Professional Documents

Culture Documents

Scientific Heat Treatment Services PVT LTD Metallurgical Inspection Report

Scientific Heat Treatment Services PVT LTD Metallurgical Inspection Report

Uploaded by

argmsfOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scientific Heat Treatment Services PVT LTD Metallurgical Inspection Report

Scientific Heat Treatment Services PVT LTD Metallurgical Inspection Report

Uploaded by

argmsfCopyright:

Available Formats

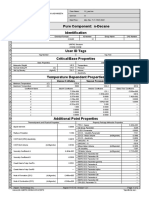

Scientific Heat Treatment Services Pvt Ltd Metallurgical Inspection Report Report No SHT-21-0027

Customer Name M/s. Timken Carburizing Hardening

Part Name / No. HH228301 Carb Batch No SC21C005/05 Hardening Batch No SC21C016/05

Drawing No B-216030 Carb Batch Qty 1248 Hardening Batch Qty 1242

Material Grade 8319 Carburizing Date 3-May-2021 Hardening Date 0-Jan-1900

Steel Heat No. E - 93769X

Green Batch No. 0

Green Material Supplier M/s. VNR

MS Inspection Report

Test Procedure : MS inspection has been Carried out as per Timken Corporate Inspection Standard 10.5 “Case Depth by the Ms Technique”. Carbides has been evaluated as per Timken Corporate Inspection Standard

10.34 “Carbide Structure Standard” to the limits defined in standard 3B.11.

Specification 0.5% C - Min 0.5% C - Max 0.8% C - Min 0.8% C - Max Decarb (µ) Carbide

Case Aim

Sample. No. 1.85 2.62 0.74 150 Figure - 03

1 2.24 2.29 1.35 1.40 Nil Nil

2 2.26 2.35 1.32 1.40 Nil Nil

3 2.23 2.32 1.34 1.42 Nil Nil

4 2.33 2.37 1.36 1.47 Nil Nil

5 2.24 2.32 1.34 1.43 Nil Nil

3/32

6 2.32 2.35 1.44 1.48 Nil Nil

7 - - - - - -

8 - - - - - -

9 - - - - - -

10 - - - - - -

0

Remaks

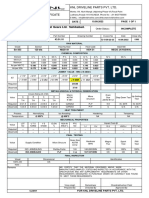

Hardening Inspection Report

Hardness testing has been done as per Timken Corporate Inspection Standard 10.7. NMTP ratting is as per Timken Corporate Inspection Standard 10.22 “Non-Martensitic Transformation Product Standard”, Retained

Austenite and Core Microstructure rating is as per Timken Corporate Inspection Standard 10.18 “General Bearing Microstructure Standard”, Carbide rating is as per Timken Corporate Inspection Standard 10.34 “Carbide

Structure Standard” to the limits defined in standard 3B.11.

Surface Hardness Core Hardness NMTP RA Core Ferrite Carbide Decarb (µ)

Specification

58 64 30 48 Figure - 02 Upto 200 µ 15 ~ 30% - Figure - 03 150

Sl No Minimum Maximum Minimum Maximum Observed Values

1 - - - - - - - - -

2 - - - - - - - - -

3 - - - - - - - - -

4 - - - - - - - - -

5 - - - - - - - - -

6 - - - - - - - - -

7 - - - - - - - - -

8 - - - - - - - - -

9 - - - - - - - - -

10 - - - - - - - - -

0

Remaks

Visual Inspection Report

Inspected Quantity Accepted Quantity Rejected Quantity Observation Remarks

0 0 0 0 -

ECT Report

Channel No 1 2 3 4 5 6 7 8

Frequency & Gain

Frequency (Hz) 0 0 0 0 0 0 0 0

Details

Gain (db) 0 0 0 0 0 0 0 0

Inspected Quantity Accepted Quantity Rejected Quantity Observation Remarks

0 0 0 - -

Dimension Inspection Report

Inspected Quantity as per AQL Accepted Quantity Rejected Quantity Observation Remarks

47 0 0 0 -

RP Oilling

- Observation - Remarks -

Disposition

Checked By Approved By

- Remarks : All Metallurgical Parameters are Within Specifications

- -

Resposibility : Shift Incharge Process Owner : HOD Prepared By : Arghya Approved By : Rishi Bhargava Issued By :

Syed Nazim Ahmed

Format No : SHT-F-004 Date of Issue : 01 January 2021 Rev No 00 Rev Date -

You might also like

- Lab Report Experiment TrussesDocument14 pagesLab Report Experiment TrussesNEWTAN100% (3)

- BS 2M 54-1991 ScanDocument9 pagesBS 2M 54-1991 ScandokuNo ratings yet

- Eric Priest - Magnetohydrodynamics of The Sun-Cambridge University Press (2014) PDFDocument580 pagesEric Priest - Magnetohydrodynamics of The Sun-Cambridge University Press (2014) PDFLaura Mora100% (1)

- 2020 07 18 Transformer Bushing FailuresDocument34 pages2020 07 18 Transformer Bushing FailuresPradeep SinghNo ratings yet

- Isometri BoilerDocument8 pagesIsometri BoilerCHRISTIAN BUDINo ratings yet

- 03-Power Cables-ECE-Rev.00Document13 pages03-Power Cables-ECE-Rev.00ehabhesham20No ratings yet

- DecaneDocument2 pagesDecaneNivasNo ratings yet

- DGA-Lung CenterDocument4 pagesDGA-Lung CenterLeo Tabita Jr.No ratings yet

- Gibbs Reactor: GBR-100: Stream NameDocument3 pagesGibbs Reactor: GBR-100: Stream NameJamesNo ratings yet

- Kocstandard FOR Indirect Type Oil Heaters DOC. NO. KOC-MV - 009Document42 pagesKocstandard FOR Indirect Type Oil Heaters DOC. NO. KOC-MV - 009Praveen Babu100% (1)

- PVT AnalysisDocument54 pagesPVT AnalysisAdmirerNo ratings yet

- NEA Electrical EstimateDocument40 pagesNEA Electrical EstimateSurendra MaharjanNo ratings yet

- TabelberatbesiDocument13 pagesTabelberatbesiMidun DuluNo ratings yet

- MeCA SHEET PC SMALL 03Document4 pagesMeCA SHEET PC SMALL 03Reza SyailendraNo ratings yet

- Recierres 2021Document190 pagesRecierres 2021Wilson Bravo G.No ratings yet

- ULTRA DIVERSITY-21 - Oct - 2022 - 06 - 03 - 14-100009554Document15 pagesULTRA DIVERSITY-21 - Oct - 2022 - 06 - 03 - 14-100009554Lee Quan DeNo ratings yet

- Toyota Motor Europe NV / SaDocument40 pagesToyota Motor Europe NV / SaMichael TuiakhovNo ratings yet

- MSA-Attribute AnalysisDocument14 pagesMSA-Attribute AnalysisAtul SharmaNo ratings yet

- Triaxial Test: (GDS Instruments)Document24 pagesTriaxial Test: (GDS Instruments)Kuan RickyNo ratings yet

- JAYANTI BARUNA-25 - Apr - 2024 - 10 - 05 - 39-100042854Document10 pagesJAYANTI BARUNA-25 - Apr - 2024 - 10 - 05 - 39-100042854BoyNo ratings yet

- CH No. Chapter Page No.: 1 The Engineering Sector 1-3Document3 pagesCH No. Chapter Page No.: 1 The Engineering Sector 1-3Sabhaya ChiragNo ratings yet

- Img20220809 07262264Document1 pageImg20220809 07262264Hafiz RahimNo ratings yet

- 1mg 200g CertificateDocument2 pages1mg 200g CertificateAmirNo ratings yet

- Lab - 0 - Tensile Strength of Mild SteelDocument7 pagesLab - 0 - Tensile Strength of Mild Steelrajeshguptarg7246No ratings yet

- Mersen Control Circuit Schema LegendsDocument3 pagesMersen Control Circuit Schema LegendsKamil Gökberk ErginNo ratings yet

- Project 2Document6 pagesProject 2bijinder06No ratings yet

- Ramy Abou El SoaadDocument10 pagesRamy Abou El SoaadAhmed Ayman AhmedNo ratings yet

- IJOGST - Volume 4 - Issue 2 - Pages 40-49Document10 pagesIJOGST - Volume 4 - Issue 2 - Pages 40-49pedro aguilarNo ratings yet

- Apph Oh & Ipc R17Document166 pagesApph Oh & Ipc R17dsgarcia26No ratings yet

- Engine Description: 2.1 Model 2.2 Engine Illustration 2.3 Lube Oil Circuit Schematic 2.4 Fuel System SchematicDocument13 pagesEngine Description: 2.1 Model 2.2 Engine Illustration 2.3 Lube Oil Circuit Schematic 2.4 Fuel System SchematicmrmisterNo ratings yet

- Toa Fluid Report Inspectorate001 PWTR POWER TRANSFORMERDocument6 pagesToa Fluid Report Inspectorate001 PWTR POWER TRANSFORMER0502208864No ratings yet

- Ficha Tecnica Superaleaciones Ni - SuperalloysDocument5 pagesFicha Tecnica Superaleaciones Ni - SuperalloysANDRES DOMINGUEZNo ratings yet

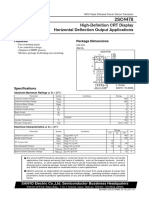

- High-Definition CRT Display Horizontal Deflection Output ApplicationsDocument4 pagesHigh-Definition CRT Display Horizontal Deflection Output ApplicationsArie DinataNo ratings yet

- UntitledDocument12 pagesUntitledAdar OsNo ratings yet

- Numeros Generadores: Obra: Ubicación: Descripcion Del Concepto: ClaveDocument20 pagesNumeros Generadores: Obra: Ubicación: Descripcion Del Concepto: ClaveMauroNo ratings yet

- Nirma MPR - JULY 22Document38 pagesNirma MPR - JULY 22Kiran Kumar PatraNo ratings yet

- 17.01.24 - SR - STAR CO-SC (MODEL-A, B&C) - Jee - Main - GTM-19 (N) - KEY & SOLDocument12 pages17.01.24 - SR - STAR CO-SC (MODEL-A, B&C) - Jee - Main - GTM-19 (N) - KEY & SOLydouneed2012No ratings yet

- Edesander INP Ver300LDocument1 pageEdesander INP Ver300LLuisAngelCordovadeSanchezNo ratings yet

- Batch 127232 Hexindo BalikpapanDocument2 pagesBatch 127232 Hexindo BalikpapanlilikNo ratings yet

- Fatigue Design CalculationDocument3 pagesFatigue Design CalculationinnovativekarthiNo ratings yet

- ISO 8752 EN 28752: Pin Materials and Hardness Pin FinishesDocument2 pagesISO 8752 EN 28752: Pin Materials and Hardness Pin FinishesstanyeahNo ratings yet

- Chemical ManufactureDocument18 pagesChemical ManufactureChellam Siva Chellam Siva100% (1)

- 2324MTC037 11361Document1 page2324MTC037 11361Shrikrushna DalviNo ratings yet

- متطلبات الرقابة على جودة التدقيق في الجزائر - مراجعة أوليةDocument17 pagesمتطلبات الرقابة على جودة التدقيق في الجزائر - مراجعة أوليةNoureddine MezianiNo ratings yet

- TM GDR-413Document2 pagesTM GDR-413Ahmat RamadaniNo ratings yet

- 4839 SorDocument8 pages4839 SorFatima MasoodNo ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- Daily Report 30-11-2021Document7 pagesDaily Report 30-11-2021Ahmed MohammedNo ratings yet

- StudPro 2500I Manual - 12 2016Document36 pagesStudPro 2500I Manual - 12 2016128BTC UnclebotNo ratings yet

- Underwater Repair WeldingDocument11 pagesUnderwater Repair WeldingmariusNo ratings yet

- UV1-5 Exploded ViewDocument2 pagesUV1-5 Exploded ViewIvo MozaraNo ratings yet

- Emeco: Intermediate Metal ConduitDocument3 pagesEmeco: Intermediate Metal Conduitkhaled aliNo ratings yet

- Contactor InformacionDocument3 pagesContactor Informacionedgar rdzNo ratings yet

- Rekap Oil AnalysisDocument46 pagesRekap Oil AnalysisSatya SentosaNo ratings yet

- DNC75 398sdc003en00Document30 pagesDNC75 398sdc003en00Anonymous Xz3PgZR8No ratings yet

- HasunDocument5 pagesHasunTurkish Islamic UrduNo ratings yet

- CHW2204-00-EL-ESD-7301 Rev1 Grounding System LayoutDocument3 pagesCHW2204-00-EL-ESD-7301 Rev1 Grounding System LayoutphongtttNo ratings yet

- 2019 - 20 - B41FG - MSC OGT FDP - Design Basis PDFDocument16 pages2019 - 20 - B41FG - MSC OGT FDP - Design Basis PDFShamsiNo ratings yet

- Corrosion Inhibitor SpecDocument2 pagesCorrosion Inhibitor SpecAmanNo ratings yet

- Equipment Process Data Sheet: 'GYPT "".SCDocument3 pagesEquipment Process Data Sheet: 'GYPT "".SCMo ZeroNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Riday: Eotf On 3CDocument1 pageRiday: Eotf On 3CargmsfNo ratings yet

- 550HV EhtDocument1 page550HV EhtargmsfNo ratings yet

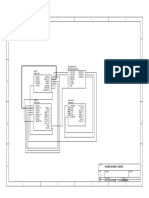

- HT Zone Layout SampleDocument5 pagesHT Zone Layout SampleargmsfNo ratings yet

- HT LayoutDocument6 pagesHT LayoutargmsfNo ratings yet

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDocument1 pagePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNo ratings yet

- HsuejdjDocument1 pageHsuejdjargmsfNo ratings yet

- UntitledDocument1 pageUntitledargmsfNo ratings yet

- Wi For Surface Grinding and Sample Cutting MachineDocument2 pagesWi For Surface Grinding and Sample Cutting MachineargmsfNo ratings yet

- Stronger.: Metallurgical RequestDocument2 pagesStronger.: Metallurgical RequestargmsfNo ratings yet

- Dhiraj: Operator Wise Production For The Month Feb'23Document55 pagesDhiraj: Operator Wise Production For The Month Feb'23argmsfNo ratings yet

- Payment Receipt: Service Provider PayerDocument1 pagePayment Receipt: Service Provider PayerargmsfNo ratings yet

- 2.3 - The Factor Theorem Math 30-1Document14 pages2.3 - The Factor Theorem Math 30-1Math 30-1 EDGE Study Guide Workbook - by RTD LearningNo ratings yet

- Pneumatic Logic ComponentsDocument17 pagesPneumatic Logic ComponentskammoNo ratings yet

- Syncfusion File FormatsDocument229 pagesSyncfusion File Formatszuhair haroon KhanNo ratings yet

- Use of Near-Infrared Spectroscopy For Qualitative and Quantitative Analyses of Grains and Cereal ProductsDocument169 pagesUse of Near-Infrared Spectroscopy For Qualitative and Quantitative Analyses of Grains and Cereal ProductsK_NEMONo ratings yet

- Linear Correlation Study and Regression Analysis of Drinking Water Quality in Mokokchung Town, Nagaland, IndiaDocument6 pagesLinear Correlation Study and Regression Analysis of Drinking Water Quality in Mokokchung Town, Nagaland, IndiaInternational Journal of Engineering Research & ManagementNo ratings yet

- Head LukasDocument43 pagesHead LukasSergent Khaos100% (1)

- Fiery Color Test Page: PMS 640CDocument3 pagesFiery Color Test Page: PMS 640CElvÏs ElvÏs100% (1)

- Iotsec OdtDocument745 pagesIotsec OdtLeonardo LatorreNo ratings yet

- Modes of Project FinancingDocument81 pagesModes of Project FinancingjasiaahmedNo ratings yet

- Data Link Layer 1Document88 pagesData Link Layer 1PalashAhujaNo ratings yet

- Math 1 Lessson PlanDocument4 pagesMath 1 Lessson Planapi-235237171No ratings yet

- Digital Autozero & Span Option: Technical DataDocument2 pagesDigital Autozero & Span Option: Technical DataGopal HegdeNo ratings yet

- NV Sir Lecture PlanDocument12 pagesNV Sir Lecture PlanmirsNo ratings yet

- CH 21 Hull Fundamentals 8 The DDocument23 pagesCH 21 Hull Fundamentals 8 The DjlosamNo ratings yet

- 2015 Recent Achievements in Solidified Floating Organic Drop MicroextractionDocument30 pages2015 Recent Achievements in Solidified Floating Organic Drop MicroextractionDidier MauricioNo ratings yet

- Name Physics Date: Class: Classwork 2 Done By: Mr. Imad DarwicheDocument2 pagesName Physics Date: Class: Classwork 2 Done By: Mr. Imad DarwicheBadoorah HaiderNo ratings yet

- 3 The MPEG Data StreamDocument12 pages3 The MPEG Data Streamanshab bedariNo ratings yet

- FRICK® POWERPAC BE Spec PowerpacDocument24 pagesFRICK® POWERPAC BE Spec PowerpacEdwin Angel Solis VitorNo ratings yet

- LFCS Domains Competencies V2.16 PDFDocument7 pagesLFCS Domains Competencies V2.16 PDFKeny Oscar Cortes GonzalezNo ratings yet

- Astronomy NotesDocument2 pagesAstronomy Notessherlyn rose v. binay-anNo ratings yet

- (PDF) Heat Transfer 10thedition by JP Holman - PDF - Mon Elvin B Jarabejo - Academia - Edu PDFDocument1,305 pages(PDF) Heat Transfer 10thedition by JP Holman - PDF - Mon Elvin B Jarabejo - Academia - Edu PDFTamaki DellosaNo ratings yet

- Probability Punnett-Squares-Intermediate Printer FriendlyDocument7 pagesProbability Punnett-Squares-Intermediate Printer FriendlyAfaq AhmadNo ratings yet

- Image Enhancement-Spatial Domain - UpdatedDocument112 pagesImage Enhancement-Spatial Domain - Updatedzain javaidNo ratings yet

- Nature of NumbersDocument57 pagesNature of NumbersArun Kumar Upadhyay100% (3)

- O o o o o o o o o o oDocument17 pagesO o o o o o o o o o oshukkurNo ratings yet

- Test2 Schedule 2020-21 Even SemDocument1 pageTest2 Schedule 2020-21 Even SemkepoNo ratings yet