Professional Documents

Culture Documents

Engine Room Emergency

Engine Room Emergency

Uploaded by

CHERRY ANN OLAJAYOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Room Emergency

Engine Room Emergency

Uploaded by

CHERRY ANN OLAJAYCopyright:

Available Formats

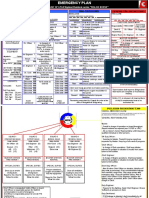

At around 1335hrs General alarm was sounded followed by PA system engine emergency drill.

Crew were gathered at engine room for the engine room emergency drill. The scenario was

steam low pressure main distribution valve pipe joint flange gasket leakage. Chief engineer

discussed to the crew the procedures to be done in an event of such engine room emergency.

Chief Engineer cited essential actions based on the ship's contingency plan and emphasized that

remaining calm and avoid to panic. Chief engineer explained to the crew the action must be

taken in such scenario was to close main steam valve. Repair the steam leakage and to renew the

gasket. At1400H drill was dismissed.

At around 1300hrs General alarm was sounded followed by PA system Engine Emergency drill.

Crew were gathered at engine room for the engine room emergency drill. The scenario was

exhaust gas leackage (Broken expansion joint from generator). Chief Engineer cited essentials

actions based on the ship contengency plan and emphasized that to be remain calm at all times to

avoid panic.Chief Engineer explained to the crew the action must be taken in such scenario was

to immediately change over generator in service and stop the generator with exhaust gas

leakage.Investigate the cause and repair, replace broken expansion joint .At 1325 hrs drill was

dismissed.

At 1145 Hr.Simulation:Engine Room Flooding …In the event of engine room flooding. We have

three engine room bilge alarm (Port.Stbd & Aft) served as pre-warning that bilge level are high.

If the the bilge water level get higher than normal we Must identify the cause/source of water

ingress to bilges then rectify as soon as possible. If the water ingress are big enough and water

level continious to rise, emergency bilge suction using the main sea water pump or the Direct

bilge suction using the Fire G.S./Ballast pump will we used. Either of the two or both can

maintain the amount of water rise on the bilge wells. Also we must take sounding of the M.E.

sump tank to test or see if the bilge water already penatrated the M.E. system oil thru the man

hole of the tank top. All engine personnel must be in the engine room to help to rectify engine

room flooding.

around 1450hrs, Crew were gathered at engine room for the engine room emergency drill. The

scenario was flooding at the engine room. Chief engineer discussed to the crew the procedures to

be done in an event of flooding in the engine room. Chief Engineer cited essential actions based

on the ship's contingency plan and emphasized that remaining calm and avoiding to panic plays a

great role in handling such situations.

Drill was completed satisfactorily at around 1500hrs.

You might also like

- Muster List Sigloo NorseDocument2 pagesMuster List Sigloo Norsesbcheah100% (10)

- Chief Engineers Standing OrdersDocument8 pagesChief Engineers Standing Ordersoffshorearmada100% (3)

- Restore Power in Case of BlackoutDocument5 pagesRestore Power in Case of Blackoutadityasahay100% (2)

- IAMI Revision Answers AuxiliaryDocument19 pagesIAMI Revision Answers AuxiliaryStewart LongNo ratings yet

- BunkeringDocument10 pagesBunkeringAnonymous UCveMQ100% (2)

- Describe EIGHT Actions To Be Taken by The Relieving Engineer Officer of The Watch Before Taking Charge of The WatchDocument26 pagesDescribe EIGHT Actions To Be Taken by The Relieving Engineer Officer of The Watch Before Taking Charge of The WatchAbishek Abi100% (1)

- 005 - Chapter 4 - Appendix 2 - Emergency PlanDocument1 page005 - Chapter 4 - Appendix 2 - Emergency Plansbcheah100% (1)

- Aramco Evalution For Chief Engineer - 240119 - 182732Document13 pagesAramco Evalution For Chief Engineer - 240119 - 182732ardi.gunawan1435No ratings yet

- Emergency Drill Report & Synopsis Subject: "Damage To Critical Machinery & Equipment" Governing Sms Procedure: S-0904Document4 pagesEmergency Drill Report & Synopsis Subject: "Damage To Critical Machinery & Equipment" Governing Sms Procedure: S-0904saurav naskarNo ratings yet

- Emergency Drill Report & Synopsis (Ship - Shore Drill) : Happy Clipper / Page 1 of 3Document3 pagesEmergency Drill Report & Synopsis (Ship - Shore Drill) : Happy Clipper / Page 1 of 3Saurav NaskarNo ratings yet

- Performance of Engine Room Watch Keeping DutiesDocument17 pagesPerformance of Engine Room Watch Keeping DutiesMike Bunoan Dumangeng83% (6)

- Steering Gear FailureDocument3 pagesSteering Gear Failuresaurav naskarNo ratings yet

- Emergency Drill Report & Synopsis Subject: "Stranding/Grounding" Governing Sms Procedure: S-0902Document5 pagesEmergency Drill Report & Synopsis Subject: "Stranding/Grounding" Governing Sms Procedure: S-0902Saurav NaskarNo ratings yet

- Genera Procedure of Preparing Sips For Entering Port 2Document11 pagesGenera Procedure of Preparing Sips For Entering Port 2Usman MohammedNo ratings yet

- By Not Practicing Safety Can Lead Into A Serious Injury or Death. So As Much As Possible I As A Seafarer Practice Safety at All TimesDocument7 pagesBy Not Practicing Safety Can Lead Into A Serious Injury or Death. So As Much As Possible I As A Seafarer Practice Safety at All TimesMichael Kevin Gomez RiveroNo ratings yet

- MarEnv WEEK 16.assignmentDocument1 pageMarEnv WEEK 16.assignmentMichael Don John J. BenipayoNo ratings yet

- Your Guide To Tackle Emergency Situations On Board ShipsDocument3 pagesYour Guide To Tackle Emergency Situations On Board ShipsGiorgi KandelakiNo ratings yet

- Emergency Drill Report & Synopsis: Happy Clipper / Page 1 of 2Document2 pagesEmergency Drill Report & Synopsis: Happy Clipper / Page 1 of 2Saurav NaskarNo ratings yet

- Assignment Meeting 12 Cecep KoswaraDocument3 pagesAssignment Meeting 12 Cecep KoswaraTheOswardoNo ratings yet

- NarrativeDocument7 pagesNarrativeSandeep KumarNo ratings yet

- Mars 243Document4 pagesMars 243CostasKNo ratings yet

- CHIEF ENGINEER Standing OrdersDocument3 pagesCHIEF ENGINEER Standing Ordersefendi kaptanNo ratings yet

- Case Study - Fire Incident On MV of SPMDocument4 pagesCase Study - Fire Incident On MV of SPMHedi Ben MohamedNo ratings yet

- Mersey: Report of The Chief Inspector of Marine Accidents Into The Explosion On The Motor TankerDocument39 pagesMersey: Report of The Chief Inspector of Marine Accidents Into The Explosion On The Motor TankerShyam KishoreNo ratings yet

- Unit 2 Safety and Emergency ProceduresDocument10 pagesUnit 2 Safety and Emergency ProceduresmarpelNo ratings yet

- Materi Kd. 3.6 MaritimDocument4 pagesMateri Kd. 3.6 MaritimRzkyy TopUpNo ratings yet

- The Ultimate Guide To Fuel Oil Bunkering Process On ShipsDocument5 pagesThe Ultimate Guide To Fuel Oil Bunkering Process On ShipsGiorgi KandelakiNo ratings yet

- Preparation of Contingency Plans For Response To EmergenciesDocument6 pagesPreparation of Contingency Plans For Response To Emergenciesharry stamperNo ratings yet

- Name: Noorul Anis Mohamed Ali MATRIC NUM: A12KP0025 Course: 3SkpgDocument4 pagesName: Noorul Anis Mohamed Ali MATRIC NUM: A12KP0025 Course: 3Skpganischan553No ratings yet

- ERM Q & A RevisedDocument53 pagesERM Q & A Revisedranjansankalp2000No ratings yet

- STI Camden 1 (General)Document40 pagesSTI Camden 1 (General)somod95239No ratings yet

- Bunkering - MeoiDocument16 pagesBunkering - MeoiYeditha Satyanarayana MurthyNo ratings yet

- Ewk Review Material For MidtermDocument4 pagesEwk Review Material For MidtermJimmy C. Enojo Jr.No ratings yet

- Maintain A Safe EngineeringDocument9 pagesMaintain A Safe EngineeringMuhamad Fery100% (1)

- Cargo Oil SystemDocument8 pagesCargo Oil SystemAayush Agrawal100% (3)

- Engine and Deck Department Effective CommunicationDocument7 pagesEngine and Deck Department Effective CommunicationjesusNo ratings yet

- Thesis Types of Drills in Engine RoomDocument3 pagesThesis Types of Drills in Engine RoomKarla Marie SimeonNo ratings yet

- Assignment 2Document2 pagesAssignment 2Mark SaramillasNo ratings yet

- 10 Situations Wherein Engine and Deck Officers Must Maintain Efficient CommunicationDocument4 pages10 Situations Wherein Engine and Deck Officers Must Maintain Efficient CommunicationYorlevy ChirinosNo ratings yet

- Assessmen UTS NaskaDocument4 pagesAssessmen UTS NaskaAsrul GadingNo ratings yet

- PETE 300 5660300 Summer Practice I: TH THDocument7 pagesPETE 300 5660300 Summer Practice I: TH THEmir MazlumNo ratings yet

- Maintaing A Safe Enginering Watch 1Document7 pagesMaintaing A Safe Enginering Watch 1bombos susiloNo ratings yet

- Engine Room Flooding Troubleshooting and Immediate ActionsDocument3 pagesEngine Room Flooding Troubleshooting and Immediate ActionsGiorgi KandelakiNo ratings yet

- Black Out ProcedureDocument3 pagesBlack Out Proceduremarkjames castroNo ratings yet

- 12 Communicating With The Engine RoomDocument17 pages12 Communicating With The Engine Roomsultan.jj7No ratings yet

- 3) EX 5,02. Accident Analysis ExerciseDocument6 pages3) EX 5,02. Accident Analysis ExerciseAndrejSukoraNo ratings yet

- Risk Assessment No. 22 LOSS OF STEERAGE Rev. 02 28.12.09Document4 pagesRisk Assessment No. 22 LOSS OF STEERAGE Rev. 02 28.12.09Devi Ratna PratiwiNo ratings yet

- Week No. 3 Construction and Operating Principles of The Different Types of Gas TurbineDocument17 pagesWeek No. 3 Construction and Operating Principles of The Different Types of Gas TurbineBeah monique FaustinoNo ratings yet

- Function of Diesel EngineDocument16 pagesFunction of Diesel EngineShienna MañiboNo ratings yet

- Muster StationDocument5 pagesMuster StationRia Mae Mateo0% (1)

- Function 3 YayayaDocument23 pagesFunction 3 YayayaYusuf Bagus PangestuNo ratings yet

- MARPOL Annex I Requires Ships To Bring SOPEP or Shipboard Oil Pollution Emergency Plan in Case They Encounter Oil Spill While On ShipboardDocument2 pagesMARPOL Annex I Requires Ships To Bring SOPEP or Shipboard Oil Pollution Emergency Plan in Case They Encounter Oil Spill While On ShipboardJohn Acel AtuanNo ratings yet

- Hse Manual: 1) Fire Fighting Installation & TrainingDocument3 pagesHse Manual: 1) Fire Fighting Installation & TrainingHany RifaatNo ratings yet

- Старпом вопросыDocument5 pagesСтарпом вопросыДима ДмитренкоNo ratings yet

- 11S Emergency Procedures - Engine FailureDocument11 pages11S Emergency Procedures - Engine FailureashishNo ratings yet

- M.V. Grand Clipper: HongkongsarDocument9 pagesM.V. Grand Clipper: HongkongsarSaurav NaskarNo ratings yet

- Case Study HMS Endurance StudentDocument5 pagesCase Study HMS Endurance StudentPrasanga MallawaarachchiNo ratings yet

- TuruttDocument30 pagesTuruttBiznes HubNo ratings yet

- Duties of Ship's Chief Officer When Entering Dock: Preparing The Ship For Dry DockingDocument12 pagesDuties of Ship's Chief Officer When Entering Dock: Preparing The Ship For Dry DockingMohan Krishnan100% (1)

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Summative 3 Oral Comm.Document3 pagesSummative 3 Oral Comm.CHERRY ANN OLAJAYNo ratings yet

- Oral Com WHLP W1 4Document6 pagesOral Com WHLP W1 4CHERRY ANN OLAJAYNo ratings yet

- Reading Text: The Happiness EffectDocument3 pagesReading Text: The Happiness EffectCHERRY ANN OLAJAYNo ratings yet

- Pre TestDocument3 pagesPre TestCHERRY ANN OLAJAYNo ratings yet

- Region X - Northern MindanaoDocument5 pagesRegion X - Northern MindanaoCHERRY ANN OLAJAYNo ratings yet

- Day & Time Learning Area Learning Competency Learning Tasks Mode of Delivery Core Subject: 12 AFA, HE-A and IA-BDocument4 pagesDay & Time Learning Area Learning Competency Learning Tasks Mode of Delivery Core Subject: 12 AFA, HE-A and IA-BCHERRY ANN OLAJAYNo ratings yet

- Creative Nonfiction W2.1Document5 pagesCreative Nonfiction W2.1CHERRY ANN OLAJAYNo ratings yet

- Day & Time Learning Area Learning Competency Learning Tasks Mode of Delivery Core Subject: 11 HE-B and 11 ABMDocument9 pagesDay & Time Learning Area Learning Competency Learning Tasks Mode of Delivery Core Subject: 11 HE-B and 11 ABMCHERRY ANN OLAJAYNo ratings yet

- Day & Time Learning Area Learning Competency Learning Tasks Mode of Delivery Core SubjectDocument2 pagesDay & Time Learning Area Learning Competency Learning Tasks Mode of Delivery Core SubjectCHERRY ANN OLAJAYNo ratings yet

- EAPP Midterm (rEVIEWERDocument3 pagesEAPP Midterm (rEVIEWERCHERRY ANN OLAJAYNo ratings yet

- Eapp LP Review Lessons, Etc.Document2 pagesEapp LP Review Lessons, Etc.CHERRY ANN OLAJAYNo ratings yet

- I. Objectives 1. Answer The Test Questions CarefullyDocument2 pagesI. Objectives 1. Answer The Test Questions CarefullyCHERRY ANN OLAJAYNo ratings yet

- Directions: Develop The Following Weak Thesis Statements.: Activity: We Chat TimeDocument4 pagesDirections: Develop The Following Weak Thesis Statements.: Activity: We Chat TimeCHERRY ANN OLAJAYNo ratings yet

- Contextualizing Literacy Development 2Document12 pagesContextualizing Literacy Development 2CHERRY ANN OLAJAYNo ratings yet

- Updated DatalatestDocument383 pagesUpdated DatalatestCHERRY ANN OLAJAYNo ratings yet

- DYP-RD-Spec of Ultrasonic Fuel Level Sensor DYP-U02-V1.0 190402-A0Document12 pagesDYP-RD-Spec of Ultrasonic Fuel Level Sensor DYP-U02-V1.0 190402-A0Juan Camilo Guarnizo BermudezNo ratings yet

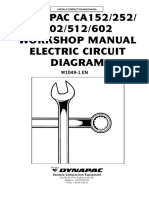

- CA 250 Manual de EletricaDocument25 pagesCA 250 Manual de EletricaAdeildo dos santos sales deildo100% (1)

- Brake Noise, Judder and Dragging Diagnosis and ServicingDocument4 pagesBrake Noise, Judder and Dragging Diagnosis and ServicingbeyondteckNo ratings yet

- Electrical Safety PosterDocument2 pagesElectrical Safety PosterDuong Chi TrungNo ratings yet

- What Are TVS DiodesDocument1 pageWhat Are TVS Diodesrajat nimjeNo ratings yet

- Automotive Sumative TestDocument5 pagesAutomotive Sumative TestRAndy rodelas100% (2)

- Directed Replacement Parts ReferenceDocument39 pagesDirected Replacement Parts ReferenceRyan Ofstie100% (1)

- NamsanDocument8 pagesNamsanmotahri22No ratings yet

- MasterPact MTZ - LV833593SPDocument2 pagesMasterPact MTZ - LV833593SPernesto floresNo ratings yet

- IPC-1720A July2014Document51 pagesIPC-1720A July2014RidwanNo ratings yet

- Index: Illustrated Sourcebook Mechanical ComponentsDocument4 pagesIndex: Illustrated Sourcebook Mechanical ComponentsBouzidnoui NouiNo ratings yet

- Datasheet 15Kw-110KW 3PH - 2021Document1 pageDatasheet 15Kw-110KW 3PH - 2021Eureka SolarNo ratings yet

- Perkins 6 354 Engine Service ManualDocument9 pagesPerkins 6 354 Engine Service ManualVinícius Assis De Oliveira0% (1)

- C ps416 1Document12 pagesC ps416 1Henrique PortesNo ratings yet

- Arduino Project ListDocument50 pagesArduino Project ListAlia Khan100% (1)

- Black Box Freedom IIDocument4 pagesBlack Box Freedom IIRedcorp_MarketingNo ratings yet

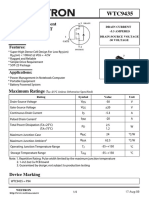

- P-Channel Enhancement Mode Power MOSFET: FeaturesDocument4 pagesP-Channel Enhancement Mode Power MOSFET: FeaturesMarco MoralesNo ratings yet

- 3500B Series II: Supplemental Application and Installation GuideDocument20 pages3500B Series II: Supplemental Application and Installation GuideJose AntonioNo ratings yet

- Black-Out PPT - PKNDocument41 pagesBlack-Out PPT - PKNpramod_nandaNo ratings yet

- Arc Protection Instruction Manual EN1.1Document65 pagesArc Protection Instruction Manual EN1.1Alexandre MorenoNo ratings yet

- Micom P126 and P127 Directional/Non Directional Overcurrent RelaysDocument2 pagesMicom P126 and P127 Directional/Non Directional Overcurrent RelaysAONLANo ratings yet

- 2007 Engine ManagementDocument51 pages2007 Engine ManagementFausto TrentiniNo ratings yet

- Manual NVT - Configuraciones e InstalaciónDocument25 pagesManual NVT - Configuraciones e InstalaciónChristian CristãoNo ratings yet

- Rapid Response Pumping Systems For Firefighting: Technical DescriptionDocument14 pagesRapid Response Pumping Systems For Firefighting: Technical DescriptionseluarbolaNo ratings yet

- Low Voltage Switchgear-R1Document23 pagesLow Voltage Switchgear-R1anirban 007No ratings yet

- MCT 272Document9 pagesMCT 272jorgelaloca0% (1)

- SFH250V PDFDocument6 pagesSFH250V PDFNishu GanvirNo ratings yet

- Oxygen SystemsDocument9 pagesOxygen SystemsShruthi S KurupNo ratings yet

- ABB Project Electrical Typical Cable Galnd LugDocument6 pagesABB Project Electrical Typical Cable Galnd LugharryNo ratings yet