Professional Documents

Culture Documents

Plate Bearing Test

Plate Bearing Test

Uploaded by

Ahmad Afeeq0 ratings0% found this document useful (0 votes)

37 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

37 views6 pagesPlate Bearing Test

Plate Bearing Test

Uploaded by

Ahmad AfeeqCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

GSTL

GEO Site & Testing Services Ltd

— california Bearing Ratio

Services Landfill Site Testing [ Plate Bearing Test} Rallways

Plate Bearing Test

BS 1377 Part 9 : 1990 Standard

In the design of shallow foundation or traffic

surface, design engineers need to know the

bearing capacity of soil underneath. Plate

bearing test is carried out in the field to

serve this purpose. Results from the test can

be used as design parameter or used to

confirm the design assumption.

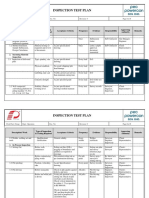

= The test shall be carried out in

general accordance with BS 1377:

Part 9 1990 ‘in-Situ Tests’.

* Accircular plate having a maximum

diameter of 300 - 600mm shall be

used.

* Excavate to the test level as

quickly as possible to minimise the

effects of stress relief, particularly

in cohesive fills. A mechanical

excavator may be used provided

that the excavator bucket does not

have teeth and the last 100mm.

depth of excavation is carried out

carefully by hand.

* Carefully trim off and remove all

loose material and any embedded

fragments so that the area for the

plate is generally level and as

undisturbed as possible.

™ Protect the test area and the

apparatus from moisture changes,

sunlight and the effects of adverse

weather as soon as the test level is

exposed and throughout the test.

info@gstl.co.uk (Search ]

Tel: 01554 a 6

784040

Fax: 01554

784041

— concrete Sampling — Coring Services — riling

Typical test setup

Schematic

Install test ig

Rig setup

Measuring

= The plate shall be placed on a thin

layer (10 to 15mm thick) of clean

dry sand to produce a level surface

on which to bed the plate.

= Set up the loading and deflection,

measuring systems so that the

load is applied to the plate without

eccentricity and the deflection

system is outside the zone of

influence of the

pattachments.ziplate. During these

operations a small seating load

may be applied to the plate to

enable adjustments to be made:

this seating load shall be less than

SkN/m2.

* The load shall be applied in five

increments. Settlement reading will

be taken at 0.50 minute intervals

for the first 2 minutes, and 1

minutes intervals thereafter, until

detectable movement of the plate

has stopped, i.e. until the average

settlement rate is less than

0.02mm per 5 minute interval.

= At each increment the pressure

shall be maintained as near as

possible constant.

* After the final test increment has

been completed, the pressure in

the hydraulic pump shall then be

released and the settlement of the

plate allowed to recover. When the

recovery is essentially complete,

the residual settlement value shall

be recorded.

= Our Range of Pressures start from

0 -1500 psi on the gauge

Test Setup

Equipment and Apparatus

= Counter weight such as box or

platform with heavy material suck

as concrete, steel, etc. Total

counter weight should be at least

10% greater than the anticipated

maximum test load.

= Hydraulic jack for applying the load

= Proving ring, 1 kg accuracy, for

measuring the load

= Bearing Plate, 350mm 450mm and

600mm Diameter

= Four Dial gauges, reference beams.

Testing Procedure

= Select test location and depth at

the point where the real foundation

will be constructed, if possible. If

the test is performed in a test pit,

width of the pit should be at least

4 to 5 times of plate diameter.

= Apply the load to the plate in steps

by means of hydraulic jack pushing

against the counter weight until

reaching the maximum test load.

Unloading should also be done in

the backward steps. Read and

record the load of every step from

proving ring.

= Read settlement from the dial

gauges. 3 to 4 dial gauges should

be placed separately at 120° or

90° respectively.

Counter Weight

Main Beam

Hydraulic Jack

Support

Pressure Gauge

Dial Gauge

Reference Beam

Bearing Plate

Interpretation of the Test

Result

Results from the test shall consist of raw

data, load-settlement curve, yield pressure,

recommended allowable pressure for

foundation design, and modulus of subgrade

reaction (K) for road design.

Illustration of Scale Effect in

Foundation Design

Plata Size

I

| | Actual Footing

Compacted Layer

Soft Material

Load-settlement curve from Plate

Bearing Test

Haring Prosser Ma

neo noe td

mn

020

0

1.60

30

100

120

a0

at

sw

sa

Stress Influence Zone

on

760)

fo

00

000

Das, B.M. (1995) suggested following

formula for calculating bearing capacity of

the actual footing to correct the scale effect.

For cohesionless soil where

4, ~. = bearing capacity of footing

qu (p, = bearing capacity of test plate

BF. = breadth of footing

Bp.

breadth of test plate

If the above method give too high bearing

capacity, Engineer should use judgment to

limit allowable pressure to be more

reasonable for each type of soil condition.

The prediction of settlement can also be

done from the load-settlement curve from

the test.

Determination of time over settlement

30 8

° s 10 Is 20

00 —- 7 T

02 = ==

04

08 -

10

2

1s -

ls

Sattement Gauge 2 Settlement Gave 3.

Advantages of the Test

= Gain understanding of foundation

behavior which will enable the

evaluation of foundation bearing

capacity and settlement under

loading condition.

* Quick and easy to perform.

tations

= Plate bearing test can give bearing

capacity of subsoil up to the depth

about twice of plate diameter only.

* There is a scale effect due to size

of testing plate is smaller than the

actual footing.

GEO Site & Testing Services Ltd

‘Tel: 01554 784040 - Fax: 01554 784041

Dafen HQ and Stores - Unit 4 , Heol Aur , Dafen Ind Estate , Dafen , Llanelli , Carmarthenshire SA14 8QN

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

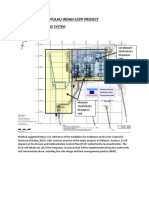

- Inspection Test Plan Piling WorkDocument4 pagesInspection Test Plan Piling WorkAhmad AfeeqNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PEC Pile Driving Record (250mm)Document1 pagePEC Pile Driving Record (250mm)Ahmad AfeeqNo ratings yet

- WD800-CZ250-00004 - Rev.0 FITP For Concrete Work (Onshore)Document31 pagesWD800-CZ250-00004 - Rev.0 FITP For Concrete Work (Onshore)Ahmad AfeeqNo ratings yet

- Non-Disclosure Agreement SampleDocument7 pagesNon-Disclosure Agreement SampleAhmad AfeeqNo ratings yet

- 0-WD800-CZ250-00003 - Rev.0 FITP For Survey Works (Onshore and Offshore)Document17 pages0-WD800-CZ250-00003 - Rev.0 FITP For Survey Works (Onshore and Offshore)Ahmad AfeeqNo ratings yet

- Delivery Order: PEC Powercon Sdn. BHDDocument1 pageDelivery Order: PEC Powercon Sdn. BHDAhmad Afeeq100% (1)

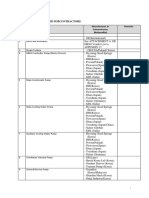

- Appendix 17 - Approved SubcontractorsDocument15 pagesAppendix 17 - Approved SubcontractorsAhmad AfeeqNo ratings yet

- Method Suggestion On Temporary Drainage SystemDocument2 pagesMethod Suggestion On Temporary Drainage SystemAhmad AfeeqNo ratings yet

- Hec P&idDocument47 pagesHec P&idAhmad Afeeq100% (2)

- TDS-MY-MacTex MXC, Apr2011Document1 pageTDS-MY-MacTex MXC, Apr2011Ahmad AfeeqNo ratings yet

- Technical ProposalDocument77 pagesTechnical ProposalAhmad AfeeqNo ratings yet

- Pile Testing Flowchart: Trial Pile Installation, 6 X Compression, 6 X Tension, 6 X LateralDocument5 pagesPile Testing Flowchart: Trial Pile Installation, 6 X Compression, 6 X Tension, 6 X LateralAhmad AfeeqNo ratings yet

- Drainage Control MethodDocument2 pagesDrainage Control MethodAhmad AfeeqNo ratings yet

- Milbank Generic Method StatementDocument24 pagesMilbank Generic Method StatementAhmad AfeeqNo ratings yet

- Thioflex 600 Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureDocument5 pagesThioflex 600 Data Sheet: Specialist Construction Supplies For Repair, Maintenance, Building & InfrastructureAhmad AfeeqNo ratings yet

- Ms 1759 2004Document194 pagesMs 1759 2004Ahmad AfeeqNo ratings yet