Professional Documents

Culture Documents

NRL Intro

NRL Intro

Uploaded by

Abdulkarim Khatri AbbanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NRL Intro

NRL Intro

Uploaded by

Abdulkarim Khatri AbbanCopyright:

Available Formats

Management

National Refinery Limited ( NRL ) was incorporated on August 19, 1963 as a public limited

company. Government of Pakistantook over the management of NRL under the Economic

Reforms Order, 1972 under the Ministry of Production, which was exercising control through its

shareholding in State Petroleum Refining and Petrochemical Corporation (PERAC).

The Government of Pakistan had decided to place the National Refinery Limited under the

administrative control of Ministry of Petroleum & Natural Resources in November 1998.

In June 2003 the Government of Pakistan decided to include NRL in its privatisation programme.

The selling of 51% equity and transfer of management control to a strategic investor had been

proposed accordingly, the due diligence process for the privatisation was initiated. After

competitive bidding NRL was acquired by Attock Oil Group in July 2005.

The Company has been privatised and the management handed over to the new owner

(Attock Oil Group) on July 7, 2005.

Production

The refinery complex of the Company comprises of three refineries, consisting of two lube

refineries and one fuel refinery. First Lube Refinery commissioned in 1966 with designed capacity

of 539,700 tons per annum of Crude Processing and 76,200 tones per annum of Lube Base Oils.

Second Lube Refinery commissioned in 1985 with designed capacity of 100,000 tons per annum

of Lube Base Oils.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

The Fuel Refinery commissioned in 1977 with designed capacity of 1,500,800 tones per annum of

Crude processing and after revamp the designed capacity comes to 2,170,800 tones per annum

of Crude processing.

The BTX unit was commissioned in 1985 with design capacity of 25,000 tons per annum of BTX.

NRL enjoys a competitive edge, as it is the only refinery producing LBO in Pakistan.

The company’s plants have a fuel refining capacity of 2,710,500 tones per annum (TPA) of crude oil,

designed capacity of 176,200 TPA of lube base oils (LBO) and a BTX unit with a designed capacity of

edge, as it is the only refinery producing LBO in Pakistan. Details of the different plants are given be

First Lube Refinery: Designed and constructed by SNAM PROGETTI of Italy with a capacity to proc

produce 76,200 TPA of LBO was commissioned in June 1966. This refinery also produces fuels, aspha

Fuel Refinery: Designed and constructed by Industrial Export Import (IEI) of Romania with a capaci

was commissioned in April 1977. Its capacity was increased to 2,170,800 TPA in February 1990. The

Gasoline, Kerosene, Jet Fuels, Diesel and Furnace oil.

Second Lube Refinery: Designed by CE Lummus of UK and constructed by Industrial Export Impor

January 1985. It has a designed capacity of 100,000 TPA of LBO and 110,000 TPA of Asphalt.

BTX (Petrochemical) Plant: Designed and constructed by Nordon et Cie of France with a capacity

commissioned in April 1979. It was the country’s first Petrochemical unit. This plant produces Benze

chemicals market. Toluene is also used in NRL’s own Dewaxing units.

NRL’s gross storage capacity, both at the Refinery site in Korangi and at Keamari harbour, comprise

crude and 90,000 tones for Petroleum products. The Petroleum products are pumped from NRL stora

(OMC) Terminals or to Karachi airport by pipelines. Other products such as Lube Base Oils, Asphalt,C

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Tank Lorries.

NRL’s production for five financial years up to the financial year ending 30th June 2009 is shown in t

Unit: Tones

Crude Processed by NRL

No. of Years Crude Processed by NRL

2004-

YEAR 2005-2006 2006-2007 2007-2008 2008-2009

2005

Local Crude 412,535 357,870 459,347 475,787 422,867

Imported

2,329,4122,405,462 2,342,524 2,258,011 2,000,817

Crude

Total 2,741,94

2,763,332 2,801,871 2,733,798 2,423,684

Processed 7

NRL’s Share of Crude Processed in Pakistan

YEAR 2004- 2005-2006 2006-2007 2007-2008 2008-2009

2005

Total Crude 11,416,40 11,504,333 11,237,545 11,691,348 N.A

Processed 4

inPakistan

NRL’s Shar

24.02% 24.02% 24.93% 23.38% N.A

e

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

The management of the Company was taken over by the (Attock) Pharaon Group in Pakistan on

July 7, 2005 from Government of Pakistan. The investment of the Pharaon Group in Pakistan have

over the past decade achieved phenomenal expansion as a result of which it has not only become

the largest stakeholder in the oil and gas sector of the country, but has in fact become one of the

largest business groups within the country.

The group emerged as a conglomerate with the following component Companies:

1. Pakistan Oilfields Limited

2. Attock Petroleum Limited

3. Attock Refinery Limited

4. Attock Cement Pakistan Limited

5. National Refinery Limited

6. And other Companies not listed on stock exchange(s)

Like all other listed companies, National Refinery Limited is governed by its Memorandum and

Articles of Association, Code of Corporate Governance and the Companies Ordinance 1984.

The Board of Directors of the Company has a Chairman and the Company is run under

management of the Chief Executive Officer & Deputy Chairman, aided by Deputy Managing

Director and an Executive Committee. All functional heads report to the Chief Executive Officer –

an Organization Chart has been put on display separately.

High Speed Diesel (HSD) Desulphurization

In order to produce clean High Speed Diesel Euro II with 500 parts per million sulfur.

Universal Oil Product (UOP) has completed the Engineering Design & Specification (EDS)

project in September 2008. The Government has advised time line for clean diesel

production by January 2012. However, the implementation of this project shall be subject

to necessary incentives being negotiated with the Government justifying its economic

feasibility and profitability of the company from the Fuel Section. NRL has awarded

contract to M/s Zeeshan Engineering as Project Management Consultant.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Debottlenecking study for increase in capacity and yields of distillates from

vacuum tower

It is planned to replace the existing cylindrical vacuum heater installed at Vacuum

Section of Two Stage Distillate unit at Lube Refinery. The capacity of new heater is

envisaged for enhanced throughput, which will be based on maximum potential of

vacuum column and associated equipments. Feasibility study of the project has been

completed to initiate modifications in vacuum column based on simulations.

Product Metering System

Company has decided to implement Product Metering System at refinery

and Keamari terminal for transfer of product to Oil Marketing Companies (OMCs). This will

bring more efficiency in operations. Commissioning target of flow meters is August 2009.

Initially project will handle HSD pumping to OMCs.

Radar Gauging System

The project is required for custody transfer of products to storage tanks to calculate the

accurate gauging. In Phase-I, Radar gauges of 41 numbers have been installed and in

Phase-II additional 64 gauges will be installed by December 2009. It will cover all 105 tanks

needed in custody transfer.

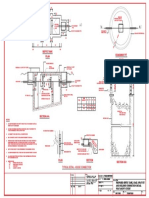

Storage Tanks

The Company has decided to construct additional tanks for crude as well as product

storage. The new tanks will increase the operational flexibility and storage capacity to

meet strategic market demand. Contract for fabrication and installation of storage tanks

has been awarded and work is in progress, which will be completed by December 2009.

New Water reservoir and Reverse Osmosis (RO) Plant-III

The refinery facing water shortage and therefore, it has been decided to undertake

following projects:

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

i. Construction of additional water reservoir of 3.0 million gallons capacity

to run the refineryat the optimum capacity.

ii. One more Reverse Osmosis Plant of 200,000 Imperial Gallon Per Day

(IGPD) would be added to existing plants. Boring of Brackish water wells is in

progress to establish feed specifications for Reverse Osmosis Plant.

The company has a strong information technology capability. Computerized

instrumentation and auto-tank gauging are being applied. The technical staff use a variety

of computer software for process design, performance monitoring, simulation and

engineering design.

NRL had implemented an Enterprise Resource planning (ERP) solution, SAP (version 4.6C)

in the year 2004 with following modules :

Finance and controlling (FICO)

Material Management (MM)

Sales & Distribution (SD)

Plant Maintenance (PM)

Human Resource (HR)

It is further planned to upgrade SAP release from 4.6C to ECC6.

The lube base oil (LBO), asphalt, BTX and specialty oils segment of NRL’s business is

deregulated and operates in a free market environment.

The Government is committed to gradual deregulation of the petroleum fuel-refining

sector. As a first step, it deregulated furnace oil and LPG by allowing refineries to fix prices

on a competitive basis. Thereafter with effect from 1st July 2001, the petroleum industry

was allowed to workout prices of fuel products through the Oil Companies’ Advisory

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Committee (OCAC) on a fortnightly basis by using a transparent pricing mechanism

approved by the Government. The Government deregulated import of high-speed diesel

(HSD) and therefore with effect from 1st September 2002 allowed OMCsto fix the final sale

price on cost competitive basis. Pricing of Regulated Fuel Products was handed over to

OGRA w.e.f. April 16, 2006.

Import parity pricing formula for fuel refineries was modified with effect from 1st July 2002.

The main objective of modification in formula was to dispense with the minimum 10% rate

of return requirement and provide incentive to oil Refineries to operate on self financing

basis without any subsidy from GOP.. Gradually, over the years, Tariff protection was

removed from all the products & Currently, the same exists only on HSD, at a reduced

level.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Frist Second

Fuel B.T.X Fuel

Lube Lube

Refinery Unit Refinery Revamp

Refinery Refinery

Date June April April January February February

Commisioned 1966 1977 1979 1985 1990 1995 & 97

Increase

Design High

LBO Crude Oil B.T.X LBO Crude Oil

Capacity Octane

76.000 1.5 Million 25,000 100,000 2.2 million

(Tons/year) Production

by 70%

Project Cost

(Million 104 608 67 2,083 125 312

Rupees)

Total Crude Oil Processing Capacity : 2.9 Million Per Year

Total Project Cost : Rs 2862 Million

stablishment : 1963

`

asic Objectives : Petroleum Refining To Produce Petroleum Products &

Petrochemicals

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

otal Capital Rs 2,862 Million

nvestment :

2.71 Million Tons Per Year

esign Capacity:

2.9 Million Tons Per Year

rude Oil Process:

Allied Bank, Faysal Bank, Habib Bank, Habib Metropolitan

ankers: Bank,

National Bank of Pakistan, United Bank.

hareholders: ARL, POL, IDB, NIT, & Others

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

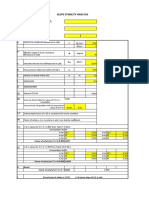

Financial Statistical

Net turnover

Gross profit

Operating profit

Profit before tax

Profit after tax

Share Capital

Reserves

Shareholder equity

Property ,plant and

equipment

Current Assets

Current Liabilities

Net current assets/

liabilities

Long term /Deferred

liabilities

Gross profit ratio

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Net profit ratio

Return on equity

Return on capital

employed

Earning per shares (EPS)

Market value per share

at year end

Inventory turnover

ratio/No. of days in

inventory

Debtor turnover ratio/

No. of days in

receivables

Total assets turnover

ratio/Fixed assets

turnover ratio

Quick /Acid test ratio

Price earning ratio

Cash Dividend per share

Dividend yield ratio

Bonus shares issued

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

1966

First Lube Refinery

The construction work of first Lube

Refinery was started in May 1964. The

Refinery came into production in June

1966, with crude oil refining capacity

of 600,000 tons per annum and

production of 76,000 tons of various

grades of Lube Base Oils and 100,000 tons of Asphalt per annum. This Refinery also

supplemented fuel products requirement of the country particularly Kerosene and Diesel.

1972

On January 16, 1972, the Government of Pakistan took over the

management of the Refinery under the Economic Reforms Order. The overall

managerial directions were entrusted to the Ministry of Production.

1977

Fuel Refinery

The growth in demand of fuel

products in the subsequent years,

after installation of first Lube Refinery,

impelled the need for further increase

in refining capacity. In the year 1974,

National Refinery Limited signed an

agreement with Industrial Export and Import of Romania to construct a Fuel Refinery

having crude refining capacity of 1.5 million tons per year on turnkey basis. Since the Fuel

Refinery was to be integrated with the first Lube Refinery, a site on the same premises was

selected.

NRL's Fuel Refinery was a fresh addition on the country's growing industrial landscape. The

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Ensure that business policies and targets are in conformity with the national goals.

Contribute in meeting the country’s demand of petroleum and petrochemical

products.

Customer’s satisfaction by providing best value and quality products.

Optimization of the value of barrel of crude oil and cost reduction through

conservation measures.

Achieving and maintaining a high standard of Occupational Heath, Safety and

Environment.

Ensure reasonable return on shareholders' existing and projected investment.

Maintain modern management system conforming to international standards needed

for an efficient organization.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Head Office 7-B, Korangi Industrial Area,

Karachi-74900, Pakistan.

Telephone PABX UAN 92-21-111 675 675

92-21-35064135-7, 92-21-35064981-83, 92-21-

35064985-8

Telephone: Direct

Contact's List

Nos.

Fax 92-21-35054663, 92-21-3506-6705

Email info@nrlpak.com

List of E-mail Address, Ext., Fax and Direct Telephone Numbers

Ext

Departme . Direct Fax

Name Designation E-Mail

nt No No. No.

.

Mr. Shuaib A. Malik CEO Chief Executive 22 35062 350608 mdsec1@nrlpak.com

Secretariat Officer 01 319 76

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

35060

874

35062

CEO Deputy Managing 22 319 350608

Mr. Jamil A. Khan mdsec1@nrlpak.com

Secretariat Director 01 35060 76

874

Comp.Secre 24 35061 35061 companysec@nrlpak.co

Shaikh AtherAhmed Company Secretary

tary 54 544 544 m

CEO 22 35062

Mr. SagheerHussain GM (Sp. Projects) gm_sp@nrlpak.com

Secretariat 17 321

Mr. Shahid Waheed 24 35063

Commercial GM (Commercial) gmcomm@nrlpak.com

Khawaja 58 329

22 35121 gm_operation@nrlpak.c

Mr. S.M. Ashqeen Operation GM (Operation)

43 792 om

Procuremen 22 35062 gm_procurement@nrlpa

Mr. Shahid Kamal GM (Procurement)

t 20 269 k.com

Brig.

22 35060

® SaleemMurad Ag Admin. GM (Admin) gmadmin@nrlpak.com

07 121

ha

22 35060

Mr. Usman Ahmed HR&P AGM (HR&P) mgrhr@nrlpak.com

02 300

Mr. 22 35066

Project AGM (M & P) gm_project@nrlpak.com

MohammadAslam 90 320

Mr. Zakir MujahidQu 22 35054

Treasurer Treasurer treasurer@nrlpak.com

reshi 69 708

Dr. Khawaja AjmalW MGR. (Quality 23 mgrqualitycontrol@nrlp

Q/C -

aheed Control) 89 ak.com

25 35060 div_head_om@nrlpak.co

Mr. Ashfaq Fazaldin OM&U Div. Head (OM&U)

22 332 m

Procuremen 23 mgrwarehouse@nrlpak.

Mr. Mohammad Ali MGR (Warehouse) -

t 73 com

22 35060

Mr. S. Qasim A.Rizvi Commercial MGR. (Supply & TR) mgr_str@nrlpak.com

11 608

25

Mr. Zaman Bhatti HSE MGR (HSE) - mgrhse@nrlpak.com

59

23 35060

Mr. M.J.A Butt SMS MGR (SMS) mgr_sms@nrlpak.com

67 369

Mr. Anwar A.Shaikh Finance, CFO/MGR (Fin/Legal) 22 35060 cfo@nrlpak.com

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

04 122

Mr. Nisar Ahmed Coordinator 25 35121

Production

Khan Production 81 797

Technical Sr 22

Mr. Shakil A. Asif MGR (TS) - mgrtech@nrlpak.com

vcs. 12

Mr. Afzal HussainKh 22 35064 mgraudit_opr-

Audit MGR (Opr.Divs.)

an 34 088 divs@nrlpak.com

Oil 25 35066 mgroilmovement@nrlpa

Mr. H.M. Qureshi MGR (Oil Movement)

Movement 57 701 k.com

22 35060 mgrengineering@nrlpak

Mr. S. ImtiazHussain Engineering MGR (Engineering)

15 844 .com

Mr. S. Instrumenta 25 mgr_instrument@nrlpak

MGR (Instrument) -

Tariq AzamMustafa tion 53 .com

25 mgr_elect&pg@nrlpak.c

Mir Shabbir Ali Elect. & PG MGR (ELEC.& P.G.) -

64 om

22 35060

Mr. Sajid Pervez Contract MGR (Contract) mgrcont@nrlpak.com

53 847

Procuremen 24 35060 mgr_purchase@nrlpak.c

Mr. Abrar Akram MGR (Purchase)

t 35 842 om

Major ® M. Abdul 22 35054 mgr_personnel@nrlpak.

Personnel MGR (Personnel)

Aziz 36 681 com

Prod.Plng.& 22

Mr. Abdul Sattar MGR (PP & E) - mgr_ppe@nrlpak.com

ECO 13

25 mgr_prodlube2@nrlpak.

Mr. Asif Iqbal Production MGR (Lube-II) -

54 com

22

Mr. Insha Ahmed Commercial MGR Prod. Supply - insha@nrlpak.com

16

25 mgr_inspection@nrlpak.

Mr. Mairaj Khwaja Inspection MGR (Inspection)

61 com

MGR / Secretary 2435060

Mr. Zafar Jawaid Pension / PF zafarjaved@nrlpak.com

Pen.&Prov Funds 74 331

2535060 mgr_maint1@nrlpak.co

Mr. FaheemSiddiqui Maint.-I MGR (Maint.-I)

50 872 m

2535121

Mr. Nisar Malik TLW MGR (TLW) mgrtlw@nrlpak.com

81 797

Mr. Nasir HamidKha 32850 mgrkeamariterminal@n

KT MGR (KT)

n 213 rlpak.com

Mr. Badar Mirza Fire MGR (FP) 23 35060 mgr_fp@nrlpak.com

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Protection 58 873

23 35054

Dr. Hifzur Rehman Medical CMO cmo_nrl@nrlpak.com

27 711

Mr. Muzaffar AliKhic

Lube-I MGR Lube – I

hi

Maintenanc 25 mgrmaint_3@nrlpak.co

Mr. DawoodPanhwar MGR Maint-III -

e 52 m

Mr. Shahab AkbarRi 25 mgrprodfuel@nrlpak.co

Fuel MGR. (Off.) (Fuel)

zvi 68 m

24 35066

Mr. Rizwan A. Khan IT&S MGR (Off.) (IT&S) mgr_its@nrlpak.com

41 339

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Energy conservation is vital for today’s refinery economics to reduce per unit cost of

production and to protect Environment. NRL contributes to sustainable development

management through the integration of Environmental Social and Economic considerations

in its work environment. The recent introduction of 90 RON unleaded motor gasoline is a

further evidence of our concern towards good health and preservation of environment.

The primary function of the HSE Department is to explore opportunities for environment

improvement and energy conservation at Refinery Units, prepare and evaluate proposals

and implement them. NRL has an HSEQ policy which is the corner stone in its decision

making process to ensure compliance with the Environmental laws (NEQS) and achieve

continuous performance improvement.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Refinery consumes enormous quantity of thermal energy, supplied by combustion of fuel

oils and fuel gas at furnaces.Number of energy conservation projects have been

implemented at National Refinery, which has reduced energy consumption per barrel of

crude oil. Large quantities of liquid effluents and gaseous emissions are also encountered

in petroleum processing. Improvement programs are constantly undertaken at NRL to

combat pollution in respect of emissions and effluent waste water. Regular monitoring of

pollutants is carried out by testing of effluents and emissions samples to measure

environmental performance. In recognition to the reality that eventually sulphur will have

to be reduced in HSD to make it environment and health friendly, the management has

already initiated a preliminary feasibility study to put-up a hydro-desulphurisation plant

for reduction of sulphur to limits set by the government.

ISO 9001, ISO - 14001 & OHSAS – 18001Certification

In order that Quality Standards and Environment practices at NRL are according to

world standards, certification for Quality ISO 9001 Environment Management System

ISO-14001 has been acquired. Likewise, for controlling of work related health and

safety risks, OHSAS-18001, certification has been acquired. Implementation of ISO

9001, ISO 14001 AND OHSAS 18001 has put NRL as the pioneer in the country in areas

of Quality, Environment and occupational health & safety certification.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

National Refinery Limited is engaged in the manufacturing of a

wide range of petroleum products with the objective to achieve

sustainable productivity, profitability and high standards of safety,

occupational health and environmental care. This entails human

resource development, enhancing value addition, implementing

conservation measures and growth by up-gradation and addition

of newer generation technologies. The company solemnly believes

in the application of business ethics as have been embodied in this

The company requires all its

repute earned over the years can employees to essentially avoid

be maintained through continued conflict of interest between

conviction in our corporate values private financial activities and

of honesty, justice, integrity and their professional role in the

respect for people. The company conduct of company business.

The company is fully committed to

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

reliability and accuracy of financial

statements and transparency of

transactions in accordance with

established procedures and

derived from the above stated

practices

corporate values and are applied

to all facets of business through

well-established party procedures. The company does not support

These procedures define behavior any political party or contribute

expected from each employee in funds to groups having political

interests. The company will

however, promote its legitimate

business interests through trade

associations.

obligations which need to be

The company, consistent with its

commitments to sustainable

development, has a systematic

approach to the management of

Safeguarding of shareholders'

health, safety and environment.

interest and suitable return on

The company is committed to

providing products, which observe laws ofPakistan

offer value in terms of price, fully aware of its social

responsibility. It would assist the

safety and environmental community in activities such as

education, sports, environment

Respect human rights, provide preservation, training programs,

skills development and

employment within the

parameters of its commercial

employment, develop human objectives.

resource and be an equal

The company supports free

market system. It seeks to

business relationship with compete fairly and ethically within

contractors, suppliers and the framework of applicable

competition laws in the country.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

he company believes that profit The company will not stop others

from, competing freely with it.

efficiency and the value that the In view of the critical importance

customer places on products and of its business, and impact on

national economy, the company

provides all relevant information

about its activities to legitimate

he company requires honesty interested parties, subject to any

and fairness in all aspects of its overriding constraints of

business and in its relationships confidentiality and cost.

with all those with whom it does

offer, payment, soliciting

and accepting of bribe in any form

employees to essentially avoid

private financial activities and

conduct of company business.

Quality Control & Research & Development

Every product leaving the refinery has to conform to stringent international or national

specification requirements. In order to achieve the fine degree of control, extensive

monitoring of crude oil feed stock, intermediates and final products is conducted with the

aid of modern sophisticated analytical equipment in our Quality Control Laboratory. Usage

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

of NRL produced base oils by numerous national and international lubricating oil companies

for producing world class lubricants authenticates the supreme quality of our lube base oils.

NRL strives to satisfy the customers by providing best products within specifications.

The role of NRL Quality Control Laboratory is, however, not limited to Quality Control alone.

Research and Development work is carried out to give a basis for innovation in processes

and products.

NRL Quality Control Department, which was certified to ISO 9002 Quality Management

System in the year 2000. Currently entire Refinery is ISO 9001:2000 certified under

Integrated Management System (IMS), which include ISO 14001 and OHSAS 18001.

In order to facilitate relief activities for the internally displaced persons of Swat, Buner and

the surrounding areas, the Attock Group of Companies and their employees rushed forward

to help the affectees in their hour of need.

The NRL donated Rs. 2.5 million to the ‘Prime Minister’s Fund’ created for the purpose of

providing relief to those affected by terrorism.

Ensure that business policies and targets are in conformity with the national goals.

Contribute in meeting the country's demand of petroleum and petrochemical products

Customer's satisfaction by providing best value and quality products.

Optimization of the value of barrel of crude oil and cost reduction through

conservation measures

Achieving and maintaining a high standard of Occupational Health, Safety and

Environment.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Ensure reasonable return on shareholders' existing and projected investment.

Maintain modern management system conforming to international standards needed

for an efficient organization.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

S. Certification / Award Period

No.

1 Credit rating of the Company: Long-term “AAA” and 2010 -

Short-term 6 Consecutive year

th

“A-1+”

Pakistan Credit Rating Agency (PACRA)

2 BS-OHSAS 18001: 2007 for Safety 2010 -

Moody International 8th Consecutive year

3 ISO 14001: 2004 for Environment Management 2010 -8th Consecutive

System year

Moody International

4 ISO 9001: 2008 for Product Quality Control 2010 -

Moody International 4th Consecutive year

5 Annual Environment Excellence Award 2010 -

National Forum for Environment & Health (NFEH) 7th Consecutive year

6 Best Corporate Environment Reporting Award 2009 and 2003

ACCA / WWF Pakistan

7 Top 25 Companies Award 2004, 2003 and 1999

Karachi Stock Exchange

8 Businessmen of the year Gold Medal (Export) 2004

9 Special Merit Trophy (Export of Naphtha) 2002

Federation of Pakistan Chamber of Commerce & Industry

10 Export Trophy 2003 and 2002

Federation of Pakistan Chamber of Commerce & Industry

11 Best Presented Corporate Accounts/Reports Award 2004, 2002, 2001

Joint Committee of Institute of Chartered and 2000

Accountants of Pakistan (ICAP) and Institute of Cost &

Management Accountants of Pakistan (ICMAP)

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

SUPPLIER LUBE BASE OILS

SAUDI ARABIAN OIL COMPANY (SAUDI

• • SHELL PAKISTAN LTD.

ARAMCO)

•OIL & GAS DEVELOPMENT COMPANY LTD • PAKISTAN STATE OIL COMPANY LTD.

•BRITISH PETROLEUM CHEVRON PAKISTAN LTD.

•

•E.N.I PAKISTAN LTD TOTAL ATLAS LUBRICANTS

•

ASPHALT

• ATTOCK PETROLEUM LIMITED (APL)

SPECIALTY PRODUCTS

CUSTOMER • ATTOCK PETROLEUM LIMITED (APL)

FUEL PRODUCTS

•ATTOCK PETROLEUM LIMITED (APL)

•PAKISTAN STATE OIL COMPANY LTD.

•SHELL PAKISTAN LTD.

•CHEVRON PAKISTAN LTD.

•TOTAL PARCO PAKISTAN LTD.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

The products manufactured at NRL

• Motor Gasoline (MOGAS)

• Kerosene (SKO)

• Jet A-1

• JP-8

• High Speed diesel Oil (HSD)

• Light diesel oil (LDO)

• Furnace Oil (F.O)

• Liquefied Petroleum Gas (LPG)

• Naphtha (For Export)

The products manufactured at NRL

•65N-HVI

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

•100N-HVI

•150N-HVI

•400N-HVI

•500-HVI

•BS-HVI

•100N-MVI

•650N-MVI

•BSMVI

LUBE BASE OILS

GUARANTEED LUBE BASE OIL SPECIFICATIONS

Flash Acid

Age

Point C(C

o

Colo Numbe

d

Pour OC) r r mg

Viscosity cS ConradsonCarbo Colo

PointDegr ASTM D- AST KOH/g

VI t. nwt.% D-189 r D-

PRODUC ee C

o

92 M D- of Lube

Mi ASTM D-445 D-97 Max Max 150

T 1500 ASTM

n Min. 0

Max D-974

Max

Max

Mi Ma Degr

n x ee C

18. 21. 0.0

100N-HVI 95 40 -6 177 0.04 1.5 -

5 0 5

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

10. 0.0

400N-HVI 95 9.4 100 -6 227 0.15 2.5 3

4 5

32. 37. 0.0

BS-HVI 95 100 -3 280 1.20 5.0 6

0 0 5

100N- 20. 24. 0.0

80 40 -6 177 - 2.0 3

MVI 0 0 5

35. 42. 0.0

BS-MVI 65 100 -3 280 - 8 -

0 0 5

650N- 10. 11. 0.0

60 100 -3 227 - 5.5 -

MVI 6 6 5

10. 12. 130 0.0

65N-HVI 95 40 -9 0.04 1.5 -

0 0 5

28. 32. 0.0

150N-HVI 95 40 -6 180 0.10 2.0 -

5 0 5

10. 11. 0.0

500N-HVI 95 100 -6 227 0.18 3.5 -

5 5 5

PMCC ASTM D-93 TEST METHOD

Paving Grade

40/50

Paving Grade

60/70

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Paving Grade

80/100

ASPHALT TESTING METHODS

S.No. TEST TEST METHOD

1. Specific Gravity at 25 / 25 Deg. C ASTM D – 70

2. Flash Point, Deg. C (Min.) ASTM D – 92

3. Softening Point R&B, Deg. C ASTM D – 36

4. Penetration at 25 C 100g, 5 sec, 1/10 mm ASTM D – 5

5. Ductility, at 25 Deg. C 5 cm, per min, cm (Min.) ASTM D– 113

Loss on heating at:

6. ASTM D – 6

163 Deg. C, 5 hrs Percent wt. (Max.)

Penetration after loss on heating test 25 Deg. C, ASTM D – 6

7.

100g, 5 sec % of Original (Min.) ASTM D – 5

8. Solubility in Carbon Tetrachloride % wt. (Min.) ASTM D–2042

ASPHALT SPECIFICATIONS (40/50)

S.No. TEST SPECIFICATIONS

1. Specific Gravity at 25 / 25 Deg. C 1.01-1.06

2. Flash Point, Deg. C (Min.) 232

3. Softening Point R&B, Deg. C 50-60

4. Penetration at 25 C 100g, 5 sec, 1/10 mm 40-50

5. Ductility, at 25 Deg. C 5 cm, per min, cm (Min.) 100

Loss on heating at:

6. 0.2

163 Deg. C, 5 hrs Percent wt. (Max.)

Penetration after loss on heating test 25 Deg. C,

7. 75

100g, 5 sec % of Original (Min.)

8. Solubility in Carbon Tetrachloride % wt. (Min.) 99

ASPHALT SPECIFICATIONS (60/70)

S.No. TEST SPECIFICATIONS

1. Specific Gravity at 25 / 25 Deg. C 1.01-1.06

2. Flash Point, Deg. C (Min.) 232

3. Softening Point R&B, Deg. C 46-57

4. Penetration at 25 C 100g, 5 sec, 1/10 mm 60-70

5. Ductility, at 25 Deg. C 5 cm, per min, cm (Min.) 100

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Loss on heating at:

6. 0.2

163 Deg. C, 5 hrs Percent wt. (Max.)

Penetration after loss on heating test 25 Deg. C,

7. 75

100g, 5 sec % of Original (Min.)

8. Solubility in Carbon Tetrachloride % wt. (Min.) 99

ASPHALT SPECIFICATIONS (80/100)

S.No. TEST SPECIFICATIONS

1. Specific Gravity at 25 / 25 Deg. C 1.01-1.06

2. Flash Point, Deg. C (Min.) 232

3. Softening Point R&B, Deg. C 43-54

4. Penetration at 25 C 100g, 5 sec, 1/10 mm 80-100

5. Ductility, at 25 Deg. C 5 cm, per min, cm (Min.) 100

Loss on heating at:

6. 0.5

163 Deg. C, 5 hrs Percent wt. (Max.)

Penetration after loss on heating test 25 Deg. C,

7. 75

100g, 5 sec % of Original (Min.)

8. Solubility in Carbon Tetrachloride % wt. (Min.) 99

Benzene

Toluene

Xylene

Wax

Slack Wax

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Rubber Process Oil

LOW MELT SLACK WAX SPECIFICATIONS)

S.N

TEST TEST METHOD SPEC. LIMIT

o.

1. SPECIFIC GRAVITY AT 60/60°F ASTM D-1298 MAX 0.88

2. VISCOSITY AT 100 °C, cSt ASTM D-445 MAX 5

3. OIL CONTENT % WT. ASTM D-721 MAX 40

4. MELTING POINT, °C ASTM D-127 MIN 42

5. COLOR ASTM ASTM D-1500 MAX 2.5

2. VISCOSITY AT 100 °C, cSt ASTM D-445 MAX 5

MEDIUM MELT SLACK WAX SPECIFICATIONS

S.N

TEST TEST METHOD SPEC. LIMIT

o.

1. SPECIFIC GRAVITY AT 60/60°F ASTM D-1298 MAX 0.90

2. VISCOSITY AT 100 °C, cSt ASTM D-445 MAX 8.5

3. OIL CONTENT % WT. ASTM D-721 MAX 40

4. MELTING POINT, °C ASTM D-127 MIN 50

5. COLOR ASTM ASTM D-1500 MAX 6.0

HIGH MELT SLACK WAX SPECIFICATIONS

S.N

TEST TEST METHOD SPEC. LIMIT

o.

1. SPECIFIC GRAVITY AT 60/60°F ASTM D-1298 MAX 0.92

2. VISCOSITY AT 100 °C, cSt ASTM D-445 MAX 30

3. OIL CONTENT % WT. ASTM D-721 MAX 40

4. MELTING POINT, °C ASTM D-127 MIN 68

5. COLOR ASTM ASTM D-1500 MAX 8.0

RUBBER PROCESS OIL SPECIFICATIONS

S.N

TEST TEST METHOD SPEC. LIMIT

o.

1. SPECIFIC GRAVITY AT 60/60°F ASTM D-1298 0.961 - 1.046

2. FLASH POINT (COC), °C ASTM D-92 MIN 204

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

VISCOSITY KINEMATIC AT 100

3. ASTM D-445 14 - 37

°C, cSt

VISCOSITY KINEMATIC AT 54

4. ASTM D-445 MAX 43

°C, cSt

5 POUR POINT, °C ASTM D-97 MAX +27

6 ANILINE POINT °C ASTM D-611 43 - 60

VISCOSITY GRAVITY CONSTANT

7 ASTM D-2501 0.94 - 0.99

(VGC)

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

HUMAN RESOURCE DEVELOPMENT

Petroleum Refining involves complex and hazardous operations, therefore, a high degree of skill

and efficiency is required for its safe operation. In order to meet this requirement, freshly qualified

professional degree holders are employed as Trainees under a Management Trainees Scheme. The

duration of Training is normally one year which may be increased or decreased depending upon

performance of the Trainee during training. Initially, the Trainees are acquainted with theoretical

concepts involved in Petroleum Refining and then they are deputed to different functional areas

for practical training. The lectures on theoretical concepts are delivered by professionals working

in Refinery having extensive experience besides possessing professional degree in the relevant

field. The Trainees are periodically evaluated to gauge their level of knowledge and skill attained

and accordingly their training program is reviewed and also revised if necessary.

Similarly, there is an Apprenticeship scheme whereby professional Diploma Holders and

Intermediates in Science are provided Training in Refinery Operations and Maintenance. The

duration of training in this scheme is 2 years for Diploma Holders and 3 years for Intermediates.

Besides training of fresh professionals, the professionals already working in NRL are also provided

training in order to update their knowledge with the latest developments in their field by

conducting Continuing Professional Development Programs.

HUMAN RESOURCE

Human Resource is the most valuable asset of Refinery as professionals trained in Refinery

Operations and Maintenance are not easily available. The human resource consists of

Management, Non-Management and Contractor staff and their total present strength is more than

1200.

In order to meet their genuine needs for maintaining good living standard and good health, there

are various benefit schemes besides Salary, notable among those are:-

o Medical Assistance for Self and Family

o Leave Fare Assistance

o Children’s Education Scholarship for Workmen

o Car Loan (Interest Free)

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

o Club Membership for Managers and above

o Membership of Professional Institution

o Hajj on Company expenses for Workmen

o Housing Assistance Scheme (Interest Free)

o Pension and Gratuity

NRL maintains a port terminal installation located at Keamari oils peers about 18 km from the

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Refinery premises. The Keamari Terminal is connected with the main Refinery through pipelines.

Very large Crude Oil storage tanks at Keamari Terminal receive imported Crude from the oil

tankers, which is then transferred to the Refinery through pipeline. Huge tankages are available

for export of Naphtha, which is also handled at Keamari Terminal.

Fuel products from the Refinery are pumped via Keamari Terminal manifolds to Oil Marketing

Companies, located adjoining Keamari Terminal

NRL’s two Lube Refineries were installed with a time gap of nearly 19 years with each

other. The starting point of first Lube Refinery is a Crude Distillation Unit and subsequent

Vacuum Distillation Unit, whereas the Second Lube Refinery directly starts with a Vacuum

Distillation as it takes feedstock from Fuel Refinery’s Crude Distillation Unit. Whereas the

downstream process units are same in basic technology, the Second Lube Refinery being

designed in Eighties has more sophisticated, advanced and energy efficient plants.

Atmospheric & Vacuum Distillation Units

The primary process unit of the Lube-I Refinery is distillation of electrically Desalted Crude

Oil in two stages. In the first stage, the atmospheric distillation; the relatively light fuel

components, Gases, Naphtha, Kerosene and Light Diesel Oil are separated from the parent

Crude Oil. The remaining reduced crude (Furnace Oil) is then processed under vacuum in

the second distillation stage to produce Gas Oil (Diesel), Lubricating Oil Distillates and

Vacuum Residue.

The second Lube Refinery starts with a vacuum distillation unit. The feedstock (Reduced

Crude) obtained from Fuel Refinery is converted into High Speed Diesel Oil, Light Diesel

Oil, Lubricating Oil Distillates and Vacuum Residue.

Propane Deasphalting Units

The heaviest residual portion of the vacuum distillation is channeled through this unit for

the production of the heavy lubricating oils and asphalts. The separation of these two

intermediates is effected at this unit by a Propane Solvent Extraction process. Same PDA

unit installed at second Lube Refinery is designed with an improved extraction of heavy

lubricating oil with minimal losses of Propane Solvent and energy.

Furfural Extraction Units

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Lubricating oils distillates from Two-Stage Unit and from Propane Deasphalting Unit are

processed here turn by turn, for extraction of undesirable hydrocarbons with furfural

solvent. This improves the colour of the oils and enhances their ability to maintain their

lubricating properties under varying temperature conditions. Nine intermediate lube base

oils are produced at this unit, which are called Raffinates. The ‘undesirables’ for lubes

called Extracts are sent to the refinery asphalt production unit or sold as Speciality Oil.

The Furfural Extraction Unit installed in second Lube Refinery, employs advanced

techniques ensuring better solvent recovery and energy conservation.

M.E.K. Dewaxing Units

In this unit, the wax content in Raffinates coming from Furfural Extraction Units is removed

by process of extraction with a mixture of Methyl Ethyl Ketone (MEK) & Toluene solvent

mixture. Subsequent filtration at very low temperature is achieved by a process of Propane

refrigeration. All the nine lube intermediates from the Furfural Extraction Unit are

subjected, in blocked-out operation to this dewaxing process. This process improves pour

point or cold flow properties of lubricating oil. The wax separated in the process is also

marketed as a product called Slack Wax.

At M..E.K. Dewaxing Unit of Lube-II Refinery, the process has been improved which has

resulted in higher yields and has considerably reduced solvent losses. Provisions have also

been made in the process for the maximum heat recovery thereby improving the

efficiency.

Hydrofinishing Unit

In this final processing stage, the lube base oils are stabilized and their colour is further

improved by hydrogenation under severe operating conditions in the presence of a

catalyst.

The hydrofinished lube oils are dispatched to refinery storage tanks for distribution to Oil

Marketing/Lube Oil Blending Companies.

Asphalt Air Blowing Unit

The residual effluents from the two Propane De-Asphalting and Furfural Extraction Units

are blended and oxidized with air for the production of paving and industrial grade

asphalts. Currently not in operation.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Crude Distillation Unit

In all refineries, crude distillation is the starting point of the refining operations. The Fuel

Refinery’s Atmospheric Crude Distillation Unit, therefore, serves the primary purpose of

separating the desalted crude oils into its fuel components; Gases, LPG, Naphtha,

Kerosene, High Speed Diesel and Furnace Oil for down-stream processing. The overhead

product of distillation column is Straight Run Naphtha. This is passed through a stabilizer

column to recover LPG. The stabilized Naphtha enters into a splitter column, Light Naphtha

is obtained from the top and Heavy Naphtha from the bottom of the splitter column. Light

Naphtha is used for Gasoline blending whereas major part of Heavy Naphtha is upgraded at

Platforming unit. Naphtha is also exported as feedstock for petrochemical plants.

This Crude Distillation Unit has been revamped for capacity enhancement by about 45% in

which a pre-flash unit was added and the heat exchanger scheme was optimized. This way

the capacity enhancement was made possible without additional fuel oil consumption.

After the revamp ;the pre-heated crude feed is now pre-flashed in a column to recover

maximum of its Naphtha. The pre-flashed crude then follows the conventional flow scheme

as narrated above.

Naphtha Hydrobon Unit

This unit is designed to hydrotreat the Heavy Naphtha fraction produced in Crude

Distillation Units of the Lube and Fuel refineries. Sulphur and Nitrogen are poisons for

reforming catalyst hence removed by Hydro treating Naphtha.

This is a high severity process operated in the presence of a catalyst and hydrogen.

Platforming Unit

The term “Platforming” is applied to catalytic reforming process where chemical conversion

of the hydrocarbon feed is achieved on a bed of platinum based catalyst under extreme

conditions of pressure and temperature. Hydrotreated Naphtha is the feed to this unit

which is converted into high Octane Motor Gasoline.

As part of the Balancing & Modernization Project, the Platforming Unit has also been

revamped for capacity enhancement by 72% of design. Adoption of Radial Flow Reactors

and new improved catalyst has further enhanced the performance and operating cycle of

the unit.

Kero Hydrobon Unit

Essentially similar to the Naphtha hydrotreating process; this unit further refines Sour

Kerosene feedstock into the commercial Aviation Turbine Fuel, JP-1 by catalytic hydro

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

treating. The fuel used in the Military Air Crafts JP-4 is also produced at Fuel Refinery by

blending JP-1 and Naphtha. Currently not in operation.

Liquefied Petroleum Gas (LPG)

Naphtha and Kerosene Sweetening Units

Liquefied Petroleum Gas (LPG) from the Crude Distillation Unit is sweetened at Merox units

and thus deodorized in the presence of catalyst and sent to storage for consumer off-take.

Naphtha and Kerosene are also sweetened at Merox and Bender units to eliminate odour

and corrosive compounds before pumping to Marketing Companies.

Propane Recovery Unit

Liquefied Petroleum Gas (LPG) from Platforming Unit is subjected to further fractional

process for production of high purity refrigeration grade Propane. Propane is used in-house

as solvent and for refrigeration purposes in NRL’s Lube Refinery processes.

Based on Reformate as feedstock from the Fuel Refinery, the unit is designed to extract

the aromatics by SHELL Sulfolane Extraction process. This aromatic mixture is fractionated

through multistage distillation for the production of high purity Benzene, Toluene and

Xylenes. To achieve fine degree of process control required, this unit is equipped with

ultra-sophisticated instrumentation. NRL owns the only BTX plant of the country, meeting

the demands of Paints, Pesticides & explosive manufacturing industries.

National Refinery utilizes a large Number of utilities to support the manufacturing at

production units. The supply of water, steam, fuel and air is the assignment of Utilities

Department. A comprehensive utilities complex exists to meet the refinery’s requirements

of utilities, steam, condensate, cooling water, instrument/plant air and fuels. This consists

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

of three Demin / Water Treatment plants, three condensate recovery plants, five high

pressure steam boilers, four induced draft cooling towers, a number of

instrumentation/plant air compressors and two units for refinery fuel gas and fuel oil

system. This all operate round the clock for smooth operation of the entire Refinery.

Power Generation

Recently, National Refinery has completed its project of Self-Power Generation. Self-Power

Generation plant has a 7.5 MW steam turbo-generator and a 4.0 MW Diesel-Fuel Oil Engine

Power Generator.

The self-power generation is meant for continuous uninterrupted power supply and to

avoid plant shut-down and production loss due to power break- down.

Oil Movement and Shipping

Huge quantity and variety of crude oils, about 3 million ton per annum and about equal

tonnage distributed in about thirty products are handled at NRL. For this, elaborate system

of pumping stations, pipelines, tankage and loading gantries are maintained. The inventory

of crude oil and products stored at refinery tankage has enormous monetary value. This

operation involves receipt and transfer of crude oil from port terminal, inland domestic

crude oil receipts, transfer to and receipts from processing units, product transfer to Oil

Marketing Companies, product shipment through tank lorry filling gantries.

A whole maze of pipelines and over one hundred and fifty crude oil and product storage

tanks are utilized for this purpose. Shipping Department works side-by-side with Oil

Movement to facilitate documentations and coordination with Excise Authorities.

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

No. of No. of % on

SHAREHOLDERS' CATEGORY Sharehol Shares Issu

der Held ed

50.0

Associated Companies 2 39,983,280

0

Individuals 3,976 6,950,640 8.69

Investment Companies 4 21,838 0.02

Joint Stock Companies 20 1,243,773 1.56

11.5

NIT/NBP/ICP 10 9,269,514 9

24.4

Banks, Insurance, Modaraba & Mutual Fund 91 19,552,910 5

Foreign investors 18 2,094,009 2.62

Charitable Trusts 12 140,865 0.18

Others 47 709,731 0.89

100.

4,180 79,966,560 00

INFORMATION AS REQUIRED UNDER CODE OF CORPORATE GOVERNANCE

Associated Companies 2 39,983,280

NIT & ICP

IDBP (ICP Unit) 1 339

National Investment Trust 3 518,764

National Bank of Pakistan Trustee Department 1 4,680,392

NBP Trustee-NI(U)T (LOC) Fund 1 4,069,502

National Bank of Pakistan 2 51

Investment Corporation of Pakistan 2 466

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

Designed & Developed by AN Interactive copyright © 2004 NATIONAL REFINERY LIMITED

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fleet Maintenance-Tyre ManagementDocument17 pagesFleet Maintenance-Tyre ManagementNeulers0% (1)

- CodesDocument9 pagesCodesAbdulkarim Khatri AbbanNo ratings yet

- SX 2000 SX 2000 SX 2000 SX 2000 SX 2000 SX 2000Document6 pagesSX 2000 SX 2000 SX 2000 SX 2000 SX 2000 SX 2000Abdulkarim Khatri AbbanNo ratings yet

- AbstractDocument1 pageAbstractAbdulkarim Khatri AbbanNo ratings yet

- Tour Theme - Classical & Cultural India TourDocument14 pagesTour Theme - Classical & Cultural India TourAbdulkarim Khatri AbbanNo ratings yet

- ScanSnap Ix500 TroubleshootDocument58 pagesScanSnap Ix500 TroubleshootrajinbacaNo ratings yet

- Relay Board Connection InstructionDocument6 pagesRelay Board Connection Instructionkum512No ratings yet

- Topic 6 Fields and Forces and Topic 9 Motion in FieldsDocument30 pagesTopic 6 Fields and Forces and Topic 9 Motion in Fieldsgloria11111No ratings yet

- Sonic Logging: M. P. Tixier R. P. AlgerDocument9 pagesSonic Logging: M. P. Tixier R. P. Algersaeed65No ratings yet

- Parts List 38 269 22 95: Helical-Bevel Gear Unit KA107, KH107, KV107, KT107, KA107B, KH107B, KV107B, KT107BDocument4 pagesParts List 38 269 22 95: Helical-Bevel Gear Unit KA107, KH107, KV107, KT107, KA107B, KH107B, KV107B, KT107BFotografia PopularNo ratings yet

- Hzt. Ammar e Yaser (R.a.)Document88 pagesHzt. Ammar e Yaser (R.a.)naqvi202No ratings yet

- ACS712 DatasheetDocument15 pagesACS712 DatasheetwirawansatriaNo ratings yet

- Truck Unloading Station111Document4 pagesTruck Unloading Station111ekrem0867No ratings yet

- Requirements For Occupation Certificates For New BuildingsDocument1 pageRequirements For Occupation Certificates For New BuildingsBernard MusonaNo ratings yet

- Warmttouch Manual TecnicoDocument113 pagesWarmttouch Manual TecnicoLeandro MontaldoNo ratings yet

- 고압세척기 메뉴얼Document51 pages고압세척기 메뉴얼박일호No ratings yet

- 00-Saip-06 Pressure TestDocument4 pages00-Saip-06 Pressure TestUzair AhmadNo ratings yet

- Fro 15210C 0510Document36 pagesFro 15210C 0510davisNo ratings yet

- Why It Does Not MatterDocument31 pagesWhy It Does Not MatterDavid I AgogoNo ratings yet

- CIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteDocument11 pagesCIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteVNo ratings yet

- Software Slope Stabilty Analysis FinalDocument1 pageSoftware Slope Stabilty Analysis FinalETTL UDAIPURNo ratings yet

- Tandy's Septic PlanDocument1 pageTandy's Septic PlanPeter AchiengNo ratings yet

- Home Security SystemDocument8 pagesHome Security SystemBiplav ChoudhuryNo ratings yet

- Inkjet RefillingDocument5 pagesInkjet RefillingpedroNo ratings yet

- GL1200. .Service - ManualDocument415 pagesGL1200. .Service - ManualIpavec RokNo ratings yet

- What Is Cloud ComputingDocument21 pagesWhat Is Cloud ComputinganilkarriiNo ratings yet

- Klasifikasi Material: Myrna Ariati Wahyuaji Narottama PutraDocument49 pagesKlasifikasi Material: Myrna Ariati Wahyuaji Narottama Putrachink07No ratings yet

- Copyright ProtectionDocument6 pagesCopyright ProtectionKamalbir KaurNo ratings yet

- Alpha BasicDocument190 pagesAlpha Basicmiguel_pinheiro_10No ratings yet

- Earth Bulge and Path ProfileDocument3 pagesEarth Bulge and Path ProfileTim LazaroNo ratings yet

- Noncontact Vital Sensing With A Miniaturized 2.4 GHZ Circularly Polarized Doppler RadarDocument4 pagesNoncontact Vital Sensing With A Miniaturized 2.4 GHZ Circularly Polarized Doppler RadarkhyatichavdaNo ratings yet

- Topic 2 Beam DesignDocument32 pagesTopic 2 Beam DesignMuhd FareezNo ratings yet

- Wireless Room Freshener Spraying Robot With Video VisionDocument5 pagesWireless Room Freshener Spraying Robot With Video Visionsai thesisNo ratings yet

- Arbore Cotit DesenDocument1 pageArbore Cotit DesenIonel Bogdan NeacșuNo ratings yet