gloss retention property. Nozzle pressure : 15 MPa ( 2100psi)

- Excellent covering and hiding property. Spray angle : 40-600

- High gloss. •Air spray : Nozzle size: (1.5 – 1.8) mm.

- Lead free. •Roller: Soft and smooth roller

(Recommended type: Dekor Nardeen 8009 - code: 1093)

CERTIFICATES: •Brush: Suitble type.

-Approved by SASO No.: 472/2002.

THINNER :

PHYSICAL CONSTANTS: “Al-Jazeera Thinner 504”.

Finish Gloss.

Gloss Above 85, at angle of 60° ASTM D523. THINNING RATIO :

Colour Produced in white and other colours (0 – 10)% by volume for airless spray.

as per Al-Jazeera colour card. (25 – 35)% by volume for air spray gun.

Specific Gravity 1.12 ASTM D1475. (15 – 20)% by volume for roller and brush.

Viscosity 90 KU ASTM D562. All above depends on the weather and application

Volume Solid 46.30 %. ASTM D2697.

conditions.

D.F.T 30 µ. Eachcoat.

Theoretical 15.43 m 2/L (618.9 ft 2/US gallon) at PAINTING SYSTEM:

spreading rate* D.F.T. 30 µ.

For masonry surfaces:

Hiding Above 95 % at 100 µ D.F.T.

-Apply one coat of “Al-Jazeera Green Prime”.

Sagging 150 µ ASTM D4400.

- Apply two coats of “Al-Jazeera Green Putty”.

Hardness Pass ASTM D3363.

-Apply two coats of “Jazetal Gloss”.

Scratch Resistance Pass ASTM D5178.

For steel surfaces:

Bending 3 mm ASTM D522.

-Apply one or two coats of “Al-Jazeera Zinc Phosphate

Adhesion Pass ASTM D3359.

Primer” or “Al-Jazeera Red Oxide Primer”.

Water Resistance Pass ASTM D870.

-Apply two coats of “Jazetal Gloss” if required, giving

Flash Point 38°C.

sufficient recoat interval time between the two coats.

*The practical spreading rate of the product depends on the

surface,ambient temperature,application method,actual DFT DRYING TIME:

and the wasted amount. Surface dry 3 hours.

(To avoid waste, be sure to buy the right amount of the paint Full dry 16 hours.

for the required surface area). Recoat interval 24 hours (minimum).

All above test results according to ASTM D5895@ 25°C.

SURFACE PREPARATION:

- All new surfaces shall be cured at least 28 days prior to CLEANING TOOLS:

application of the primer. “Al-Jazeera Thinner 504”.

-Remove old paints completely from previously painted

surfaces .

PACKING:

- The substrate should have sufficient strength and free from 3.65 Ltr. Gallon.

unsounded areas, pug holes, protrusions and pops. 18 Ltr. Drum.

- Make sure that the surface is clean, dry, free from dust, Gallon: Base 3 Ltr.( Tintable base by coloring machine).

Drum: Base 17 Ltr.( Tintable base by coloring machine).

oil, grease, salt and mold .

- Fill the holes and cracks with suitable fillers such as SHELF LIFE & STORAGE:

"Al-Jazeera Ultimate", ”Al-Jazeera Unique Filler” or “Jaz Shelf life : 24 months @ 25 °C.

Epoxy Crack Filler ESP” prior to application of the primer Storage: The container should be kept in sealed, dry, cool, well

(Refer to TSD). -ventilated place and stored in accordance with national regulations.

APPLICATION GUIDE:

1. The required surface temperature during application,

must not be less than 10°C; the surface moisture should not

exceed 8% and the relative humidity at work place should

not exceed 70%.

2. pH of surface should not exceed 9.

3. Paint should be stirred carefully before use.

Disclaimer Issued 2017

To the best of our knowledge the technical data listed herein is true and accurate up to publication date and is subject to change without prior notice. User must

contact Al-Jazeera Paints Company to verify of any modifications before specifying or ordering the product. Thus, information given in this sheet is not intended

to be exhaustive and any person using the product other than the recommendations in this sheet or without reverting to our Al-Jazeera TSD, he should take his

accountability in this connection.

As we are not capable to control the quality and the substrate's conditions as well as the factors that affect on using, or applying the product, so we never give

any written or implied guarantee in these documents, but we guarantee our products to conform to Al-Jazeera quality while we assume no responsibility for

coverage, performance or injuries resulting from application. Liability "if any" is limited to replace the products mentioned above.

Technical Data Sheet

JAZETAL GLOSS JA-38001

SAFETY PRECAUTIONS:

Please read and follow the precautionary notices

displayed on the container, and all caution statements on

the MSDS of this product.

- Handle with care before and during use.

- During application of paint, contact of liquid paint with eyes,

skin, inhalation of paint mist and paint vapour, should be

strongly avoided.

- Recommended to use the product in well-ventilated area

when applying the paint in insufficient ventilated areas, forced

ventilation should be provided.

- Keep away from the reach of children.

For environmental safety: please donate the leftover paint

and packaging to your local authorized institution for usage

or recycling purpose.

Note: Wastes and empty containers should be disposed of in

accordance with local regulations made under the Control of

Pollution Act and the Environmental Protection Act.

Disclaimer Issued 2017

To the best of our knowledge the technical data listed herein is true and accurate up to publication date and is subject to change without prior notice. User must

contact Al-Jazeera Paints Company to verify of any modifications before specifying or ordering the product. Thus, information given in this sheet is not intended

to be exhaustive and any person using the product other than the recommendations in this sheet or without reverting to our Al-Jazeera TSD, he should take his

accountability in this connection.

As we are not capable to control the quality and the substrate's conditions as well as the factors that affect on using, or applying the product, so we never give

any written or implied guarantee in these documents, but we guarantee our products to conform to Al-Jazeera quality while we assume no responsibility for

coverage, performance or injuries resulting from application. Liability "if any" is limited to replace the products mentioned above.

You might also like

- Masterseal DR1: Geotextile Drainage Fleece For Use With MASTERSEAL 340/345 Spray Applied Waterproofing MembranesDocument2 pagesMasterseal DR1: Geotextile Drainage Fleece For Use With MASTERSEAL 340/345 Spray Applied Waterproofing MembranesFrancois-No ratings yet

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- Tds-Al-Jazeera Zinc Phosphate Primer QDDocument2 pagesTds-Al-Jazeera Zinc Phosphate Primer QDferoz khanNo ratings yet

- Jazeera Tetra Zinc l1Document3 pagesJazeera Tetra Zinc l1salam nazarNo ratings yet

- Jazeera Epo MasticDocument3 pagesJazeera Epo Masticm.deghadyNo ratings yet

- Polypropylene 4820WZ: DescriptionDocument1 pagePolypropylene 4820WZ: DescriptionChivuAlexandruNo ratings yet

- RF TransmitterDocument7 pagesRF Transmitterchandra sekharNo ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- Polypropylene 4720WZ: DescriptionDocument1 pagePolypropylene 4720WZ: DescriptionChivuAlexandruNo ratings yet

- Ds - INTERDRAIN GMG 620 - enDocument1 pageDs - INTERDRAIN GMG 620 - enThameem SharaafNo ratings yet

- Data Sheet C25.30 4D 8060 PDFDocument1 pageData Sheet C25.30 4D 8060 PDFNavneet NarayanNo ratings yet

- Neenah Gessner Air FiltrationDocument19 pagesNeenah Gessner Air FiltrationSurajPandeyNo ratings yet

- Astmproperty Astmproperty: Grade ResintypeDocument2 pagesAstmproperty Astmproperty: Grade Resintypejulius hasan33No ratings yet

- Dow Integraflux™ Ultrafiltration Modules: Product Data SheetDocument3 pagesDow Integraflux™ Ultrafiltration Modules: Product Data SheetArunkumar ChandaranNo ratings yet

- Line Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKDocument3 pagesLine Item 11 To 17 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F Duct MTUA SS PE BKSadiqNo ratings yet

- Nya 8896 PDFDocument1 pageNya 8896 PDFSaor PakpahanNo ratings yet

- Vor inkGravureFall2009Document1 pageVor inkGravureFall2009don-carli-6370No ratings yet

- Waterman Filter PapersDocument34 pagesWaterman Filter PapersDAve QINNo ratings yet

- Abs sr101 DatasheetDocument2 pagesAbs sr101 Datasheetphanplastic299No ratings yet

- Stepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)Document4 pagesStepan Polyester Polyols For Rigid: Polyisocyanurate (PIR) and Polyurethane (PUR Foam)s0n1907No ratings yet

- UF IntegraFlux SFP 2860XP SFD 2860XP SFP 2880XP SFD 2880XP PDS 45 D01048 enDocument4 pagesUF IntegraFlux SFP 2860XP SFD 2860XP SFP 2880XP SFD 2880XP PDS 45 D01048 enOsama AhmedNo ratings yet

- MSDS Denso-LT-TapeDocument2 pagesMSDS Denso-LT-TapeEMPATI LUWU TIMURNo ratings yet

- FLR2X11Y CablesDocument1 pageFLR2X11Y CablesKristaNo ratings yet

- LFTD Panel MSDS (Updated)Document5 pagesLFTD Panel MSDS (Updated)Ernane RitaNo ratings yet

- FLR2X11Y CablesDocument1 pageFLR2X11Y CablesVijay KarthikeyanNo ratings yet

- Ega CatalogueDocument13 pagesEga CatalogueaaquilNo ratings yet

- Premier Coatings Premcote 500Document2 pagesPremier Coatings Premcote 500Im ChinithNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous zBSE9MNo ratings yet

- Ductmate Lag ItDocument2 pagesDuctmate Lag ItAbdykapar BatyrovNo ratings yet

- Denso Densopol 60 TapeDocument2 pagesDenso Densopol 60 TapeDwi SutiknoNo ratings yet

- FLR4G11Y-FL4G11Y CablesDocument1 pageFLR4G11Y-FL4G11Y CablesVijay KarthikeyanNo ratings yet

- Sika Fiber T48 - DoP SIKA Eng PDFDocument4 pagesSika Fiber T48 - DoP SIKA Eng PDFMarko StojanovicNo ratings yet

- A6M LTCC SystemDocument2 pagesA6M LTCC SystemkaleemafridiNo ratings yet

- RT-duroid 5870 - 5880 Data SheetDocument2 pagesRT-duroid 5870 - 5880 Data SheetDenis CarlosNo ratings yet

- D139FKDocument1 pageD139FKsonhungdoanNo ratings yet

- Premier Coatings Premtape TropicalDocument2 pagesPremier Coatings Premtape TropicalIm ChinithNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- Catologue Mang MBR LG-KOReD 03.2021Document16 pagesCatologue Mang MBR LG-KOReD 03.2021shjnbe18No ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Ohmnews 180Document2 pagesOhmnews 180motorciNo ratings yet

- TDS Fastflex - Eng - Rev.14 23 07 19 1Document5 pagesTDS Fastflex - Eng - Rev.14 23 07 19 1Swapnil JadhavNo ratings yet

- Technical Performance Certificate: Technical Compliance of ProductDocument1 pageTechnical Performance Certificate: Technical Compliance of ProductashishvaidNo ratings yet

- Linear Low Density Polyethylene: LL 22402 (Basell Grade: 22402)Document1 pageLinear Low Density Polyethylene: LL 22402 (Basell Grade: 22402)Jaime222No ratings yet

- 8 LD Mesh Ribbon AnodesDocument2 pages8 LD Mesh Ribbon AnodesFareed KhanNo ratings yet

- Sigma 36Document2 pagesSigma 36EngTamerNo ratings yet

- Alfdrain SHP10-D255Document1 pageAlfdrain SHP10-D255Aladin AbrashNo ratings yet

- Sae PC Wonderlite Characteristics PC-110L: February 6, 2014Document1 pageSae PC Wonderlite Characteristics PC-110L: February 6, 2014Ilton EduardoNo ratings yet

- Impactos Ingles 7600Document2 pagesImpactos Ingles 7600casillasfigjcNo ratings yet

- RO4835IND LoPro Laminate Data SheetDocument2 pagesRO4835IND LoPro Laminate Data SheetChar OuzoNo ratings yet

- 10-6000MHz Wideband Transformer TCM1-63AXDocument1 page10-6000MHz Wideband Transformer TCM1-63AXMichael Dave MyersNo ratings yet

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocument1 pageMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiAchraf BoudayaNo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- Denso Densyl TapeDocument2 pagesDenso Densyl TapeDianWidodoNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Carboguard 890 GF PDSDocument2 pagesCarboguard 890 GF PDSfazeel mohammedNo ratings yet

- Rma 223Document2 pagesRma 223Sergio ChicNo ratings yet

- JKR Presentation (15-3-2017) PDFDocument288 pagesJKR Presentation (15-3-2017) PDFWall Panel100% (2)

- Ds - TECHDRAIN GTG 720 - enDocument1 pageDs - TECHDRAIN GTG 720 - enThameem SharaafNo ratings yet

- 02 622320 0000100120 Dah Des Sow 000001 - ADocument84 pages02 622320 0000100120 Dah Des Sow 000001 - AJafffar Mahasneh100% (2)

- Selection TablesDocument6 pagesSelection TablesJafffar MahasnehNo ratings yet

- 10 603174 1100001334 Aac Civ MST 000013 - 01Document35 pages10 603174 1100001334 Aac Civ MST 000013 - 01Jafffar MahasnehNo ratings yet

- Updated Drawings OrthoPhoto Road LayoutDocument1 pageUpdated Drawings OrthoPhoto Road LayoutJafffar MahasnehNo ratings yet

- Updated Drawings Road LayoutDocument1 pageUpdated Drawings Road LayoutJafffar MahasnehNo ratings yet

- CTW320 Msy 03 El Abd 5002 01Document1 pageCTW320 Msy 03 El Abd 5002 01Jafffar MahasnehNo ratings yet

- CTW320 Msy 00 El Abd 5002 04Document1 pageCTW320 Msy 00 El Abd 5002 04Jafffar MahasnehNo ratings yet

- CTW320 Msy 00 El Abd 5002 03Document1 pageCTW320 Msy 00 El Abd 5002 03Jafffar MahasnehNo ratings yet

- CTW320 Msy 00 El Abd 5002 05Document1 pageCTW320 Msy 00 El Abd 5002 05Jafffar MahasnehNo ratings yet

- 2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Document3 pages2020.10.04-AL JAZEERA-Red Oxide Primer (JI-71001)Jafffar MahasnehNo ratings yet

- CTW320 Msy 00 El Abd 5002 01Document1 pageCTW320 Msy 00 El Abd 5002 01Jafffar MahasnehNo ratings yet

- Epilux 200 Polyamide Cured Coaltar EpoxyDocument3 pagesEpilux 200 Polyamide Cured Coaltar EpoxyIqra AngelsNo ratings yet

- NIOZ 1 (In Organic Zinc Silicate)Document3 pagesNIOZ 1 (In Organic Zinc Silicate)abdulhadiNo ratings yet

- Por 15 CatalogDocument56 pagesPor 15 CatalogPOR 1567% (3)

- Hempel WB Primer 28830Document3 pagesHempel WB Primer 28830Noman AhmedNo ratings yet

- IMO RequirementsDocument23 pagesIMO Requirementsshahid khanNo ratings yet

- Mechanical Building Services Specification 2007Document167 pagesMechanical Building Services Specification 2007Son Cao ThanhNo ratings yet

- 604 Dr. Fixit PrimesealDocument2 pages604 Dr. Fixit Primesealkkundan52No ratings yet

- EPC ScheduleDocument81 pagesEPC ScheduleSatyajit MondalNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- BS 04147 1980 1999 PDFDocument16 pagesBS 04147 1980 1999 PDFvivim109No ratings yet

- Dulux GuideDocument24 pagesDulux GuideReedwan GaniyuNo ratings yet

- Painting 1-35 Scale Figures in AcrylicsDocument5 pagesPainting 1-35 Scale Figures in AcrylicsErisieNo ratings yet

- Royale Play DuneDocument2 pagesRoyale Play Dunevenkat26740% (1)

- Test Methods For The Evaluation of Protective Organic CoatingsDocument10 pagesTest Methods For The Evaluation of Protective Organic Coatingsnikopigni2100% (1)

- EURO INOX - Colouring Stainless SteelDocument24 pagesEURO INOX - Colouring Stainless SteelFernando Casanova RicaldoniNo ratings yet

- DR Fixit Raincoat NeoDocument3 pagesDR Fixit Raincoat Neoprakash iyerNo ratings yet

- LCP LYCORRIB 35 SpecificationDocument2 pagesLCP LYCORRIB 35 SpecificationGarfieldNo ratings yet

- Work Method Statement For Painting WorkDocument3 pagesWork Method Statement For Painting WorkMicheal B Haizen67% (9)

- Mastertop 1270 AsDocument3 pagesMastertop 1270 AsDoby YuniardiNo ratings yet

- CHAPTER 15 and 16Document21 pagesCHAPTER 15 and 16Johnro LebasteNo ratings yet

- Luxepoxy T: Tintable Two Pack Epoxy FinishDocument2 pagesLuxepoxy T: Tintable Two Pack Epoxy FinishlivefreakNo ratings yet

- BS 8204-5-1994-Screeds, Bases and in Situ Floorings-Code ofDocument24 pagesBS 8204-5-1994-Screeds, Bases and in Situ Floorings-Code ofgops1963No ratings yet

- Bus Body Regulations PDFDocument106 pagesBus Body Regulations PDFUsha Kiran KumarNo ratings yet

- Drying and Curing Time: Technical Data Sheet Hardtop AlfaDocument1 pageDrying and Curing Time: Technical Data Sheet Hardtop AlfaTamerTamerNo ratings yet

- Solventbased SS7Document2 pagesSolventbased SS7Arun StarlightNo ratings yet

- Technical Data Sheet Priomat® Pore Filler 3311: Substrate Application Recoating StorageDocument4 pagesTechnical Data Sheet Priomat® Pore Filler 3311: Substrate Application Recoating StorageАртем ШевчукNo ratings yet

- Understanding Paint: HAT S AintDocument9 pagesUnderstanding Paint: HAT S AintMohan MalavNo ratings yet

- Luna and The Lie - Zapata MarianaDocument793 pagesLuna and The Lie - Zapata MarianaKassandraNo ratings yet

- Plastiseal : Rubber-Bitumen Cold Applied Joint SealantDocument4 pagesPlastiseal : Rubber-Bitumen Cold Applied Joint SealantzeroicesnowNo ratings yet

- Examination of Alternative Pretreatments To Hexavalent Chromium-Based DOD-P-15328D Wash Primer For MIL-A-46100D High Hard Steel ArmorDocument52 pagesExamination of Alternative Pretreatments To Hexavalent Chromium-Based DOD-P-15328D Wash Primer For MIL-A-46100D High Hard Steel ArmorCordova RaphaelNo ratings yet