Professional Documents

Culture Documents

PIT H114 15 P354Ldfgh

PIT H114 15 P354Ldfgh

Uploaded by

ernarendersainiCopyright:

Available Formats

You might also like

- RDSO Vendor ListDocument7 pagesRDSO Vendor Listernarendersaini62% (13)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Introduction To Chemical Engineering Thermodynamics by Halder, Gopinath PDFDocument2 pagesIntroduction To Chemical Engineering Thermodynamics by Halder, Gopinath PDFs9n9No ratings yet

- 4 Balanced CantileverDocument28 pages4 Balanced Cantileverernarendersaini100% (1)

- Project No.: PIT-H147-10: Impact Toe Response Toe Response DefectDocument1 pageProject No.: PIT-H147-10: Impact Toe Response Toe Response DefecternarendersainiNo ratings yet

- Pit E103 11Document13 pagesPit E103 11PLANiN Innovation & Consultancy Services Pvt. Ltd.No ratings yet

- Quantifying The Potential Impacts of Disturbances On Power System ProtectionDocument4 pagesQuantifying The Potential Impacts of Disturbances On Power System ProtectionmohsinamanNo ratings yet

- Finalized CMU Guideline Dec 2013Document46 pagesFinalized CMU Guideline Dec 2013rhunriang9977No ratings yet

- Investigation of Transformer Failure in Indonesia 231022 204837Document6 pagesInvestigation of Transformer Failure in Indonesia 231022 204837kvramananNo ratings yet

- O/C & E/F Relay Test Report: - M/S.Grasim Industries Limited Ganjam, OdissaDocument9 pagesO/C & E/F Relay Test Report: - M/S.Grasim Industries Limited Ganjam, OdissaDhivagar NamakkalNo ratings yet

- STANDARD TEST METHOD PIT (Pile Integrity Test)Document5 pagesSTANDARD TEST METHOD PIT (Pile Integrity Test)senthilNo ratings yet

- IJREAMV06I0666053Document3 pagesIJREAMV06I0666053Yan Lin AungNo ratings yet

- Wavelet Based Demodulation of Vibration Signals Generated by Defects in Rolling Element BearingsDocument15 pagesWavelet Based Demodulation of Vibration Signals Generated by Defects in Rolling Element BearingsAnonymous OFwyjaMyNo ratings yet

- PSP Practical No 3,5,7Document11 pagesPSP Practical No 3,5,7Vivek BendeNo ratings yet

- Analysis of Failed and Working Power Transformer and Their DiagnosticsDocument6 pagesAnalysis of Failed and Working Power Transformer and Their DiagnosticsPrasanth ThomasNo ratings yet

- CT Failure Diagnostic Paper ITMF 2011 JunaidiDocument6 pagesCT Failure Diagnostic Paper ITMF 2011 JunaidiHari Krishna.M100% (1)

- Pit Report Pier04 Pile01 06Document11 pagesPit Report Pier04 Pile01 06Priodeep ChowdhuryNo ratings yet

- 10 11-19-407 Qiao 1b Incipient Bearing Fault Article 2 ModeloDocument6 pages10 11-19-407 Qiao 1b Incipient Bearing Fault Article 2 ModeloAnselmo LeonardoNo ratings yet

- An Acoustic Emission Technique For Crack Modes ClaDocument12 pagesAn Acoustic Emission Technique For Crack Modes ClaNhà Quê Ra TỉnhNo ratings yet

- United States Naval Academy: Division ofDocument13 pagesUnited States Naval Academy: Division ofdrdinglechengNo ratings yet

- Wavelet Spectrum Analysis For Bearing Fault Diagnostics: Jie Liu, Wilson Wang, Farid Golnaraghi and Kefu LiuDocument9 pagesWavelet Spectrum Analysis For Bearing Fault Diagnostics: Jie Liu, Wilson Wang, Farid Golnaraghi and Kefu Liuandi_wijayaNo ratings yet

- CL-E131 Stator Earth Fault Protection 90%: Commissioning Check List EDocument2 pagesCL-E131 Stator Earth Fault Protection 90%: Commissioning Check List Emirage1977No ratings yet

- 048 Venkatesh AUPEC01paperDocument5 pages048 Venkatesh AUPEC01paperDante FilhoNo ratings yet

- Poljak 2009Document11 pagesPoljak 2009amrutha cNo ratings yet

- Power Transformer Testing and Commissioning PDFDocument6 pagesPower Transformer Testing and Commissioning PDFEric Stanton100% (1)

- Example Ramping Overcurrent ENU PDFDocument21 pagesExample Ramping Overcurrent ENU PDFOscar Ordoñez VelasquezNo ratings yet

- On-Load Tap Changer's Dynamic Resistance Measurement: Settings and InterpretationDocument5 pagesOn-Load Tap Changer's Dynamic Resistance Measurement: Settings and InterpretationBaharin Hashim100% (1)

- Investigation of 150/66 KV 100 MVA Transformer Internal FailureDocument6 pagesInvestigation of 150/66 KV 100 MVA Transformer Internal Failuredavid23281dNo ratings yet

- 18 - Aizam - HV IT in TNB Substations - Paper PDFDocument5 pages18 - Aizam - HV IT in TNB Substations - Paper PDFbcqbaoNo ratings yet

- Lifetime Prediction For Bearing in Induction Motors by Shu Tzu Chang (Paper-2019)Document5 pagesLifetime Prediction For Bearing in Induction Motors by Shu Tzu Chang (Paper-2019)emmanuel799100% (1)

- Impact of Startup Scheme On Francis Runner Life ExpectancyDocument9 pagesImpact of Startup Scheme On Francis Runner Life ExpectancyFolpoNo ratings yet

- Condition Assessment of Transformer by Park's Vector and Symmetrical Components To Detect Inter Turn FaultDocument6 pagesCondition Assessment of Transformer by Park's Vector and Symmetrical Components To Detect Inter Turn FaultdimasairlanggaNo ratings yet

- Novel Technique For Fault Location Estimation On Parallel Transmission Lines Using WaveletDocument7 pagesNovel Technique For Fault Location Estimation On Parallel Transmission Lines Using WaveletRachana MeenaNo ratings yet

- Fatigue TestingDocument7 pagesFatigue Testingromesaali23No ratings yet

- Transformer Testing by Afees Ahamed Egger IndiaDocument27 pagesTransformer Testing by Afees Ahamed Egger IndialrpatraNo ratings yet

- Riser TestDocument22 pagesRiser TestAbraham RojasNo ratings yet

- Gen Write UpDocument11 pagesGen Write Upsarirag100% (3)

- Vibration Monitoring On Power TransformerDocument2 pagesVibration Monitoring On Power TransformerPriya Surya HarijantoNo ratings yet

- 7 Detection of Mechanical DeformationDocument9 pages7 Detection of Mechanical DeformationMohamed BoughalNo ratings yet

- Real-Time Nondestructive Evaluation of Airframe Structures For Health Monitoring and Residual Life PredictionDocument12 pagesReal-Time Nondestructive Evaluation of Airframe Structures For Health Monitoring and Residual Life PredictionArunNo ratings yet

- Transformer Condition Monitoring Sethuraman MuthukaruppDocument8 pagesTransformer Condition Monitoring Sethuraman MuthukaruppAnantha RkNo ratings yet

- TIA Grubic2011 LibreDocument8 pagesTIA Grubic2011 LibreMariut Elena LarisaNo ratings yet

- Construction of Multi Storied Housing Complex at Fort Kochi, Kerala Report For Pile Integrity Testing On 06 Nos. R.C. Bored PilesDocument11 pagesConstruction of Multi Storied Housing Complex at Fort Kochi, Kerala Report For Pile Integrity Testing On 06 Nos. R.C. Bored PilesTaak ConstructionsNo ratings yet

- MOM Lab Manuals OrigionalDocument95 pagesMOM Lab Manuals OrigionalMansoob BukhariNo ratings yet

- Planning of Operation & Maintenance Using Risk and Reliability Based MethodsDocument8 pagesPlanning of Operation & Maintenance Using Risk and Reliability Based Methodsfaz143No ratings yet

- Astm D5778 - 07Document19 pagesAstm D5778 - 07Black GokuNo ratings yet

- Wronkowicz 2018Document39 pagesWronkowicz 2018stajicin kullanımNo ratings yet

- Seismic Damage and Damage-Control Design For RC Frames 1990Document20 pagesSeismic Damage and Damage-Control Design For RC Frames 1990Tinh T. LeNo ratings yet

- ACI ITG/T1.1R-99: Reported by ACI Innovation Task Group 1 and CollaboratorsDocument7 pagesACI ITG/T1.1R-99: Reported by ACI Innovation Task Group 1 and CollaboratorsCorui Mihai ValerNo ratings yet

- E751E751M-12 Standard Practice For Acoustic Emission Monitoring During Resistance Spot - WeldingDocument7 pagesE751E751M-12 Standard Practice For Acoustic Emission Monitoring During Resistance Spot - WeldingAnder EscobedoNo ratings yet

- A Wavelet Power Based Algorithm For Synchronous Generator ProtectionDocument6 pagesA Wavelet Power Based Algorithm For Synchronous Generator ProtectionsunitharajababuNo ratings yet

- Influence of Damage in The Acoustic Emission ParametersDocument8 pagesInfluence of Damage in The Acoustic Emission Parameters윤대성No ratings yet

- CT Failure Diagnostic Paper ITMF 2011 Junaidi ENU PDFDocument6 pagesCT Failure Diagnostic Paper ITMF 2011 Junaidi ENU PDFJose Antonio Huamani ChuquirimayNo ratings yet

- Application of Wavelet Packets in Bearing Fault DiagnosisDocument8 pagesApplication of Wavelet Packets in Bearing Fault DiagnosisjudarangocaNo ratings yet

- E2760-10E2 Creep-Fatigue Crack Growth TestingDocument19 pagesE2760-10E2 Creep-Fatigue Crack Growth TestingAnonymous B7pghhNo ratings yet

- Amplitude Distribution of Emission Wave For CrackingDocument7 pagesAmplitude Distribution of Emission Wave For CrackingmustaqqimNo ratings yet

- ASTM C1740-16 en-USDocument10 pagesASTM C1740-16 en-USRavi MehtaNo ratings yet

- AA OptimProtDocument12 pagesAA OptimProtIAMATMANo ratings yet

- Practical Eddy Current Testing: - General ProcedureDocument7 pagesPractical Eddy Current Testing: - General Procedurekhizer mohamedNo ratings yet

- Measurement of Creep Crack Growth Times in Metals: Standard Test Method ForDocument25 pagesMeasurement of Creep Crack Growth Times in Metals: Standard Test Method ForCristian DíazNo ratings yet

- Failure Assessment and Evaluation of DamageDocument44 pagesFailure Assessment and Evaluation of DamageRamancoronaNo ratings yet

- Monitoring Low Cycle Fatigue Damage in Turbine Blade Using Vibration CharacteristicsDocument22 pagesMonitoring Low Cycle Fatigue Damage in Turbine Blade Using Vibration Characteristicssajjad_naghdi241No ratings yet

- Description of OperationDocument7 pagesDescription of OperationHeri MunirNo ratings yet

- 3Document1 page3ernarendersainiNo ratings yet

- 5Document1 page5ernarendersainiNo ratings yet

- 2Document1 page2ernarendersainiNo ratings yet

- PIT H114 15 P354LsdfghDocument1 pagePIT H114 15 P354LsdfghernarendersainiNo ratings yet

- PIT H118 15 P354LwerDocument1 pagePIT H118 15 P354LwerernarendersainiNo ratings yet

- DISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TestDocument1 pageDISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TesternarendersainiNo ratings yet

- Project No.: PIT-H147-10: Impact Toe Response Toe Response DefectDocument1 pageProject No.: PIT-H147-10: Impact Toe Response Toe Response DefecternarendersainiNo ratings yet

- Project No.: PIT-H147-10: Pile: P96-1Document1 pageProject No.: PIT-H147-10: Pile: P96-1ernarendersainiNo ratings yet

- Project No.: PIT-H147-10: ULR - TC752120000006415FDocument1 pageProject No.: PIT-H147-10: ULR - TC752120000006415FernarendersainiNo ratings yet

- Technical Specifications (NCRTC) DM/CN/COR-OF/108Document1 pageTechnical Specifications (NCRTC) DM/CN/COR-OF/108ernarendersainiNo ratings yet

- Manufactures of Lime Based Blocks PDFDocument9 pagesManufactures of Lime Based Blocks PDFernarendersainiNo ratings yet

- Book 1Document16 pagesBook 1ernarendersainiNo ratings yet

- 653 Linoleum Sheets & TilesDocument8 pages653 Linoleum Sheets & TilesernarendersainiNo ratings yet

- 3622 Sand Stone For Slab & TilesDocument7 pages3622 Sand Stone For Slab & TilesernarendersainiNo ratings yet

- Elastic Model of Space-Time Continuum: B.Tech in Civil EngineeringDocument4 pagesElastic Model of Space-Time Continuum: B.Tech in Civil EngineeringShashi PrakashNo ratings yet

- Free Fall Problems: PHY1121 Assignment 1 APRIL 2014Document1 pageFree Fall Problems: PHY1121 Assignment 1 APRIL 2014Mani MalNo ratings yet

- Airplane AxesDocument4 pagesAirplane AxesbnolascoNo ratings yet

- Implementation of An Adaptive Controller On A Ball Balancing Robot Jordy AnningaDocument92 pagesImplementation of An Adaptive Controller On A Ball Balancing Robot Jordy AnningaSteve DemirelNo ratings yet

- Rumus MKMDocument4 pagesRumus MKM175Kevin Ben LodaNo ratings yet

- 17chp06 Process Heat Transfer LabDocument50 pages17chp06 Process Heat Transfer LabpandianvijaybharathiNo ratings yet

- Elements of Partial Differential Equations. by Ian N. SneddonDocument7 pagesElements of Partial Differential Equations. by Ian N. SneddonAhduibNo ratings yet

- Day 6 - Summative AssessmentDocument8 pagesDay 6 - Summative Assessmentapi-540199646No ratings yet

- Abaqus Automatic Stabilization When and How To Use ItDocument8 pagesAbaqus Automatic Stabilization When and How To Use ItBingkuai bigNo ratings yet

- Pressure VesselDocument2 pagesPressure VesselbobNo ratings yet

- 11th Physics Question Paper May 2022 - Governmentexams - Co.inDocument12 pages11th Physics Question Paper May 2022 - Governmentexams - Co.indevichandiran85No ratings yet

- Module 3 and 5 PDFDocument55 pagesModule 3 and 5 PDFSaptadip SahaNo ratings yet

- New Microsoft Word DocumentDocument11 pagesNew Microsoft Word Documenthareeshp64No ratings yet

- Chap 1 Wave 2Document10 pagesChap 1 Wave 2Arnold EdwardNo ratings yet

- Avogadro LawDocument10 pagesAvogadro LawLerr Real RelleNo ratings yet

- Full-Range Stress-Strain Curves For Stainless SteelDocument15 pagesFull-Range Stress-Strain Curves For Stainless SteelNurul HudaNo ratings yet

- Free Fall Motion: Golf Ball Paper Golf Ball Crumpled PaperDocument6 pagesFree Fall Motion: Golf Ball Paper Golf Ball Crumpled PapernorhaslizaNo ratings yet

- Metode Conjugate BeamDocument5 pagesMetode Conjugate Beamnurul saniyyahNo ratings yet

- MF 04Document21 pagesMF 04Carlos De la CruzNo ratings yet

- DS - en 1997-1 DK Na - 2010 eDocument37 pagesDS - en 1997-1 DK Na - 2010 ep_meulendijks108No ratings yet

- Load Distribution Along Fully Grouted Bolts With Emphasis On Cable Bolt ReinforcementDocument29 pagesLoad Distribution Along Fully Grouted Bolts With Emphasis On Cable Bolt ReinforcementCyrillus Arthur SaputraNo ratings yet

- Introduction To Convective Heat TransferDocument49 pagesIntroduction To Convective Heat TransferSangita SangamNo ratings yet

- Cie - 462 - Test Two 23.05.2022Document2 pagesCie - 462 - Test Two 23.05.2022Chris KapendaNo ratings yet

- Thermodynamics Full NotesDocument120 pagesThermodynamics Full NotesBalram Purnaa100% (3)

- Factor de Friccion FluidosDocument11 pagesFactor de Friccion FluidosGilmer Rojas ChavezNo ratings yet

- Heat Transfer ACEDocument122 pagesHeat Transfer ACERamnarayan MeenaNo ratings yet

- FMMDocument4 pagesFMMMohanraj KabilanNo ratings yet

- Thermodynamics - Example Problems Problems and Solutions: 1 Examining A Power PlantDocument7 pagesThermodynamics - Example Problems Problems and Solutions: 1 Examining A Power PlantUmangtarangNo ratings yet

- Calicut University Civil Engineering Fourth Semester Model Question PapersDocument9 pagesCalicut University Civil Engineering Fourth Semester Model Question PapersRanjith SomanNo ratings yet

PIT H114 15 P354Ldfgh

PIT H114 15 P354Ldfgh

Uploaded by

ernarendersainiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PIT H114 15 P354Ldfgh

PIT H114 15 P354Ldfgh

Uploaded by

ernarendersainiCopyright:

Available Formats

Project No.

: PIT- H114-15

3.0 TESTING EQUIPMENT

Integrity tests were performed using the most advanced state of art data collection system available to

estimate pile integrity by surface impact methods. In this system the PIT Collector allows for detection

of wave reflections from changes in pile impedance. The Collector can acquire, enhance, display and

plot data. The conclusion and interpretation of the results are based on the pile top velocity against

time curve.

The testing involves attachment

chment of accelerometer on the pile top. After attachment, the impact device

(a nylon tipped hammer) generates a low strain compressive wave, which travels down the pile. The

acceleration and velocity records of the impact, along with subsequent reflecti

reflections

ons from either pile toe

and/or discontinuities are graphically displayed.

The integrity testing method separates the effect of impact and surface reflections from other relevant

reflections (i.e. pile toe or other discontinuities) by averaging records of several impacts. This

averaging technique tends to cancel random signals in any particular blow while amplifying the effect

of the relevant repetitive response.

The signal records obtained are also expo

exponentially amplified with time. This enhances the identification

id

of relevant reflections in records, which have low energy due to signals being dampened out by skin

friction.

4.0 INTERPRETATION OF RESULTS

The interpretation of results consists of evaluation of data based on the reflections recorded during

testing as described above. Reflections are produced by variations in shape, material, soil resistance

changes, joints etc. The deepest reflector is the pile’s toe and its reflection is last observed. All such

reflections are in acceleration form and arare

e numerically integrated to velocity before being displayed.

The integrity of the pile thus tested is based on such reflections and detected changes in impedance

(EA/c) along the pile length, when subjected to an impact blow. Here E is the elastic modulus of the

pile material, A is cross-sectional

sectional area of the pile and c is the wave speed. Impedance variation

usually refers to cross-sectional

sectional change.

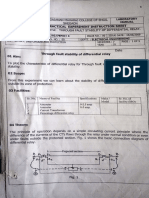

The typical data sets for good or damaged shall generally be as shown in Figures 1a and 1b

respectively and are also defined in ASTM D5882.

IMPACT

TOE RESPONSE DEFECT

Fig.1a Typical Velocity Trace - Good Pile Fig.1b Typical Velocity Trace - Damaged Pile

Refer to the typical trace for a defect

defective pile in Figure 1b;; the method cannot identify

identif nature of defect

as the wave reflects from a reduction in either elastic modulus or crosscross-section.

section. Thus whether the

defect is necking, honeycombs, voids, soil inclusions, tremie choke etc. they are all classified as

defects.

Note: 1) This test report or part of the same shall not be reproduced wit

without written permission from the GEO DYNAMICS ULR - TC752121000000190F

2) The results are related to the test performed at location shown

wn by client

Doc. No.: F/7.8/01F/Issue No.02/Issue Date: 16-03-2020/ Am

Amend No.:00 / Amend Date: - / Page 4 of 10 CONTROLLED

C copy

You might also like

- RDSO Vendor ListDocument7 pagesRDSO Vendor Listernarendersaini62% (13)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Introduction To Chemical Engineering Thermodynamics by Halder, Gopinath PDFDocument2 pagesIntroduction To Chemical Engineering Thermodynamics by Halder, Gopinath PDFs9n9No ratings yet

- 4 Balanced CantileverDocument28 pages4 Balanced Cantileverernarendersaini100% (1)

- Project No.: PIT-H147-10: Impact Toe Response Toe Response DefectDocument1 pageProject No.: PIT-H147-10: Impact Toe Response Toe Response DefecternarendersainiNo ratings yet

- Pit E103 11Document13 pagesPit E103 11PLANiN Innovation & Consultancy Services Pvt. Ltd.No ratings yet

- Quantifying The Potential Impacts of Disturbances On Power System ProtectionDocument4 pagesQuantifying The Potential Impacts of Disturbances On Power System ProtectionmohsinamanNo ratings yet

- Finalized CMU Guideline Dec 2013Document46 pagesFinalized CMU Guideline Dec 2013rhunriang9977No ratings yet

- Investigation of Transformer Failure in Indonesia 231022 204837Document6 pagesInvestigation of Transformer Failure in Indonesia 231022 204837kvramananNo ratings yet

- O/C & E/F Relay Test Report: - M/S.Grasim Industries Limited Ganjam, OdissaDocument9 pagesO/C & E/F Relay Test Report: - M/S.Grasim Industries Limited Ganjam, OdissaDhivagar NamakkalNo ratings yet

- STANDARD TEST METHOD PIT (Pile Integrity Test)Document5 pagesSTANDARD TEST METHOD PIT (Pile Integrity Test)senthilNo ratings yet

- IJREAMV06I0666053Document3 pagesIJREAMV06I0666053Yan Lin AungNo ratings yet

- Wavelet Based Demodulation of Vibration Signals Generated by Defects in Rolling Element BearingsDocument15 pagesWavelet Based Demodulation of Vibration Signals Generated by Defects in Rolling Element BearingsAnonymous OFwyjaMyNo ratings yet

- PSP Practical No 3,5,7Document11 pagesPSP Practical No 3,5,7Vivek BendeNo ratings yet

- Analysis of Failed and Working Power Transformer and Their DiagnosticsDocument6 pagesAnalysis of Failed and Working Power Transformer and Their DiagnosticsPrasanth ThomasNo ratings yet

- CT Failure Diagnostic Paper ITMF 2011 JunaidiDocument6 pagesCT Failure Diagnostic Paper ITMF 2011 JunaidiHari Krishna.M100% (1)

- Pit Report Pier04 Pile01 06Document11 pagesPit Report Pier04 Pile01 06Priodeep ChowdhuryNo ratings yet

- 10 11-19-407 Qiao 1b Incipient Bearing Fault Article 2 ModeloDocument6 pages10 11-19-407 Qiao 1b Incipient Bearing Fault Article 2 ModeloAnselmo LeonardoNo ratings yet

- An Acoustic Emission Technique For Crack Modes ClaDocument12 pagesAn Acoustic Emission Technique For Crack Modes ClaNhà Quê Ra TỉnhNo ratings yet

- United States Naval Academy: Division ofDocument13 pagesUnited States Naval Academy: Division ofdrdinglechengNo ratings yet

- Wavelet Spectrum Analysis For Bearing Fault Diagnostics: Jie Liu, Wilson Wang, Farid Golnaraghi and Kefu LiuDocument9 pagesWavelet Spectrum Analysis For Bearing Fault Diagnostics: Jie Liu, Wilson Wang, Farid Golnaraghi and Kefu Liuandi_wijayaNo ratings yet

- CL-E131 Stator Earth Fault Protection 90%: Commissioning Check List EDocument2 pagesCL-E131 Stator Earth Fault Protection 90%: Commissioning Check List Emirage1977No ratings yet

- 048 Venkatesh AUPEC01paperDocument5 pages048 Venkatesh AUPEC01paperDante FilhoNo ratings yet

- Poljak 2009Document11 pagesPoljak 2009amrutha cNo ratings yet

- Power Transformer Testing and Commissioning PDFDocument6 pagesPower Transformer Testing and Commissioning PDFEric Stanton100% (1)

- Example Ramping Overcurrent ENU PDFDocument21 pagesExample Ramping Overcurrent ENU PDFOscar Ordoñez VelasquezNo ratings yet

- On-Load Tap Changer's Dynamic Resistance Measurement: Settings and InterpretationDocument5 pagesOn-Load Tap Changer's Dynamic Resistance Measurement: Settings and InterpretationBaharin Hashim100% (1)

- Investigation of 150/66 KV 100 MVA Transformer Internal FailureDocument6 pagesInvestigation of 150/66 KV 100 MVA Transformer Internal Failuredavid23281dNo ratings yet

- 18 - Aizam - HV IT in TNB Substations - Paper PDFDocument5 pages18 - Aizam - HV IT in TNB Substations - Paper PDFbcqbaoNo ratings yet

- Lifetime Prediction For Bearing in Induction Motors by Shu Tzu Chang (Paper-2019)Document5 pagesLifetime Prediction For Bearing in Induction Motors by Shu Tzu Chang (Paper-2019)emmanuel799100% (1)

- Impact of Startup Scheme On Francis Runner Life ExpectancyDocument9 pagesImpact of Startup Scheme On Francis Runner Life ExpectancyFolpoNo ratings yet

- Condition Assessment of Transformer by Park's Vector and Symmetrical Components To Detect Inter Turn FaultDocument6 pagesCondition Assessment of Transformer by Park's Vector and Symmetrical Components To Detect Inter Turn FaultdimasairlanggaNo ratings yet

- Novel Technique For Fault Location Estimation On Parallel Transmission Lines Using WaveletDocument7 pagesNovel Technique For Fault Location Estimation On Parallel Transmission Lines Using WaveletRachana MeenaNo ratings yet

- Fatigue TestingDocument7 pagesFatigue Testingromesaali23No ratings yet

- Transformer Testing by Afees Ahamed Egger IndiaDocument27 pagesTransformer Testing by Afees Ahamed Egger IndialrpatraNo ratings yet

- Riser TestDocument22 pagesRiser TestAbraham RojasNo ratings yet

- Gen Write UpDocument11 pagesGen Write Upsarirag100% (3)

- Vibration Monitoring On Power TransformerDocument2 pagesVibration Monitoring On Power TransformerPriya Surya HarijantoNo ratings yet

- 7 Detection of Mechanical DeformationDocument9 pages7 Detection of Mechanical DeformationMohamed BoughalNo ratings yet

- Real-Time Nondestructive Evaluation of Airframe Structures For Health Monitoring and Residual Life PredictionDocument12 pagesReal-Time Nondestructive Evaluation of Airframe Structures For Health Monitoring and Residual Life PredictionArunNo ratings yet

- Transformer Condition Monitoring Sethuraman MuthukaruppDocument8 pagesTransformer Condition Monitoring Sethuraman MuthukaruppAnantha RkNo ratings yet

- TIA Grubic2011 LibreDocument8 pagesTIA Grubic2011 LibreMariut Elena LarisaNo ratings yet

- Construction of Multi Storied Housing Complex at Fort Kochi, Kerala Report For Pile Integrity Testing On 06 Nos. R.C. Bored PilesDocument11 pagesConstruction of Multi Storied Housing Complex at Fort Kochi, Kerala Report For Pile Integrity Testing On 06 Nos. R.C. Bored PilesTaak ConstructionsNo ratings yet

- MOM Lab Manuals OrigionalDocument95 pagesMOM Lab Manuals OrigionalMansoob BukhariNo ratings yet

- Planning of Operation & Maintenance Using Risk and Reliability Based MethodsDocument8 pagesPlanning of Operation & Maintenance Using Risk and Reliability Based Methodsfaz143No ratings yet

- Astm D5778 - 07Document19 pagesAstm D5778 - 07Black GokuNo ratings yet

- Wronkowicz 2018Document39 pagesWronkowicz 2018stajicin kullanımNo ratings yet

- Seismic Damage and Damage-Control Design For RC Frames 1990Document20 pagesSeismic Damage and Damage-Control Design For RC Frames 1990Tinh T. LeNo ratings yet

- ACI ITG/T1.1R-99: Reported by ACI Innovation Task Group 1 and CollaboratorsDocument7 pagesACI ITG/T1.1R-99: Reported by ACI Innovation Task Group 1 and CollaboratorsCorui Mihai ValerNo ratings yet

- E751E751M-12 Standard Practice For Acoustic Emission Monitoring During Resistance Spot - WeldingDocument7 pagesE751E751M-12 Standard Practice For Acoustic Emission Monitoring During Resistance Spot - WeldingAnder EscobedoNo ratings yet

- A Wavelet Power Based Algorithm For Synchronous Generator ProtectionDocument6 pagesA Wavelet Power Based Algorithm For Synchronous Generator ProtectionsunitharajababuNo ratings yet

- Influence of Damage in The Acoustic Emission ParametersDocument8 pagesInfluence of Damage in The Acoustic Emission Parameters윤대성No ratings yet

- CT Failure Diagnostic Paper ITMF 2011 Junaidi ENU PDFDocument6 pagesCT Failure Diagnostic Paper ITMF 2011 Junaidi ENU PDFJose Antonio Huamani ChuquirimayNo ratings yet

- Application of Wavelet Packets in Bearing Fault DiagnosisDocument8 pagesApplication of Wavelet Packets in Bearing Fault DiagnosisjudarangocaNo ratings yet

- E2760-10E2 Creep-Fatigue Crack Growth TestingDocument19 pagesE2760-10E2 Creep-Fatigue Crack Growth TestingAnonymous B7pghhNo ratings yet

- Amplitude Distribution of Emission Wave For CrackingDocument7 pagesAmplitude Distribution of Emission Wave For CrackingmustaqqimNo ratings yet

- ASTM C1740-16 en-USDocument10 pagesASTM C1740-16 en-USRavi MehtaNo ratings yet

- AA OptimProtDocument12 pagesAA OptimProtIAMATMANo ratings yet

- Practical Eddy Current Testing: - General ProcedureDocument7 pagesPractical Eddy Current Testing: - General Procedurekhizer mohamedNo ratings yet

- Measurement of Creep Crack Growth Times in Metals: Standard Test Method ForDocument25 pagesMeasurement of Creep Crack Growth Times in Metals: Standard Test Method ForCristian DíazNo ratings yet

- Failure Assessment and Evaluation of DamageDocument44 pagesFailure Assessment and Evaluation of DamageRamancoronaNo ratings yet

- Monitoring Low Cycle Fatigue Damage in Turbine Blade Using Vibration CharacteristicsDocument22 pagesMonitoring Low Cycle Fatigue Damage in Turbine Blade Using Vibration Characteristicssajjad_naghdi241No ratings yet

- Description of OperationDocument7 pagesDescription of OperationHeri MunirNo ratings yet

- 3Document1 page3ernarendersainiNo ratings yet

- 5Document1 page5ernarendersainiNo ratings yet

- 2Document1 page2ernarendersainiNo ratings yet

- PIT H114 15 P354LsdfghDocument1 pagePIT H114 15 P354LsdfghernarendersainiNo ratings yet

- PIT H118 15 P354LwerDocument1 pagePIT H118 15 P354LwerernarendersainiNo ratings yet

- DISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TestDocument1 pageDISCIPLINE: Non-Destructive Testing GROUP: Building Materials - Reinforced Concrete Structures Test: Pile Integrity TesternarendersainiNo ratings yet

- Project No.: PIT-H147-10: Impact Toe Response Toe Response DefectDocument1 pageProject No.: PIT-H147-10: Impact Toe Response Toe Response DefecternarendersainiNo ratings yet

- Project No.: PIT-H147-10: Pile: P96-1Document1 pageProject No.: PIT-H147-10: Pile: P96-1ernarendersainiNo ratings yet

- Project No.: PIT-H147-10: ULR - TC752120000006415FDocument1 pageProject No.: PIT-H147-10: ULR - TC752120000006415FernarendersainiNo ratings yet

- Technical Specifications (NCRTC) DM/CN/COR-OF/108Document1 pageTechnical Specifications (NCRTC) DM/CN/COR-OF/108ernarendersainiNo ratings yet

- Manufactures of Lime Based Blocks PDFDocument9 pagesManufactures of Lime Based Blocks PDFernarendersainiNo ratings yet

- Book 1Document16 pagesBook 1ernarendersainiNo ratings yet

- 653 Linoleum Sheets & TilesDocument8 pages653 Linoleum Sheets & TilesernarendersainiNo ratings yet

- 3622 Sand Stone For Slab & TilesDocument7 pages3622 Sand Stone For Slab & TilesernarendersainiNo ratings yet

- Elastic Model of Space-Time Continuum: B.Tech in Civil EngineeringDocument4 pagesElastic Model of Space-Time Continuum: B.Tech in Civil EngineeringShashi PrakashNo ratings yet

- Free Fall Problems: PHY1121 Assignment 1 APRIL 2014Document1 pageFree Fall Problems: PHY1121 Assignment 1 APRIL 2014Mani MalNo ratings yet

- Airplane AxesDocument4 pagesAirplane AxesbnolascoNo ratings yet

- Implementation of An Adaptive Controller On A Ball Balancing Robot Jordy AnningaDocument92 pagesImplementation of An Adaptive Controller On A Ball Balancing Robot Jordy AnningaSteve DemirelNo ratings yet

- Rumus MKMDocument4 pagesRumus MKM175Kevin Ben LodaNo ratings yet

- 17chp06 Process Heat Transfer LabDocument50 pages17chp06 Process Heat Transfer LabpandianvijaybharathiNo ratings yet

- Elements of Partial Differential Equations. by Ian N. SneddonDocument7 pagesElements of Partial Differential Equations. by Ian N. SneddonAhduibNo ratings yet

- Day 6 - Summative AssessmentDocument8 pagesDay 6 - Summative Assessmentapi-540199646No ratings yet

- Abaqus Automatic Stabilization When and How To Use ItDocument8 pagesAbaqus Automatic Stabilization When and How To Use ItBingkuai bigNo ratings yet

- Pressure VesselDocument2 pagesPressure VesselbobNo ratings yet

- 11th Physics Question Paper May 2022 - Governmentexams - Co.inDocument12 pages11th Physics Question Paper May 2022 - Governmentexams - Co.indevichandiran85No ratings yet

- Module 3 and 5 PDFDocument55 pagesModule 3 and 5 PDFSaptadip SahaNo ratings yet

- New Microsoft Word DocumentDocument11 pagesNew Microsoft Word Documenthareeshp64No ratings yet

- Chap 1 Wave 2Document10 pagesChap 1 Wave 2Arnold EdwardNo ratings yet

- Avogadro LawDocument10 pagesAvogadro LawLerr Real RelleNo ratings yet

- Full-Range Stress-Strain Curves For Stainless SteelDocument15 pagesFull-Range Stress-Strain Curves For Stainless SteelNurul HudaNo ratings yet

- Free Fall Motion: Golf Ball Paper Golf Ball Crumpled PaperDocument6 pagesFree Fall Motion: Golf Ball Paper Golf Ball Crumpled PapernorhaslizaNo ratings yet

- Metode Conjugate BeamDocument5 pagesMetode Conjugate Beamnurul saniyyahNo ratings yet

- MF 04Document21 pagesMF 04Carlos De la CruzNo ratings yet

- DS - en 1997-1 DK Na - 2010 eDocument37 pagesDS - en 1997-1 DK Na - 2010 ep_meulendijks108No ratings yet

- Load Distribution Along Fully Grouted Bolts With Emphasis On Cable Bolt ReinforcementDocument29 pagesLoad Distribution Along Fully Grouted Bolts With Emphasis On Cable Bolt ReinforcementCyrillus Arthur SaputraNo ratings yet

- Introduction To Convective Heat TransferDocument49 pagesIntroduction To Convective Heat TransferSangita SangamNo ratings yet

- Cie - 462 - Test Two 23.05.2022Document2 pagesCie - 462 - Test Two 23.05.2022Chris KapendaNo ratings yet

- Thermodynamics Full NotesDocument120 pagesThermodynamics Full NotesBalram Purnaa100% (3)

- Factor de Friccion FluidosDocument11 pagesFactor de Friccion FluidosGilmer Rojas ChavezNo ratings yet

- Heat Transfer ACEDocument122 pagesHeat Transfer ACERamnarayan MeenaNo ratings yet

- FMMDocument4 pagesFMMMohanraj KabilanNo ratings yet

- Thermodynamics - Example Problems Problems and Solutions: 1 Examining A Power PlantDocument7 pagesThermodynamics - Example Problems Problems and Solutions: 1 Examining A Power PlantUmangtarangNo ratings yet

- Calicut University Civil Engineering Fourth Semester Model Question PapersDocument9 pagesCalicut University Civil Engineering Fourth Semester Model Question PapersRanjith SomanNo ratings yet