Professional Documents

Culture Documents

TensarPave Design Methods August 2014 Jakarta

TensarPave Design Methods August 2014 Jakarta

Uploaded by

noto.sugiartoCopyright:

Available Formats

You might also like

- Tech Spec 4Document28 pagesTech Spec 4Mo'men Abu-SmaihaNo ratings yet

- 1.8 - Ms. K.L.I. Ranasoma - Deputy Director (R & D), RDADocument27 pages1.8 - Ms. K.L.I. Ranasoma - Deputy Director (R & D), RDAmpchanakaNo ratings yet

- Project Report On Pavement DesignDocument50 pagesProject Report On Pavement Designsagar kumar100% (1)

- Aashto 1972 CarolDocument30 pagesAashto 1972 CarolIjeal KuNo ratings yet

- BSPP 2014Q Sec15 Flexible Pavement Design v2014x6 PDFDocument12 pagesBSPP 2014Q Sec15 Flexible Pavement Design v2014x6 PDFศิวาเวช อบมาNo ratings yet

- Design Guide IntroductionDocument39 pagesDesign Guide IntroductionsyxomphousNo ratings yet

- Flexible Pavement Design Tool 060622Document36 pagesFlexible Pavement Design Tool 060622abmtestlab82No ratings yet

- 2.1 - Pavement Types and LayersDocument33 pages2.1 - Pavement Types and Layersmark lionNo ratings yet

- Lecture 6-Asphalt Mix DesignDocument5 pagesLecture 6-Asphalt Mix DesignKeshav SomaniNo ratings yet

- Flexible Pavement Design Tool 060622Document38 pagesFlexible Pavement Design Tool 060622CANAL VERMELHONo ratings yet

- ACI 330.2R-17: Nigel Parkes, PNA Construction TechnologiesDocument15 pagesACI 330.2R-17: Nigel Parkes, PNA Construction TechnologiesSubramanian MuruganNo ratings yet

- Chapter 4Document28 pagesChapter 4noddyjohnNo ratings yet

- Theyse, H L Et Al - 10th Conference On Asphalt Pavements For South Africa (2) - 2011Document20 pagesTheyse, H L Et Al - 10th Conference On Asphalt Pavements For South Africa (2) - 2011ahgreyling01No ratings yet

- Evaluation of Flexible Foundation & Pavement Design According To The DMRBDocument1 pageEvaluation of Flexible Foundation & Pavement Design According To The DMRBAguero AgueroNo ratings yet

- Tech Spec 10: Application Guide For Interlocking Concrete PavementsDocument8 pagesTech Spec 10: Application Guide For Interlocking Concrete PavementsSilvio GenaoNo ratings yet

- Design of Paving Stone PavementsDocument28 pagesDesign of Paving Stone PavementsAlexious Demide100% (1)

- Flexible Pavements - Evolution of IRC 37Document85 pagesFlexible Pavements - Evolution of IRC 37DIT TRAFFIC100% (2)

- Application Guide For Interlocking Concrete PavementsDocument9 pagesApplication Guide For Interlocking Concrete PavementsComaNo ratings yet

- Tech Spec: Structural Design of Interlocking Concrete Pavement For Roads and Parking LotsDocument28 pagesTech Spec: Structural Design of Interlocking Concrete Pavement For Roads and Parking LotsMichael HurtadoNo ratings yet

- AAPA_IG-6_Selection_and_Design_of_Flexible_Pavements_OCRDocument68 pagesAAPA_IG-6_Selection_and_Design_of_Flexible_Pavements_OCRtejas.dorNo ratings yet

- ADM Pavement Design RequirementsDocument8 pagesADM Pavement Design RequirementsMahmoud ZidanNo ratings yet

- Technical Note TN 29 Concrete Pavement Types PDFDocument2 pagesTechnical Note TN 29 Concrete Pavement Types PDFWaldo SchaefferNo ratings yet

- Pavement MaterialsDocument126 pagesPavement MaterialsSaleemAhmadMalikNo ratings yet

- Pavement AashtoDocument28 pagesPavement AashtoJoe Ady ShaputraNo ratings yet

- Flexible Pavement Design Tool 060622Document36 pagesFlexible Pavement Design Tool 060622Pramudyo Bayu Pamungkas, S.T.No ratings yet

- Final TechAbutment - MIAL Casestudy 17112014Document2 pagesFinal TechAbutment - MIAL Casestudy 17112014Ankit GuptaNo ratings yet

- Andvanced Pavement Designe CompleteDocument28 pagesAndvanced Pavement Designe CompleteShikha SinghNo ratings yet

- AAPA IG-6 Selection and Design of Flexible Pavements OCRDocument68 pagesAAPA IG-6 Selection and Design of Flexible Pavements OCRChristopher CarrilloNo ratings yet

- 5 Design of Surfaces and GuidewaysDocument90 pages5 Design of Surfaces and GuidewaysRenalyn Andrade0% (1)

- Comparacion Entre Metodos MEPDG 2022Document6 pagesComparacion Entre Metodos MEPDG 2022André BerninzonNo ratings yet

- Stabilizer Construction MethodDocument35 pagesStabilizer Construction Methodsfsdgdfngfm esefsgNo ratings yet

- 2.5 Details of Asphalt Institute Method of Design of Flexible PavementsDocument55 pages2.5 Details of Asphalt Institute Method of Design of Flexible PavementsRajesh Khadka100% (7)

- Asphalt Pavement Design GuideDocument28 pagesAsphalt Pavement Design Guiderendy50% (2)

- Code of Practice RC 50022 Selection and Design of Pavement and Surfacings December 2018Document33 pagesCode of Practice RC 50022 Selection and Design of Pavement and Surfacings December 2018Barry LibertyNo ratings yet

- Tech Spec 4 Structural DesignDocument28 pagesTech Spec 4 Structural DesignHuascar Medrano LazarteNo ratings yet

- Chapter 4Document28 pagesChapter 4singhconstNo ratings yet

- Geometric Design Procedure Revised FinalDocument12 pagesGeometric Design Procedure Revised FinalRebi HamzaNo ratings yet

- Stabilizer Construction MethodDocument38 pagesStabilizer Construction Methodsfsdgdfngfm esefsgNo ratings yet

- Introduction 2014 E.CDocument60 pagesIntroduction 2014 E.CMamush LetaNo ratings yet

- 3 Design Considerations StandardsDocument117 pages3 Design Considerations StandardsAldwin Joseph Abainza100% (2)

- 2000 RTR Al-Suleiman Vol9 1 PDFDocument14 pages2000 RTR Al-Suleiman Vol9 1 PDFTNo ratings yet

- Flexible Pavement Aspects of Basic DesignDocument92 pagesFlexible Pavement Aspects of Basic DesignGanesh Gupta100% (1)

- GN042Document43 pagesGN042Riko Chy MakNo ratings yet

- 4 - Structural ComponentsDocument32 pages4 - Structural Componentsawais.mfbzoneNo ratings yet

- Pavement Design - V1Document26 pagesPavement Design - V1DEBALEENA MUKHERJEENo ratings yet

- Recent Research of Track Technology Division: ArticlesDocument6 pagesRecent Research of Track Technology Division: ArticlesMantripragada RajuNo ratings yet

- Intersection Design Principles Design Elements MidtermDocument99 pagesIntersection Design Principles Design Elements MidtermJed mariñasNo ratings yet

- Pavement Design & Traffic Census WorkshopDocument38 pagesPavement Design & Traffic Census WorkshopJK HallNo ratings yet

- Fact Sheet Paving A Residential DrivewayDocument4 pagesFact Sheet Paving A Residential DrivewayDenise2512No ratings yet

- Design Parametr PDFDocument8 pagesDesign Parametr PDFAlok ThakurNo ratings yet

- IRC Method of Design of Flexible Pavements: Lecture Notes in Transportation Systems EngineeringDocument8 pagesIRC Method of Design of Flexible Pavements: Lecture Notes in Transportation Systems EngineeringAlok ThakurNo ratings yet

- Plain PDFDocument8 pagesPlain PDFB RAMUNo ratings yet

- Lecture Notes On IRC 37Document8 pagesLecture Notes On IRC 37AdhirajNo ratings yet

- Lecture8 - CE 600132 - AASHTO - 18032024Document84 pagesLecture8 - CE 600132 - AASHTO - 18032024Pratik AgarwalNo ratings yet

- Rational Structural Design of Highway/Airport Pavements: New Evapave, the Strongest & Toughest Paving MaterialFrom EverandRational Structural Design of Highway/Airport Pavements: New Evapave, the Strongest & Toughest Paving MaterialNo ratings yet

- Adhesive Rebar For PerliteDocument8 pagesAdhesive Rebar For Perlitenoto.sugiartoNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- GTA 308 - Maximum Gradient: August 2020Document17 pagesGTA 308 - Maximum Gradient: August 2020noto.sugiartoNo ratings yet

- Company Profile and Project Experience GulfPerliteDocument68 pagesCompany Profile and Project Experience GulfPerlitenoto.sugiartoNo ratings yet

- MSDS Cement Tiga Roda - Dec 2019Document5 pagesMSDS Cement Tiga Roda - Dec 2019noto.sugiarto100% (1)

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- Appendix E.1. Pipe Support PS-CP-01Document10 pagesAppendix E.1. Pipe Support PS-CP-01noto.sugiartoNo ratings yet

- Soil Mixing Wall System: Product InformationDocument8 pagesSoil Mixing Wall System: Product Informationnoto.sugiartoNo ratings yet

- Full Displacement Pile System BAUER BG-System: Produktinformation Product InformationDocument8 pagesFull Displacement Pile System BAUER BG-System: Produktinformation Product Informationnoto.sugiartoNo ratings yet

- CSM Cutter Soil Mixing: Equipment Construction ProcedureDocument12 pagesCSM Cutter Soil Mixing: Equipment Construction Procedurenoto.sugiartoNo ratings yet

- Appendix B. Basic Load & Load CombinationsDocument2 pagesAppendix B. Basic Load & Load Combinationsnoto.sugiartoNo ratings yet

- Attachment E.3. Wind CalculationDocument48 pagesAttachment E.3. Wind Calculationnoto.sugiartoNo ratings yet

- Interline 955: Novolac Vinyl EsterDocument4 pagesInterline 955: Novolac Vinyl Esternoto.sugiartoNo ratings yet

- Appendix E.2. Pipe Support PS-CP-02Document13 pagesAppendix E.2. Pipe Support PS-CP-02noto.sugiartoNo ratings yet

- Appendix E.1. Pipe Support Calculation - PS-CP-01Document10 pagesAppendix E.1. Pipe Support Calculation - PS-CP-01noto.sugiarto50% (2)

- Appendix A. Structural Modeling and Loadings (19.09.13) .1Document19 pagesAppendix A. Structural Modeling and Loadings (19.09.13) .1noto.sugiartoNo ratings yet

- Interline 975: Solvent Free Epoxy Tank CoatingDocument4 pagesInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoNo ratings yet

- Appendix C. SACS Input of In-Place AnalysisDocument14 pagesAppendix C. SACS Input of In-Place Analysisnoto.sugiartoNo ratings yet

- Contoh Score TBE MOM Pre-Bid Meeting BID-15-0024Document13 pagesContoh Score TBE MOM Pre-Bid Meeting BID-15-0024noto.sugiartoNo ratings yet

- Intertherm 50: Silicone AluminiumDocument4 pagesIntertherm 50: Silicone Aluminiumnoto.sugiartoNo ratings yet

- Lamination Recipe PN20Document6 pagesLamination Recipe PN20noto.sugiartoNo ratings yet

- Edexcel Igcse ElectrolysisDocument86 pagesEdexcel Igcse ElectrolysisshoshoNo ratings yet

- Experiment FiveDocument4 pagesExperiment FiveSusana DakoraNo ratings yet

- Chapter 5Document22 pagesChapter 5Aftab AhmedNo ratings yet

- #10 - Energy Balance - 01 (Rev01)Document48 pages#10 - Energy Balance - 01 (Rev01)Valentino LunardiNo ratings yet

- Exercise Problems of Chapter-Two Ch-2 Tension Members: R L A I R Mpa F Mpa FDocument7 pagesExercise Problems of Chapter-Two Ch-2 Tension Members: R L A I R Mpa F Mpa FEng Abdikarim Walhad100% (3)

- Prestressing Systems For Structural Strengthening With Sika CarboDur CFRP PlatesDocument5 pagesPrestressing Systems For Structural Strengthening With Sika CarboDur CFRP PlatesManuel PetroNo ratings yet

- Pompe Wilden PDFDocument184 pagesPompe Wilden PDFverat81100% (1)

- Grease MSDSDocument3 pagesGrease MSDSSiva Naga Prasad TadipartiNo ratings yet

- Total Area 272 Sq. Meters: Waste DisposalDocument1 pageTotal Area 272 Sq. Meters: Waste DisposalMANPOWER ORMOCNo ratings yet

- Tds Viacrete Pu MF VMDocument3 pagesTds Viacrete Pu MF VMSubrina IslamNo ratings yet

- EST ReportDocument20 pagesEST Reportkrishna kumavatNo ratings yet

- Annisa Indah Kirana - Tugas Evaporasi PDFDocument5 pagesAnnisa Indah Kirana - Tugas Evaporasi PDFANNISA KIRANANo ratings yet

- Impact TestDocument11 pagesImpact TestMohsin AbbasNo ratings yet

- Introduction To Industrial Minerals-Springer Netherlands (1995)Document287 pagesIntroduction To Industrial Minerals-Springer Netherlands (1995)Kathleen SuanzoNo ratings yet

- Organic Chemistry P2 Questions (2020-2023)Document28 pagesOrganic Chemistry P2 Questions (2020-2023)moiz.8450No ratings yet

- Element - 111 - 128-Petrol Station BOQDocument6 pagesElement - 111 - 128-Petrol Station BOQMrweNo ratings yet

- Mil PRF 61002BDocument27 pagesMil PRF 61002BAbdullah PalNo ratings yet

- Za 304 MZ Paint: Product Data Resistance GuideDocument2 pagesZa 304 MZ Paint: Product Data Resistance GuidechepurthiNo ratings yet

- 欧盟CLP化学品分类名单Document644 pages欧盟CLP化学品分类名单Yang YangNo ratings yet

- Properties of SteamDocument4 pagesProperties of SteamAndrew Grogan100% (1)

- Ashby 2003Document11 pagesAshby 2003Gajaraj GajapathiNo ratings yet

- NOCDocument11 pagesNOCVedam Shanmukha HrushikeshNo ratings yet

- Strengthening Mechanisms Notes - 2024Document55 pagesStrengthening Mechanisms Notes - 2024achieng.omondi2No ratings yet

- KML100374 - Drywall Manual AddendumDocument15 pagesKML100374 - Drywall Manual Addendumivg8562No ratings yet

- Pararrayos Tipo BalestroDocument3 pagesPararrayos Tipo BalestroBladimir Michel100% (1)

- Application Note Stainless SteelDocument6 pagesApplication Note Stainless SteelVictoria TechiNo ratings yet

- Edexcel GCE Chemistry Unit-5 June 2014 Question Paper (R)Document28 pagesEdexcel GCE Chemistry Unit-5 June 2014 Question Paper (R)AvrinoxNo ratings yet

- Material Safety Data Sheets: (MSDS)Document5 pagesMaterial Safety Data Sheets: (MSDS)DucNo ratings yet

- Chromium Trioxide Is An Inorganic Compound With The Formula CrO3Document3 pagesChromium Trioxide Is An Inorganic Compound With The Formula CrO3Lihini NimsaraNo ratings yet

- BDA 30803 Notes (Student Version - Printable) Sem 2 2012 - 2013 PDFDocument203 pagesBDA 30803 Notes (Student Version - Printable) Sem 2 2012 - 2013 PDFIlenggeswaran Murugesu100% (1)

TensarPave Design Methods August 2014 Jakarta

TensarPave Design Methods August 2014 Jakarta

Uploaded by

noto.sugiartoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TensarPave Design Methods August 2014 Jakarta

TensarPave Design Methods August 2014 Jakarta

Uploaded by

noto.sugiartoCopyright:

Available Formats

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

Half-Day Seminar – Jakarta, 14th August 2014 Outline of presentation

Design and Application of Mechanically Stabilised Layers

for Highways, Rail Trackbed and Haul Roads

Mechanically stabilised layers

Design of pavements and trafficked areas

Workshop: TensarPave • Benefits of

Design of pavements and trafficked placing geogrid

under compacted

areas using mechanical stabilisation pavement layer

• Interlock and

Mike Dobie confinement

Tensar International Limited • Trafficking trials

and performance

Regional Manager Asia Pacific

• Design of

pavements using

TensarPave

2 Pavement design with mechanical stabilisation 14th August 2014

Design of (road) pavements Design of (road) pavements

Methods available incorporating mechanical stabilisation Methods available incorporating mechanical stabilisation

Based on the principle of confinement Based on the principle of confinement

Ground stabilisation (GS) method Ground stabilisation (GS) method

Single layer, sub-base quality Design method for unpaved roads referenced in the UK Highway

Design of pavement sub-base as temporary road during construction Agency Design Manual for Roads and Bridges HD25/94, Volume 7,

Final design of single layer pavements Section 2, Part 2 and detailed in TRL Report LR1132

Design process AASHTO method AASHTO method

All pavements must be built Multiple layer, sub-base to AC AASHTO Guide for Design of

• Sub-base (or initial layer) Final design of full pavement Pavement Structures 1993

used as temporary access

road during construction

• Still important to design as Design methods

pavement to protect the All are published design

lower layers and subgrade guidelines or methods

3 Pavement design with mechanical stabilisation 14th August 2014 4 Pavement design with mechanical stabilisation 14th August 2014

Design of (road) pavements Design of (road) pavements

Ground stabilisation method (LR1132) AASHTO Guide for Design of Pavements 1993

Single granular layer Full pavement design

Sub-base condition Construction traffic given Review of AASHTO 1993 method for flexible pavements

given by deformation by number of 80kN ESA N40

limited to 40mm • Empirical design method based on the AASHTO Road Test

Sub-base (carried out mid 1950’s to early 1960’s)

represented by its

thickness h (mm) • Method for flexible pavements provides design for the full

pavement section

• This may be done using a nomograph (Part II, Figure 3.1)

h h

• Or by solving the controlling equation (Part I, Chapter 1.2

Subgrade properties

and Part II, Figure 3.1)

given by CBR (%)

190(log10 N40 + 0.24) May be adjusted for • This is summarised on the following slides

h= different axle loads and

CBR0.63 different deformations

using Giroud & Noiray

5 Pavement design with mechanical stabilisation 14th August 2014 6 Pavement design with mechanical stabilisation 14th August 2014

TensarPave: design of pavements & trafficked areas 1

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

Design of (road) pavements Design of (road) pavements

AASHTO Guide for Design of Pavements 1993 AASHTO Guide for Design of Pavements 1993

Full pavement design Full pavement design

• Based on • Based on

AASHTO Road AASHTO Road

Test Test

• Carried out in • Carried out in

Illinois 1958-60 Illinois 1958-60

• Heavy clay

subgrade

7 Pavement design with mechanical stabilisation 14th August 2014 8 Pavement design with mechanical stabilisation 14th August 2014

Design of (road) pavements Design of (road) pavements

AASHTO Guide for Design of Pavements 1993 AASHTO Guide for Design of Pavements 1993

Full pavement design Full pavement design

• Based on • Based on

AASHTO Road AASHTO Road

Test Test

• Carried out in • Carried out in

Illinois 1958-60 Illinois 1958-60

• AC surfacing • Trafficked by

trucks available at

that time

• IMPORTANT:

method is based

on performance

9 Pavement design with mechanical stabilisation 14th August 2014 10 Pavement design with mechanical stabilisation 14th August 2014

Design of (road) pavements Design of (road) pavements

AASHTO Guide for Design of Pavements 1993 AASHTO Guide for Design of Pavements 1993

Controlling equation Resilient modulus (MR)

Pavement condition Traffic given by number of

given by its present 18 kip (80kN) ESA W18

serviceability index Pavement layers

PSI (p) represented by their

structural number SN

Subgrade Subgrade

represented represented

by its resilient by its resilient

modulus MR ∆PSI modulus MR

log10

log10 W18 = ZRS0 + 9.36 log10 (SN + 1) − 0.2 + 4.2 − 1.5 + 2.32 log M − 8.07 Subgrade condition most commonly given by

10 R CBR (%) or undrained shear strength (Su)

1094

0.4 +

(SN + 1)5.19 MR (psi) ≈ 1500 × CBR (AASHTO Part I, Chapter 1.5)

For given reliability, SN and MR – ∆PSI related to W18 MR (MPa) ≈ 10.34 × CBR

11 Pavement design with mechanical stabilisation 14th August 2014 12 Pavement design with mechanical stabilisation 14th August 2014

TensarPave: design of pavements & trafficked areas 2

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

Design of (road) pavements Design of (road) pavements

AASHTO Guide for Design of Pavements 1993 AASHTO Guide for Design of Pavements 1993

Structural number of pavement layers (SN) Structural number of pavement layers (SN)

Pavement layers Designing for water conditions Pavement layers

represented by their represented by their

structural number SN structural number SN

d1 d1

d2 d2

d3 d3

SN = a1d1 + a2d2 + a3d3 SN = a1d1 + a2d2m2 + a3d3m3 (AASHTO Part I, Ch 1.2 & Part II, Ch 2.3 &

2.4)

where: a1, a2, and a3 are structural layer coefficients

d1, d2 and d3 are layer thicknesses (inches) where: m2 and m3 take into account drainage quality and duration of

conditions approaching saturation for untreated layers

13 Pavement design with mechanical stabilisation 14th August 2014 14 Pavement design with mechanical stabilisation 14th August 2014

Design of (road) pavements Design of (road) pavements

AASHTO Guide for Design of Pavements 1993 AASHTO Guide for Design of Pavements 1993

Structural number of pavement layers (SN) Traffic (W18)

For design traffic given by number

Designing for water conditions NB: water has a major influence of 18 kip (80kN) ESA (W18)

AASHTO Part II, Ch 2.4.1 & Table 2.4 provide modification factors (m2 and m3)

to be applied to unbound layers to allow for their drainage capacity

Quality of drainage Percentage of time pavement structure is exposed to

(time to remove water) moisture conditions approaching saturation

< 1% 1% - 5% 5% - 25% > 25%

Excellent (2 hours) 1.40 – 1.35 1.35 – 1.30 1.30 – 1.20 1.20

Good (1 day) 1.35 – 1.25 1.25 – 1.15 1.15 – 1.00 1.00

Fair (1 week) 1.25 – 1.15 1.15 – 1.05 1.00 – 0.80 0.80 Traffic is given by the number of 18 kip equivalent standard axles ESA

Poor (1 month) 1.15 – 1.05 1.05 – 0.80 0.80 – 0.60 0.60 where: 18 kip = 18 kilopounds = 80.17 kN

Very poor (never) 1.05 – 0.95 0.95 – 0.75 0.75 – 0.40 0.40 fortunately AASHTO ESA almost exactly = metric ESA

15 Pavement design with mechanical stabilisation 14th August 2014 16 Pavement design with mechanical stabilisation 14th August 2014

Design of (road) pavements Design of (road) pavements

AASHTO Guide for Design of Pavements 1993 AASHTO Guide for Design of Pavements 1993

Traffic (W18) Present serviceability index PSI (p0)

For design traffic given by number Real traffic given by distributions Pavement condition

of 18 kip (80kN) ESA (W18) of various axle loads “Lx” kip (Wx) given by its present

serviceability index

PSI (p) (AASHTO Part II, Ch 2.2.1)

AASHTO Appendix MM gives relationship to convert real axles into ESA

W G G

log10 x = 4.79 log10 (18 + 1) − 4.79 log10 (L x + L2 ) + 4.33 log10 L 2 + t − t

W18 βx β18

Pavement condition at any point in time is defined by PSI (present

Lx = load on a single axle or total load on one tandem axle set (kips)

serviceability index)

L2 = axle code (1 for single axle, 2 for tandem axle set)

pt = terminal serviceability index PSI: related to rut depth and shape, and pavement surface damage

β18 = value of βx when Lx is equal to 18 kips and L2 is equal to 1

17 Pavement design with mechanical stabilisation 14th August 2014 18 Pavement design with mechanical stabilisation 14th August 2014

TensarPave: design of pavements & trafficked areas 3

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

Design of (road) pavements Design of (road) pavements

AASHTO Guide for Design of Pavements 1993 AASHTO Guide for Design of Pavements 1993

Present serviceability index PSI (p0) Present serviceability index PSI (pt)

Pavement condition Pavement condition

given by its present given by its present ∆PSI = p0 - pt

serviceability index serviceability index

PSI (p) (AASHTO Part II, Ch 2.2.1) PSI (p) (AASHTO Part II, Ch 2.2.1)

At start of pavement life initial PSI defined as p0 Pavement deteriorates until terminal PSI is reached defined as pt

p0: p0 = 5 for perfect pavement (but this can never be attained) pt: pt = 3 for 12% stating unacceptable

p0 = 4.2 normally used for flexible pavements pt = 2.5 for 55% stating unacceptable (normal limit for major highways)

pt = 2.0 for 85% stating unacceptable (normal for minor roads)

19 Pavement design with mechanical stabilisation 14th August 2014 20 Pavement design with mechanical stabilisation 14th August 2014

Design of (road) pavements Campaign Materials

AASHTO Guide for Design of Pavements 1993

Reliability

Reliability term = ZR × S0

(AASHTO Part I Ch 4 &

Part II, Ch 2.1.3)

The reliability term takes into account uncertainties in material

properties and the prediction, similar to geotechnical safety factor

ZR: Defines the level of reliability required

50% reliability results in ZR = 0, or “factor of safety” = 1.0

21 Pavement design with mechanical stabilisation 14th August 2014

Stabilisation with TriAx geogrids Stabilisation with TriAx geogrids

Design of Pavements Design of Pavements

Radial performance TRL unpaved trials

• Unsurfaced

pavement

• 40kN wheel load

23 Pavement design with mechanical stabilisation 14th August 2014 24 Pavement design with mechanical stabilisation 14th August 2014

TensarPave: design of pavements & trafficked areas 4

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

Continuing research in pavement performance

Full scale pavement trial carried out by US Corps of

Engineers to investigate behaviour of full pavement

50mm

AC

200mm

base

Base CBR = 100%

Target subgrade CBR = 3%

25 Pavement design with mechanical stabilisation 14th August 2014

Stabilisation with TriAx geogrids

Concept of the mechanically stabilised layer - MSL

Control 24,282 ESALs TX 170 111,410 ESALs

~1” rut > 0.5” rut

28 Pavement design with mechanical stabilisation 14th August 2014

Stabilisation with TriAx geogrids Stabilisation with TriAx geogrids

Concept of the mechanically stabilised layer - MSL Concept of the mechanically stabilised layer - MSL

29 Pavement design with mechanical stabilisation 14th August 2014 30 Pavement design with mechanical stabilisation 14th August 2014

TensarPave: design of pavements & trafficked areas 5

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

Stabilisation with TriAx geogrids Stabilisation with TriAx geogrids

Concept of the mechanically stabilised layer - MSL Independent assessment

of fSN – CROW

fSN Report published in

Netherlands

Based on testing, mechanical stabilisation

results in enhancement of the layer properties:

- Higher layer coefficient “a” defined by fSN

- Higher effective modulus

31 Pavement design with mechanical stabilisation 14th August 2014 32 Pavement design with mechanical stabilisation 14th August 2014

Stabilisation with TriAx geogrids Design of (road) pavements

Independent assessment of fSN - CROW Ground stabilisation method (LR1132)

Single granular layer

2.0 0.5

Punched & stretched geogrids Sub-base condition Construction traffic given

None

given by deformation by number of 80kN ESA N40

0.4 Extruded & limited to 40mm

Thickness reduction

stretched geogrids Sub-base

represented by its

0.3 Woven thickness h (mm)

geogrids

0.2

Woven hs

geotextiles h

fSN 0.1 Subgrade properties

given by CBR (%) Mechanically stabilised

Non-woven 190(log10 N40 + 0.24)

hs = layer may be used to

1.0 0 fSNCBR0.63 reduce sub-base thickness

0 1 2 3 4 5

CBR (%)

33 Pavement design with mechanical stabilisation 14th August 2014 34 Pavement design with mechanical stabilisation 14th August 2014

Design of (road) pavements

AASHTO Guide for Design of Pavements 1993

Design with a mechanically stabilised layer

Pavement condition Traffic given by number of

given by its present 18 kip (80kN) ESA W18

serviceability index Pavement layers

PSI (p) represented by their

structural number SN

Subgrade

represented

by its resilient

fSN applied

modulus MR

to this layer

∆PSI

log10

log10 W18 = ZRS0 + 9.36 log10 (SN * fSN + 1) − 0.2 + 4.2 − 1.5 + 2.32 log10 MR − 8.07

1094

0. 4 +

(SN * fSN + 1)5.19

36 Pavement design with mechanical stabilisation 14th August 2014

TensarPave: design of pavements & trafficked areas 6

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

Design of (road) pavements

AASHTO Guide for Design of Pavements 1993

Design with a mechanically stabilised layer

Pavement condition Traffic given by number of

given by its present 18 kip (80kN) ESA W18

serviceability index Pavement layers

PSI (p) represented by their

structural number SN

Subgrade

represented

by its resilient

fSN applied

modulus MR

to this layer

∆PSI

log10

log10 W18 = ZRS0 + 9.36 log10 (SN * fSN + 1) − 0.2 + 4.2 − 1.5 + 2.32 log10 MR − 8.07

1094

0. 4 +

(SN * fSN + 1)5.19

37 Pavement design with mechanical stabilisation 14th August 2014

Half-Day Seminar – Jakarta,14th August 2014

Design and Application of Mechanically Stabilised Layers

for Highways, Rail Trackbed and Haul Roads

Workshop: TensarPave

Design of pavements and trafficked

areas using mechanical stabilisation

Any questions?

Specification (essential part of the design):

A communication which protects the quality of the

design and minimises the risk of a reduced performance

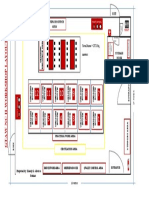

A Case Study (paper by Ted James, 2006) A Case Study (paper by Ted James, 2006)

Pantura - The North Java Coastal Road Pantura - The North Java Coastal Road

Situation pre 2005 Major reconstruction in 2005

• Wet season storm • Traffic greater than Asphalt - 280mm

water keeps water BP-07B 20,000 vehicles per

Aggregate base A - 200mm

within 1m to 1.2m of day, mainly trucks

BP-07A

pavement surface Aggregate base B - 300mm Geogrid

• Capping layer used

• Suffers extreme BP-07

to bring base of River gravel capping - 300mm

axle loads common pavement layers

in Indonesia (20t) 10.455 km above wet season Wet season standing water

• Notorious for BP-07C standing water

River gravel capping - 1000mm

pavement failures • Geogrid used to

in both the existing stabilise Aggregate

road and recent base B

reconstruction Subgrade CBR = 1.0 to 1.5%

41 Pavement design with mechanical stabilisation 14th August 2014 42 Pavement design with mechanical stabilisation 14th August 2014

TensarPave: design of pavements & trafficked areas 7

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

A Case Study A Case Study

Pantura - The North Java Coastal Road Pantura - The North Java Coastal Road

Situation in 2014 Situation in 2014

• Headlines in local • Headlines in local

papers papers

• Road has • Road has

become almost become almost

impassable in impassable in

places places

• Massive delays • Massive delays

especially at especially at

peak times peak times

• Some sections

performing very

well

43 Pavement design with mechanical stabilisation 14th August 2014 44 Pavement design with mechanical stabilisation 14th August 2014

A Case Study A Case Study

Pantura - The North Java Coastal Road Pantura - The North Java Coastal Road

Situation in 2005 Situation in 2014

• Investigation • Investigation

shows that these shows that these

are the sections are the sections

with a stabilised with a stabilised

base course base course

• 2005 • 2014 same view

• Note shoulder

where geogrid

was not used

45 Pavement design with mechanical stabilisation 14th August 2014 46 Pavement design with mechanical stabilisation 14th August 2014

A Case Study A Case Study

Pantura - The North Java Coastal Road Pantura - The North Java Coastal Road

Situation in 2005 Situation in 2014

• Investigation • Investigation

shows that these shows that these

are the sections are the sections

with a stabilised with a stabilised

base course base course

• 2005 • 2014 same view

47 Pavement design with mechanical stabilisation 14th August 2014 48 Pavement design with mechanical stabilisation 14th August 2014

TensarPave: design of pavements & trafficked areas 8

Tensar Workshop on Stabilisation of Aggregate Layers 14th August 2014

A Case Study A Case Study

Pantura - The North Java Coastal Road Pantura - The North Java Coastal Road

Situation in 2005 Situation in 2014

• Investigation • Investigation

shows that these shows that these

are the sections are the sections

with a stabilised with a stabilised

base course base course

• 2005 • 2014 same view

49 Pavement design with mechanical stabilisation 14th August 2014 50 Pavement design with mechanical stabilisation 14th August 2014

Four key points

• Mechanically stabilised layer (MSL): confinement of

aggregate by interlocking with apertures of geogrid

• Not only for soft ground, also applied higher in the

pavement

• Design using MSL is empirical, based on observing

performance

• Product tensile strength is not a reliable indicator of

performance

TensarPave: design of pavements & trafficked areas 9

You might also like

- Tech Spec 4Document28 pagesTech Spec 4Mo'men Abu-SmaihaNo ratings yet

- 1.8 - Ms. K.L.I. Ranasoma - Deputy Director (R & D), RDADocument27 pages1.8 - Ms. K.L.I. Ranasoma - Deputy Director (R & D), RDAmpchanakaNo ratings yet

- Project Report On Pavement DesignDocument50 pagesProject Report On Pavement Designsagar kumar100% (1)

- Aashto 1972 CarolDocument30 pagesAashto 1972 CarolIjeal KuNo ratings yet

- BSPP 2014Q Sec15 Flexible Pavement Design v2014x6 PDFDocument12 pagesBSPP 2014Q Sec15 Flexible Pavement Design v2014x6 PDFศิวาเวช อบมาNo ratings yet

- Design Guide IntroductionDocument39 pagesDesign Guide IntroductionsyxomphousNo ratings yet

- Flexible Pavement Design Tool 060622Document36 pagesFlexible Pavement Design Tool 060622abmtestlab82No ratings yet

- 2.1 - Pavement Types and LayersDocument33 pages2.1 - Pavement Types and Layersmark lionNo ratings yet

- Lecture 6-Asphalt Mix DesignDocument5 pagesLecture 6-Asphalt Mix DesignKeshav SomaniNo ratings yet

- Flexible Pavement Design Tool 060622Document38 pagesFlexible Pavement Design Tool 060622CANAL VERMELHONo ratings yet

- ACI 330.2R-17: Nigel Parkes, PNA Construction TechnologiesDocument15 pagesACI 330.2R-17: Nigel Parkes, PNA Construction TechnologiesSubramanian MuruganNo ratings yet

- Chapter 4Document28 pagesChapter 4noddyjohnNo ratings yet

- Theyse, H L Et Al - 10th Conference On Asphalt Pavements For South Africa (2) - 2011Document20 pagesTheyse, H L Et Al - 10th Conference On Asphalt Pavements For South Africa (2) - 2011ahgreyling01No ratings yet

- Evaluation of Flexible Foundation & Pavement Design According To The DMRBDocument1 pageEvaluation of Flexible Foundation & Pavement Design According To The DMRBAguero AgueroNo ratings yet

- Tech Spec 10: Application Guide For Interlocking Concrete PavementsDocument8 pagesTech Spec 10: Application Guide For Interlocking Concrete PavementsSilvio GenaoNo ratings yet

- Design of Paving Stone PavementsDocument28 pagesDesign of Paving Stone PavementsAlexious Demide100% (1)

- Flexible Pavements - Evolution of IRC 37Document85 pagesFlexible Pavements - Evolution of IRC 37DIT TRAFFIC100% (2)

- Application Guide For Interlocking Concrete PavementsDocument9 pagesApplication Guide For Interlocking Concrete PavementsComaNo ratings yet

- Tech Spec: Structural Design of Interlocking Concrete Pavement For Roads and Parking LotsDocument28 pagesTech Spec: Structural Design of Interlocking Concrete Pavement For Roads and Parking LotsMichael HurtadoNo ratings yet

- AAPA_IG-6_Selection_and_Design_of_Flexible_Pavements_OCRDocument68 pagesAAPA_IG-6_Selection_and_Design_of_Flexible_Pavements_OCRtejas.dorNo ratings yet

- ADM Pavement Design RequirementsDocument8 pagesADM Pavement Design RequirementsMahmoud ZidanNo ratings yet

- Technical Note TN 29 Concrete Pavement Types PDFDocument2 pagesTechnical Note TN 29 Concrete Pavement Types PDFWaldo SchaefferNo ratings yet

- Pavement MaterialsDocument126 pagesPavement MaterialsSaleemAhmadMalikNo ratings yet

- Pavement AashtoDocument28 pagesPavement AashtoJoe Ady ShaputraNo ratings yet

- Flexible Pavement Design Tool 060622Document36 pagesFlexible Pavement Design Tool 060622Pramudyo Bayu Pamungkas, S.T.No ratings yet

- Final TechAbutment - MIAL Casestudy 17112014Document2 pagesFinal TechAbutment - MIAL Casestudy 17112014Ankit GuptaNo ratings yet

- Andvanced Pavement Designe CompleteDocument28 pagesAndvanced Pavement Designe CompleteShikha SinghNo ratings yet

- AAPA IG-6 Selection and Design of Flexible Pavements OCRDocument68 pagesAAPA IG-6 Selection and Design of Flexible Pavements OCRChristopher CarrilloNo ratings yet

- 5 Design of Surfaces and GuidewaysDocument90 pages5 Design of Surfaces and GuidewaysRenalyn Andrade0% (1)

- Comparacion Entre Metodos MEPDG 2022Document6 pagesComparacion Entre Metodos MEPDG 2022André BerninzonNo ratings yet

- Stabilizer Construction MethodDocument35 pagesStabilizer Construction Methodsfsdgdfngfm esefsgNo ratings yet

- 2.5 Details of Asphalt Institute Method of Design of Flexible PavementsDocument55 pages2.5 Details of Asphalt Institute Method of Design of Flexible PavementsRajesh Khadka100% (7)

- Asphalt Pavement Design GuideDocument28 pagesAsphalt Pavement Design Guiderendy50% (2)

- Code of Practice RC 50022 Selection and Design of Pavement and Surfacings December 2018Document33 pagesCode of Practice RC 50022 Selection and Design of Pavement and Surfacings December 2018Barry LibertyNo ratings yet

- Tech Spec 4 Structural DesignDocument28 pagesTech Spec 4 Structural DesignHuascar Medrano LazarteNo ratings yet

- Chapter 4Document28 pagesChapter 4singhconstNo ratings yet

- Geometric Design Procedure Revised FinalDocument12 pagesGeometric Design Procedure Revised FinalRebi HamzaNo ratings yet

- Stabilizer Construction MethodDocument38 pagesStabilizer Construction Methodsfsdgdfngfm esefsgNo ratings yet

- Introduction 2014 E.CDocument60 pagesIntroduction 2014 E.CMamush LetaNo ratings yet

- 3 Design Considerations StandardsDocument117 pages3 Design Considerations StandardsAldwin Joseph Abainza100% (2)

- 2000 RTR Al-Suleiman Vol9 1 PDFDocument14 pages2000 RTR Al-Suleiman Vol9 1 PDFTNo ratings yet

- Flexible Pavement Aspects of Basic DesignDocument92 pagesFlexible Pavement Aspects of Basic DesignGanesh Gupta100% (1)

- GN042Document43 pagesGN042Riko Chy MakNo ratings yet

- 4 - Structural ComponentsDocument32 pages4 - Structural Componentsawais.mfbzoneNo ratings yet

- Pavement Design - V1Document26 pagesPavement Design - V1DEBALEENA MUKHERJEENo ratings yet

- Recent Research of Track Technology Division: ArticlesDocument6 pagesRecent Research of Track Technology Division: ArticlesMantripragada RajuNo ratings yet

- Intersection Design Principles Design Elements MidtermDocument99 pagesIntersection Design Principles Design Elements MidtermJed mariñasNo ratings yet

- Pavement Design & Traffic Census WorkshopDocument38 pagesPavement Design & Traffic Census WorkshopJK HallNo ratings yet

- Fact Sheet Paving A Residential DrivewayDocument4 pagesFact Sheet Paving A Residential DrivewayDenise2512No ratings yet

- Design Parametr PDFDocument8 pagesDesign Parametr PDFAlok ThakurNo ratings yet

- IRC Method of Design of Flexible Pavements: Lecture Notes in Transportation Systems EngineeringDocument8 pagesIRC Method of Design of Flexible Pavements: Lecture Notes in Transportation Systems EngineeringAlok ThakurNo ratings yet

- Plain PDFDocument8 pagesPlain PDFB RAMUNo ratings yet

- Lecture Notes On IRC 37Document8 pagesLecture Notes On IRC 37AdhirajNo ratings yet

- Lecture8 - CE 600132 - AASHTO - 18032024Document84 pagesLecture8 - CE 600132 - AASHTO - 18032024Pratik AgarwalNo ratings yet

- Rational Structural Design of Highway/Airport Pavements: New Evapave, the Strongest & Toughest Paving MaterialFrom EverandRational Structural Design of Highway/Airport Pavements: New Evapave, the Strongest & Toughest Paving MaterialNo ratings yet

- Adhesive Rebar For PerliteDocument8 pagesAdhesive Rebar For Perlitenoto.sugiartoNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- GTA 308 - Maximum Gradient: August 2020Document17 pagesGTA 308 - Maximum Gradient: August 2020noto.sugiartoNo ratings yet

- Company Profile and Project Experience GulfPerliteDocument68 pagesCompany Profile and Project Experience GulfPerlitenoto.sugiartoNo ratings yet

- MSDS Cement Tiga Roda - Dec 2019Document5 pagesMSDS Cement Tiga Roda - Dec 2019noto.sugiarto100% (1)

- Makrolon 3206 - en - 56817747 00003433 19231690Document4 pagesMakrolon 3206 - en - 56817747 00003433 19231690noto.sugiartoNo ratings yet

- Appendix E.1. Pipe Support PS-CP-01Document10 pagesAppendix E.1. Pipe Support PS-CP-01noto.sugiartoNo ratings yet

- Soil Mixing Wall System: Product InformationDocument8 pagesSoil Mixing Wall System: Product Informationnoto.sugiartoNo ratings yet

- Full Displacement Pile System BAUER BG-System: Produktinformation Product InformationDocument8 pagesFull Displacement Pile System BAUER BG-System: Produktinformation Product Informationnoto.sugiartoNo ratings yet

- CSM Cutter Soil Mixing: Equipment Construction ProcedureDocument12 pagesCSM Cutter Soil Mixing: Equipment Construction Procedurenoto.sugiartoNo ratings yet

- Appendix B. Basic Load & Load CombinationsDocument2 pagesAppendix B. Basic Load & Load Combinationsnoto.sugiartoNo ratings yet

- Attachment E.3. Wind CalculationDocument48 pagesAttachment E.3. Wind Calculationnoto.sugiartoNo ratings yet

- Interline 955: Novolac Vinyl EsterDocument4 pagesInterline 955: Novolac Vinyl Esternoto.sugiartoNo ratings yet

- Appendix E.2. Pipe Support PS-CP-02Document13 pagesAppendix E.2. Pipe Support PS-CP-02noto.sugiartoNo ratings yet

- Appendix E.1. Pipe Support Calculation - PS-CP-01Document10 pagesAppendix E.1. Pipe Support Calculation - PS-CP-01noto.sugiarto50% (2)

- Appendix A. Structural Modeling and Loadings (19.09.13) .1Document19 pagesAppendix A. Structural Modeling and Loadings (19.09.13) .1noto.sugiartoNo ratings yet

- Interline 975: Solvent Free Epoxy Tank CoatingDocument4 pagesInterline 975: Solvent Free Epoxy Tank Coatingnoto.sugiartoNo ratings yet

- Appendix C. SACS Input of In-Place AnalysisDocument14 pagesAppendix C. SACS Input of In-Place Analysisnoto.sugiartoNo ratings yet

- Contoh Score TBE MOM Pre-Bid Meeting BID-15-0024Document13 pagesContoh Score TBE MOM Pre-Bid Meeting BID-15-0024noto.sugiartoNo ratings yet

- Intertherm 50: Silicone AluminiumDocument4 pagesIntertherm 50: Silicone Aluminiumnoto.sugiartoNo ratings yet

- Lamination Recipe PN20Document6 pagesLamination Recipe PN20noto.sugiartoNo ratings yet

- Edexcel Igcse ElectrolysisDocument86 pagesEdexcel Igcse ElectrolysisshoshoNo ratings yet

- Experiment FiveDocument4 pagesExperiment FiveSusana DakoraNo ratings yet

- Chapter 5Document22 pagesChapter 5Aftab AhmedNo ratings yet

- #10 - Energy Balance - 01 (Rev01)Document48 pages#10 - Energy Balance - 01 (Rev01)Valentino LunardiNo ratings yet

- Exercise Problems of Chapter-Two Ch-2 Tension Members: R L A I R Mpa F Mpa FDocument7 pagesExercise Problems of Chapter-Two Ch-2 Tension Members: R L A I R Mpa F Mpa FEng Abdikarim Walhad100% (3)

- Prestressing Systems For Structural Strengthening With Sika CarboDur CFRP PlatesDocument5 pagesPrestressing Systems For Structural Strengthening With Sika CarboDur CFRP PlatesManuel PetroNo ratings yet

- Pompe Wilden PDFDocument184 pagesPompe Wilden PDFverat81100% (1)

- Grease MSDSDocument3 pagesGrease MSDSSiva Naga Prasad TadipartiNo ratings yet

- Total Area 272 Sq. Meters: Waste DisposalDocument1 pageTotal Area 272 Sq. Meters: Waste DisposalMANPOWER ORMOCNo ratings yet

- Tds Viacrete Pu MF VMDocument3 pagesTds Viacrete Pu MF VMSubrina IslamNo ratings yet

- EST ReportDocument20 pagesEST Reportkrishna kumavatNo ratings yet

- Annisa Indah Kirana - Tugas Evaporasi PDFDocument5 pagesAnnisa Indah Kirana - Tugas Evaporasi PDFANNISA KIRANANo ratings yet

- Impact TestDocument11 pagesImpact TestMohsin AbbasNo ratings yet

- Introduction To Industrial Minerals-Springer Netherlands (1995)Document287 pagesIntroduction To Industrial Minerals-Springer Netherlands (1995)Kathleen SuanzoNo ratings yet

- Organic Chemistry P2 Questions (2020-2023)Document28 pagesOrganic Chemistry P2 Questions (2020-2023)moiz.8450No ratings yet

- Element - 111 - 128-Petrol Station BOQDocument6 pagesElement - 111 - 128-Petrol Station BOQMrweNo ratings yet

- Mil PRF 61002BDocument27 pagesMil PRF 61002BAbdullah PalNo ratings yet

- Za 304 MZ Paint: Product Data Resistance GuideDocument2 pagesZa 304 MZ Paint: Product Data Resistance GuidechepurthiNo ratings yet

- 欧盟CLP化学品分类名单Document644 pages欧盟CLP化学品分类名单Yang YangNo ratings yet

- Properties of SteamDocument4 pagesProperties of SteamAndrew Grogan100% (1)

- Ashby 2003Document11 pagesAshby 2003Gajaraj GajapathiNo ratings yet

- NOCDocument11 pagesNOCVedam Shanmukha HrushikeshNo ratings yet

- Strengthening Mechanisms Notes - 2024Document55 pagesStrengthening Mechanisms Notes - 2024achieng.omondi2No ratings yet

- KML100374 - Drywall Manual AddendumDocument15 pagesKML100374 - Drywall Manual Addendumivg8562No ratings yet

- Pararrayos Tipo BalestroDocument3 pagesPararrayos Tipo BalestroBladimir Michel100% (1)

- Application Note Stainless SteelDocument6 pagesApplication Note Stainless SteelVictoria TechiNo ratings yet

- Edexcel GCE Chemistry Unit-5 June 2014 Question Paper (R)Document28 pagesEdexcel GCE Chemistry Unit-5 June 2014 Question Paper (R)AvrinoxNo ratings yet

- Material Safety Data Sheets: (MSDS)Document5 pagesMaterial Safety Data Sheets: (MSDS)DucNo ratings yet

- Chromium Trioxide Is An Inorganic Compound With The Formula CrO3Document3 pagesChromium Trioxide Is An Inorganic Compound With The Formula CrO3Lihini NimsaraNo ratings yet

- BDA 30803 Notes (Student Version - Printable) Sem 2 2012 - 2013 PDFDocument203 pagesBDA 30803 Notes (Student Version - Printable) Sem 2 2012 - 2013 PDFIlenggeswaran Murugesu100% (1)