Professional Documents

Culture Documents

AliFax Roller 20 Manual GB

AliFax Roller 20 Manual GB

Uploaded by

Ксения НемихинаCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AliFax Roller 20 Manual GB

AliFax Roller 20 Manual GB

Uploaded by

Ксения НемихинаCopyright:

Available Formats

Table of Contents

Table of Contents

1 - Introduction ...................................................... 5

Intended Use ..............................................................................................................................5

How to Use the Operator’s Manual .............................................................................................5

Accessing a Section Using the Bookmark Navigation Pane ..................................................6

Following a Link inside the Manual ........................................................................................6

Warnings and Precautions: Symbols – Definitions ......................................................................7

Notes ....................................................................................................................................7

Cautions ................................................................................................................................7

Warnings ...............................................................................................................................7

Biological Warnings ...............................................................................................................7

Symbols ......................................................................................................................................8

Manufacturer ...............................................................................................................................9

Beckman Coulter Contact Information .........................................................................................9

Terminology ..............................................................................................................................10

Warnings...................................................................................................................................11

2 – System Description ........................................ 13

Theory of Operation ..................................................................................................................13

Internal Automated Mode ....................................................................................................13

Manual Mode ......................................................................................................................13

Front View ...........................................................................................................................14

Rear View ...........................................................................................................................15

Internal Components ...........................................................................................................16

Rotor with 20 Positions ..................................................................................................16

Wash Tank ....................................................................................................................16

External Retractable Probe............................................................................................16

Smart Card ...............................................................................................................................17

Starting the Instrument ..............................................................................................................18

Software....................................................................................................................................19

Levels of Access .................................................................................................................19

Main Menu ..........................................................................................................................20

Setup Menu .........................................................................................................................20

Availability Menu .................................................................................................................21

Warning Level ...............................................................................................................21

Display Availability .........................................................................................................22

Comm Menu .......................................................................................................................22

Tech Menu ..........................................................................................................................22

Installation.................................................................................................................................23

Location ..............................................................................................................................23

Installation Requirements ....................................................................................................23

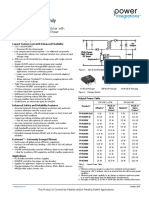

Technical Specifications............................................................................................................24

301-4331-English Rev AA 06/2013 Operator’s Manual 1

Table of Contents

3 - Configuration ................................................. 25

Setup Menu ..............................................................................................................................25

Log In ..................................................................................................................................26

Date and Time Menu.................................................................................................................27

Changing the Date ..............................................................................................................27

Changing the Time ..............................................................................................................28

FL Menu ..............................................................................................................................28

Settings Menu ...........................................................................................................................29

Software Version .................................................................................................................30

Print in Run .........................................................................................................................31

Print Expanded....................................................................................................................32

Language Setup ..................................................................................................................33

Wash Time ..........................................................................................................................34

4 – Specimen Processing ................................... 35

Sample Requirements...............................................................................................................35

Automatic Sampling ............................................................................................................35

Manual Sampling ................................................................................................................35

Tube Requirements ..................................................................................................................36

Tube Dimensions ................................................................................................................36

Tube Volume .......................................................................................................................36

Tube Caps ..........................................................................................................................36

Sample Mixing.....................................................................................................................36

Switching the Instrument ON.....................................................................................................37

Perform a Wash Cycle ........................................................................................................37

Internal Wash ................................................................................................................38

Manual Wash ................................................................................................................39

Running Samples......................................................................................................................40

Sample Processing Flowchart .............................................................................................40

Selecting the Type of Measure Mode ..................................................................................41

Internal Measurement....................................................................................................41

External Measurement ..................................................................................................41

External Measurement without Mixing ...........................................................................41

Entering the Patient Identification ........................................................................................42

External Barcode Reader Patient ID ..............................................................................42

Manual Patient ID Entry .................................................................................................43

Autogenerated Patient ID ..............................................................................................44

Verifying the Patient Identification .......................................................................................45

Internal Sampling ......................................................................................................................46

Loading the Samples on the Rotor ......................................................................................46

Manual Sampling ......................................................................................................................48

Internal Sample Mixing ........................................................................................................48

Manual Priming Procedure ..................................................................................................48

Manual Sampling Procedure ...............................................................................................50

Cleaning the External Probe................................................................................................51

Manual Sampling Completion..............................................................................................51

Emptying the Roller ...................................................................................................................52

301-4331-English Rev AA 06/2013 Operator’s Manual 2

Table of Contents

Switching the Instrument Off .....................................................................................................53

5 – Quality Control .............................................. 54

Quality Control ..........................................................................................................................54

Control Material.........................................................................................................................54

Control Frequency ...............................................................................................................55

Handling Control Material ....................................................................................................55

Shelf Life .......................................................................................................................55

Storage conditions .........................................................................................................55

Running QC on the Rotor ..........................................................................................................56

Internal Wash with 0.5% Bleach Solution before Controls ...................................................56

Entering Control ID and Loading Latex QC Tubes on the Rotor .......................................... 58

Entering the Control Identification ..................................................................................59

Loading the Tubes on the Rotor ....................................................................................60

Running Latex QC on the External Probe .................................................................................61

Latex Priming – Sampling Procedures ...........................................................................61

QC Results ...............................................................................................................................62

Reviewing QC Results ........................................................................................................63

Latex Individual Control Printout ..........................................................................................64

QC Statistics .............................................................................................................................65

QC Screen Selections .........................................................................................................66

QC Statistics from Samples ......................................................................................................67

Average Statistics from Samples .........................................................................................67

Average Printout from Normal Samples Range .............................................................68

Global Average Printout from Samples ..........................................................................69

Cumulative Distribution from Samples .................................................................................69

Cumulative Distribution Printout from Normal Samples .................................................70

Global Cumulative Distribution Printout from Samples ...................................................70

Daily Distribution from Samples ..........................................................................................71

Daily Distribution Printout from Normal Samples ...........................................................72

Global Daily Distribution Printout from Samples ............................................................72

QC Statistics from Latex Controls Distribution .....................................................................73

Latex Statistic Report ....................................................................................................74

Wash Distribution Quality Control Printout ...........................................................................75

Average Printout from Wash Distribution .......................................................................76

6 - Results ............................................................. 77

Analysis Results........................................................................................................................77

Display ................................................................................................................................77

Printout................................................................................................................................77

Statistical Results Printouts .......................................................................................................78

QC Screen Selections .........................................................................................................78

301-4331-English Rev AA 06/2013 Operator’s Manual 3

Table of Contents

7 – Maintenance and Service............................ 79

Maintenance .............................................................................................................................79

Daily Maintenance ...............................................................................................................79

Consumable Replenishment ...............................................................................................79

Daily Maintenance ....................................................................................................................80

Wash Procedures .....................................................................................................................80

Wash Options......................................................................................................................81

Wash Menu .........................................................................................................................81

Internal Wash ................................................................................................................82

Automatic Wash ............................................................................................................83

Manual Wash ................................................................................................................83

Wash Procedure with 0.5% Diluted Bleach Solution ............................................................84

Internal Wash with Bleach .............................................................................................84

Manual Wash with Bleach .............................................................................................88

Run Controls .......................................................................................................................90

Clean Instrument Surfaces ..................................................................................................91

Perform a Wash and Sleep Procedure ................................................................................91

Manual Wash and Sleep ...............................................................................................91

Internal Wash and Sleep ...............................................................................................93

As Needed Maintenance ...........................................................................................................97

Refill the Wash Tank ...........................................................................................................97

Empty the Waste Tank ........................................................................................................99

Replace the Printer Paper .................................................................................................101

Tallies -FL (Flag) Menu .....................................................................................................102

Troubleshooting ......................................................................................................................106

Before Calling for Service ..................................................................................................106

Hardware issues ..........................................................................................................106

Instrument applications issues .....................................................................................106

Washing Errors .................................................................................................................107

Photometer Not OK .....................................................................................................107

Error Messages .................................................................................................................108

Service ....................................................................................................................................111

Probe Replacement...........................................................................................................111

Fuse Replacement ............................................................................................................116

Sanitation Procedure .........................................................................................................117

Sanitation Form ...........................................................................................................118

Maintenance Log ....................................................................................................................119

8 - Appendix ..................................................... 120

Limitations...............................................................................................................................120

References .............................................................................................................................122

301-4331-English Rev AA 06/2013 Operator’s Manual 4

1 - Introduction

1 - Introduction

Intended Use

For professional in vitro diagnostic use only.

The Roller 20PN is an automated Erythrocyte Sedimentation Rate analyzer;

classified as a Class I device and exempt from the premarket notification

requirement.

The Roller 20PN is a fully automated analyzer for the determination of the

Erythrocyte Sedimentation Rate (ESR) in human blood, and provides results in

thirty-five (35) seconds after an initial pre-mix by measuring red blood cell

aggregation; overcoming the variables and limitations of the Westergren method.

The analyzer is equipped with a hand-held barcode reader for specimen

identification, internal mixing system, automated closed vial cap pierce and

aspiration, external probe for manual mode open vial sampling for small

specimens, automatic wash, and on-board quality control for latex controls and

patient samples.

How to Use the Operator’s Manual

Use the Operator's Manual as a guide to daily operations, maintenance and

quality control as well as a reference for system components, and

troubleshooting. This document is provided electronically on a CD with the Roller

20PN system.

It is intended to explain the instrument operations in detail, to be a training guide

for new operators and to be a troubleshooting reference resource.

301-4331-English Rev AA 06/2013 Operator’s Manual 5

1 - Introduction

Accessing a Section Using the Bookmark Navigation Pane

The Bookmark navigation pane, located on the left side of the screen, can be

used as a “linked” table of contents.

Click on a bookmark to go automatically to the starting page of the selected

section.

1. To expand the selection, click on the + sign located next to the bookmark.

2. To collapse the selection, click on the - sign located next to the bookmark.

Following a Link inside the Manual

In order to avoid searching for a specific section, links have been created to jump

to other locations and to give immediate access to the related information. Links

are indicated in the following manner: the text is displayed in blue and bold

italics. Example: see Beckman Coulter Contact Information.

1. Select the hand tool .

2. Position the pointer over the linked area on the page until the pointer changes

to the hand with a pointing finger .

3. Click the link, the destination screen is displayed.

4. To return to the previous section, click the Go to Previous View button.

301-4331-English Rev AA 06/2013 Operator’s Manual 6

1 - Introduction

Warnings and Precautions: Symbols – Definitions

The Operators Manual includes information and warnings that must be observed

by the operator to ensure safe operation of the system.

There are four types of messages.

Notes

NOTE: Highlights important facts, gives helpful information and tips, and clarifies

procedures.

Cautions

CAUTION: Identifies electrical caution! Unplug before handling.

CAUTION: International symbol for “Attention, see instructions for use” or

“Caution, consult accompanying documents.”

Warnings

WARNING: Identifies potentially hazardous situations that could result in serious

injury to laboratory personnel.

Biological Warnings

WARNING: Identifies potential biological hazards.

301-4331-English Rev AA 06/2013 Operator’s Manual 7

1 - Introduction

Symbols

The following is a list of symbols used on the product labeling and their meaning:

Symbol Meaning

Caution Consult Accompanying Documents

Consult Operating Instructions

Control

Manufacturer

Date of Manufacture

Reference Number

In Vitro Diagnostic

Serial Number

Caution: Laser Radiation

Caution: Moving Parts Inside

Caution: Sharp Objects Inside

Ground terminal plug on the equipment

Compliant with Waste Electrical and Electronic Equipment (WEEE)

directive

301-4331-English Rev AA 06/2013 Operator’s Manual 8

1 - Introduction

Manufacturer

Alifax S.P.A

SIRE Analytical Systems s.r.l

Via Bella 121/3

33100 Udine, Italy

ISO 9001:2000 certified by TÜV Italia (n. 50 100 6107/A)

ISO 13485:2003 certified by TÜV Italia (n. 50 100 6107/B)

Distributed by Beckman Coulter

www.beckmancoulter.com

250 Kraemer Blvd.

Bread CA 92821

All trademarks are property of their respective owners.

Beckman Coulter, the stylized logo are trademarks of Beckman Coulter, Inc. and

are registered with the USPTO

Beckman Coulter Contact Information

Attention Clinical Support

9172 Eton Avenue

Chatsworth, CA 91311

USA

Telephone:

From U.S. locations +1-800-776-4747 Option 2

Fax: +1-800-239-2864

E-mail: clinsupport@beckman.com

301-4331-English Rev AA 06/2013 Operator’s Manual 9

1 - Introduction

Terminology

Term Meaning

Automatic Wash Wash performed with DI water directly from the Wash

Tank

BCR External Barcode Reader

ESR Erythrocyte Sedimentation Rate

Manual Wash Wash performed using tubes filled with DI water

presented manually to the external probe

FIFO First In First Out

Internal Wash Wash performed using tubes filled with DI water loaded

on the rotor

Sensor 1 Internal Sensor

Sensor 2 External Sensor

Smart Card A pre-programmed card used to load available tests onto

the instrument.

Standard Select this option to run Latex Control Materials on the

instrument

Wash and Sleep Wash procedure performed at the end of a working day.

Wash Tank Container located inside the front door filled with DI

water for automatic wash

Waste Tank Container located inside the front filled with discarded

blood, latex, and DI water

301-4331-English Rev AA 06/2013 Operator’s Manual 10

1 - Introduction

Warnings

The manufacturer does not assume any responsibility for eventual damages to

persons or things due to improper use of the instrument, installation by

unauthorized person(s), use of the instrument while safety interlocks and sensors

are defeated, use of the instrument in a manner other than specified and

operation by untrained individuals.

WARNING risk of operator injury if:

• all doors and covers are not secured in place prior to and during

operation

• integrity of safety interlocks and sensors are compromised

• contact with moving or broken parts

Report any broken parts to your Iris representative. Use the tools provided with

the system for troubleshooting

Operate the instrument as instructed in the Operator's Manual.

The instrument is designed for indoor use only

Check that the instrument is connected to a ground outlet before use.

Switch OFF the instrument before connecting to any external peripheral, external

barcode reader, and/or RS232 serial cables.

Check the waste tank level before operation; empty the waste tank if filled to

security level. Follow the Laboratory standard safety procedures.

The blood samples must remain capped. Do not uncap and recap them which

could affect the instrument’s performances except if analyzed using the external

manual sampling probe.

Never mix Bleach with Blood in the system. Always run DI water before and after

Bleach.

Always follow the Wash Maintenance procedure to ensure instrument

performance.

Use only original spare parts supplied by the manufacturer.

The instrument can be exposed to potential infective materials. Therefore, it is

required to follow all precautions and necessary warnings, in accordance with

Federal and State laws.

301-4331-English Rev AA 06/2013 Operator’s Manual 11

1 - Introduction

Keep away from the instrument any kind of objects, liquids, or substances not

required for the instrument’s use.

Do not remove the instrument panels or tamper with the reading sensor. The

service operations must be carried out only by technical personnel authorized by

the manufacturer.

Avoid the use of the instrument near electromagnetic sources, such as cellular

phones, CB’s, radio transmitting units and similar.

In order to avoid possible mistakes with the Query-Host communication and/or

the transmission of patient ID to the Host computer, use the barcode

identification "check digit" option to ensure correct transmission of specimen

identification.

301-4331-English Rev AA 06/2013 Operator’s Manual 12

2 – System Description

2 – System Description

Theory of Operation

The Roller 20PN uses stopped flow kinetic analysis with capillary photometry to

measure the optical density of red blood cell aggregation.

The Roller 20PN has two specimen sampling modes - manual and automated, each

equipped with a sample probe, micro capillary tube and blood aspiration pump.

The instrument is first primed before sample analysis can be performed. Priming

is accomplished by aspirating additional volume of specimen from tubes in

position one and two in the rotor. Once primed, the system will then aspirate a

second time from tube one for the analysis cycle. Each sample is separated by

an air bubble. After analysis, the sample is discarded into the waste tank.

If the internal sampling is selected, up to twenty (20) sample tubes can be loaded

on the rotor. The system performs the measurements automatically.

If the external probe is selected, sample tubes are presented individually for

sampling.

Internal Automated Mode

• Minimum volume requirement is 1.3 mL

• Priming specimen volume is 116 μL whole blood from tubes one and two

• Analysis specimen volume is 175 μL for the first tube and all subsequent

tubes loaded in the rotor

The first result is available after 7 minutes. Thereafter, results are available every

35 seconds per sample. Up to sixty (60) samples can be processed in one hour,

twenty (20) samples in 20 minutes.

Manual Mode

• Priming specimen volume is 100 μL from the first tube

• Analysis specimen volume is 100 μL from the first and all subsequent

tubes

After priming, the first result is available in 35 seconds (analysis). Mixing of the

manual mode sample can be accomplished either internally following the display

screen instructions, or externally by hand, or on a separate mixer.

If the specimen is short for analysis in the manual mode, then priming should be

completed with an alternative available specimen volume before proceeding.

301-4331-English Rev AA 06/2013 Operator’s Manual 13

2 – System Description

Front View

2 1

3

5

Legend: 1 – Smart Card Slot

2 – Sample Loading Door

3 – Touchscreen LCD

4 – Internal Thermal Printer

5 - Stylus

301-4331-English Rev AA 06/2013 Operator’s Manual 14

2 – System Description

Rear View

3 2 1

4

6

7

Legend: 1 – Power Cord Plug

2 – Fuses Box

3 – Main Power Switch

4 – Power Supply Fan Intakes

5 – Instrument Cooling Fan

6 – Instrument Cooling Fan Intake

7 – External Barcode Reader Serial Port

8 – Host Computer (LIS) Serial Port

9 – USB Port (for future applications)

301-4331-English Rev AA 06/2013 Operator’s Manual 15

2 – System Description

Internal Components

Rotor with 20 Positions

Located underneath the Sample Loading Door, one (1) rotor allows for a total of

20 tubes to be loaded on the instrument.

Wash Tank

Located inside the front door on the instrument, the Wash Tank is filled with DI

water to perform the manual or automated wash procedures. Following a wash

and latex control procedure, the system checks the photometer and displays its

status. The maximum Washing Tank capacity is 500 mL.

External Retractable Probe

Located next to the Touchscreen LCD, the External Probe is used for manual

mode sampling from uncapped tubes. This option is useful for low volume or

pediatric specimens.

301-4331-English Rev AA 06/2013 Operator’s Manual 16

2 – System Description

Smart Card

The Smart Card is loaded into the slot located on the top right of the instrument.

Each smart card contains a specified number of tests from 1,000 to 20,000. Any

number of smart cards can be loaded. The system will display the number of

tests available to run. When a smart card is loaded, all the tests on the card will

be downloaded to the instrument. If required, Service can move all the tests from

one instrument to another.

If the instrument runs out of tests while processing, the current batch can be

completed in the automated mode. The number of tests in deficit will be deducted

when a new smart card of tests is loaded.

To ensure adequate tests are always available, the system has a threshold alarm

that will display a warning message when reached. It is possible to adjust the

threshold level via the Availability > Warning Level screen. The Threshold can be

set between 3 and 30,000 remaining tests. When the warning message occurs,

check or order a new smart card. See Display Availability.

Conform to ISO 7816-1 specifications – 85.6 x 54 x 0.8 mm

Coded using SIRE Analytical Systems / Alifax Group proprietary algorithm.

Four different cards are available:

Part Number Number of Tests

700-2011 1,000

700-2012 4,000

700-2013 10,000

700-2014 20,000

301-4331-English Rev AA 06/2013 Operator’s Manual 17

2 – System Description

Starting the Instrument

Press the Main Power Switch located on the upper rear side of the instrument.

The analyzer automatically starts the internal checkup, and then displays the

Main Menu screen.

301-4331-English Rev AA 06/2013 Operator’s Manual 18

2 – System Description

Software

This instrument is controlled using the Touch Screen. Each option, function,

process is activated/deactivated by touching the corresponding button.

Button Function

Main Used to access the common functions: measure, wash, empty roller,

and mixer.

Setup Accessible only to Admin level 2 users or technical service.

Used to access some common configuration functions, and specific

functions protected by password.

Availability Used to set the test credit warning alarm, and to display/print the

credits availability.

Comm Accessible only to technical service.

Tech Accessible only to technical service.

More Information lists manufacturer’s phone numbers.

For use inside the USA contact Beckman Coulter.

+1-800-776-4747

or email clinsupport@beckman.com

Last Session

Print last session results

The Start Up screen displays four (4) touchscreen options allowing the operator

to access directly specific functions:

• Measure

• Wash

• Empty Roller

• Mixer

Levels of Access

Not all the functions inside the menus are freely accessible. The instrument has

three levels of access:

Level Access

Level 1 - OPERATOR No password required. Allows access only to the basic

functions

Level 2 – ADMIN LEVEL Password required.

Allows access to the basic setup functions. When the

instrument is switched off, the instrument is reset to Level 1

Operator.

Level 3 – TECH LEVEL Password required.

This level is reserved only for Iris Technical Service

Personnel.

301-4331-English Rev AA 06/2013 Operator’s Manual 19

2 – System Description

Main Menu

From the Main Screen, press Main to displays the following options:

Setup Menu

From the Main Screen, press Setup to displays the following options:

301-4331-English Rev AA 06/2013 Operator’s Manual 20

2 – System Description

Availability Menu

From the Main Screen, press Availability to display the following options:

Warning Level

This function is used to setup the number of tests available remaining at which

the instrument will issue a warning. The tests are loaded on the instrument, see

Smart Card. The instrument will stop running samples when the number of tests

remaining is 0.

301-4331-English Rev AA 06/2013 Operator’s Manual 21

2 – System Description

Display Availability

This function is used to display and print the number of tests available on the

currently used Smart Card.

Comm Menu

NOTE: This function is password protected and is reserved only for Technical

Service Personnel.

Tech Menu

NOTE: This function is password protected and is reserved only for Technical

Service Personnel.

301-4331-English Rev AA 06/2013 Operator’s Manual 22

2 – System Description

Installation

The Roller 20PN will be installed by a Beckman Coulter trained representative. If

the installation is performed by other personnel, then the warranty will be void.

Location

The Roller 20PN weighs about 35 pounds and should be installed on a stable

bench with four inches of clearance around all sides to allow for connection of

cables, including hand held bar code reader, power cord and RS232 interface

cable.

Installation Requirements

The instrument should be located in a dry moisture free area away from direct

sunlight to increase operational reliability. Sunlight can interfere with the door

sensor.

Avoid using extension leads and while a dedicated outlet is not required it is

preferable that the system does not share an outlet with devices that create a

voltage imbalance such as centrifuges or refrigerators.

As reported in the technical specifications, the instrument uses alternating

current from 85 VAC to 256 VAC; therefore it is not necessary to use a voltage

selector.

301-4331-English Rev AA 06/2013 Operator’s Manual 23

2 – System Description

Technical Specifications

Specimen Processing Barcode or manual entry of ID

Up to 20 EDTA whole blood tubes per run

Closed and open tube sampling

Specimen Tubes 13 x 75 mm 4 mL EDTA tubes

Specimen Volume Auto Mode: 1 mL up to 60% of total tube volume

External Mode / Manual mode: 100 μL of blood

Auto Mode Sampling 175 μL closed tube

Measurement Principle Measures the kinetics of red blood cell aggregation by

capillary photometry

Reportable Range 2 – 120 mm/hr

Result Storage 6,000 (First In First Out) used for statistics only

Result Time 35 seconds

Throughput Up to 60 samples/hour

QC Data Storage 30 days

Correlation to Modified r => 0.94

Westergren

Quality Control Tri-level latex control

Reproducibility CV=5.1% from 2-210 mm/hour

Stability 4°C 24 hours r=>0.980

4°C 48 hrs r=>0.95

20-25°C 24 hours r=>0.917

Communication 2 serial RS232 ports

Optional CCD Barcode Reader

LIS Interface Bi-directional

Electrical Power Req. 115 - 230 VAC 50/60 Hz

Power Consumption 115 VA

Dimensions 10” W x 15” D x 18’ H

Weight 35 lbs.

Fluid Waste Waste is pumped from the instrument into a Waste Tank

Ambient Temperature Temperature control 37°C

Control, Relative Ambient temperature must be 50° - 86° F (10° - 30°C)

Humidity, and Heat Relative humidity must be between 15% and 85% non-

Output condensing.

Heat output approximately 230 British Thermal Units or BTUs

Maximum Rated Altitude 9840 feet - 3000 meters alignment signal locator (ASL)

301-4331-English Rev AA 06/2013 Operator’s Manual 24

3 – Configuration

3 - Configuration

Setup Menu

NOTE: Only a Level 2 Administrator can modify the user-defined settings. Any

user can view the settings. See Levels of Access.

From the Main Menu, press Setup. The following screen is displayed.

301-4331-English Rev AA 06/2013 Operator’s Manual 25

3 – Configuration

Log In

The Log In screen is used to access administrator settings as well as by

technical service functions.

Level Access

Level 1 - OPERATOR No password required. Allows access only to the basic

functions

Level 2 – ADMIN LEVEL Password required. Enter 1010, left arrow

Allows access to Date / Time setting and Wash Time option.

When the instrument is switched off, the instrument is reset

to Level 1 Operator.

Level 3 – TECH LEVEL Password required.

This level is reserved only for Iris Technical Service

Personnel.

1. From the Setup Menu, press LOGIN. The numerical keyboard is displayed.

2. Enter 1010 password to access the Admin Level, and then press .

3. Press Back to return to the Main Menu.

4. On the Main screen, the logged in user level will be displayed.

301-4331-English Rev AA 06/2013 Operator’s Manual 26

3 – Configuration

Date and Time Menu

From the Setup Menu, select Date time. The following screen is displayed.

If the Admin Password has been entered into the Log in screen then the display

below will be visible to set the date/time.

Changing the Date

1. Press the SET option, the numerical keyboard is displayed.

2. The instrument prompts to modify in the following order: Year,

Month and Day

3. Enter the appropriate value, and then press to validate the

entry and update the Date on the screen.

301-4331-English Rev AA 06/2013 Operator’s Manual 27

3 – Configuration

Changing the Time

1. Press the SET option, the numerical keyboard is displayed.

2. The instrument prompts to modify in the following order: Hour

and Minutes.

3. Enter the appropriate value, and then press to validate the

entry and update the Time on the screen.

FL Menu (Flag List)

This option is used to print tallies of instrument runs, and test availability.

301-4331-English Rev AA 06/2013 Operator’s Manual 28

3 – Configuration

Settings Menu

From the Setup Menu, select Settings. The following screen is displayed.

301-4331-English Rev AA 06/2013 Operator’s Manual 29

3 – Configuration

Software Version

This function is used to display the instrument software version, and the

processors software versions. The instrument uses five (5) different processors

and not all of them may have the same version installed.

1. From the Setup Menu, select SW version. The following screen is displayed.

2. Press Back to return to the Settings menu.

301-4331-English Rev AA 06/2013 Operator’s Manual 30

3 – Configuration

Print in Run

If this function is enabled, the instrument will print the IDs and ESR results after

the completion of each sample analysis. If this function is disabled, the

instrument will print the IDs and ESR results after completion of all sample

analyses.

1. From the Setup Menu, select Print in Run. The following screen is

displayed.

2. Select YES to enable the function.

3. Select NO to disable the function.

3. Press Back to validate the change and return to the Settings menu.

301-4331-English Rev AA 06/2013 Operator’s Manual 31

3 – Configuration

Print Expanded

If this function is enabled, the instrument will print the IDs and ESR results with

enlarged (expanded) text. If this function is disabled, the instrument will print the

IDs and ESR results with the default size text.

1. From the Setup Menu, select Print Expanded. The following screen is

displayed.

2. Select YES to enable the function.

3. Select NO to disable the function.

4. Press Back to validate the change and return to the Settings menu.

301-4331-English Rev AA 06/2013 Operator’s Manual 32

3 – Configuration

Language Setup

This function allows the user to select the language for displaying messages and

warnings on the instrument screen.

The available languages are:

English Italian Spanish

French Russian

1. From the Setup Menu, select Language. The following screen is displayed.

2. Select the desired language.

3. Press Back to validate the change and return to the Settings menu.

301-4331-English Rev AA 06/2013 Operator’s Manual 33

3 – Configuration

Wash Time

CAUTION: This option must be used to avoid residual blood clotting inside

the capillary after completion of the analysis cycle. The recommended time

is 15 minutes.

This option allows setting up the time delay, in minutes, after which an automatic

wash procedure is performed. The countdown starts at the end of the analysis

cycle. This will be set on installation.

NOTE: Log in as the Admin to access the menu to change the washing time.

1. From the Setup Menu, select Login.

2. Enter the password 1010, press

3. From the Setup Menu, select Wash Time. The keyboard screen is displayed.

4. Type the new time delay in minutes, and then press to validate the

change.

5. Press Back to return to the Settings menu.

301-4331-English Rev AA 06/2013 Operator’s Manual 34

4 – Specimen Processing

4 – Specimen Processing

Sample Requirements

Automatic Sampling

• The sample must be of whole blood collected in EDTA anti-coagulant.

• The blood sample must be neither coagulated nor hemolyzed.

• It is recommended to test the sample within 4-6 hours from venipuncture or

within 48 hours if kept at +4 / +8 °C, allowing it to return to room temperature

before testing.

• The minimum blood volume for the sampling (dead volume) is 1.3 mL.

• The minimum blood working volume required for the analysis is about 175

microliters. When running a batch or single run, the first two samples required

an additional 116 microliters withdrawn for priming. In total, 232 microliters

are withdrawn from the first two samples. If there is only one sample, the

amount withdrawn is around 232 microliters.

• Samples separation inside the capillary are performed using air bubble.

Manual Sampling

• The minimum blood volume required for the analysis is about 100 microliters;

except for the first sample after a wash from which supplementary 100

microliters are withdrawn for priming.

• Samples separation inside the capillary is performed using air bubble.

301-4331-English Rev AA 06/2013 Operator’s Manual 35

4 – Specimen Processing

Tube Requirements

Tube Dimensions

Test-tubes 13x75 mm like BD Vacutainer® or Greiner Bio-one or with 13 mm

diameter and from 75 to 83 mm high, cap included (like for example the Sarstedt

tubes that measure 11.5x66 mm without cap).

Tube Volume

The sample volume must not exceed 50-60% of the total volume of the test tube.

Tube Caps

Optional Terumo® cap adapter for Terumo Venojet II® tubes

Optional Sarstedt® cap adapter for Sarstedt Monovette® tubes

Sample Mixing

Sample mixing can be programmed in three speeds (60, 32, and 24 RPM) and in

number of rotations from 2 to 1,000 rotations

The system is pre-programmed at the recommended setting of 32 RPM at 200

rotations, about 6 minutes of mixing time.

301-4331-English Rev AA 06/2013 Operator’s Manual 36

4 – Specimen Processing

Switching the Instrument ON

1. Turn on the instrument using the power switch located on the top back panel

2. Remove any Wash and Sleep Tube loaded previously from the rotor.

3. Check the Waste container and empty if needed.

4. Check the Wash tank and fill if needed.

5. Check the printer paper roll and replace if needed.

6. Perform a wash cycle.

Perform a Wash Cycle

1. From the Main Menu or the Main Screen, press Wash.

2. The instrument prompts to select the wash option.

301-4331-English Rev AA 06/2013 Operator’s Manual 37

4 – Specimen Processing

3. Select the appropriate wash option. The instrument will activate the

corresponding procedure.

Internal Wash

1. After selecting Internal, the instrument will prompt to insert washing tube on

the rotor.

2. Load two (2) wash tubes filled to 3/4 volume with DI water in positions 1 and 2

of the rotor.

3. At the end of the wash cycle, the instrument will display and print a report

indicating the photometer parameters.

4. When a wash procedure is not successful, the instrument will generate a

PHOTOMETER NOT OK error and the washing procedure must be repeated.

301-4331-English Rev AA 06/2013 Operator’s Manual 38

4 – Specimen Processing

Manual Wash

1. After selecting External, the instrument moves the external probe to the

sampling position.

2. Insert the external probe inside the DI water wash tube, and then press Start.

3. Repeat the procedure with a second tube filled to 3/4 volume with DI water.

4. At the end of the wash cycle, the instrument will display and print a report

indicating the photometer status, OK or Not OK. When a wash procedure is

not successful, the instrument will generate a PHOTOMETER NOT OK error

and the washing procedure must be repeated.

301-4331-English Rev AA 06/2013 Operator’s Manual 39

4 – Specimen Processing

Running Samples

Sample Processing Flowchart

From Main Menu,

Select Measure

Type of Measure

Mode? Select

External with External

Internal

Internal Mixing without Mixing

Barcode Label

on the tube?

YES YES NO

Select Auto.

Scan the barcode Select Manual ID.

Enter the

label using the Enter the Patient

Patient ID using

external Barcode ID from Barcode

autogenerated

Reader Label

values

Measure Selected

External

External with

without

Internal Internal

Internal

Mixing

Mixing

Load all the

Load all the Present the

sample tubes on

sample sample tube

the rotor for

tubes on for external

mixing. Press

the rotor sampling

Measure

Remove individual

tube from the rotor

Press Measure position as

requested

Present the sample

tube for external

sampling

301-4331-English Rev AA 06/2013 Operator’s Manual 40

4 – Specimen Processing

Selecting the Type of Measure Mode

From the Main menu, press Measure. The following screen is displayed.

Internal Measurement

The tube will be loaded on the rotor for automatic sampling with mixing.

From the Measure screen, press Internal.

External Measurement

The tube will be loaded on the rotor for mixing, and then will be presented to the

external probe for sampling, press External.

External Measurement without Mixing

The tube will be presented to the external probe for sampling without mixing.

From the Measure screen, press External without mixing.

NOTE: This measure must be selected if the sample tubes are uncapped, or

when measuring short samples.

From the Measure screen, press External without mixing.

301-4331-English Rev AA 06/2013 Operator’s Manual 41

4 – Specimen Processing

After selecting the type of measurement, the instrument checks the

following:

• The position of the rotor,

• The level of the waste tank,

• The availability of test credits.

NOTE: If the waste tank is full, it must be emptied before starting a new session.

If not, the instrument remains in standby mode until when the waste tank is

emptied.

Proceed with the Patient Identification. See Entering the Patient Identification.

Entering the Patient Identification

If a barcode label has been applied to the sample tube, the following options are

available:

• The Patient identification is entered automatically by scanning the

barcode label using the external CCD barcode reader.

• If an external barcode reader is not available, the sample ID can be

entered using the keyboard.

If the sample is not identified by manual input or with a barcode label, a unique

autogenerated ID will be assigned.

External Barcode Reader Patient ID

1. After selecting type of measurement, the instrument displays the following

screen.

301-4331-English Rev AA 06/2013 Operator’s Manual 42

4 – Specimen Processing

2. Scan the barcode on the sample tube using the external scanner. The

instrument will display the patient ID number in the ID field.

Manual Patient ID Entry

1. After selecting type of measurement, the instrument displays the following

screen.

2. Press the Manual ID button. The instrument will display the keyboard.

3. Enter the Patient ID, and then press .

4. The instrument will display the patient ID number in the ID field.

301-4331-English Rev AA 06/2013 Operator’s Manual 43

4 – Specimen Processing

Autogenerated Patient ID

The autogenerated code is composed of a numeric sequence made by the

following series of numbers:

• The cycle number,

• The serial number of Roller 20,

• The wheel number,

• The position of tube in the rack (1-10).

Example: 0307920106

1. After selecting the type of measurement, the instrument displays the following

screen.

2. Press the Auto button.

3. The instrument will display the keyboard.

4. Enter the Patient ID, and then press .

301-4331-English Rev AA 06/2013 Operator’s Manual 44

4 – Specimen Processing

Verifying the Patient Identification

1. After the Patient Identification has been entered, the instrument will display

the patient ID number in the ID field.

2. Verify the patient ID with the number on the barcode label or the

autogenerated number. If the wrong patient ID is displayed, press Delete to

erase the ID and re-enter the patient ID using the barcode reader, manual

entry option, or the autogenerated option.

3. If the correct ID is displayed, press OK. The following screen is displayed.

4. Proceed with specimen processing. See Loading the Sample on the Rotor

or Manual Withdrawal Sampling .

301-4331-English Rev AA 06/2013 Operator’s Manual 45

4 – Specimen Processing

Internal Sampling

Loading the Samples on the Rotor

The samples must be loaded on the Rotor when the following measurements are

selected:

• Internal

• Manual with internal mixing

1. Open the tilting door, and then insert the tube in the next available tube

holder according to the screen display.

2. The instrument is equipped with two sensors to detect the presence of the

tube’s cap, and the presence of fingers. If after few seconds the external

sensor still detects the fingers, the instrument will display the following

message: “Remove hands from the instrument”.

3. After loading the sample, the instrument displays the Measure button.

301-4331-English Rev AA 06/2013 Operator’s Manual 46

4 – Specimen Processing

4. If more samples need to be processed, repeat the procedure for the next

tube.

5. When all tubes have been loaded on the rotor, press the Measure button to

proceed with the analysis or the internal mixing.

6. When the analysis is completed, the instrument displays the sample results.

Based on the printer setup, the individual results are printed immediately or

delayed until the end of the analysis cycle.

301-4331-English Rev AA 06/2013 Operator’s Manual 47

4 – Specimen Processing

Manual Sampling

WARNING: When using the manual sampling procedure, it is mandatory to use

protective gloves and all others protective tools, precautions and warnings

necessary in order to avoid the contact with biohazardous material in accordance

with Federal, State, and local regulations.

Internal Sample Mixing

If the selected measurement is external sampling with internal mixing, the

instrument will prompt to load the samples on the rotor and will mix them. See

Loading the Samples on the Rotor.

For the priming procedure, the instrument will mix the blood loaded on the rotor

for half of the total mixing cycles. The minimum number of mixing cycles is not

less than 10.

After the mixing cycle has been completed, the instrument will prompt to remove

the first sample from the rotor for manual priming. See Manual Priming

Procedure.

Manual Priming Procedure

NOTE: The instrument will start a Priming procedure only if the analysis is

performed after a Washing procedure.

NOTE: If pediatric samples are measured, since they contain a small quantity of

blood, the aspiration for the priming can be performed using a previously

analyzed blood sample or blood sample belonging to an adult.

1. After the internal sample mixing is completed, the instrument prompts to

remove the tube from position 1.

2. The external probe moves out for access, and the Mixing is displayed.

3. Remove the tube, and then uncap the tube from position 1.

4. Insert the external probe inside the tube all the way down.

301-4331-English Rev AA 06/2013 Operator’s Manual 48

4 – Specimen Processing

5. From the Priming screen, press START .

6. The instrument aspirates a small quantity of blood from the tube to prepare

the capillary to receive the blood.

7. When three (3) beeps sound, remove the tube, recap and clean the probe.

8. The instrument prompts to reload the tube on the rotor in position 1; close the

door and the mixing procedure continues until the programmed mixing cycles

are completed.

301-4331-English Rev AA 06/2013 Operator’s Manual 49

4 – Specimen Processing

Manual Sampling Procedure

1. After the internal sample mixing is completed, the instrument prompts to

remove the tube from position 1.

2. The external probe moves out for access, and the Sample screen is

displayed.

3. Remove the tube, and then uncap the tube from position 1.

4. Insert the external probe inside the tube all the way down.

5. From the Sample screen, press START.

6. The instrument aspirates a small quantity of blood from the tube for

measurement.

7. When three (3) beeps sound, remove and then recap the tube.

8. The tube can be reloaded on the rotor or left outside the instrument (external

rack) for other analysis.

9. When the analysis is completed, the instrument displays the sample results.

Based on the printer setup, the individual results are printed immediately or

delayed until the end of the analysis cycle.

10. From the Result screen, press Back . The instrument prompts to clean the

external probe. See Cleaning the External Probe.

301-4331-English Rev AA 06/2013 Operator’s Manual 50

4 – Specimen Processing

Cleaning the External Probe

1. To clean the external probe, use a dry lint free tissue.

2. Gently, wipe the probe from the top to the bottom.

3. When the probe has been cleaned, from the Wipe Probe screen, press OK .

CAUTION: To avoid damaging the probe, do not pull on the probe.

4. The instrument will move the rotor to the next position and will ask to remove

the next sample to be analyzed. See Manual Sampling Procedure.

Manual Sampling Completion

When all samples have been processed on the manual mode, perform a Manual

wash, see Manual Wash.

301-4331-English Rev AA 06/2013 Operator’s Manual 51

4 – Specimen Processing

Emptying the Roller

1. From the Main Menu, press Empty Roller.

2. Open the tilting door, and then remove all the loaded tubes. The instrument

checks as the tubes are removed from the rotor.

301-4331-English Rev AA 06/2013 Operator’s Manual 52

4 – Specimen Processing

Switching the Instrument Off

Before switching OFF the instrument, it is mandatory to perform the Wash and

Sleep procedure. See Perform a Wash and Sleep Procedure.

When the Washing procedure is completed, the instrument can be switched OFF

using the main power switch located on the back.

301-4331-English Rev AA 06/2013 Operator’s Manual 53

5 – Quality Control

5 – Quality Control

Quality Control

The Quality Control program is used to collect QC data and display QC reports

and statistics. These functions are used to obtain data, verify and monitor the

proper system operation.

Quality Control Tools

The Roller 20PN System has a series of tools to enable monitoring of instrument

performance. These include:

• Latex Quality Control material and monitoring of daily and cumulative

values versus reference value.

• Patient Population daily average, cumulative average ESR values and

Cumulative distribution of ESR ranges.

• Photometer value monitoring during daily wash procedures.

Control Material

The Latex Controls kit is used to verify system function. The results of the control

simulate three ESR values, one low level (≅5 mm/h), one medium level (≅20

mm/h) and one high level (≅60mm/h).

By comparing the results obtained from the analyzer with those reported on the

kit package, it is very easy to verify that the instrument is reporting reliable

results.

Part Number Kit Tubes

800-2007 Latex Control Kit 6 tests Greiner tubes 13x75 mm

800-2008 Latex Control Kit 30 tests Greiner tubes 13x75 mm

Latex Control Kit 6 tests Latex Control Kit 30 tests

301-4331-English Rev AA 06/2013 Operator’s Manual 54

5 – Quality Control

Control Frequency

All controls should be run at least once every 24 hours or as specified in the

Laboratory’s QC Procedure manual. Beckman Coulter recommends running the

controls at the beginning of the day.

Handling Control Material

Refer to the control material package insert for more information.

Shelf Life

From production: 6 months.

From the first piercing: 6 weeks.

Storage conditions

Before use: between 4 to 25°C

From the first piercing: keep refrigerated between 2° to 8°C.

Refrigerated control material should be returned to room temperature before

running on the instrument.

301-4331-English Rev AA 06/2013 Operator’s Manual 55

5 – Quality Control

Running QC on the Rotor

NOTE: Since the system is equipped with two reading circuits, the Rotor and the

External Probe, controls must be run on both circuits.

It is recommended to first run the Control Material on the Rotor, and then run the

same Control Material using the External Probe.

Before running the latex controls, run one (1) wash procedure using 2 wash

tubes of DI water, followed by one (1) wash procedure with one tube of 0.5%

Diluted Bleach and the 2nd filled with DI water.

Internal Wash with 0.5% Bleach Solution before Controls

NOTE: Wash tubes must be single use only and should not be refilled and re-

used. Only use Beckman Coulter provided Wash tubes.

NOTE: Starting with a 5% solution of household bleach, dilute the bleach solution

1:10 (one part Bleach and nine parts DI Water) to obtain a final working dilution

of 0.5%.

1. From the Main Menu or the Main Screen, press Wash.

2. The instrument will check the rotor status, prompting to remove any tube

present on the rotor.

3. The instrument prompts to select the wash option.

301-4331-English Rev AA 06/2013 Operator’s Manual 56

5 – Quality Control

4. Select Internal, the instrument will prompt to insert the washing tubes on the

rotor.

5. Load one (1) wash tube filled to ¾ volume with 0.5% diluted Bleach in

position 1 of the rotor. Load one (1) wash tube filled to ¾ volume with DI

water in position 2 of the rotor.

6. Close the door; the instrument will start the wash automatically.

7. At the end of the wash cycle, the instrument will display and print a report

indicating the status of the photometer parameters.

8. Continue with latex QC only if Photometer OK is displayed. Otherwise refer

to Washing Errors.

301-4331-English Rev AA 06/2013 Operator’s Manual 57

5 – Quality Control

Entering Control ID and Loading Latex QC Tubes on the Rotor

1. From the Main Menu or the Main Screen, press Standard.

NOTE: Standard menu is for running latex control. The QC menu is for

displaying QC statistics.

2. The instrument will check the rotor status, prompting to remove any tube

present on the rotor.

3. The instrument prompts to select the measurement mode. Select Internal.

4. The system prompts to load the tubes on the rotor. Open the rotor door.

5. The tubes must be loaded in the following order:

301-4331-English Rev AA 06/2013 Operator’s Manual 58

5 – Quality Control

Position Tube

1 Wash tube filled to ¾ volume with DI water

2 Low level control tube

3 Medium level control tube

4 High level control tube

5 Wash tube filled to ¾ volume with DI water

6 Wash tube filled to ¾ volume with DI water

Entering the Control Identification

NOTE: The Control Identification located on the Barcode Label must match the 3

Latex Levels. The numbers 2, 3, and 4 indicate the tube position on the rotor.

1. Before loading the Control Tubes, the instrument prompts to enter each

Control Identification printed on the barcode label attached on the tube.

2. Using the Barcode Reader:

a. Scan the barcode label on the tube. The ID is displayed inside the ID

field.

b. Verify the ID.

3. Manual entry using the keyboard:

a. Select the Manual option. The screen displays the keyboard.

b. Enter the Latex ID, and then press .

c. Verify the ID.

4. Recall a tri-level ID stored in the database.

a. Select the Memo option. The screen displays the stored Latex ID.

b. If the correct Latex ID is displayed, press OK.

301-4331-English Rev AA 06/2013 Operator’s Manual 59

5 – Quality Control

Loading the Tubes on the Rotor

1. Load a wash Tube willed to ¾ volume with DI water in position 1 on the rotor.

2. Load the Low Level Control in position 2 on the rotor.

3. Load the Medium Level Control in position 3 on the rotor.

4. Load the High Level Control in position 4 on the rotor.

5. Load a wash Tube filled to ¾ volume with DI water in position 5.

6. Load a wash Tube filled to ¾ volume with DI water in position 6.

7. Close the rotor door.

8. The system will check the following:

• Latex expiration date: if the controls are expired, the screen prompt will

appear – latex control lot expired, cannot run.

• The three tubes belong to the same kit: if not, will prompt that the codes

are inconsistent. Press Clear. The instrument will prompt to remove the

tubes from the rotor.

• Always discard all 3 sequestered tubes and do not mix tubes.

301-4331-English Rev AA 06/2013 Operator’s Manual 60

5 – Quality Control

Running Latex QC on the External Probe

1. After mixing, the external probe will move down, and the instrument will

display the following screen.

2. Wipe the probe from top to bottom using a dry lint free tissue.

3. Open the rotor door, and then remove the tube in position 1.

4. Close the rotor door, and then insert the external probe all the way inside the

tube.

5. The screen displays Wash. Press Start .

5. The instrument performs a washing procedure. When three (3) beeps sound,

remove and then recap the tube.

6. Wipe the probe from top to bottom using a dry lint free tissue.

Latex Priming – Sampling Procedures

1. Wipe the probe from top to bottom using a dry lint free tissue.

2. Open the rotor door, and then remove the low level control in position 2.

3. Insert the external probe all the way inside the tube.

4. Close the door.

5. The screen displays Priming. Press Start .

6. The instrument performs a priming procedure using the latex control. When

three (3) beeps sound, remove the tube.

7. Wipe the probe from top to bottom using a dry lint free tissue.

8. Insert the external probe all the way inside the tube.

9. The screen displays Latex. Press Start .

10. The instrument performs a sampling procedure using the latex control. When

three (3) beeps sound, remove the tube.

11. Wipe the probe from top to bottom using a dry lint free tissue.

301-4331-English Rev AA 06/2013 Operator’s Manual 61

5 – Quality Control

12. Repeat the procedure for the two remaining Latex controls.

13. Repeat the wash procedure for the two remaining tubes filled with DI water.

QC Results

After the Quality Control measurements are completed, the instrument displays

the obtained values and the expected ranges.

From the Latex Absolute Levels screen, select OK . The Reference values

screen is displayed.

301-4331-English Rev AA 06/2013 Operator’s Manual 62

5 – Quality Control

Reviewing QC Results

The printout displayed on the next page is an example of a report after a Latex

Control.

At the end of the procedure, compare the printed results with the expected range

printed in Table 2 on the latex control kit box.

If the results obtained by the analyzer are within the expected range, the

analyzer is correctly calibrated.

If one or more results are not within the expected range printed on the latex

control kit box, re-run the controls. If the results are still out of range, then contact

Customer Service.

301-4331-English Rev AA 06/2013 Operator’s Manual 63

5 – Quality Control

Latex Individual Control Printout

Printout Section Meaning

Latex Lot number and Kit number.

Values before and after washing.

Washing Sequence water tubes

Tube 1 (before Latex Control)

Tube 5 (after Latex Control)

Tube 6 (after Latex Control)

Report photometer status (OK – not OK)

Operating parameters

Results obtained after the Control procedure

Level = Measured values (expected range)

Sensor 1 Measured Value 1

Sensor 2 Measured Value 2

301-4331-English Rev AA 06/2013 Operator’s Manual 64

5 – Quality Control

QC Statistics

Results obtained during the latex control procedure are stored by the instrument

for 30 days.

Up to 6,000 ESR sample results are included in the QC statistics. When the total

of stored results reaches 6,000 the first 1,000 are removed from the internal

memory (First In First Out).

1. From the Main Menu or the Main Screen, press Q.C..

2. The QC screen is displayed.

301-4331-English Rev AA 06/2013 Operator’s Manual 65

5 – Quality Control

QC Screen Selections

The options AVERAGE, CUMULATIVE, and DAILY, allow the user to print the

corresponding distribution of ESR sample results obtained by the instrument.

Option Selection Function

Normal (1-1) Average distribution of the normal result range

(2 to 30)

AVERAGE

Global (1-2) Average distribution of the global result range

(2 to 120)

Normal (2-1) Cumulative distribution of the normal result range

(2 to 30)

CUMULATIVE

Global (2-2) Cumulative distribution of the global result range (2

to 120)

DAILY Normal (3-1) Daily distribution of the normal result range

(2 to 30)

Global (1-2) Daily distribution of the global result range

(2 to 120)

LATEX Print (4-1) Print the Latex QC results from the last 30 days

WASH Print (5-1) Print the Wash

301-4331-English Rev AA 06/2013 Operator’s Manual 66

5 – Quality Control

QC Statistics from Patient Samples

Results from a reference population are used as statistical daily controls. There

are four different printouts, see QC Screen Selections.

Average Statistics from Samples

Select this option to print the statistical data relative to the ESR population

average:

• average of the “Normal” range (ESR from 2 to 30)

• average of the “Global” range (ESR from 2 to 120)

From the Main Menu, press QC. From the QC Menu, press Normal (1-1) or

press Global (1-2).

Assuming a constant patient population, the average ESR value will remain

relatively constant. As more data points are added each day so the cumulative

average ESR value becomes more statistically significant. Based on population

variances the average ESR value of the laboratories normal range being more

stable than the average ESR value of the reportable or global range.

Daily variations in instrument performance can be evaluated by comparing the

daily ESR average value to the cumulative average ESR value. A normal in

control value is one that oscillates around the cumulative average value. A daily

average ESR value that shows directional change over time indicates a systemic

instrument drift. The percentage of pathological samples varies day to day and

influences the daily average, however the cumulative average over time is

unaffected.

301-4331-English Rev AA 06/2013 Operator’s Manual 67

5 – Quality Control

Average Printout from Normal Samples Range

Indicates a cumulative average.

o Indicates a daily average

Printout Section Meaning

Number of today samples results inside the

normal range

Lower and Upper values for the normal range

8.88 cumulative average

4.11 day 1 average

6.69 cumulative average (day 1 + day 2)

8.67 day 2 average

7.14 cumulative average (day 1 + day 2 +

day 3)

8.82 day 3 average

Data for today’s analysis

Daily SD average - # of samples analyzed during

the day

SD cumulative average - # of samples analyzed

during the last 30 days

>5 and <10 Limits of the cumulative CV%

This graphical printout represents the last 30 days of analysis, and an anomalous

tendency of the daily average with respect to the cumulative average, can be

easily spotted. The data are printed from oldest (top of the graph) to most recent

(bottom of the graph).

Consider the number of daily sample results. The cumulative average line

becomes stable after more than 100 samples, and the daily average moves

around the cumulative trend line. This way, a problem could be immediately

evidenced by a rapid deflection of the trend line of daily and cumulative

averages.

The instrument is able to store 6,000 sample results to calculate the average, so

a large variation on daily statistics will not change in determinant way the

cumulative average. As soon as the instrument reaches 6,000 sample results, it

will discard the first 1,000 (using the First In First Out rule), conserving 5,000