Professional Documents

Culture Documents

Commissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method Statement

Commissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method Statement

Uploaded by

Mohammad OsmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method Statement

Commissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method Statement

Uploaded by

Mohammad OsmanCopyright:

Available Formats

Commissioning Methodologies (CM) – MUS-01

Pipework Flushing and Cleaning Method

Statement

Client: Project Name: Project No:

Area: Drawing No’s: Date: Sheet: 1 of 2

Check Signature: Check Approved By: Signature:

Conducted

By:

INTRODUCTION

The test procedure guideline has been prepared to explain the minimum standard for pre-commissioning flushing

required to be undertaken on a pipe work system prior to final filling, addition of chemicals and water balancing.

The methodology is based on local Australian water quality.

The main contaminants found in water systems are installation debris, scale, corrosion products and biological

fouling. The extent of cleaning and any associated water treatment during or after cleaning is required to be

addressed by a qualified water treatment expert.

Typical stages of cleaning include static flushing, dynamic flushing, degreasing, biocide wash, removal of surface

oxides, effluent flushing, neutralisation, passivation and corrosion inhibitor/biocide dosing as applicable to the

pipework system as well as terminal pipework connected to coils/equipment and the like.

The pipework system should be flushed so that all sensitive plant and equipment is either bypassed or temporarily

looped out during the course of flushing and cleaning process.

Dynamic flushing entails either use of system pumps or some form of supplementary pumps to allow flushing

velocities to be achieved as nominated in the BSIRA Guidelines or design flow rate + 10% as applicable in all

mains, branch and terminal pipe work runs and which flows can be verified using the installed measuring facilities

and/or ultra-sonic measuring facilities.

Material in the water systems shall be removed by one of the options being in-line fine mesh strainers, side-stream

filters drained to waste or some other method that provides actual removal of the material.

Provide adequate air vents and adequate drain points in pipework to allow the system to be purged of air and to be

drained quickly.

REFERENCE STANDARDS

BSIRA - Pre-commission Cleaning of Pipework Systems AG 1/2001.0

CIBSE Commissioning Code W - Water Distribution

NEBB - Procedural Standards for Testing, Adjustment and Balancing Environmental Systems

Commissioning Methodologies (CM) – MUS-01

Pipework Flushing and Cleaning Method

Statement

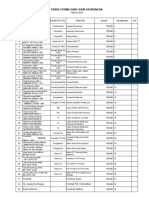

CHECKLIST

Area/Level/Zone

System Reference

Drawing Number

VERIFICATION RESULT RESULT RESULT

ITEM METHOD

Pressure

1 Pipework pressure testing complete

Test Report

Circulation pumps operating, aligned and commissioned OR Site Inspection

2

external pumps provided for flushing

Site Inspection

3 Water supply and drain facility available

Site Inspection

4 All isolation valves open

Site Inspection

5 Auto vent valves open

Site Inspection

6 Drain valves open

Site Inspection

7 Water fully drained from pipework

Drain valves closed before re-filling with clean water Site Inspection

8

Pipework re-filled with chemically dosed water for Site Inspection

9 descaling/washing as applicable

All flushing loop valves open and isolation valves closed to all Site Inspection

10 water coils/equipment

Side stream filter sock/pump strainers/ coil strainers are installed Site Inspection

11 and are clean

Flushing velocities through pipework complies with minimum Minimum Flushing

12 velocities and recorded on water balance test report Velocities

Side stream filter sock/pump strainers/ coil strainers are removed Site Inspection

13

All drains, dirt legs drained Site Inspection

14

Water clean and appropriate chemicals added by water treatment Chemical report

15

company

Water samples taken and test report provided by water treatment Chemical report

16

specialist

All flushing loop valves shut and isolation valves open to all water Site Inspection

17 coils/equipment and drains before final connection to main system

water

Commissioning Methodologies (CM) – MUS-01

Pipework Flushing and Cleaning Method

Statement

Final chemical concentrations from various representative points Chemical report

18 taken and tested / recorded to ensure complete dispersal of

chemicals

Certified By Sub Contractor (initial):

Date:

Confirmed By (Head Contractor / Client) (initial):

Date:

You might also like

- Handbook of Psychotherapy Integration 2019Document841 pagesHandbook of Psychotherapy Integration 2019Vanessa Granada Jiménez100% (3)

- Cleaning and Flushing of The Chilled Water Piping SystemDocument2 pagesCleaning and Flushing of The Chilled Water Piping Systemsujan198086% (14)

- OQ Protocol For Purified WaterDocument5 pagesOQ Protocol For Purified WaterNorhasma Ismail100% (4)

- Method Statement FOR Testing and Commissioning: Plumbing, Sanitary and Drainage SystemDocument10 pagesMethod Statement FOR Testing and Commissioning: Plumbing, Sanitary and Drainage SystemJazz SicatNo ratings yet

- Dosing Pumps ChecklistDocument2 pagesDosing Pumps ChecklistDeshan Sing100% (2)

- Standard Flushing Procedures PDFDocument6 pagesStandard Flushing Procedures PDFmadan mohan kattaNo ratings yet

- Construction Procedure For HydrotestingDocument7 pagesConstruction Procedure For HydrotestingEddie Tai100% (1)

- METHOD STATEMENT FLUSHING - StampedDocument3 pagesMETHOD STATEMENT FLUSHING - StampedMohammad OsmanNo ratings yet

- Final Bangus Value ChainDocument8 pagesFinal Bangus Value ChainSandy SandyNo ratings yet

- 7.hospital Registration Application FormDocument4 pages7.hospital Registration Application Formu2mailrahul75% (4)

- NCP For Dizziness and HeadacheDocument4 pagesNCP For Dizziness and HeadacheDharyl Joshua67% (12)

- Diabetes Mellitus-I: Garis Besar Kuliah Untuk Mahasiswa Semester-6 Fakultas Kedokteran Universitas Airlangga, SurabayaDocument40 pagesDiabetes Mellitus-I: Garis Besar Kuliah Untuk Mahasiswa Semester-6 Fakultas Kedokteran Universitas Airlangga, Surabaya'ifa Iffa100% (4)

- Neuroanatomy Through Clinical Cases, 2E PDFDocument3 pagesNeuroanatomy Through Clinical Cases, 2E PDFjwongggg55140% (6)

- Section 02760 Performance Testing of Pressure Pipelines Part 1 - GeneralDocument5 pagesSection 02760 Performance Testing of Pressure Pipelines Part 1 - Generaldương_thành_28No ratings yet

- Method of statement CHW FLUSHINGDocument18 pagesMethod of statement CHW FLUSHINGsafeer SulaimanNo ratings yet

- Section 02760 Performance Testing of Pressure Pipelines Part 1 - GeneralDocument5 pagesSection 02760 Performance Testing of Pressure Pipelines Part 1 - Generaljungzki jungzkiNo ratings yet

- Flushing Chemical Cleaning-1Document4 pagesFlushing Chemical Cleaning-1Tameem Zaka100% (1)

- JIEYUAN Project Execution Plan of Chemical Cleaning and Oil Flushing For Cooling Medium SystemDocument12 pagesJIEYUAN Project Execution Plan of Chemical Cleaning and Oil Flushing For Cooling Medium SystemTao QuNo ratings yet

- Commissioning Methodologies (CM) - MUS-07 Water Balancing Method StatementDocument2 pagesCommissioning Methodologies (CM) - MUS-07 Water Balancing Method StatementFahad MuhammadNo ratings yet

- Method Statement - Chilled Water Chemical Flushing - HEAT & POWER GEMS SCHOOLDocument19 pagesMethod Statement - Chilled Water Chemical Flushing - HEAT & POWER GEMS SCHOOLAnash RajanNo ratings yet

- G6 Spec Mechanical TestingDocument5 pagesG6 Spec Mechanical Testingsyahirah natasyaNo ratings yet

- Flushing ProcedureDocument7 pagesFlushing ProcedureAzrul Hanif100% (3)

- Validation ProtocolDocument63 pagesValidation ProtocolIndústria Petys64% (22)

- Pipeline Testing and DisinfectionDocument10 pagesPipeline Testing and DisinfectionWayjantha Sunethra Bandara JayawardhanaNo ratings yet

- Section 15189 - HVAC Water TreatmentDocument20 pagesSection 15189 - HVAC Water Treatmentnermeen ahmedNo ratings yet

- Reducer SB 169Document7 pagesReducer SB 169VinceChristian FerryNo ratings yet

- Flushing Procedure For Chilled Water SystemDocument3 pagesFlushing Procedure For Chilled Water SystemJohnna CenaNo ratings yet

- Hydranautics TAB142 LDocument9 pagesHydranautics TAB142 LMax JunghannsNo ratings yet

- Pipeline-Testing-and-Disinfection AWWA B300Document10 pagesPipeline-Testing-and-Disinfection AWWA B300Jason Angel BuñagNo ratings yet

- Ensuring LNG Liquefaction Facilities Sys PDFDocument12 pagesEnsuring LNG Liquefaction Facilities Sys PDFdhurjatibhuteshNo ratings yet

- Validation Protocol PDFDocument63 pagesValidation Protocol PDFmarwa100% (1)

- Flushing Procedure For Chilled Water System - Chemical Treatment - Method Statement HQDocument3 pagesFlushing Procedure For Chilled Water System - Chemical Treatment - Method Statement HQابوزيد عبد الجوادNo ratings yet

- S Inspect ProcDocument11 pagesS Inspect ProcDi Quan Di QuanNo ratings yet

- 715007923v00Document9 pages715007923v00Chí NguyễnNo ratings yet

- API 570 Study Notes PDFDocument25 pagesAPI 570 Study Notes PDFBoulHich BoulHichNo ratings yet

- Quad Pipe Hydrotest Procedure Rev1Document16 pagesQuad Pipe Hydrotest Procedure Rev1Trust EmmaNo ratings yet

- Water System ValidationDocument49 pagesWater System ValidationJelly Anne Barrera100% (1)

- Baher M. EL-Gendy Section (2) B.N.Document7 pagesBaher M. EL-Gendy Section (2) B.N.Baher M. El-GendyNo ratings yet

- Pressure Test - Flushing - Pickling - Passivation Hyd-Cw-GrDocument12 pagesPressure Test - Flushing - Pickling - Passivation Hyd-Cw-GrVidal Choque N.100% (1)

- Pressure Testing of Pipelines: CR Asia GroupDocument7 pagesPressure Testing of Pipelines: CR Asia Groupvishal bailurNo ratings yet

- VolDocument110 pagesVoldep_vinNo ratings yet

- Flushing and Hydrotest Procedure Rev 0Document10 pagesFlushing and Hydrotest Procedure Rev 0OkeymanNo ratings yet

- Kualifikasi Sitem Pengolahan Air Dan Tata UdaraDocument72 pagesKualifikasi Sitem Pengolahan Air Dan Tata UdaraAnnisa MartilasariNo ratings yet

- Water Treatment and Chemical Cleaning System 15189Document2 pagesWater Treatment and Chemical Cleaning System 15189Munir RasheedNo ratings yet

- Testing & Commissioning Procedure For Plumbing WorkDocument16 pagesTesting & Commissioning Procedure For Plumbing WorkUmar FarooqNo ratings yet

- ChecklistDocument7 pagesChecklister.saddam85No ratings yet

- (Water Treatment & Cleaning System)Document5 pages(Water Treatment & Cleaning System)Mohamed MansourNo ratings yet

- WorkScopeTypeH PDFDocument5 pagesWorkScopeTypeH PDFZev ZekNo ratings yet

- Hydrotest ProcedureDocument9 pagesHydrotest ProcedurejeszzymenNo ratings yet

- Ebs1 Aaaa00 Saqa Prqa 0006Document10 pagesEbs1 Aaaa00 Saqa Prqa 0006SERT-QA/QC- BUZNo ratings yet

- Hvac Water TreatmentDocument9 pagesHvac Water Treatmentadel rihanaNo ratings yet

- JG-SC-004 Cleaning, Gauging, and Hydrostatic TestDocument8 pagesJG-SC-004 Cleaning, Gauging, and Hydrostatic Testarsil5840No ratings yet

- SOP of PrehydrotestDocument7 pagesSOP of PrehydrotestVenkateswarlu BoduguNo ratings yet

- 8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureDocument5 pages8.2.4 - JSL QMS QP 14 Hydrotest - ProcedureGbenga MoboladeNo ratings yet

- 020 15140 - Testing and Disinfection Standard SpecificationDocument11 pages020 15140 - Testing and Disinfection Standard SpecificationbereketNo ratings yet

- Flow MeterDocument140 pagesFlow MeterSaravanan Rasaya100% (1)

- Standardsof Wastewater DesignDocument97 pagesStandardsof Wastewater DesignMagin Idelfonso Torreblanca100% (1)

- HDRSF WWC 2Document8 pagesHDRSF WWC 2xav81No ratings yet

- Project Standards and Specifications Precommissioning Piping Cleaning Rev01Document5 pagesProject Standards and Specifications Precommissioning Piping Cleaning Rev01Tiago HenriquesNo ratings yet

- Method Statement For Chemical Cleaning of Carbon Steel Pipelines - Method Statement HQDocument3 pagesMethod Statement For Chemical Cleaning of Carbon Steel Pipelines - Method Statement HQMohammad OsmanNo ratings yet

- Technical Service Bulletin: Commissioning Procedure For HydracapDocument10 pagesTechnical Service Bulletin: Commissioning Procedure For HydracapValesh MonisNo ratings yet

- QCS-2010 Section 19 Part 6 Commissioning of SystemsDocument6 pagesQCS-2010 Section 19 Part 6 Commissioning of Systemsbryanpastor106No ratings yet

- Water DisinfectionDocument24 pagesWater DisinfectionJaycen RussellNo ratings yet

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- Water Treatment Plant Performance Evaluations and OperationsFrom EverandWater Treatment Plant Performance Evaluations and OperationsNo ratings yet

- Analytical Methods for Drinking Water: Advances in Sampling and AnalysisFrom EverandAnalytical Methods for Drinking Water: Advances in Sampling and AnalysisNo ratings yet

- HVAC DX Design Plan for VillaDocument1 pageHVAC DX Design Plan for VillaMohammad OsmanNo ratings yet

- VRV Piping & Wiring -01.07.24Document2 pagesVRV Piping & Wiring -01.07.24Mohammad OsmanNo ratings yet

- OHIO241-RAIF-SUB-0011_Rev-00Document1 pageOHIO241-RAIF-SUB-0011_Rev-00Mohammad OsmanNo ratings yet

- O & M and Method Statement: Abu Dhabi Banyas East 2-3, Sector: EB2-03, Plot No.: C19Document2 pagesO & M and Method Statement: Abu Dhabi Banyas East 2-3, Sector: EB2-03, Plot No.: C19Mohammad OsmanNo ratings yet

- Method Statement For Flusing & Treatment of Chilled WaterDocument6 pagesMethod Statement For Flusing & Treatment of Chilled WaterMohammad OsmanNo ratings yet

- Method Statement For Chemical Cleaning of Carbon Steel Pipelines - Method Statement HQDocument3 pagesMethod Statement For Chemical Cleaning of Carbon Steel Pipelines - Method Statement HQMohammad OsmanNo ratings yet

- Best Practices On 7 Healthy HabitsDocument6 pagesBest Practices On 7 Healthy HabitsHAZEL PELIASNo ratings yet

- Vulkanox BKF: Technical InformationDocument3 pagesVulkanox BKF: Technical Informationhemya7No ratings yet

- Guidelines For Open Plant StructuresDocument6 pagesGuidelines For Open Plant StructuresIndrawNo ratings yet

- Assessment Diagnosis Planning Intervention Rationale Evaluation Subjective: Short Term Goals: Independent: Short Term GoalsDocument1 pageAssessment Diagnosis Planning Intervention Rationale Evaluation Subjective: Short Term Goals: Independent: Short Term GoalskyawNo ratings yet

- Pie+ Future Line - Sample and Exercises ..Document6 pagesPie+ Future Line - Sample and Exercises ..Nha LinhNo ratings yet

- Patient Rights Audit ToolsDocument4 pagesPatient Rights Audit ToolsAbdur Rashid KhanNo ratings yet

- 132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Document134 pages132-LogSat JRC JLN-720 Instruct Manual 1-10-2019Sunil S I ShippingNo ratings yet

- Q. David Copperfield and His Representation of The Victorian EraDocument3 pagesQ. David Copperfield and His Representation of The Victorian EraAashrey SatijaNo ratings yet

- Absen 2019Document19 pagesAbsen 2019siska damayantiNo ratings yet

- Mental Health Resources-3Document1 pageMental Health Resources-3api-492010604No ratings yet

- IMMERSION Week5Document10 pagesIMMERSION Week5Jhener NonesaNo ratings yet

- Clinical Trial Gadavala SarahDocument60 pagesClinical Trial Gadavala SarahSejal khuman100% (1)

- DAF Brochure Centerfold PDFDocument3 pagesDAF Brochure Centerfold PDFJulio TovarNo ratings yet

- Method of Statement PCDocument8 pagesMethod of Statement PCAbada SaadNo ratings yet

- Detail Information - PHARMACIST AND CLINIC ASSISTANTDocument4 pagesDetail Information - PHARMACIST AND CLINIC ASSISTANTSahil AgnihotriNo ratings yet

- Umer Mehmood: Personal ProfileDocument3 pagesUmer Mehmood: Personal ProfileMuhammad sufyan Muhammad sufyanNo ratings yet

- Radiologi DR Budi - Pediatric Congenital Neurological DiseasesDocument30 pagesRadiologi DR Budi - Pediatric Congenital Neurological DiseasesPusparasmi Mas Ayu SuprabhaNo ratings yet

- Ophirtech CPDocument21 pagesOphirtech CPJexter MorojoNo ratings yet

- Saudi Pharmaceutical JournalDocument10 pagesSaudi Pharmaceutical JournalDiky ArdianNo ratings yet

- 15 BOSH - Module 6 OSH LegislationsDocument87 pages15 BOSH - Module 6 OSH Legislationsbeng acostaNo ratings yet

- Catalogo Gopharma Mayo Hvca 2022Document20 pagesCatalogo Gopharma Mayo Hvca 2022Naths GMnNo ratings yet

- Antibiotic Microbial Resistance (AMR) Removal Efficiencies by 2019 PDFDocument13 pagesAntibiotic Microbial Resistance (AMR) Removal Efficiencies by 2019 PDFdebleenaNo ratings yet

- Diabetes Resommendations Laboratory AnalysisDocument120 pagesDiabetes Resommendations Laboratory AnalysisAleja Coneja BonifazNo ratings yet

- Transforming Shame in Context Practical Applications and Exercises For GrowthDocument2 pagesTransforming Shame in Context Practical Applications and Exercises For GrowthjohanakuninNo ratings yet