Professional Documents

Culture Documents

Activity - Mechanical Review - Answers

Activity - Mechanical Review - Answers

Uploaded by

Theerayoot PoomchaiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Activity - Mechanical Review - Answers

Activity - Mechanical Review - Answers

Uploaded by

Theerayoot PoomchaiCopyright:

Available Formats

Activity: Evaluate Compressor/Piping Layout and Supports

Review these reciprocating compressor application photos. Can you spot any potential

vibration problems? Mark up supports or changes that you would recommend on the next

project.

Lower

flange

Support

elbow

Wedges are

too tall

Wood Vibrations, Dynamics, and Noise Vibration Activities

Unsupported

elbow

Unsupported

valve

Wood Vibrations, Dynamics, and Noise Vibration Activities

Expansion looks High point vent

are too flexible SBC

Elevated PSV

and isolation

valve

Wood Vibrations, Dynamics, and Noise Vibration Activities

Unsupported

PSV

Level indication

with flange

isolation valves

Suction bottle

is over-hung

Tall, small

diameter scrubber

Wood Vibrations, Dynamics, and Noise Vibration Activities

Large mass and long

projection of vent and

pressure indicator

Crosshead guide

support is too flexible

HE support is

too flexible

Wood Vibrations, Dynamics, and Noise Vibration Activities

Very good design. No

changes.

Wood Vibrations, Dynamics, and Noise Vibration Activities

Add gusset to prevent

web from flexing

Too many structural

elements welded together

will make a flexible support.

Use epoxy grout to ensure

contact between concrete

and support base

Wood Vibrations, Dynamics, and Noise Vibration Activities

U-bolt pipe restraint on

a small L-section (too

flexible)

Wood Vibrations, Dynamics, and Noise Vibration Activities

You might also like

- Risk Assessment ReferenceDocument12 pagesRisk Assessment Referenceramilnavarra62No ratings yet

- X To Y and Y To XDocument1 pageX To Y and Y To XTheerayoot PoomchaiNo ratings yet

- Vibration Point Set-Up For Paper MachineDocument6 pagesVibration Point Set-Up For Paper MachineTheerayoot PoomchaiNo ratings yet

- Method Statement of Pipeline Pigging Services: Polmaz LimitedDocument10 pagesMethod Statement of Pipeline Pigging Services: Polmaz LimitedVineet Agrawal100% (1)

- T Annoy' S Dual Concentric by DefinitionDocument27 pagesT Annoy' S Dual Concentric by DefinitionГригорий БоржковскийNo ratings yet

- Silencio Price ListDocument12 pagesSilencio Price ListmohindarNo ratings yet

- En - ART710A Spec Sheet MKII PDFDocument4 pagesEn - ART710A Spec Sheet MKII PDFNeda GambyNo ratings yet

- Aria 926 Specification Sheet GBDocument1 pageAria 926 Specification Sheet GBK BNo ratings yet

- Hi End Bluray Disc Player Catalogue 1105Document16 pagesHi End Bluray Disc Player Catalogue 1105Bitogno Jean-PaulNo ratings yet

- Information Sheet Lsim SeriesDocument4 pagesInformation Sheet Lsim SeriesjimmymacbootNo ratings yet

- Aluminum Vs UPVCDocument1 pageAluminum Vs UPVCchriscivil12No ratings yet

- Acoustic Treatment and DesignDocument54 pagesAcoustic Treatment and Designcalm_seaNo ratings yet

- tx8 Overview PDFDocument2 pagestx8 Overview PDFMagtanggol Relucio100% (1)

- Debut 2.0 Series by Andrew Jones.: Debut B6.2 Aramid-Fiber Bookshelf SpeakersDocument2 pagesDebut 2.0 Series by Andrew Jones.: Debut B6.2 Aramid-Fiber Bookshelf SpeakersSarmishtha DeNo ratings yet

- Sound Proof Canopy Model:: Industrial RangeDocument1 pageSound Proof Canopy Model:: Industrial Rangesales3 iaescoNo ratings yet

- C10cen Cut SHDocument1 pageC10cen Cut SHDufourNo ratings yet

- Sound Proof Canopy Model:: Industrial RangeDocument1 pageSound Proof Canopy Model:: Industrial RangedachinicuNo ratings yet

- C109 Cut SHDocument1 pageC109 Cut SHDufourNo ratings yet

- Sound Proof Canopy Model:: Industrial RangeDocument1 pageSound Proof Canopy Model:: Industrial Rangesales3 iaescoNo ratings yet

- Sound Proof Canopy Model:: Industrial RangeDocument1 pageSound Proof Canopy Model:: Industrial Rangesales3 iaescoNo ratings yet

- Onkyo Sks-ht588 Datasheet enDocument1 pageOnkyo Sks-ht588 Datasheet enKántor ErvinNo ratings yet

- Infinity - Minuette Sys & Minuette MCS (Depliant)Document2 pagesInfinity - Minuette Sys & Minuette MCS (Depliant)nesadNo ratings yet

- Whisper Trim® IDocument2 pagesWhisper Trim® IAhmed KhairyNo ratings yet

- 1,000W Active Speaker Rental - Iowa City, Cedar Rapids, IADocument1 page1,000W Active Speaker Rental - Iowa City, Cedar Rapids, IATim ThurmanskiNo ratings yet

- Sony MDR xb500 ManualDocument2 pagesSony MDR xb500 Manualessexrookie8No ratings yet

- Altavoces EmpotrablesDocument2 pagesAltavoces EmpotrablesCarlos Rafael Acosta MolinaNo ratings yet

- Agricultural Solution-Asoe HoseDocument4 pagesAgricultural Solution-Asoe HoseChris GengNo ratings yet

- Parker Guitar Catalogo 2015Document32 pagesParker Guitar Catalogo 2015alessandroNo ratings yet

- Active 2-Way Sound Reinforcement Speaker SystemDocument6 pagesActive 2-Way Sound Reinforcement Speaker SystemAndyNo ratings yet

- Application Note #12:: Building An Effective, 12 Bandpass SubwooferDocument14 pagesApplication Note #12:: Building An Effective, 12 Bandpass SubwooferpurwadiNo ratings yet

- The Neumann KH Line. The Neumann KH Line.: Studio Monitor SystemsDocument36 pagesThe Neumann KH Line. The Neumann KH Line.: Studio Monitor SystemsRo HenNo ratings yet

- Wall Mount SpeakersDocument2 pagesWall Mount Speakersikponmwosa olotuNo ratings yet

- Bosch 20162017 Catalog - DrillingfasteningDocument60 pagesBosch 20162017 Catalog - DrillingfasteningAbhisek RoyNo ratings yet

- Unit 21. Sound (Source: My Pals Are Here! Science 4BDocument19 pagesUnit 21. Sound (Source: My Pals Are Here! Science 4BYosephine Susie SaraswatiNo ratings yet

- Dva Riser SystemDocument1 pageDva Riser System1mmahoneyNo ratings yet

- PDF Hydrill Wedge Thread Drill Pipe Tool Joint CompressDocument4 pagesPDF Hydrill Wedge Thread Drill Pipe Tool Joint CompressStanislavNo ratings yet

- Punchy & Rhythmical Bass: 30cm (12") Champion Series 4Ω Dual Voice Coil SubwooferDocument2 pagesPunchy & Rhythmical Bass: 30cm (12") Champion Series 4Ω Dual Voice Coil SubwooferPeterson BandeiraNo ratings yet

- Ystsw 012Document2 pagesYstsw 012César Arturo Ilizaliturri HdzNo ratings yet

- Cyber-Ho-60w Rev001 Rotw LDDocument16 pagesCyber-Ho-60w Rev001 Rotw LDPedro Pablo GonzalezNo ratings yet

- Om Swe-843e enDocument12 pagesOm Swe-843e enCarsten BakNo ratings yet

- Cinema 100 DatasheetDocument7 pagesCinema 100 Datasheetsangram jadhavNo ratings yet

- Active 2-Way Sound Reinforcement Speaker SystemDocument6 pagesActive 2-Way Sound Reinforcement Speaker SystemBrandy ThomasNo ratings yet

- 2010 2011 Parker Guitars CatalogDocument28 pages2010 2011 Parker Guitars CatalogGiangregorio SuraceNo ratings yet

- Vibration IsolationDocument8 pagesVibration Isolationofitecnicajg100% (1)

- Small-Format Foreground/Fill Loudspeaker: Arenamatch Utility Amu208Document4 pagesSmall-Format Foreground/Fill Loudspeaker: Arenamatch Utility Amu208Amit KidechaNo ratings yet

- Logitech G560 Gaming Speaker Technical SpecificationsDocument2 pagesLogitech G560 Gaming Speaker Technical SpecificationsJason CorayNo ratings yet

- Manual Quanta - Litho 30WDocument12 pagesManual Quanta - Litho 30WLeandro PhillipNo ratings yet

- AN Ngineering: Fan Installation, Operation & MaintenanceDocument8 pagesAN Ngineering: Fan Installation, Operation & MaintenanceAvery OppegardNo ratings yet

- Small-Format Foreground/Fill Loudspeaker: Arenamatch Utility Amu206Document4 pagesSmall-Format Foreground/Fill Loudspeaker: Arenamatch Utility Amu206Amit KidechaNo ratings yet

- Vibration Induced Fatigue Failure in Process Pipework: Acoustic Induced Vibrations (AIV)Document20 pagesVibration Induced Fatigue Failure in Process Pipework: Acoustic Induced Vibrations (AIV)Srisaran Srinivas ArasavelliNo ratings yet

- Catalogue 2021 Pied A Coulisse B ENDocument44 pagesCatalogue 2021 Pied A Coulisse B ENRudolf OppermannNo ratings yet

- CL150301HQ 2Document17 pagesCL150301HQ 2Juan AlmeidaNo ratings yet

- Introduction To AcousticsDocument4 pagesIntroduction To AcousticsClarence MamucodNo ratings yet

- Horn CatalogueDocument44 pagesHorn CatalogueRaihan Fajar PratamaNo ratings yet

- Ultrasonic Installation of Inserts in Thermoplastic ComponentsDocument4 pagesUltrasonic Installation of Inserts in Thermoplastic ComponentsRobertoNo ratings yet

- MArket Survey GRP 10Document9 pagesMArket Survey GRP 10shraddhaNo ratings yet

- Laser Welding MiyachiDocument66 pagesLaser Welding Miyachijesus100% (2)

- Bridge - Tuning BookletDocument4 pagesBridge - Tuning BookletJohn TimomeNo ratings yet

- HD 380 Pro: and Comfortable Monitoring HeadphoneDocument2 pagesHD 380 Pro: and Comfortable Monitoring HeadphoneSteveNo ratings yet

- Rivulis ProFlat English US 20190512 WebDocument2 pagesRivulis ProFlat English US 20190512 WebMehdi BassouNo ratings yet

- Infinity - Bass Tubes Kappa 100BT, Kappa 120BT (2001) (English)Document2 pagesInfinity - Bass Tubes Kappa 100BT, Kappa 120BT (2001) (English)Bmwmotorsport GabriNo ratings yet

- UT Day2Document38 pagesUT Day2Mohammed ShareefNo ratings yet

- Propagation of Sound PDFDocument11 pagesPropagation of Sound PDFVedika SinghNo ratings yet

- Subwoofer Box 10 Inch Subwoofer - Sealed BoxDocument2 pagesSubwoofer Box 10 Inch Subwoofer - Sealed BoxTheerayoot PoomchaiNo ratings yet

- Smaart v8.2 Quick Start: Sound Level Calibration/Logging WorkflowDocument9 pagesSmaart v8.2 Quick Start: Sound Level Calibration/Logging WorkflowTheerayoot PoomchaiNo ratings yet

- Smaart v7 IR GuideDocument70 pagesSmaart v7 IR GuideTheerayoot PoomchaiNo ratings yet

- Choosing Gear For Your Smaart Measurement SystemDocument17 pagesChoosing Gear For Your Smaart Measurement SystemTheerayoot PoomchaiNo ratings yet

- Pulsation & Mech Analysis Selection Guide - Recip CompDocument3 pagesPulsation & Mech Analysis Selection Guide - Recip CompTheerayoot PoomchaiNo ratings yet

- Advances in Centrifugal Gas Compressor TechnologyDocument35 pagesAdvances in Centrifugal Gas Compressor TechnologyTheerayoot PoomchaiNo ratings yet

- Full Spectrum What Is A Full Spectrum?Document5 pagesFull Spectrum What Is A Full Spectrum?Theerayoot PoomchaiNo ratings yet

- Forces Acting On A RotorDocument12 pagesForces Acting On A RotorTheerayoot PoomchaiNo ratings yet

- Dynamic Stiffness and Rotor ResponseDocument70 pagesDynamic Stiffness and Rotor ResponseTheerayoot PoomchaiNo ratings yet

- Why Useful Full Spectrum PlotDocument3 pagesWhy Useful Full Spectrum PlotTheerayoot PoomchaiNo ratings yet

- 2 Noise & Error SourcesDocument31 pages2 Noise & Error SourcesTheerayoot PoomchaiNo ratings yet

- 6 Transducer SelectionDocument20 pages6 Transducer SelectionTheerayoot PoomchaiNo ratings yet

- Gagemaker Catalog 1Document1 pageGagemaker Catalog 1Mark JurichNo ratings yet

- Parts Catalog: 630D Advanced Draper PlatformDocument260 pagesParts Catalog: 630D Advanced Draper Platformagroverde solucoesNo ratings yet

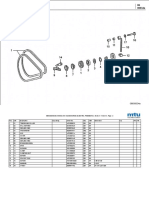

- Catalogo Partes JT-30 JetsprayDocument4 pagesCatalogo Partes JT-30 JetsprayEdwin Alfaro GNo ratings yet

- Tle-Ia-Eim: Quarter 2 - Module 2A: Electrical Wiring DevicesDocument22 pagesTle-Ia-Eim: Quarter 2 - Module 2A: Electrical Wiring DevicesTaki TroyNo ratings yet

- PvMini Install Manual PDFDocument10 pagesPvMini Install Manual PDFCARLOS ANDRES SARMIENTO CUEVASNo ratings yet

- Enclosed Safety Switches: Catalog 3100CT1602 Class 3100Document76 pagesEnclosed Safety Switches: Catalog 3100CT1602 Class 3100SendohNo ratings yet

- A Comparison of Dry Versus Gel Filled Optical Cables: Cat6 Utp - Armored CableDocument2 pagesA Comparison of Dry Versus Gel Filled Optical Cables: Cat6 Utp - Armored Cablekumar aNo ratings yet

- RSS SectionDocument8 pagesRSS SectionMarcos BarrosNo ratings yet

- PF5700 00 1.8TS Master US Dec 06Document1,654 pagesPF5700 00 1.8TS Master US Dec 06mohammedNo ratings yet

- Introduction & History of Computers, Their Applications: Sarhad University of Science & Information Technology PeshawarDocument26 pagesIntroduction & History of Computers, Their Applications: Sarhad University of Science & Information Technology PeshawarAvian DwijayaNo ratings yet

- Omni 848igDocument96 pagesOmni 848igDeon StrydomNo ratings yet

- Pressure Controls: Hydro-Electric Pressure SwitchDocument3 pagesPressure Controls: Hydro-Electric Pressure Switchsamsularief03No ratings yet

- DN 60975Document3 pagesDN 60975ANDREINo ratings yet

- Digital SLR Photography 2013-12Document164 pagesDigital SLR Photography 2013-12WillimSmith100% (2)

- SWP Brush Cutter Line Trimmer Petrol OperatedDocument2 pagesSWP Brush Cutter Line Trimmer Petrol OperatedDavidNo ratings yet

- Yokogawa: Y/11AM Pneumatic Absolute Pressure Transmitter User's ManualDocument5 pagesYokogawa: Y/11AM Pneumatic Absolute Pressure Transmitter User's ManualRabah AmidiNo ratings yet

- 20 AccessoriesDocument14 pages20 AccessoriesTayfun SezişNo ratings yet

- Hydro Test ProcedureDocument5 pagesHydro Test ProceduregauravNo ratings yet

- Altivar 212 Drive - VW3A8106Document2 pagesAltivar 212 Drive - VW3A8106galvangrrNo ratings yet

- CSR1S 24dyaDocument2 pagesCSR1S 24dyaNileshNo ratings yet

- RKI GD 70D ManualDocument142 pagesRKI GD 70D ManualBobby RinaldiNo ratings yet

- LIST of BSIDocument2,145 pagesLIST of BSIhady8100% (1)

- Cke1350 1F1Document12 pagesCke1350 1F1AndriNo ratings yet

- Plans 8 Sided PlanterDocument3 pagesPlans 8 Sided Planterhmam_88No ratings yet

- Workshop 2 Electrical Installations Single PhaseDocument3 pagesWorkshop 2 Electrical Installations Single PhaseDIAN NUR AIN BINTI ABD RAHIM A20MJ0019No ratings yet

- Tes Log Sengon: Kriteria Hasil Satuan RendemenDocument37 pagesTes Log Sengon: Kriteria Hasil Satuan RendemenAris SusantoNo ratings yet

- HR Katalog PDFDocument78 pagesHR Katalog PDFImran MehboobNo ratings yet

- HINO FM 1000 HR Service SheetDocument7 pagesHINO FM 1000 HR Service SheetYudi AriantoNo ratings yet