Professional Documents

Culture Documents

Cladding Mechanical Testing

Cladding Mechanical Testing

Uploaded by

MohammedCopyright:

Available Formats

You might also like

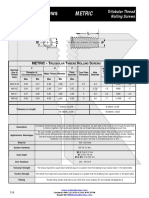

- DIN 7500 - Trilobular Thread Rolling ScrewsDocument3 pagesDIN 7500 - Trilobular Thread Rolling ScrewsDerek100% (1)

- GMAW Welding GuideDocument96 pagesGMAW Welding GuideJUAN VASCONo ratings yet

- ConX Modular Pipe Rack Brochure PDFDocument26 pagesConX Modular Pipe Rack Brochure PDFCESARNo ratings yet

- ABS 2005 Steel Vessels Corrigenda January 2005Document18 pagesABS 2005 Steel Vessels Corrigenda January 2005Erick Cruz MontañezNo ratings yet

- Aggregates FMDocument5 pagesAggregates FMabualamalNo ratings yet

- ABS Welding With Backing StripDocument1 pageABS Welding With Backing StripAbuBakarSiddkeRumiNo ratings yet

- Met Thread RollDocument3 pagesMet Thread Rollalfred2000No ratings yet

- Details of Laboratory Equipments Required For Hubli - Dharwad (SH - 73) Project (Karnataka)Document8 pagesDetails of Laboratory Equipments Required For Hubli - Dharwad (SH - 73) Project (Karnataka)Bscpl Repalle to EeppurpalemNo ratings yet

- SDR41 - J: Size (3')Document6 pagesSDR41 - J: Size (3')Frederick Atienza ReyesNo ratings yet

- Sample Connection ReportDocument14 pagesSample Connection ReportNirajNo ratings yet

- Job Sheet OverhaulDocument8 pagesJob Sheet Overhaulfanny ozziNo ratings yet

- Ramos Copper Piping For The Refrigeration System Layout2Document1 pageRamos Copper Piping For The Refrigeration System Layout2Piolo Gabrielle RamosNo ratings yet

- Fy 45 TF: Square Flanged Ball Bearing UnitsDocument5 pagesFy 45 TF: Square Flanged Ball Bearing UnitsAlexander AlvarezNo ratings yet

- Sem 1 Riveting WorksheetDocument4 pagesSem 1 Riveting WorksheetKamarul NizamNo ratings yet

- Analysis of Die Angle in Deep Drawing Process Using FEMDocument5 pagesAnalysis of Die Angle in Deep Drawing Process Using FEMEduardoNo ratings yet

- Evr Instruction Manual enDocument8 pagesEvr Instruction Manual enKjsNo ratings yet

- Testing-Drill Screw SpecificationsDocument3 pagesTesting-Drill Screw SpecificationsJerry Huang100% (1)

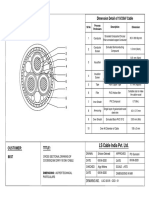

- CSD - 33KV (E) 3C X 300 SQ - MM 2xwy - BestDocument1 pageCSD - 33KV (E) 3C X 300 SQ - MM 2xwy - Bestshivam dwivediNo ratings yet

- Evr Instruction Manual enDocument8 pagesEvr Instruction Manual enAnupam MaityNo ratings yet

- Accurate, Temperature Readings Through Radio or Conduction EnvironmentsDocument2 pagesAccurate, Temperature Readings Through Radio or Conduction EnvironmentsGERMANNo ratings yet

- WalterGPS Report 2023-12-22Document4 pagesWalterGPS Report 2023-12-22lanhtraitim81No ratings yet

- Enquiry - ValvesDocument6 pagesEnquiry - Valvesrkpatel40No ratings yet

- Self Drill Screw With Flange WurthDocument4 pagesSelf Drill Screw With Flange WurthentosektosNo ratings yet

- Tapered Roller Bearings, Single Row: Bearing Data Bearing InterfacesDocument4 pagesTapered Roller Bearings, Single Row: Bearing Data Bearing InterfacesDuc NguyenNo ratings yet

- Member Code: Dyntek Pte. LTDDocument1 pageMember Code: Dyntek Pte. LTDHerbert BishopNo ratings yet

- Building Anchor BoltsDocument2 pagesBuilding Anchor BoltskumsbamaNo ratings yet

- Especificaciones Kwik BoltDocument12 pagesEspecificaciones Kwik BoltjaimepwpsNo ratings yet

- Metal Tek ScrewDocument2 pagesMetal Tek ScrewAmin SalahNo ratings yet

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- Problem Input: Particulars UnitDocument43 pagesProblem Input: Particulars UnitChinmay PatilNo ratings yet

- Test Data Sheet: Date of Sampling Date of TestingDocument5 pagesTest Data Sheet: Date of Sampling Date of TestingChandan MondalNo ratings yet

- Test Data Sheet: Ref: IS 1608-2005 / ISO: 6892-1998 Format No. F01 (5.4) Issue Date: 01.01.2018Document3 pagesTest Data Sheet: Ref: IS 1608-2005 / ISO: 6892-1998 Format No. F01 (5.4) Issue Date: 01.01.2018chandan mondalNo ratings yet

- serviceSink 7798.030Document1 pageserviceSink 7798.030Ryan WinklerNo ratings yet

- AAP S3 Buttweld SDocument17 pagesAAP S3 Buttweld Salimsaadun alimsaadunNo ratings yet

- 1 Duties and Responsibilities Section 1Document22 pages1 Duties and Responsibilities Section 1Danilo BritoNo ratings yet

- Experimental Analysis of Friction Welding For Dissimilar MetalsDocument45 pagesExperimental Analysis of Friction Welding For Dissimilar MetalsSumaiya BegamNo ratings yet

- Spit Multi-Max Metacrylato para Uso en Concreto No FisuradoDocument7 pagesSpit Multi-Max Metacrylato para Uso en Concreto No FisuradoduraeduNo ratings yet

- Terminal Chambers, Mini StyleDocument2 pagesTerminal Chambers, Mini StyleRobert OberfrankNo ratings yet

- Astm Reference Block For MetalDocument10 pagesAstm Reference Block For Metalrupam100% (1)

- A-01-006n+ÜTaper Pipe Threads For Water LineDocument1 pageA-01-006n+ÜTaper Pipe Threads For Water LinerjrabeeshNo ratings yet

- Hot Stamping Printing Type SpecificationsDocument2 pagesHot Stamping Printing Type SpecificationsXavier MilkeNo ratings yet

- Xa 310850BDocument1 pageXa 310850BBenny YacilaNo ratings yet

- TDS Self Drilling Screws GeneralDocument1 pageTDS Self Drilling Screws Generalgraziella njeimNo ratings yet

- Arcaloy MC439TiDocument1 pageArcaloy MC439Tijoao guilhermeNo ratings yet

- Plastic Pipe Sizes Chart - Epco PlasticsDocument1 pagePlastic Pipe Sizes Chart - Epco Plasticsdattu33No ratings yet

- 3X185 RM HT (Test Report)Document1 page3X185 RM HT (Test Report)jamilNo ratings yet

- Austenite Stainless SteelDocument13 pagesAustenite Stainless SteelYuvaraj RajuNo ratings yet

- 604-2Z Deep Groove Ball Bearings - 20210902Document4 pages604-2Z Deep Groove Ball Bearings - 20210902meen87No ratings yet

- Replace With EXACT Text Entries From The 2015 Edition, Which Are Shown On Pages 3 and 4 of This Proposal FileDocument4 pagesReplace With EXACT Text Entries From The 2015 Edition, Which Are Shown On Pages 3 and 4 of This Proposal FileMadhubalan PNo ratings yet

- 10 ScrewDocument4 pages10 ScrewSaikatNo ratings yet

- Wps Pqrwelding SCSP COUPON Phpapp02Document14 pagesWps Pqrwelding SCSP COUPON Phpapp02Oladimeji TaiwoNo ratings yet

- K-020 Kinetic For SewageDocument2 pagesK-020 Kinetic For SewageironeousNo ratings yet

- Fytj 35 TF: Oval Flanged Ball Bearing UnitsDocument5 pagesFytj 35 TF: Oval Flanged Ball Bearing UnitsmerlingNo ratings yet

- Technical Data: Drillfast Stainless Df12-Ss Standard FastenersDocument6 pagesTechnical Data: Drillfast Stainless Df12-Ss Standard FastenersJonathan DouglasNo ratings yet

- Bi-Metal Tek Screw: Product DatasheetDocument1 pageBi-Metal Tek Screw: Product Datasheetbravo deltafoxNo ratings yet

- UNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherDocument1 pageUNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherrimshadtpNo ratings yet

- Narrow Gap Gas Metal Arc (GMA) Welding Technologies: AbstractDocument7 pagesNarrow Gap Gas Metal Arc (GMA) Welding Technologies: Abstracttiepnh.ameccNo ratings yet

- Scrubber Level Control System (SLS)Document2 pagesScrubber Level Control System (SLS)Edison GomezNo ratings yet

- Female Threaded Hex Standoff: 12L14 Steel, 4.5 MM Hex, 37 MM Long, M3 X 0.5 MM ThreadDocument2 pagesFemale Threaded Hex Standoff: 12L14 Steel, 4.5 MM Hex, 37 MM Long, M3 X 0.5 MM ThreadYossi JerasiNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesLaurence SarmientoNo ratings yet

- 2tr Fe Engine MechanicalDocument4 pages2tr Fe Engine Mechanicalalexander bayuNo ratings yet

- Quality Requirements For Sub ContractorDocument103 pagesQuality Requirements For Sub ContractorMohammed100% (1)

- Paint Specification Package CDocument32 pagesPaint Specification Package CMohammedNo ratings yet

- Paint Specification - Package ADocument53 pagesPaint Specification - Package AMohammedNo ratings yet

- Nde Table Package C RevisedDocument6 pagesNde Table Package C RevisedMohammedNo ratings yet

- Nde Table Package A RevisedDocument6 pagesNde Table Package A RevisedMohammed100% (1)

- Performance Management FrameworkDocument15 pagesPerformance Management FrameworkMohammedNo ratings yet

- Permit For Radiography Work - PDF 2.2Document1 pagePermit For Radiography Work - PDF 2.2MohammedNo ratings yet

- Flange With Length Adjust Pup Piece: Epc Contractor: Project Title: ClientDocument1 pageFlange With Length Adjust Pup Piece: Epc Contractor: Project Title: ClientMohammedNo ratings yet

- Documet Transmittal FormDocument2 pagesDocumet Transmittal FormMohammedNo ratings yet

- Proposed Weld NumberingDocument1 pageProposed Weld NumberingMohammedNo ratings yet

- Refresher 2 (MDSP)Document9 pagesRefresher 2 (MDSP)Kira YagamiNo ratings yet

- Psq6000 Rexroth Manual DatasheetDocument114 pagesPsq6000 Rexroth Manual DatasheetJorge Alberto Perez SandovalNo ratings yet

- Research Paper On Manufacturing ProcessDocument8 pagesResearch Paper On Manufacturing Processgw21tcyd100% (1)

- Supercored 71MAG: Hyundai Welding Co., LTDDocument8 pagesSupercored 71MAG: Hyundai Welding Co., LTDNguyen ToanNo ratings yet

- SmartPlant Spoolgen Plus White Paper March 2012 PDFDocument40 pagesSmartPlant Spoolgen Plus White Paper March 2012 PDFrkarthikmtmrNo ratings yet

- Pipe - Line Bevel MachineDocument24 pagesPipe - Line Bevel MachineSun SunNo ratings yet

- Instruction - Macroscopic Testing: 1. ScopeDocument2 pagesInstruction - Macroscopic Testing: 1. ScopeMohammed Ady GanjarNo ratings yet

- Welding of Dissimilar Ferritic Joints For New Power Plant SteelsDocument21 pagesWelding of Dissimilar Ferritic Joints For New Power Plant SteelsspinpinNo ratings yet

- CRR20 40 - MP D PDFDocument200 pagesCRR20 40 - MP D PDFMelissa Macias100% (4)

- Std-Insp-0058 (Procedure For Internal Floating Roof Water Floatation Test For Tank)Document4 pagesStd-Insp-0058 (Procedure For Internal Floating Roof Water Floatation Test For Tank)Mitesh BairagiNo ratings yet

- Trailer: Superior Construction. Excellent Performance. Rely On Our ExperienceDocument2 pagesTrailer: Superior Construction. Excellent Performance. Rely On Our ExperienceMilton PeñaNo ratings yet

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- Carried Out Magnetic Particle Inspection On Nozzle WeldsDocument9 pagesCarried Out Magnetic Particle Inspection On Nozzle WeldssheikbbaNo ratings yet

- Method Statement For Piping Fabrication and InstallationDocument9 pagesMethod Statement For Piping Fabrication and Installationwiwit aji pamungkasNo ratings yet

- As-NZS 1554.1 Testing RequirementsDocument2 pagesAs-NZS 1554.1 Testing RequirementsSyed Mahmud Habibur RahmanNo ratings yet

- Comp Sem1Document24 pagesComp Sem1Gift Munyinda (G-Man)No ratings yet

- Guidelines For Gas Metal Arc Welding (GMAW)Document2 pagesGuidelines For Gas Metal Arc Welding (GMAW)jonjonjon0No ratings yet

- Oxy-Acet. Equipment Inspection ChecklistsDocument2 pagesOxy-Acet. Equipment Inspection Checklistssoomro.hafeez45No ratings yet

- Fillet Weld Safe Loads Per UnitDocument4 pagesFillet Weld Safe Loads Per UnitTarek AbulailNo ratings yet

- Ruane PTDocument27 pagesRuane PT9703422499No ratings yet

- 23 GinzelDocument12 pages23 Ginzelmusaismail8863No ratings yet

- Soldering and BrazingDocument25 pagesSoldering and BrazingSumma ThanNo ratings yet

- TIGDocument10 pagesTIGMuhamad Irwan Ismail100% (1)

- Welding ReportDocument11 pagesWelding ReportJia Yee Ten100% (1)

- Steel Plates For Offshore StructuresDocument8 pagesSteel Plates For Offshore StructuresYiengeChanYeeNo ratings yet

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNo ratings yet

- Chemical Composition of Welding Wire % (Typical) StandardsDocument1 pageChemical Composition of Welding Wire % (Typical) StandardsAli KayaNo ratings yet

- High Security Welded Wire Mesh FenceDocument16 pagesHigh Security Welded Wire Mesh FenceGopi KrishnanNo ratings yet

Cladding Mechanical Testing

Cladding Mechanical Testing

Uploaded by

MohammedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cladding Mechanical Testing

Cladding Mechanical Testing

Uploaded by

MohammedCopyright:

Available Formats

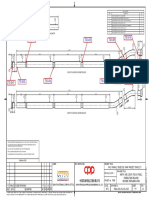

Part 7 Rules for Survey After Construction

Appendix

Section 11 Repair and Cladding of Shafts 7-A-11

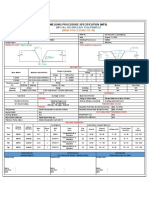

FIGURE 7

Weld Procedure Test Specimens for Shafts with

Built-up Welded Stainless Steel or Carbon Steel Cladding (2009)

Four macro specimens

3

2

Base metal

1 9.5 mm (3/8 in.)

Weld

metal

19 to 25.4 mm

(3/4 to 1.0 in.)

Four sets of hardness readings

1 weld metal

2 line of fusion

3 heat affected zone

n.)

1 2i

e no. t o 1

mp

l (1 0

Sa mm

05

t o3

Shaft 254

4

l e no.

mp

Sample Sa

no. 2

Weld Force

metal

Sample no. 3

Four guided side bend tests

For test jig see 2-4-3/Figure 7 of

the Rules for Materials and

Welding (Part 2)

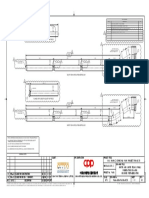

FIGURE 8

Welder Qualification Test Cladding (2009)

9.5 mm (3/8 in.) Side bend

Side bend 102 mm

(4.0 in.) min.

Direction of

152 mm

welding torch

(6.0 in.) min.

travel Side bend

Side bend

152 mm (6.0 in.) min. 12.5 mm (1/2 in.) min.

203 mm (8.0 in.) min.

Weld overlay

6.4 mm (1/4 in.) min.

25.4 mm

(1.0 in.) min. Comprised

of not less

than two layers

500 ABS RULES FOR SURVEY AFTER CONSTRUCTION . 2017

You might also like

- DIN 7500 - Trilobular Thread Rolling ScrewsDocument3 pagesDIN 7500 - Trilobular Thread Rolling ScrewsDerek100% (1)

- GMAW Welding GuideDocument96 pagesGMAW Welding GuideJUAN VASCONo ratings yet

- ConX Modular Pipe Rack Brochure PDFDocument26 pagesConX Modular Pipe Rack Brochure PDFCESARNo ratings yet

- ABS 2005 Steel Vessels Corrigenda January 2005Document18 pagesABS 2005 Steel Vessels Corrigenda January 2005Erick Cruz MontañezNo ratings yet

- Aggregates FMDocument5 pagesAggregates FMabualamalNo ratings yet

- ABS Welding With Backing StripDocument1 pageABS Welding With Backing StripAbuBakarSiddkeRumiNo ratings yet

- Met Thread RollDocument3 pagesMet Thread Rollalfred2000No ratings yet

- Details of Laboratory Equipments Required For Hubli - Dharwad (SH - 73) Project (Karnataka)Document8 pagesDetails of Laboratory Equipments Required For Hubli - Dharwad (SH - 73) Project (Karnataka)Bscpl Repalle to EeppurpalemNo ratings yet

- SDR41 - J: Size (3')Document6 pagesSDR41 - J: Size (3')Frederick Atienza ReyesNo ratings yet

- Sample Connection ReportDocument14 pagesSample Connection ReportNirajNo ratings yet

- Job Sheet OverhaulDocument8 pagesJob Sheet Overhaulfanny ozziNo ratings yet

- Ramos Copper Piping For The Refrigeration System Layout2Document1 pageRamos Copper Piping For The Refrigeration System Layout2Piolo Gabrielle RamosNo ratings yet

- Fy 45 TF: Square Flanged Ball Bearing UnitsDocument5 pagesFy 45 TF: Square Flanged Ball Bearing UnitsAlexander AlvarezNo ratings yet

- Sem 1 Riveting WorksheetDocument4 pagesSem 1 Riveting WorksheetKamarul NizamNo ratings yet

- Analysis of Die Angle in Deep Drawing Process Using FEMDocument5 pagesAnalysis of Die Angle in Deep Drawing Process Using FEMEduardoNo ratings yet

- Evr Instruction Manual enDocument8 pagesEvr Instruction Manual enKjsNo ratings yet

- Testing-Drill Screw SpecificationsDocument3 pagesTesting-Drill Screw SpecificationsJerry Huang100% (1)

- CSD - 33KV (E) 3C X 300 SQ - MM 2xwy - BestDocument1 pageCSD - 33KV (E) 3C X 300 SQ - MM 2xwy - Bestshivam dwivediNo ratings yet

- Evr Instruction Manual enDocument8 pagesEvr Instruction Manual enAnupam MaityNo ratings yet

- Accurate, Temperature Readings Through Radio or Conduction EnvironmentsDocument2 pagesAccurate, Temperature Readings Through Radio or Conduction EnvironmentsGERMANNo ratings yet

- WalterGPS Report 2023-12-22Document4 pagesWalterGPS Report 2023-12-22lanhtraitim81No ratings yet

- Enquiry - ValvesDocument6 pagesEnquiry - Valvesrkpatel40No ratings yet

- Self Drill Screw With Flange WurthDocument4 pagesSelf Drill Screw With Flange WurthentosektosNo ratings yet

- Tapered Roller Bearings, Single Row: Bearing Data Bearing InterfacesDocument4 pagesTapered Roller Bearings, Single Row: Bearing Data Bearing InterfacesDuc NguyenNo ratings yet

- Member Code: Dyntek Pte. LTDDocument1 pageMember Code: Dyntek Pte. LTDHerbert BishopNo ratings yet

- Building Anchor BoltsDocument2 pagesBuilding Anchor BoltskumsbamaNo ratings yet

- Especificaciones Kwik BoltDocument12 pagesEspecificaciones Kwik BoltjaimepwpsNo ratings yet

- Metal Tek ScrewDocument2 pagesMetal Tek ScrewAmin SalahNo ratings yet

- Wps MainlineDocument5 pagesWps MainlineAlfian FebriansyahNo ratings yet

- Problem Input: Particulars UnitDocument43 pagesProblem Input: Particulars UnitChinmay PatilNo ratings yet

- Test Data Sheet: Date of Sampling Date of TestingDocument5 pagesTest Data Sheet: Date of Sampling Date of TestingChandan MondalNo ratings yet

- Test Data Sheet: Ref: IS 1608-2005 / ISO: 6892-1998 Format No. F01 (5.4) Issue Date: 01.01.2018Document3 pagesTest Data Sheet: Ref: IS 1608-2005 / ISO: 6892-1998 Format No. F01 (5.4) Issue Date: 01.01.2018chandan mondalNo ratings yet

- serviceSink 7798.030Document1 pageserviceSink 7798.030Ryan WinklerNo ratings yet

- AAP S3 Buttweld SDocument17 pagesAAP S3 Buttweld Salimsaadun alimsaadunNo ratings yet

- 1 Duties and Responsibilities Section 1Document22 pages1 Duties and Responsibilities Section 1Danilo BritoNo ratings yet

- Experimental Analysis of Friction Welding For Dissimilar MetalsDocument45 pagesExperimental Analysis of Friction Welding For Dissimilar MetalsSumaiya BegamNo ratings yet

- Spit Multi-Max Metacrylato para Uso en Concreto No FisuradoDocument7 pagesSpit Multi-Max Metacrylato para Uso en Concreto No FisuradoduraeduNo ratings yet

- Terminal Chambers, Mini StyleDocument2 pagesTerminal Chambers, Mini StyleRobert OberfrankNo ratings yet

- Astm Reference Block For MetalDocument10 pagesAstm Reference Block For Metalrupam100% (1)

- A-01-006n+ÜTaper Pipe Threads For Water LineDocument1 pageA-01-006n+ÜTaper Pipe Threads For Water LinerjrabeeshNo ratings yet

- Hot Stamping Printing Type SpecificationsDocument2 pagesHot Stamping Printing Type SpecificationsXavier MilkeNo ratings yet

- Xa 310850BDocument1 pageXa 310850BBenny YacilaNo ratings yet

- TDS Self Drilling Screws GeneralDocument1 pageTDS Self Drilling Screws Generalgraziella njeimNo ratings yet

- Arcaloy MC439TiDocument1 pageArcaloy MC439Tijoao guilhermeNo ratings yet

- Plastic Pipe Sizes Chart - Epco PlasticsDocument1 pagePlastic Pipe Sizes Chart - Epco Plasticsdattu33No ratings yet

- 3X185 RM HT (Test Report)Document1 page3X185 RM HT (Test Report)jamilNo ratings yet

- Austenite Stainless SteelDocument13 pagesAustenite Stainless SteelYuvaraj RajuNo ratings yet

- 604-2Z Deep Groove Ball Bearings - 20210902Document4 pages604-2Z Deep Groove Ball Bearings - 20210902meen87No ratings yet

- Replace With EXACT Text Entries From The 2015 Edition, Which Are Shown On Pages 3 and 4 of This Proposal FileDocument4 pagesReplace With EXACT Text Entries From The 2015 Edition, Which Are Shown On Pages 3 and 4 of This Proposal FileMadhubalan PNo ratings yet

- 10 ScrewDocument4 pages10 ScrewSaikatNo ratings yet

- Wps Pqrwelding SCSP COUPON Phpapp02Document14 pagesWps Pqrwelding SCSP COUPON Phpapp02Oladimeji TaiwoNo ratings yet

- K-020 Kinetic For SewageDocument2 pagesK-020 Kinetic For SewageironeousNo ratings yet

- Fytj 35 TF: Oval Flanged Ball Bearing UnitsDocument5 pagesFytj 35 TF: Oval Flanged Ball Bearing UnitsmerlingNo ratings yet

- Technical Data: Drillfast Stainless Df12-Ss Standard FastenersDocument6 pagesTechnical Data: Drillfast Stainless Df12-Ss Standard FastenersJonathan DouglasNo ratings yet

- Bi-Metal Tek Screw: Product DatasheetDocument1 pageBi-Metal Tek Screw: Product Datasheetbravo deltafoxNo ratings yet

- UNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherDocument1 pageUNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherrimshadtpNo ratings yet

- Narrow Gap Gas Metal Arc (GMA) Welding Technologies: AbstractDocument7 pagesNarrow Gap Gas Metal Arc (GMA) Welding Technologies: Abstracttiepnh.ameccNo ratings yet

- Scrubber Level Control System (SLS)Document2 pagesScrubber Level Control System (SLS)Edison GomezNo ratings yet

- Female Threaded Hex Standoff: 12L14 Steel, 4.5 MM Hex, 37 MM Long, M3 X 0.5 MM ThreadDocument2 pagesFemale Threaded Hex Standoff: 12L14 Steel, 4.5 MM Hex, 37 MM Long, M3 X 0.5 MM ThreadYossi JerasiNo ratings yet

- Untitled Extract PagesDocument1 pageUntitled Extract PagesLaurence SarmientoNo ratings yet

- 2tr Fe Engine MechanicalDocument4 pages2tr Fe Engine Mechanicalalexander bayuNo ratings yet

- Quality Requirements For Sub ContractorDocument103 pagesQuality Requirements For Sub ContractorMohammed100% (1)

- Paint Specification Package CDocument32 pagesPaint Specification Package CMohammedNo ratings yet

- Paint Specification - Package ADocument53 pagesPaint Specification - Package AMohammedNo ratings yet

- Nde Table Package C RevisedDocument6 pagesNde Table Package C RevisedMohammedNo ratings yet

- Nde Table Package A RevisedDocument6 pagesNde Table Package A RevisedMohammed100% (1)

- Performance Management FrameworkDocument15 pagesPerformance Management FrameworkMohammedNo ratings yet

- Permit For Radiography Work - PDF 2.2Document1 pagePermit For Radiography Work - PDF 2.2MohammedNo ratings yet

- Flange With Length Adjust Pup Piece: Epc Contractor: Project Title: ClientDocument1 pageFlange With Length Adjust Pup Piece: Epc Contractor: Project Title: ClientMohammedNo ratings yet

- Documet Transmittal FormDocument2 pagesDocumet Transmittal FormMohammedNo ratings yet

- Proposed Weld NumberingDocument1 pageProposed Weld NumberingMohammedNo ratings yet

- Refresher 2 (MDSP)Document9 pagesRefresher 2 (MDSP)Kira YagamiNo ratings yet

- Psq6000 Rexroth Manual DatasheetDocument114 pagesPsq6000 Rexroth Manual DatasheetJorge Alberto Perez SandovalNo ratings yet

- Research Paper On Manufacturing ProcessDocument8 pagesResearch Paper On Manufacturing Processgw21tcyd100% (1)

- Supercored 71MAG: Hyundai Welding Co., LTDDocument8 pagesSupercored 71MAG: Hyundai Welding Co., LTDNguyen ToanNo ratings yet

- SmartPlant Spoolgen Plus White Paper March 2012 PDFDocument40 pagesSmartPlant Spoolgen Plus White Paper March 2012 PDFrkarthikmtmrNo ratings yet

- Pipe - Line Bevel MachineDocument24 pagesPipe - Line Bevel MachineSun SunNo ratings yet

- Instruction - Macroscopic Testing: 1. ScopeDocument2 pagesInstruction - Macroscopic Testing: 1. ScopeMohammed Ady GanjarNo ratings yet

- Welding of Dissimilar Ferritic Joints For New Power Plant SteelsDocument21 pagesWelding of Dissimilar Ferritic Joints For New Power Plant SteelsspinpinNo ratings yet

- CRR20 40 - MP D PDFDocument200 pagesCRR20 40 - MP D PDFMelissa Macias100% (4)

- Std-Insp-0058 (Procedure For Internal Floating Roof Water Floatation Test For Tank)Document4 pagesStd-Insp-0058 (Procedure For Internal Floating Roof Water Floatation Test For Tank)Mitesh BairagiNo ratings yet

- Trailer: Superior Construction. Excellent Performance. Rely On Our ExperienceDocument2 pagesTrailer: Superior Construction. Excellent Performance. Rely On Our ExperienceMilton PeñaNo ratings yet

- MNT-INTG-2007OP - Maintenance Welding InspectionDocument43 pagesMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNo ratings yet

- Carried Out Magnetic Particle Inspection On Nozzle WeldsDocument9 pagesCarried Out Magnetic Particle Inspection On Nozzle WeldssheikbbaNo ratings yet

- Method Statement For Piping Fabrication and InstallationDocument9 pagesMethod Statement For Piping Fabrication and Installationwiwit aji pamungkasNo ratings yet

- As-NZS 1554.1 Testing RequirementsDocument2 pagesAs-NZS 1554.1 Testing RequirementsSyed Mahmud Habibur RahmanNo ratings yet

- Comp Sem1Document24 pagesComp Sem1Gift Munyinda (G-Man)No ratings yet

- Guidelines For Gas Metal Arc Welding (GMAW)Document2 pagesGuidelines For Gas Metal Arc Welding (GMAW)jonjonjon0No ratings yet

- Oxy-Acet. Equipment Inspection ChecklistsDocument2 pagesOxy-Acet. Equipment Inspection Checklistssoomro.hafeez45No ratings yet

- Fillet Weld Safe Loads Per UnitDocument4 pagesFillet Weld Safe Loads Per UnitTarek AbulailNo ratings yet

- Ruane PTDocument27 pagesRuane PT9703422499No ratings yet

- 23 GinzelDocument12 pages23 Ginzelmusaismail8863No ratings yet

- Soldering and BrazingDocument25 pagesSoldering and BrazingSumma ThanNo ratings yet

- TIGDocument10 pagesTIGMuhamad Irwan Ismail100% (1)

- Welding ReportDocument11 pagesWelding ReportJia Yee Ten100% (1)

- Steel Plates For Offshore StructuresDocument8 pagesSteel Plates For Offshore StructuresYiengeChanYeeNo ratings yet

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNo ratings yet

- Chemical Composition of Welding Wire % (Typical) StandardsDocument1 pageChemical Composition of Welding Wire % (Typical) StandardsAli KayaNo ratings yet

- High Security Welded Wire Mesh FenceDocument16 pagesHigh Security Welded Wire Mesh FenceGopi KrishnanNo ratings yet