Professional Documents

Culture Documents

Drill 9

Drill 9

Uploaded by

Sr. Diego LastreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill 9

Drill 9

Uploaded by

Sr. Diego LastreCopyright:

Available Formats

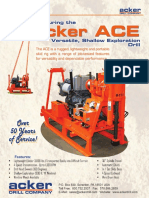

Bulletin 98

R.A.D. STANDARD FEATURES:

A. Power Unit - 58 HP @ 2,300 RPM diesel engine with 12-volt electric start engine. Optional Electric TEFC

3-phase 460VAC induction motor @ 1,800 RPM. Other power options available.

B. Feed Mechanism - The main feed consists of a chain drive mechanism with options of a 3 ft., 7 ft. or 11 ft. feed,

through a planetary hydraulic drive unit. Thrust and pull @ 10,900 lbs.

C. Drill Drive - Taken from prime mover through a variable volume over center piston pump and tandem fixed vol-

ume pump.

D. Drill Head - 3-5/8” open spindle.

1st gear (0-120 RPM @ 3,028 ft./lbs. torque) 2nd gear (0-252 RPM @ 1,452 ft./lbs. torque

3rd gear (0-456 RPM @ 788 ft./lbs. torque) 4th gear (0-750 RPM @ 458 ft./lbs. torque

Drill head has a lateral slide feature. “Optional” hinge-type available.

E. Mast - Welded rectangular structural steel tube construction that supports and guides the rotation of feed compo-

nents. Positioned with one (1) hydraulic cylinder and rigidly held in the vertical position for drilling and is lowered

to the travel position for moving from hole to hole. Mast mounting allows for angle as well as 90 degree vertical

drilling. Mast is capable of drilling under 8 ft. ceilings with low clearance sheaves.

F. Main Drum Hoist - 4,500 lbs. Planetary type with 75 ft. of 5/16” cable (hydraulically powered).

G. Track Mounting - The entire drill is mounted on a structural steel frame and is self-propelled by 9” rubber crawler

tracks with independent reversible hydraulic motor drive. Tracks are 33-1/2” wide retracted and 39-1/2” wide ex-

tended. Includes provision for (4) lifting points for crane lift.

H. Hydraulic Oil Cooler

I. Hydraulic Leveling Jacks - (4) “Swing Away”

R.A.D. OPTIONAL FEATURES:

1. Cathead Hoist - Hydraulically powered cargo type hoist.

2. Quick Disconnect Adapter - U-Joint type for augers, 1-5/8” hex.

3. Auger Guide - Specify size required.

4. Water Pump - Hydraulically driven with infinitely variable speed controls from the operator’s station. Moyno type

3L4, 3L6 or equal.

5. Front Winch - Hydraulically driven, front-mounted with 12,000 lbs. capacity. Capable of operating in conjunction

with tracks from remote control.

6. Ackermatic Hydraulic Chuck - 4” chuck handles rod and casing up to 3-1/2” O.D.

7. Probe Hammer

8. Full Function Remote Radio Control for Tramming/Winch Operations with Emergency Shutdown

Contact factory for additional details. A complete line of optional accessories are available.

P.O. Box 830, Scranton, PA 18501

Toll Free: 800.752.2537 Fax: 570.586.2659

E-Mail: sales@ackerdrill.com Website: www.ackerdrill.com

Policy: The policy of Acker Drill Co., Inc. being one of continual improvement, we reserve the right to change design or materials at any time, without giving notice or creating any obligation

to previous or future customers.

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Hawker 8TS Battery Charger - Technical Programing HandbookDocument15 pagesHawker 8TS Battery Charger - Technical Programing HandbookDaniel Aguirre100% (4)

- NCK Orion HC80 Spec Book BWDocument28 pagesNCK Orion HC80 Spec Book BWNitin PatelNo ratings yet

- Dredger SpecificationsDocument8 pagesDredger SpecificationsSherin Shihabudeen100% (2)

- Diamec U4Document2 pagesDiamec U4geovanny_ort100% (1)

- Stelkraft CT ProductsDocument40 pagesStelkraft CT ProductsLuis GonzalezNo ratings yet

- # 1 Pavement Test Core Drill in The USA!: Watch Video atDocument2 pages# 1 Pavement Test Core Drill in The USA!: Watch Video atSr. Diego LastreNo ratings yet

- Weil Mclain Radiant HeatDocument112 pagesWeil Mclain Radiant HeatBen Sharp100% (1)

- Submersible Pump Cal. SheetDocument5 pagesSubmersible Pump Cal. SheetIrfan Ahmed100% (1)

- Acker Rig Specs PDFDocument2 pagesAcker Rig Specs PDFAsif KhanzadaNo ratings yet

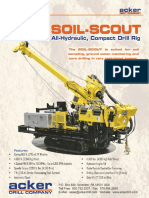

- Acker SOIL-SCOUT: All-Hydraulic, Com Pact Drill RigDocument2 pagesAcker SOIL-SCOUT: All-Hydraulic, Com Pact Drill RigEmmanuel BNo ratings yet

- Acker AD-II: Over 40 Years of Service!Document2 pagesAcker AD-II: Over 40 Years of Service!Sr. Diego LastreNo ratings yet

- High-Torque, All-Hydraulic Auger DrillDocument2 pagesHigh-Torque, All-Hydraulic Auger DrillAsif KhanzadaNo ratings yet

- Acker Mark III Hillbilly PDFDocument2 pagesAcker Mark III Hillbilly PDFLuis Fernando PazmiñoNo ratings yet

- Kershaw 12-12BridgeCraneDocument3 pagesKershaw 12-12BridgeCranecamelia_pirjan5776No ratings yet

- 6308AN FlyerDocument2 pages6308AN FlyerZeckNo ratings yet

- Catalogo - Ge752 - Curvas PDFDocument61 pagesCatalogo - Ge752 - Curvas PDFjuanpnuss100% (1)

- C87SDocument7 pagesC87SbourneremembersNo ratings yet

- Koike Aronson/Ransome Inc.: Cutting, Positioning & Welding EquipmentDocument12 pagesKoike Aronson/Ransome Inc.: Cutting, Positioning & Welding EquipmentfernavapNo ratings yet

- Dando Geotec 6 (Dando Drilling Indonesia)Document2 pagesDando Geotec 6 (Dando Drilling Indonesia)Dando Drilling IndonesiaNo ratings yet

- 500 600 Eci 1350Document2 pages500 600 Eci 1350Jack Yang100% (1)

- 777 Manitowoc Lattice Truck CraneDocument40 pages777 Manitowoc Lattice Truck Cranemanurung4No ratings yet

- Automatic High Speed Single Head Screw Capping MachineDocument2 pagesAutomatic High Speed Single Head Screw Capping MachinePharmaceuticals Machinery KailashNo ratings yet

- QY50K Truck Crane Technical SpecificationDocument9 pagesQY50K Truck Crane Technical Specificationkim alfonsoNo ratings yet

- Canrig Product InfoDocument69 pagesCanrig Product InfoGiorgiana Rosu83% (6)

- Engrape - Bloqueo e IzajeDocument30 pagesEngrape - Bloqueo e IzajeHenryMonteagudoParedesNo ratings yet

- 500 or 650 Ton 900 HP AC Electric Top Drive: TescoDocument2 pages500 or 650 Ton 900 HP AC Electric Top Drive: TescoJack Yang100% (1)

- Dando Watertec 4000 Waterwell Drilling RigDocument2 pagesDando Watertec 4000 Waterwell Drilling RigTom WayNo ratings yet

- Faxe2 PDFDocument43 pagesFaxe2 PDFleo100% (1)

- Jingong's ProductDocument10 pagesJingong's Productapi-19651590No ratings yet

- Little John: Modular, Limited Access Core Drill!Document2 pagesLittle John: Modular, Limited Access Core Drill!Sr. Diego LastreNo ratings yet

- 96 64000e Tesco Power CatwalkDocument4 pages96 64000e Tesco Power CatwalkSoufiane HazelNo ratings yet

- 4100xpc StandardDocument4 pages4100xpc StandardJuanCarlosValenzuelaMedinaNo ratings yet

- Beaver 1200C 02Document2 pagesBeaver 1200C 02Rheyza Gigih PrakosoNo ratings yet

- 26105F Spec BrochureDocument5 pages26105F Spec Brochureابومحمد نايفNo ratings yet

- 5031Document2 pages5031memelo3100% (1)

- ZJ70 (4500DB) Technical SpecDocument44 pagesZJ70 (4500DB) Technical SpecSteveih100% (5)

- EDM 95K SeriesDocument2 pagesEDM 95K SerieskingsfordathleeNo ratings yet

- Geysir Drillmec HH 200 3.3MB1Document34 pagesGeysir Drillmec HH 200 3.3MB1Bullet Dass100% (1)

- ManitowocDocument44 pagesManitowocJITENDRA KUMAR SHARMANo ratings yet

- D-25 Spec SheetDocument5 pagesD-25 Spec SheetHou RasmeyNo ratings yet

- Dando Terrier Percussion (Dando Drilling Indonesia)Document2 pagesDando Terrier Percussion (Dando Drilling Indonesia)Dando Drilling IndonesiaNo ratings yet

- Canrig Product InfoDocument71 pagesCanrig Product InfoBabi Lakhdari100% (5)

- Drill 2Document2 pagesDrill 2Sr. Diego LastreNo ratings yet

- Manitowoc 2250Document108 pagesManitowoc 2250Michael SerraNo ratings yet

- Column Drilling MachineDocument8 pagesColumn Drilling MachineShubhadeep MajumdarNo ratings yet

- P. O. Box 244100 Montgomery, AL 36124 Telephone (334) 387-9100 Fax (334) 387-9375Document1 pageP. O. Box 244100 Montgomery, AL 36124 Telephone (334) 387-9100 Fax (334) 387-9375camelia_pirjan5776No ratings yet

- SpecificationDocument2 pagesSpecificationQ8123No ratings yet

- Technical SpecificationsDocument11 pagesTechnical Specificationsmiguel marcialNo ratings yet

- MOW Equipment Manufacturing: Kershaw 12-12 Tie CraneDocument3 pagesMOW Equipment Manufacturing: Kershaw 12-12 Tie Cranecamelia_pirjan5776No ratings yet

- TDS & ComparisonDocument8 pagesTDS & ComparisonSyed Tauseef Haider100% (1)

- 02-Crown Intstacker MDocument4 pages02-Crown Intstacker MJacob GrechNo ratings yet

- 11 Lifting Blocking Clamping PDFDocument48 pages11 Lifting Blocking Clamping PDFEbied Yousif AlyNo ratings yet

- NOV Gill Services Handling Tools BrochureDocument8 pagesNOV Gill Services Handling Tools BrochureAnonymous VNu3ODGavNo ratings yet

- Hh-1500Hp VFD Rig: H Ong H Ua A Merica, LLCDocument3 pagesHh-1500Hp VFD Rig: H Ong H Ua A Merica, LLCMax MendonçaNo ratings yet

- Elliott Boom Trucks 10 To 18 TonsDocument47 pagesElliott Boom Trucks 10 To 18 TonsPaula PlataNo ratings yet

- Atlas Copco: Metric UnitsDocument12 pagesAtlas Copco: Metric Unitsanemoss100% (1)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Indices de Consolidacio CR CCDocument31 pagesIndices de Consolidacio CR CCSr. Diego LastreNo ratings yet

- Acker Bushm Aster: Bulletin 53Document2 pagesAcker Bushm Aster: Bulletin 53Sr. Diego LastreNo ratings yet

- TripodDocument2 pagesTripodSr. Diego LastreNo ratings yet

- Gro EterDocument1 pageGro EterSr. Diego LastreNo ratings yet

- Acker AD-II: Over 40 Years of Service!Document2 pagesAcker AD-II: Over 40 Years of Service!Sr. Diego LastreNo ratings yet

- PT-HD: Core 36" Holes For Airport Runway Lights!Document2 pagesPT-HD: Core 36" Holes For Airport Runway Lights!Sr. Diego LastreNo ratings yet

- Kodiak: Taking Limited Access Drilling To A New Level!Document2 pagesKodiak: Taking Limited Access Drilling To A New Level!Sr. Diego LastreNo ratings yet

- Little John: Modular, Limited Access Core Drill!Document2 pagesLittle John: Modular, Limited Access Core Drill!Sr. Diego LastreNo ratings yet

- Drill 5Document2 pagesDrill 5Sr. Diego LastreNo ratings yet

- Drill 2Document2 pagesDrill 2Sr. Diego LastreNo ratings yet

- Owner's Manual MFL70422906Document80 pagesOwner's Manual MFL70422906Suneel LeoNo ratings yet

- DTS 3000 ManualDocument24 pagesDTS 3000 ManualTrever TomesNo ratings yet

- BJT As An Amplifier: Biasing and Small Signal Model: ECE60L Lecture Notes, Spring 2002Document15 pagesBJT As An Amplifier: Biasing and Small Signal Model: ECE60L Lecture Notes, Spring 2002anon020202100% (1)

- Kerala State Electricity Board LimitedDocument12 pagesKerala State Electricity Board LimitedPuma PumaNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- Solar Pump Inverter PV100 PV200 User Manuel Rev1Document49 pagesSolar Pump Inverter PV100 PV200 User Manuel Rev1faitgpsNo ratings yet

- Physical ChangesDocument5 pagesPhysical ChangesMaria Cristina ItaoNo ratings yet

- Enza CT - ENP3 Series 75-500ADocument2 pagesEnza CT - ENP3 Series 75-500Aanbuchelvam96No ratings yet

- Hydroconversion Tut Sheet Tut 6BDocument2 pagesHydroconversion Tut Sheet Tut 6BRohit SahuNo ratings yet

- Financial Calculations - CBG - JsDocument7 pagesFinancial Calculations - CBG - JsJanardhana SharmaNo ratings yet

- Helium Leak TestingDocument21 pagesHelium Leak TestingSaut Maruli Tua Samosir100% (1)

- List of Condemned MT Store in R/O CRPF Academy, Kadarpur, Gurugram (HR) Lot No.5 (MT Spare Part Stores)Document2 pagesList of Condemned MT Store in R/O CRPF Academy, Kadarpur, Gurugram (HR) Lot No.5 (MT Spare Part Stores)Shubham JainNo ratings yet

- SAEnergyStorage 2018 Presentation Template Prince MoyoDocument17 pagesSAEnergyStorage 2018 Presentation Template Prince MoyoprinceNo ratings yet

- Home Power Magazine - Issue 010 - Apr - May 1989 - Renewable Solar Wind EnergyDocument48 pagesHome Power Magazine - Issue 010 - Apr - May 1989 - Renewable Solar Wind EnergydarktidussNo ratings yet

- LECH3874-08 Industrial Engine Ratings GuideDocument34 pagesLECH3874-08 Industrial Engine Ratings GuideDDemin12345100% (1)

- Pioneer SX-D5000HG - Art-545-0Document12 pagesPioneer SX-D5000HG - Art-545-0Loic FabroNo ratings yet

- Labordental EnglischDocument64 pagesLabordental EnglischConstantin SturzaNo ratings yet

- 2015 ENR Top 500 Design Firms Sourcebook 1Document57 pages2015 ENR Top 500 Design Firms Sourcebook 1iabhiuceNo ratings yet

- Fire Sprinkler Systems ExplainedDocument3 pagesFire Sprinkler Systems ExplainedRomzy KutonNo ratings yet

- The Periodic Table - FSC 112Document29 pagesThe Periodic Table - FSC 112ogbedivineleonardNo ratings yet

- BRC4C82 Operation ManualDocument11 pagesBRC4C82 Operation Manualsomchaik.19No ratings yet

- BillDocument1 pageBillZeeshan Haider RizviNo ratings yet

- 11 Transportation Systems 2007 Petroleum Production EngineeringDocument26 pages11 Transportation Systems 2007 Petroleum Production EngineeringHaziq YussofNo ratings yet

- Problemas TermoDocument3 pagesProblemas TermocleonardoeNo ratings yet

- PDU Lab Reports 8 To 14Document11 pagesPDU Lab Reports 8 To 14Shahroze TayyebNo ratings yet

- Internal Audit ChecklistDocument12 pagesInternal Audit ChecklistLakshmi BalaNo ratings yet

- BR0007 - 20 SP PRO Series 2i Data Sheet August 2022Document2 pagesBR0007 - 20 SP PRO Series 2i Data Sheet August 2022zacfoster9191No ratings yet