Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

20 viewsMuhammad Fahad Israr (F2018132032)

Muhammad Fahad Israr (F2018132032)

Uploaded by

Israr MuhammadCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lecture 3 - Trip Generation: Transportation PlanningDocument49 pagesLecture 3 - Trip Generation: Transportation PlanningIsrar MuhammadNo ratings yet

- Hydrology PosterDocument1 pageHydrology PosterIsrar MuhammadNo ratings yet

- To Study The Bending Behavior of Z SectionDocument8 pagesTo Study The Bending Behavior of Z SectionIsrar MuhammadNo ratings yet

- Transportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreDocument3 pagesTransportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreIsrar MuhammadNo ratings yet

- Transportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreDocument3 pagesTransportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreIsrar MuhammadNo ratings yet

- Experiment No. 1 Determination of Standard Consistency of Hydraulic CementDocument4 pagesExperiment No. 1 Determination of Standard Consistency of Hydraulic CementIsrar MuhammadNo ratings yet

- Transportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreDocument3 pagesTransportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreIsrar MuhammadNo ratings yet

- Experiment No 1Document20 pagesExperiment No 1Israr MuhammadNo ratings yet

- Hydrology and Water Resources ManagementDocument7 pagesHydrology and Water Resources ManagementIsrar MuhammadNo ratings yet

- Resource Person: H M Osaid UMT, LahoreDocument47 pagesResource Person: H M Osaid UMT, LahoreIsrar MuhammadNo ratings yet

- Basic Concepts in EthicsDocument36 pagesBasic Concepts in EthicsIsrar MuhammadNo ratings yet

- Hm-221 Social and Ethical Aspects in EngineeringDocument31 pagesHm-221 Social and Ethical Aspects in EngineeringIsrar MuhammadNo ratings yet

Muhammad Fahad Israr (F2018132032)

Muhammad Fahad Israr (F2018132032)

Uploaded by

Israr Muhammad0 ratings0% found this document useful (0 votes)

20 views84 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

20 views84 pagesMuhammad Fahad Israr (F2018132032)

Muhammad Fahad Israr (F2018132032)

Uploaded by

Israr MuhammadCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 84

pared

vey ane Abana

of

Ce-352L Advanced Fuld Machanes Lab

mesttonser Irony de dary Ge)

suntoene: FZ0IVI720 32 se AL

[examine nin nd rb win

* peoccuom

aed el ce

t

wre

i aa [otrbne oot crm aca atcoine 6

lor PsvcHOMOTOR OOMAIN (3) (CLO-5

4 frtenar be rendings of preaure end | an _| Matric eae et

sata

Ler kttcteeioss

[ing ochometer 2 | aadettarg .so| Mavtearnayects) |" aswrnay O63 \

[AFFECTIVE DOMAINCA wn A) (CLO.3 0)

Tore

x ten ea | ant nenees om | eet

fel cn Noe | [ \

[fous ao es a =

- fariemeneonias |» ps 7 ce

oaaeoem | a - =| \

* |session (42) (CLO-4)

a prey : oS ~ | |

cv

1 fees ib repet(A3)(CLO“D | ‘\

Total Marks:

Instructor's Signature:

Scanned with CamScanner

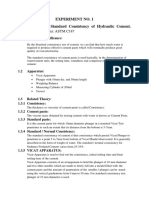

piMENT NO: |

¢ of un form

EXPE diameter (d) and

T ip

To measure the head loss (li) in a PH

to investigate:

Critical Reynold’s Number

Relationship between hydra gradi

Relationship between frietion factor and

locity of 08

Number.

sit and Ve

eynalds

1, Apparatus:

1, Hydraulic Bench

2. Stop Watch

3. Thermometer.

1.1 Related Theory

1, Laminar Flow

ticles move in laminations and the paths of the fluid particles

The type of flow in which fluid part component of velocity i. in the

do not intersect each other. The fluid particles have only one

direction of flow. In this flow, viscous forces are dominant.

For laminar flow in pipes, Reynolds Number is generally less than 2000.

2. Turbulent Flow

The type of flow in which the particles of fluid move in a disorderly manner, and the paths of the

fluid particles intersect cach other, In this type of flow, fluid particles do have velocity

components in lateral directions. Usually, it is answered that turbulent-flow takes place in pipes

when the Reynolds Number exceeds 2000.

3. Critical point

It is the point on Log i verses Log V curve at which flow changes from laminar to turbulent or

vice versa.

ee

Scanned with CamScanner

4. Critical Velocity

Tis the velocity of fo

‘SrEO OF itis Pe at which flow jn the om laminar to turbulent

nge! inar to 1

i w pipe changes f

orviee versa : fe

* Velocity comesponding to critical point.

5: Critical Reynolas Number

Itis the Reynold's Number at which flow changes from laminar to turbulent or vice versa or the

Reynolds Number Coresponding to critical point

yughness. the

For normal cases of the flow in straight pipes of uniform diameter and usual rough

Critical Reynolds Number ‘Value may be taken as 2000 (Daugherty , 1989)

Figure 1.1: Loj

smooth- Wall

——- rW@

log plot for flow in a uniform pipe, (n=2.00,rough wall pipe; n=1.75

\e.) (Daugherty, 1989)

Scanned with CamScanner

6. Higher eri o turbulent.

al point sanow enanges romain

eis the point on Log (i) Verses Log (V) eu

7. Higher ci

ical velocity fo turbulent or the

ing to higher

at which Mow

It is the velocity: of Now in the pipe

locity of Now in the pip or it is fl

critical velocity. in the ascending order of Mow

critical point

8. Hi i e) be

ligher Critical Reynolds Number jene in the ascending

m laminar to turbul

itical point

It is the Reynolds number at which Mow changes from

order of flow or the Reynolds number corresponding (© higher er a

jn circular pips has been maintained up to

in (Daugherty, 1989)

Iewanie # about ut laminar flow

flue is normally about 4000, but sat disturbance

50,000 depending upon the care taken to prevent any 10"

9. Lower Critical point

hen flow changes from turbulent fo Jaminar

It is the point on Log (i) versus Log (V) curve wh

10. Lower Critical velocity

om turbulent to Jaminar or it is the

It is the velocity of flow in the pipe at which flow changes fe

velocity corresponding to lower critical point.

11. Lower critical Reynold’s Number

It is the Reynolds Number at which flow changes from turbulent to laminar or the Reynolds

Number corresponding to lower critical point. Its value is 2000.

12. True Critical Reynold’s Number

It is the Reynolds Number corresponding to lower critical point. It is true critical Reynolds

Number as whatever is the order of flow, flow is always laminar below this point.

For all practical purposes Critical Reynolds Number is taken as 2000.

13. Pipe

it is a conduit (circular or non-circular) in which a fluid flows under pressure by completely

wetting its internal perimeter.

Scanned with CamScanner

14. Head

Itis a y , 7

he energy of water per unit weight. Units of head are m of liquids.

15, Head Loss

Itis the loss of energy

4 Per unit weight within a passage of the fluid. Total head loss is the sum of

major and minor head

losses,

hL = hf +E(hm)

‘Where bis the toxl loss of head hr'is the head loss due to ition and (hm) is the surnmation

of all minor head losses,

1.2 Fluid Friction Apparatu

Tt consists of a long pipe of known diameter (d); one end of the pipe is connected to @ pump

‘wihile the other end is free. A valve is connected to the free end to contzol the discharge. A

Container is placed under the free end to collect the water for measuring the discharge. The pipe

is connected with a differential manometer at two points near both the ends as shown in Figure

1.3 to measure the difference of pressure heads and then head loss.

1.3 Differential Manometer

It is a device to measure the difference of pressure heads between the two sections where it is

connected.

aa

Figure 1.2 Conceptual diagram of the Fluid Friction Apparatus

Scanned with CamScanner

1.4 Setting of i

ntl

tubes of DiNTere"

The process of removal of air from the

setting of Differential Manometer.

15 vernit ie

Governing Equations scnae ie moss

of the pipe D

From the container placed under the free €n

Volume

Q=—me

time

¢ computed a

in the pipe can bs

Q

Vea

So the velocity of the flvid flo.

; si

Hence putting the values of diameter of pipe. velocity and viseo

Reynolds Number.

vD

RNa

red aS

ty of the fluid We

can find the

—..wc—

Scanned with CamScanner

Fluid Friction Apparatus

1.6 Procedure

1. Mei

Measure the length of the pipe between the two sections and the room temperature.

2. Switch on the motor of the pump

5. Perform Setting of Differential Manometer.

4. Close the valve and not the zero error reading.

5. Slightly open the valve and note down

* Time (1), to collect known volume of water, with the help of stopwatch.

© Differential monomeric reading (hI and h2).

6. Repeat step 5 by opening the valve gradually till the full valve opening is achieved.

7. Switch off the motor of the pump.

1.7 Precautions

1. Setting of Differential Manometer must be carried out before starting the observation

Zero error reading should be observed after carrying out the Setting of the Differential

2.

Manometer.

— 8

Scanned with CamScanner

Fapression

between SV for | |

wwrbulent ow |

a)Relationship 0 eR

between fand RNfor | Y= 1 f= hu

laminar flow met

b)Relationship crolt <

between F& RN for | = |) f

turbulent flow soe tH

Table 1.1: Table

of Observations

Description

Values

Units

Temperature

DAD.

cedsios

lootZTx lo”

“4

|

| Kinematic Viscosity

| ‘Length of pipe

|

| | —} 1 —-—

pipe

0+ 000176

| Volume of container :

| ©- 005 re

Diameter of pipe

Ta

Cross sectional area of a

Zero correction

Scanned with CamScanner

cr ‘i ions

Table 1.2: Table of Observations & Calculat

—— —+T7 1 |

glee cl a] 2) 28/24

B) 25 2] é eee a

a/aa] 2] 2| 2] 23]24

Z/Sc} F] & | 7 [elle 2

= al 4) 2) BI

Ne | 2 3\ 8

Mls Timjsec| - | *

1 FOaleT oy s15 S08

2 Pee oy He

3 [35eo"}o-967.

4 hy hes 5-258,

5 Hasvs) . pRbNs p

6 IO DATS .

7 1yle'|o-465 side

; yy

8 5 [r!] 2 Aa

9 \Bixts 9-15?

10 l22oxh'} 1251

Hn

12 |

Scanned with CamScanner

Ha

_ ex

Scanned with CamScanner

Goa tos ao ard depts)

Scanned with CamScanner

Scanned with CamScanner

Scanned with CamScanner

Scanned with CamScanner

Scanned with CamScanner

Scanned with CamScanner

"Eee = Goa he Fay aed Ap

0 otc

Scanned with CamScanner

it Contortiton xh blr Fexp aed y

wat: pep eee

Scanned with CamScanner

1.9 Comments

(hy expertmenk ota setking €

- , tu vt aa a

I Hlowrd ch meromtix van eat hore befow- heed

de ts heh Urine wove onery Prolene

I

™ sey aby Lenkare Qo weaker in

the aPPerekus Th ceve. Covvectina bes

¢

ates aed check

inbod uc ed Some

ro.

which Co Ad Reve

Scanned with CamScanner

J

Lr

School of Engineering Aer st Means 29

‘Prepared by: Boge Ala Nie

CE-352L Advanced Fluid Mechanies Lab

Mesttspeinens i PvIre to mentoos Preci¢he aeimattas QZ

Beguundoanae Y Lol§\Z2032 se AA bas

lo) coonreve postr cent. 4 2)

x ates cit Levels orAtsiament a

1 [Esaming laminas nd tutes tein | ag Seamer tome! | Sows

fren tcLoen an-15) detertind (26-28),

2 [Peteinee imp foreomdetecirs | ag (gitar Scertate.| “eiassyeniay” | neers

EE 1% ‘determing (11-15) ‘determin (16-20),

scans beeen spe rg Foieo sath eva | aesesiawer

, raat | asta Sree

eco f “

[apesvewoworon powats en (0%

4 Siena rdapsstrmnrebed | 20 ‘Stacey pasongco|

Jtsere te var weg te

«lfc and minnie dcoree | 38

lr pier peaee

overesselndsonhngerd rpm ty | gy | tatintr nt

© lasing chomeser evened nvaraay (0-10)

|

le AFFECTIVE DOMAIN (A nA) (CLO on 0

a can rT mi ee

> [Fotns ub CLO * a [oe

7 [ramuvimeiereaeton | ve ia ;

eave and opentadareasien |g we io Le

* Session (A2) (CLO)

esis oe inert) . is &

'* \icLo4y

1 [sa pe (9) (CLO 2 a i

Toast “ou Obtained Mai

Instructor's Sigatore:

Scanned with CamScanner

To verify the “Impulse Momentum Principle” for a jet of water

striking on 90°,120° and 180° deflectors and to investigate the effect

of velocity of flow on impulse force of the jet for various deflectors.

> Apparatus:-

Impact of Jet apparatus with deflectors(90",

© Hydraulic Bench

Stop Watch

0°, 180°)

© Thermometer

Related Theory

> Impulse Momentum Principle:

‘According to impulse momentum principle, the algebraic sum of all the external forces

‘acting on the contro] volume of the fluid is equal to the rate of change of momentum

(Doughlas. 2003)

According to the Newion’s second law of motion:

Drama

Where J F is the net force, m is the mass of object and a is the acceleration or rate of

change of velocity.

‘So we can write:

aw

Fmy

And re-arranging:

Fe ev

FeM (dV)

Where M is the mass of flow rate and dV is the change in velocity,

Now by Impulse Momentum Principle in y direction:

3 Fy=pQ (V2y-Viy) where p is the density of the fluid Q is the discharge and (V)-Vs,)

is the change in velocity in y direction. In the case of deflector of 90° the equation

becomes

Scanned with CamScanner

F=pQcovy

Fas pQV=pave

Where A is the area of flow and V is the velocity of the fluid.

> Impact of Jet Apparatus:-

Impact of jet apparatus is a very simple apparatus. The photo;

‘with hydraulic bench is shown in figure

Parts of Jet Apparatus:-

© Nozale

+ Valve

* Glass Chamber

* Vertical Rod having collar on upper part

© Flatand Curve Plates(Deflectors)

* Weights

* Pointer

Hydraulic Bench

graph of the apparatus

Scanned with CamScanner

Impact of jet apparatus directly measures the impulse force of the jet by an equivalent

Weight placed in the pan. The direction of axis of the jet is vertical. When a j

t of steady

flowing water strikes a solid surface, the water is deflected to flow along the surface. Unlike

the impact of solid bodies there is no rebound and unless the flow is highly turbulent there

will be no splashing. In this experiment, the fluid is assumed as in viscid fluid hence friction

is neglected. Secondly it is assumed that there is no loss because of shocks.

> Procedure:

Level the apparatus

At zero loads and zero flow rates, adjust the position of the pointer.

‘Switch on the pump

Place the load of 100gram and gradually open the valve till collar reaches its

original position. Note down the time t to collect the known volume of water.

Repeat step 4 for 100gram load increments till the valve is completely opened.

Switch off the motor of the pump.

Impact of Jet Apparatus

14

Scanned with CamScanner

Nin and haw

Vy

As

Me

Sr OC flew vate)

$0, 2¢% Ci) becomes

the Mdy __

We kno thek “7

fem of O- y

a Ee

So Ve OL

“op = ™s fot

Plt me POL im Ci),

ar- LO (du)

se

er £OCdv)

[we i ea

Thin doves phlei) W known ow

14 hvodey anim < force .

Scanned with CamScanner

a a a a a ae i ae ee

{Zz

» toy Fo" Def feckar :

ee =F f0 (us vat) _

-FE O (Vz oO 10

. east Sead

: -f© (o-\ poy WOE

Xr Oz |Z

——_—_—,

Scanned with CamScanner

oe ee

Fev. Tet De flilo. 5).

Citys . h cose

fo (ve Coe ar sy

ft £00, “all2e)e Ww

i J).

Scanned with CamScanner

ons and Calculations:= 4 isthe intereert

Consider a e where m is a slope and

‘equanon of straight li

From graph of log (Fa) verses Log Vestope ofthe tine 1

Log: (Fey) © mon (V9 *C

Let CaLog (K)

1 becomes

Then the equatt Loe «k)

sentence aR |, Base

Log (Fag) = Log (V") LO differen

Pek"

Jalee

> Observations and Calculations:

6 ~ aPorondm

eoS L Gr

T=

S Jikee => Orool m

= k 20°C

Deflector | SrNo | Mass FaeMe | Time] O-velt | V=QIA

a [te] 5 ai |

A 1 VW 4

1p i AbOLG

| ! J tr |¥ 1339]

| els Ag

Scanned with CamScanner

Scanned with CamScanner

pe.

FEBS. scno0t of engineering ait

Aa Soe Prepared by Ringe Abdalla Nazi

(CE-352L Advanced Fluid Mechanics Lab

risettapetae ( hlom Whid spot

‘amerenenes Fol 01012- we Al a

|) Cocxrrive pomans «co (cLo-t & ex

ray pet we

ae peta

deemined 15)

ener Maasoutie

4+ [stance ne renting of prewore aa | ne | cmon) mi ae “xe

weerercinvaed |Oow cniewctmsptraed | fora w.cwelhn

nd paitom of pour

‘ » ‘wsiatnined aceuraicly (O—

Sree pee “

« fomememetmseentnaser rombr | ag | eam] “terme 8)

lo AFFECTIVE DOMAIN A nd 3) (CLOO3 ant 0 \

fe criteria Aaesiet | aaitctry satiny om | a \

7 frown 03) (€103) e 7 at =|

1 [Follows tab Iastroctions (A2) (CLO-3) ” a3 aot |

Bebaves and ecoperstes during the lab o a te |

* session (AZ) (CLO)

[soins in group internetions (42) .

"\c04)

71 Pee repo 9) (CLO-D

Tos Ma

Instructor's Signature:

Scanned with CamScanner

EXPERIMENT NO.3

“

To make the study of the ‘Pelton Wheel’ Turbine.

3. Theory

3.1 Introduction

ever generation means production of eesti ene, which is the most usefil form of ene

and can easily be transmitted from one place to another just by using cables, The compon

hydropower plants where turbines and generators are installed is called Powerhouse.

3.2 What is meant by study of machine?

3.3 Turbine

It’s a machine, which converts hydraulic ener

available in the river in the form of head

the shaft of the turbine gives a fet

‘gy into mechanical cnergy. Hydraulic energy is

(usually raised) and discharge, whereas the rotation of

ig of the mechanical energy.

3.4 Types of Turbine

@ Impulse Turbine / Velocity Turbine

Gi) Reaction Turbine / Pressure Turbine

Impulse Turbine

In this type the total energy of the water is converted into kinetic energy

water by providing nozzle at the end of the penstock. This jet strikes on th

of the turbine, which applies an impulse force on the buckets and torque on the runner of the

turbine, which rotates the turbine runner, As runner is Keyed to the shaft so this mechanical

In field the shaft of the turbine is coupied with the shaft of the

_— CL ————

17

eee

Scanned with CamScanner

Senerator and hence mechanical energy produced by the turbine is transmitted to the generator.

The jet of water is open to atmosphere, so the pressure energy of the jet

high kinetic energy that's why ‘Impulse Turbine" is also called as “Veloci

3.5 Types of Impulse Turbine

zero, it has only very

Turbine’.

(i) Pelton Wheet

(ii) Turgo Wheel

3.5.1 Pelton Wheel

Pelton wheel was first introduced by Lester A. Pelton (1829-1908) in California (Massey. 1990).

In Pelton wheel the total available energy of the fluid is converted into kinetic energy in the form

of jet of water by providing a nozzle, Jet of water strikes on the splitter of the buckets, which are

‘mounted on the periphery of the wheel. The laboratory layout of the Pelton wheel is to be drawn

in 3.1 given space. Splitter of the bucket divides the jet of water in to 2 parts, half of the water

slides on one side and half on the other side of the bucket, exerting an impulse force on the

‘buckets and torque on the runner, which will produce rotation of the wheel. In this way hydraulic

energy is converted into mechanical energy. The photograph of the Pelton wheel is shown in

Figure 3.2, As jet of water is divided into 2 parts so shaft of the turbine is free of any axial thrust.

Scanned with CamScanner

F “Tangential Flow

AAs jet strikes tangentially to the wheel so Pelton wheel is also known as “Tangs

Turbine”.

3.5.1.1 Main Components of Pelton Wheel

‘The Pelton Wheel consists ofthe following components:

1) Nozzle

2) Spear Headed Nozzle

3) Runner

4). Shaft

5) Casing

6) Braking Drum

7) Tachometer

8) Drum Cooling Pipes

9) Bourdon Gaug

1) Nozzle

It isa converging tube fited at the end of penstock. The nozzle is so designed that contraction

ratio is optimum for least losses, hence maximum efficiency.

Function

It converts total energy of water into the kinetic energy in the form of jet of water.

Scanned with CamScanner

2) Spear Headed Needle

{Cis the conical needle kept inside the nozzle and can axially move in forward and backward

direction by turning the handle accordingly (in the fild by governor), tacts as a valve for

nozzle. The backward and forward movement of thé needle increases and decreases the arca of

flow, respectively, which in tum changes the flow fate through the nozzle.

Function

To regulate the flow through the nozzle keeping constant diameter of the jet.

3) Runner

‘The runner of the Pelton wheel consists of a number of double cupped buckets, hemispherical

‘or ellipsoidal in shape, fixed to periphery of the wheel at equal spacing. The buckets may be

bolted to the wheel if the diameter is too large or cast monolithically for small sizes. Each

‘bucket has a sharp edge at the mid in the radial direction called the splitter. The jet strikes the

splitter and is divided into 2 parts, thus avoiding any unbalanced thrust on the shaft. AS in

Figure 3.3

‘The splitter ofthe bucket is to bear full impact of jet hence it is made very strong. Therefore, it

is not practical to provide a sharp edge and zero angles a the center ofthe bucket. Usually this

angle is kept 3-6 degrees. The photograpin of the runner of the Pelton wheel turbine is in Figure

34.

Scanned with CamScanner

jae the frictional

¢ smooth to minim!

‘The runner is made of brass. Its internal surface is made smooth to

losses,

p 1 (Consult

For figure 3.5, sketch orthographic projections for the bucket of the Pelton Whee! (

Lewitt (1993), Page 600).

Function

its this mechanical

Runner converts hydraulic energy in to mechanical energy and transmits this mechan’

energy tothe shaft

4) Shaft

. eghaft

It is the rotating rod of the turbine supported by the bearings. The runner is keyed to the shat

which is made of mild steel

Function

Ittansmits mechanical energy from the runner to the braking drum (Generator in the field).

5) Casing

‘The cover provided around the Runner is known as casing. It is made of cast iron; its upper

Part can be easily removed as itis bolted with the lower part. The pressure of the water inside

the casing is atmospheric (Douglas, 1989).

Functions

Casing does no! maintain any hydraulic pressure. Following are its main functions:

(i) To provide safety around the runner or to avoid accidents,

(i) To limit splashing of water and to guide it to tailrace channel

Scanned with CamScanner

Figure 3.4: Photograph of ranner of Pelion Wheel

©) Braki

System

A rotating system used to measure the brake power of the turbine. One side of the system has

clamp for application of tbraking torque and on the other side there is @ lever system

arrangements for measuring this torque by applying known weights

Function

Itis used to measure the brake power or output of the turbine,

7) Tachometer

A gauge used to measure the revolution per minute (1pm) of the runner is termed as

tachometer. It is attached on the far end of the shaft by a belt and gives a direct reading.

Function

It gives the rpm of the shaft at un-braked and various braked positions.

8) Bourdon Gauge

It is a gauge, which is used to measure the pressure head of water at the base of the nozzle,

H=Hg+Z

Where, H is the head available at the base of the nozzle, Hg is the head given by the gauge

at its centroid and Z is the vertical distance between the center of the nozzle base and the

center of the bourdon gauge.( Elevation Correction)

Scanned with CamScanner

_ pre

Figure 3.5: Bourdon Gauge fitted over the base of the nozzle

Scanned with CamScanner

a

Manoa

rare: ge: Abi NaF

Tieoterpeimee Cuferinent on pelten w \atll

(CE-3S2L Advanced Fluid Mechanies Lab

lm) cocxmrve OMAN (cn coe &e

ie ee me rixhinamiaan | ue,

1 [Examine tina sod turbaent ow in Sand tr ie ro eres JA fae fr iret

lines (CLO-D) ao | Risteedneteraimeens | Rovere dermnt { sence

_2 | Peterimoe the impals fore on defectors

jo diterent gies (cLO-02) so |éebes na deers =

peer aioe

tern he sen ped re

jecLo-02) ite ®

lorrsvcHoMorox poNAR on ey

fine tpmemnins | 5 ns [oscar

one 3

“Posecatemaanconmmne | |Myatoecgsai® | toacante™*| Sie,

as aoe: 20 | saaintnined wecerately (0 — est sceursiely (maintained accurately (16

ee = incon at

| Jonenesctauontmcranety | ag [,_tupunemen | ttn ttn et

ni oa EG on haa |/ecrmcreeia

los AFrECTIVE pOMAIN (2 9 43)(CLOAS 0

= cri asst [tam cmhecen |

+ [raion ves 96109) 7 wo i |

1s [Follows lab Instructions (42) (CLO-3) wo 0-3 4-7 se \

y Betars a open ring tb Qi G rf ve |

mare

— esi ep irero ) 2 ws o |

cto

we Porta eer 4311.04) 3 Ga ue |

‘Total Marks:

Toa Oba Mase

instructor's Signature:

Scanned with CamScanner

EXPERIME)

To perform experiment on Pelton Wheel and hence to plot its

Characteristics Curves.

4.1 Apparatus

1. Pelton Wheel

2.Weights

3 Discharge Measuring Tank

4.Tachometer

5. Stop Watch

4.2 Related Theory

4.2.1 Introduction

In this type of turbine totat energy of the fluid is converted into the kinetic energy in the form of

jet of water through nozzle and then the jet of water impinges on spliters of the series of

buckets, which are mounted on the wheel, A torque will be produced equal to the product of

force and radius, which rotates the runner. As the runner is keyed with the shaft, so mechanical

energy is transmitted to the shaft and from there to Braking Drum. Impulse turbine is ¢ tangential

flow turbine.

4.2.2Braking Torque

Product of lever arm length and weight or load is called Braking Torque. It is applied to the

rotating drum to apply brake on it

T=WxL

Where, T is the braking torque, W is the weight in the pan and L is the lever arm.

4.2.3. Brake Horse Power (B.H.P)

Iris the output power available atthe shaft of Pelton Wheel and is measured by applying brakes

to the rotating braking drum.

P =B.H.P = 2nNT/60

Where P is the output power or brake power, Nis the np.m of the shaft at braked position and T

is the braking torque. 1 H.P. is the rate of performing 550 fi-Ibs of work per second. (1 HP.=746

watts).

a

24

Scanned with CamScanner

Table 4.1: Observations& Calculations for 10

0% Gate opening

Unit —|

Parameter Value

Hg eof water

Zz inches ___|

H=Hg+Z ih of water

L inches

Temp °C

Y ; Nina

Tank Dimension = inches

Tank Vol. Onos m3

Time to fill the tank. t $47 sec

Q=Voi/t Siyie 3 /ooe

Pin= YQH LY ba Watts

Sr.No. Ww T=WxL N Po= ==

les | N Wm) (rpm) | 2nNT/60 | (Po/Pin)100

- (Watts) (%)

1 O n S Bo

2 755 ~

5

+

5

6

7

8

3

10

11

Scanned with CamScanner

---§--= datal

Scanned with CamScanner

~--&-- data3

quadratic

Scanned with CamScanner

: f set verte i

5 aan SUNT LL A

0 1000 “2000 1" BQ00! 4000 5000 bite 6000

i Peon

Hy

POM | iT i

- Scanned with CamScanner

42.4 Indicated Horse Power (LH.P.)

"ris the input power supplied to the Peon wheel i hydaul

Pin= 1. W= ron

form,

Where ¥ js f

Niet sthe specific weigh of water, Q isthe discharge though the nozale and isthe head

a lable at the base of the nozzle (H=Hg+Z). Hg is the pressure head given by the Bourdon:

auge and Z isthe elevation correction

423 Efficiency

{Wis the ¢éage ratio between the output power available at the shaft of pelion Wheel (B.H.P) and

input power supplied to it (LHP)

T=PolPinx 100 =

4.2.6 Gate Opening

It is the opening of the nozzle mouth in % age. Suppose if 6 turns are required in anticlockwise

j Girection for 100%gate opening then 3 tums in clockwise direction are required for 50% gate

opening.

‘This experiment is being performed on two gate openings i.e. 100% of 50%

4.2.7 Characteristic Curves

It is the graphical representation of the response of Pelton Wheel at varying speed (0-Nmax) for

efficiency. output power and braking torque.

Characteristics curves are required to study the behavior of the machine under varying speed and

to determine the important parameters of the machine, like maximum efficiency of the machine.

normal speed, maximum braking torque,

‘A turbine is always designed and manufactured to work under a given set of conditions such as

discharge, head of water, speed, power generated, efficiency etc. but a turbine may have to be

used under conditions different than those for which it has been designed. It is essential that

exact behavior of turbine under varied conditions should be predetermined. This can be predicted

graphically by means of the characteristics curves.

These curves are drawn for constant head and discharge or constant input power. The

characteristics curves are provided by the Manufacturer of the turbine and are essentially

required at the time of its purchase.

ES

Scanned with CamScanner

4.2.8 Normal Speed

Its the speed of the shaft of the turbine (r,p.m.) corresponding to its maximum efficiency.

4.2.9 Procedure

1. Switch on the motor of the pump.

Adjust the spear headed needle to have the 100% gate opening.

3. Note down the head available the bourdon gauge.

4. Note down the atmospheric temperature and determine the specific weight of water

corresponding to that temperature.

5. Note down the r-p.m. of the revolving shaft with the help of Tachometer.

6. Observe the time required to fil the tank of known volume,

7. Put some load on the pan and apply brakes to the drum by tightening the clamp, which will

reduce the r.p.m. of the shaft. Note down the weight applied and corresponding speed in to the

table.

8, Switch off the motor of the pump.

4.3 Results

Results of the experiment (characteristics curves) are shown and in Table 4.5 in Tabular form.

4.4 Comments

In Ahi enpermarhs UX vals

t dde coeg ak different Cpm vere (ou, 633%,

Wary, SOM, V4 Bory ah ov)

¢ ff rieres ney eet voy high oy thee team’

‘ wall staal Hn

ne bith hed fudhne) ne

mo hed &

\ivbice trou gene

tho,

Scanned with CamScanner

ts) Cocsrrmve powars (C4) (C10. 4 03)

CE-3S2L Advanced Fluid Mechanics Lab

Vein Expermaene: 7

[so] nn Lees ot Ansinment \ &

1 [Examine ine ad tat Soa tances [RSID eer San be

erm (chon) 20 | geen) fo. |

1

2 |Peerimae tempat force on dec, pana

oineren sae (CLO) * cannery

Prime teens spd & wre Toners |

2 lors aS = SS eeial

cides) ace

J FSvcromoTOR DOMAIN CLO

4 |Mensore tbe readinesotsremre ead | 2» | omar om,

JOtserve the varios weight on he fe ae we,

«| etctrs and mintninthe dchrge ai | eeeeeren

[ere pint poston

«¢ [Ooarve the ons on banger pty

ing tachometer os

le) AFFECTIVE DOMALN (Az and A3) (CLO. and 4)

& Tae ane

A Criteria ee Satatcry mt 2

7 Prete ab es 429 (CL0-) 1" 7 7

1 [Fators a estrone (43) (C103) © oo = 110

| [Betas aod conperates doing he ib va 7

session (42) (CLO-4)

vo [ses ingroup interactions (42) it i a6

cro)

11 [votes ab report (A3) (CLO) » 7 te

“otal Mark ‘Total Obtained Mark

Scanned with CamScanner

EXPERIMENT No. 5

To make study

Characteristic C

5. Theory

of “Francis Reaction Turbine” and to plot its

‘urves,

5.1 Reaction Turbine

in this turbine water is supplied to the runner with pressure energy’ well as kinetic energy. I

‘Works due to the drop in pressure energy between the inlet and outlet of the casing. Water glides

ver the vanes and applies a torque on the runner, which produces the rotation ofthe shaft.

5.2 Types of Reaction Turbine

1. Francis Turbine

2. Kaplan Turbine

5.3 Types of the reaction Turbine according to the direction of flow

1, Axial Flow Reaction Turbine (Kaplan Turbine)

2. Radial Flow reaction Turbine

(i) Inward radial Flow Reaction Turbine (Francis Turbine)

Gi) Outward Radial Flow Reaction Turbine.

3. Mixed Flow Reaction Turbine (all modern types of turbines are mixed flow)

In Radial Flow Reaction Turbines, the fluid flows mainly in a direction perpendicular to the axis

of the rotation (James, 2003).

5.4 Francis Reaction Turbine

It is an inward radial flow reaction turbine in which vanes are radial at inlet and discharge is

radial at outlet,

5.5 Main Components/ Parts of the Francis Reaction Turbine

1. Spiral Casing

Guide Mechanism

(i) Fixed Guide Blades

(ii) Moveable Guide Blades.

eC

28

Se ————— ——

Scanned with CamScanner

WN.

Ww

ee ei

3. Runner

4. Shaft

5. Draft Tube

6. Braking System

7. Tachometer

Figure 5.1: Photograph of the Francis Reaction Turbine

pee al

=o

noha .

3 sPired

Caring

bebe

~UGR i.

(ahem hesewor)

Figure 5.2: Laboratory Layout of Francis Reaction Turbine.

—_—__.

29

SS

Scanned with CamScanner

(Undue own

4 bo

Figure 5.3: Section of the scroll easing showing the Guide Mechanism and Runner.

1. Spiral Casing

It is a closed (air tight) chamber, which accommodates the guide mechanism and runner,

cross-sectional area of the casing, reduces in the direction of flow. which converts pressure

energy of water into kinctic energy. Pressure energy at the inlet of the casing is above

atmospheric and at the outlet of the casing itis below atmospheric (-ve.

2. Guide Mechanism

These are the guide blades, which guide the water to foow towards the runner with least

losses of energy. Guide Mechanism consists of the following:

i Fixed Guide Blades.

+

ii Moveable Guide Blades.

i Fixed Guide Blades

‘These are the'blades, which are fixed in position, and they guide the flow of water towards

movable guide biatles in proper direction with the minimum loss of energy.

Scanned with CamScanner

ii Moveable Guide Blades

e about their frictionless

Moveable guide blades consist of the number of blades, which can rotate about their

Functions \

in proper direction for

i To guide the water coming from thre fixed guide blades to the runner in proper dire

shock less entry to the runner.

i eed of the turbine.

1i To regulate the flow of water to the runner and to maintain the constant speed of th

is rotating wheel of the Francis Reaction Turbine, which is keyed to the shaft of the ul it

ists of series of curved vanes connected with circular dises on both sides. ‘The surface of the

made smooth to minimize the losses due to friction. For low heads, the runner may be,

is made of steel or alloy. The photograph of the runners of

‘ure (Duncan, 1960),

runner

made of cats iron, for higher heads

the Francis Reaction Turbine is shown in

Function

converts the hydraulic energy into mechanical energy.

4. Shaft

I Js a rotating rod supported by the bearings. It transmits mechanical energy ftom runner to the

Braking Dram.

5. Draft Tube

It is a diverging pipe which connects the oulet of the casing and the tail race level. (TRL).

Lower end of the Draft Tube is kept submerged. Pressure at the inlet of the Drafi Tube is —ve and

at outlet itis atmospheric,

Functions

1 enables the turbine to be installed above the tail race level without losing any appreciable

loss of energy (head) to facilitate the easy inspection and maintenance an d to prevent from

rusting.

ii As the area of flow of the Draft Tube gradually increases so it increases the Pressure energy

from —ve at the inlet to. atmospheric at outlet of the Draft Tube.

©. Braking System

A rotati

g dram used 1 measure the brake power of th called as Braking Drum, One

side

F the Drum has a clamp for the application of br aye on the inner side there is a

{ever system arrangements for measuring this torue by apply ing known weights

7. Tachometer

X rauge used to measure the speed of rotation of the runner in terms of revolutions per rvinute

("P.N). Its attached to the shaft through a belt and gives a direct reading

32

eS SSS SSE

Scanned with CamScanner

5.6 Water Circulation in F

un

Reservoir

Pump

Pen Stock

Scroll

Casing

Moveable Guide Blades

Runner

Vv

Draft Tube

Vw

Underground

Reservoir

re rr

33

a

Scanned with CamScanner

5.7 Braking Torque

Product of lever arm length and weight or load is called Braking Torque. Its applied to the

rotating drum to apply brake on it

T=WxL

torque, W is the weight in the pan and L is the lever arm.

Where, T is the braki

rakes.

5.8 Brake Horse Power (B.H.P)

available at the shaft of Francis turbine and is measured by apply

It is the output pow:

to the rotating braking drum.

P = B.H.P = 2xNT/60

Where P is the output power or brake power, N is the r.p.m of the shaft at braked position and T

is the braking torque. 1 H.P. is the rate of performing 550 fi-Ibs of work per second. (1 H.P.=746

watts).

ee

Scanned with CamScanner

Exp: 5

LZ

s& Calculations for 100% Gate opening

Table : Observa

—terameter L Value

P 3 -

= YH,H=P/y __m of water

L Inches

Temp °C

y N/m

Tank Dimension Inches.

___ Tank Vol m3

Time to fill the tank,t | Sec

Q=Vol/t ™3/oo

Pin= YQH Watts

Sr.No. | M w oT N Po= =

g ke N) =WXL] (pm) | 2aNT/60 | (Po/PinyL00

(N-m) (Watts) (%)

1 ) Joto fo S472 [0 0

| 2 [90 fo) Toit oo? | Sars VW6o [We

[3] o-e74 [| B47 T1867 [ty

i 45 oo | Wot 14-6) | 26:34

5 | oi? \j02 oro | 26°42

[6 alot 60 3) | raze

[7 22] Hy 4 bo 1v-84

| 8 ore 269 227 | a6

[9 1S yy 18)

[10 » 267 0 0

{i

Scanned with CamScanner

4 Masirougn Power Cw) |

Man ef frieney Cv) 26-92

BAT.

—\VRo2

‘Mow. Aorwe. Gn cm). Vt U6

an ter wl oN)

Maw Seed CR: em

_N ovmal Sted (2m)

joe = For

loow ny |

*| a ie

euecun

neal

4000-1800

i ee ae cs

Scanned with CamScanner

5.9 Comments

Qn Ania bovbine »

odd a f

ianide

Vern and produeed =

o.|

ve to

199 ONT, of8Y 0-22]

runner. AL Ahene

and oul put

Scanned with CamScanner

wat

yd Mesias

‘Advanced UREN sp Maral

\:. School of Engineering eared: Bag. Abdul NE

Se? reser

CE-352L Advanced Fluid Mechanics Lab :

tilan “Tvving sein

Tike of Experinen \caphan Turd 2

Rerisraton sas F2o\)/i203% se A} wee

[scoovrrnowarnece ct0.01 8.)

x Marks

ne ome Les otAtimeat Fv

» RO, Fand ML for different | RN, fund ML for dierent

+ [Pete mine and ai oa x totic | sy

[Pipes (CLO-01 20 | news no determina (0-10) 18) ‘dutormind (16-28

Nfencterspraay | "weber acorsiy

‘ermiedc-20)

rcewsyet ore | geese

stoi parity" gy sand 6

2 [Peterimee he impulse teres on deters | 4g

of itereat aglee (CLO) ‘Meine 19)

Deterimne the efceny, peed & torque

3 for a Terbine fermi!

Noe 3) a |

[0 PsycHomoToR DOMAIN (r3 (CLO-5 -

Musared Manemeivic. | Mesnred Marowtric

Manan eines wet | see poraty [ding racer 16-

4 |Mtennare te readies ofpressre bead | 29 |trregacasagon)| Mn re =

worms

va

aed cra

[Observe the varius weight 9 the Sees

« Joencors sa » oe

osaae heeds anger 8p Lents posture | Ln andy ones

‘ (eigmcteaser mY] os erocaraycretg) | “aco 6-30

Joy AFFECTIVE DOMAIN (2 an 3) (CLO a 09

ina Bint

] Criteria ane Vasetectre Satetiiry Geos ey

1 [Fotow ib rales (42) (C103) 5 ws = to

+ [fates aarcines 2}(c103) | ~ S

| [Bator ool peat eb |g wo ns ne

senso (42) (CLO)

yp [lie roe teractions (43) . wo wo

cu

1 [Os tb epee A) (CLO-I " a u

‘Total Obtained Marks:

1

‘Total Mae

Instructor's Sigaatare:

Scanned with CamScanner

EXPERIMENT No. 6

lot its

To make study of “Kaplan Turbine” and hence to p!

Characteristic Curves,

6. Theory

6.1 Kaplan Turbine

The Kaplan turbine is a propeller-type water turbine which has adjustable blades . i he]

developed in 1913 by Austrian professor Viktor Kaplan, who combined automatically —

Propeller blades with automatically adjusted wicket gates to achieve efficiency over a Wi rt

of flow and water Jevel. Kaplan turbine is a low head turbine and used for heads of less than

meters. It is a pure axial flow turbine.

6.2 Theory of Operation

‘The Kaplan turbine is an outward flow reaction turbine, which means that the working fluid

changes pressure as it moves through the turbine and gives up its energy. Power is recovered

from both the hydrostatic head and from the kinetic ener:

combines features of radial and axial turbines,

‘gy of the flowing water. The design

The inlet is a scroll-shaped tube that wraps around the turbine's wicket gate. Water is directed

tangentially through the wicket gate and spirals on to a propeller shaped runner,

spin.

causing it to

The outlet is a specially shaped draft tube that helps decelerate the water and recover ki

energy.

6.3 Main Components/ Parts of the Francis Reaction Turbine

1. Spiral Casing

2. Guide Mechanism

(i) Fixed Guide Blades

(ii) Moveable Guide Blades,

3. Runner

4. Shaft

5. Draft Tube

6. Braking System

ee”

Scanned with CamScanner

7. Tachometer

Figure 6.1: Photograph of the Kaplan Reaction Turbine

6.4 Working Principle

Water under pressure flushes draft tube through the guide vanes and falls on the adjustable

blades, which enables to adjust the flow. After crossing propeller, the kinetic energy of water

converted into rotational motion shaft. The shaft powered generator and produce electric power.

6.5 Classification of Kaplan Turbine

The Kaplan turbine can be divided in double and single regulated turbines. A Kaplan turbine

with adjustable runner blades and adjustable guide vanes is double regulated while one with only

adjustable runner blades is single regulated. The double regulated Kaplan turbines can werk

i

38 |

SS

Scanned with CamScanner

scan

etweati 1 gulated turbine

‘and 100% of the maximum design discharge and the single re

only work between 30% and100 percent of the maximum design discharge»

6.6 Advantages of Kaplan turbine:

Runner vanes are adjusted in the Kaplan

Very low heads are required

Very small no of blades are used nearly 3 to 8 blades

Less resistance has to be overcome.

6.7 Disadvantages of Kaplan Turbine:

Position of the shaft is only in vertical

+ Speed of the turbine is 250 to 850

+ High speed generator is required

Large Flow rate must be required

6.8 Detail of Different Parts of Kaplan Turbine

1. Spiral Casing

It is a closed (air tight) chamber, which accommodates the guide mechanism and runner,

cross-sectional area of the casing reduces in the direction of flow, which converts pressure

energy of water into kinetic energy. Pressure energy at the inlet of the casing is above

atmospheric and at the outlet of the casing it is below atmospheric (-ve)

2. Guide Mechanism

These are the guide blades, which guide the water to flow towards the runner with least

losses of energy. Guide Mechanism consists of the following:

i Fixed Guide Blades.

ii Moveable Guide Blades.

i Fixed Guide Blades

These are the blades, which are fixed in position, and they guide the flow of water towards

movable guide blades in proper direction with the minimum loss of energy.

ii Moveable Guide Blades

Moveable guide blades consist of the number of blades, w!

pivots

ich can rotate about their frictionless

39

Scanned with CamScanner

Functions

') To guide the water coming from there fixed guide blades to the runner in proper direction for

shock less entry to the runner.

ii) To regulate the flow of water to the runner and to maintain the constant speed of the turbine.

3. Runner

It is rotating wheel of the Kaplan Turbine, which is keyed to the shaft of the turbine. It consists

of series of curved vanes connected with circular dises on both sides. The surface of the runner is

made smooth to minimize the losses due to friction. For low heads, the runner may be made of

cast iron, for higher heads it is made of steel or alloy. The photograph of the runners of the

Francis Reaction Turbine is shown in Figure (Duncan, 1960).

Function

Weonverts the hydraulic energy into mechanical energy.

4, Shaft

It is a rotating rod supported by the bearings. It transmits mechanical energy from runner to the

Braking Drom.

5. Draft Tube

It is a diverging pipe which connects the outlet of the casing and the tail race level. (T-R.L).

Lower end of the Draft Tube is kept submerged. Pressure at the inlet of the Draft Tube is —ve and

at outlet it is atmospheric.

Functions

i It enables the turbine to be installed above the tail race level without losing any appreciable

loss of energy (head) to facilitate the easy inspection and maintenance an d to prevent from

rusting,

ii As the area of flow of the Draft Tube gradually increases so it increases the pressure energy

from —ve at the inlet to atmospheric at outlet of the Draft Tube

6. Braking System

‘A rotating drum used to measure the brake power of the turbine is called as Braking Drum. One

side of the Drum has a clamp for the application of braking torque on the inner side there is a

40

Scanned with CamScanner

lever system arrangements for measuring this torque by a

Tachometer

5 i inute

A gauge used to measure the speed of rotation of the runner in terms of revolutions per min

(p.m). Its attached to the shaft through a belt and gives a direct reading

6.9 Water Circulation in Kaplan Turbine

Underground

Reservoir

Pump

Pen,

Moveable Guide Blades

| Runner

. Underground

Draft Tube — Reservoir

41

Scanned with CamScanner

Figure 6.2: Runner of the Kaplan Turbine

6.10 Braking Torque

Product of lever arm length and weight or load is called Braking Torque. It is applied to the

rotating drum to apply brake om it

T=WxL

‘Where, T is the braking torque, W is the weight in the pan and L is the lever arm.

6.11 Brake Horse Power (B.H.P)

It's the output power available atthe shaft of Kaplan turbine and is measured by applying brakes

to the rotating braking drum.

P = B.H.P = 2nNT/60

Where P is the output power or brake power, N isthe

is the braking torque. | HLP. is the rate

watts).

pn of the shaft at braked position and T

of performing 550 ft-lbs of work per second, (1 H.P. =746

Scanned with CamScanner

Table : Observations& Calculations for 100% Gate opening

Parameter Value tat 4

P i Ty Be _

P 12) Pa (N/m*)

P= YH,H = P/Y¥ W492 m of water

t vol, Inches

Temp Zo °C

r 470 - Nia

Tank Dimension = Inches A

___Tank Vol. 0-005 m3

Time to fill the tank, t q4 Sec_

Q=Vol/t v2 elo) ™3 [coe

L Pin=YQH 61-44 Waus

Table : Observations & Calculations for 100% Gate Opening

Sr. No. N Po= =

(rpm) | 2nNT/60. | (Po/Pin)100

(Watts) (%)

1 si To o

2 A ¥ Ds

3 25 1

4 Mo Wy] Oro 5 4

5 W962] o ro S4 2-2 +6

6 vipa oro? orb \02

7 benz] on 38 oO °

8 \

9 { \

10 \

i L \

Scanned with CamScanner

[vinnie Power CWI 7:

_ Maen ef fivency. c: a —

Man SPeed CR: Rew Ths 4 /

Q9

tne ne

nn cnn

Scanned with CamScanner

Nowe speed (0-0) | Ugol

Mow tovwe On wm) Orodh

— wl. 0: owl

ne

1000 | 2000

‘Scanned with CamScanner

9 1000 (2000 3000 4000 5000 6000

N

|

Scanned with CamScanner

4% 342A 02% acd

vey seal beceve

aed oc hgh fle

rodvead |,

(

Scanned with CamScanner

{zZ

Advanced Pat Mechanes Lad

‘ab Maca

reparaby ag. Abdallah Nase

CE-352L Advanced Fluid Mechanies Lab

Bwectrpeimer Awl 4)... TWwobine Spates, *)

Retiontoana: PT olf isi2 see DV

[CONTE pomary, {C4 (CLO-O1 & 02)

: [sz |

+ |tstnnetninrsosnusnreme ™ Greta ene [Beth or ret

jircwcexoceny a | evince, [Revie | Soa

= [Pein timp rete Tacenaae” \"Zicepeocy”

of different ansies (CLO.03) ‘determing (14-18) Aetermind (16-20)

iam an GT cama aemn) ERS

» [fren eatoncweszom | Fart erm | are eae

cio = rneclrrety [ec eerie

|mPsvcHomoron pow em (clog \

Means Mmwmete | Maret Maem

4 |Mensare the readings of preasure bead ae | Maswoste readlon oat | reads re partally

ecrredccraan(o-30] OB we ari

tom stewr eign | tw rae

«¢ [Observe toe losds en banger & rpm by

ssing tachometer co

Teaccerany (Ine 15) | — necerataly (6-20)

lc) AFFECTIVE DOMAIN (A2 and A3)(CLO-E3 and 0)

ie Criteria Niet | Vaattactery sess | nt \ ae

7 [roltows ta rates (A2)(C1.0-3) 1° os rz |

1s [Fottows lab Tastructions (A2) (CLO-3) 10 13 1 | \

| |Betaves and conperatrderingtbenb |g ao oe | vue |

seston (A2)(CLO-®)

vy bs in rupert) . a o | \

(cto)

11 [tsa pert (43) (CLO-1 ” as oe \

Tota tonnes

Instructor's Sigoatare:

Scanned with CamScanner

IMENT No. 7,

«ow e to plot

To make study of “Axial Flow Impulse Turbine” and hence to Pp!

its Characteristic Curves.

7. Theory

7.1 Axial Flow Impulse Turbine

impulse turbines change the direction of flow of a high velocity fluid jet. The resulting impulse

Spins the turbine and leaves the fluid flow with diminished kinetic energy. There is no pressure

change of the fluid in the turbine blades (the moving blades), all the pressure drop takes place in

the stationary blades (the nozzles).

‘Newton's second law deseribes the transfer of energy for impulse turbines.

7.2 According to the type of energy at inlet

In the impulse turbine, the total head of incoming fluid is converted in to a large velocity head at

the exit of the supply nozzle. That is the entire available energy of water is conserved in to

Kinetic energy.

‘The fluid leaves the nozzle at very high velocity

Impulse Turbine——_> High Head, Low flow rate device

Reaction Turbines Low Head, High flow rate device.

7.3 Main Components/ Parts of the Axial Flow Impulse Turbine

3. Spiral Casing

4. Guide Mechanism

(i) Fixed Guide Blades

(i) Moveable Guide Blades.

3. Runner

4. Shaft

5. Drafi Tube

6. Braking System

7. Tachometer

—— ———

45,

Scanned with CamScanner

Figure 6.1: Photograph of the axial flow impulse Turbine

“+ Different Water turbines

Pelton turbine, a type of impulse water turbine.

Francis turbine, a type of widely used water turbine.

Kaplan turbine, a variation of the Francis Turbine

Turgo turbine, « modified form of the Pelton wheel.

Cross-flow turbine, also known as Banki-Michell turbine, or Ossberger turbine.

Scanned with CamScanner

Impulse turbine

IMPULSE TURBINE YS REACT!

Reaction turbine

> The steam completely expands in the

nozzle and its pressure remains

constant during its flow through the

blade passages

expands partially in the

> The ste YT ie

nozzle and further expansi

place in the rotor blades

© The relative velocity of sicam passing

over the blade remains constant in the

absence of friction

} The relative velocity of steam passing

‘over the blade increases as the steam

‘expands while passing over the blade

>_ Blades are symmetrical

Blades are asymmetrical

> The pressure on both ends of the

moving blade is same

© For the same power developed, as

pressure drop is more, the number of

stages required are less

The blate efficiency curve is less lat

} The pressure on both ends of the

moving blade is different

> For the same power developed. 3

pressure drop is small, the number of

stages required are more

The blade efficiency curve is more flat

The steam velocity is very high and

> The steam velocity is not very high and

therefore the speed of turbine is low.

therefore the speed of turbi

7.4. Operational Mechanism of Impulse Turbine

— Splitter vege

Section through

bucket

Scanned with CamScanner

7.8 Water Circulation in Axial Flow Impulse

Underground |

Renervolt

MZ

AP

GH

Scroll

casing

Fixed Guide

Blades

Moveable Guide

Blades

Runner

Underground

Reservoir

Scanned with CamScanner

7.6 Braking Torque

Prohict of lever arm length and weight load called Braking Torque Wt is applied ro she

rotating drum to apply brake on it

T=Wxh

Where. Tis the braking torque, Wis the weight in the pan and L. is the lever arm:

7.7 Brake Horse Power (B.H.P)

flow impulse turbine and is measured by

It is the output power available at the shaft of axial

applying brakes to the rotating braking drum.

P = B.H.P = 2nNT/60

m of the shaft at braked position and T

Where P is the output power or brake power. N is the rp.

ficlbs of work per second. (1 H.P. =746

is the braking torque. 1 H.P. is the rate of performing 550

watts)

49

Scanned with CamScanner

Unit

| Bar

Po Pain’)

P=YHH=P/y_ | m of water

: 7 7

r Temp 5

y 978% Wag

[Tank Dimension | - Inches a

___ Tank Vol. Oroud m3

Time to fill the tank, t qv) Sec

Yslvle m3

5 Sec.

Ty-07 Watts

Sr. No. | M Ww T N Po= =

ke D NT =WXE| (pm) 2nNT/60 | (Po/Pin)100

pe ik (N-m) (Watts) | (%)

[1 [o [o Jo jo a [0 Oo

[2 | te]ot fol 0-037 | 763) | told \S¥o |

; 3 | toe | Tei | 24-33

[4 f= TU 16-74 [| 28-67

Los] 630 lo 1) | Vol

[ve | 6 Lz? [Ut

[7 34 oF 163

fC 8 oO ° 2

| 9

[ 10

u

Scanned with CamScanner

cence aime

— Desey a tkiva

| Mawiaye Power WD! 16 1S

oe ef frvency | Cu) l a4 ‘35

aw SPeed CR. § (Rem 3142

Noval 5 sted (En) 0 a4

Mon torwe Cn. a Je

Novyve | Cn Fas)

Scanned with CamScanner

ined with CamScanner

hfe =o =

y

4

:

t

i

i

:

:

4

Gee

Scanned with CamScanner

Scanned with CamScanner

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lecture 3 - Trip Generation: Transportation PlanningDocument49 pagesLecture 3 - Trip Generation: Transportation PlanningIsrar MuhammadNo ratings yet

- Hydrology PosterDocument1 pageHydrology PosterIsrar MuhammadNo ratings yet

- To Study The Bending Behavior of Z SectionDocument8 pagesTo Study The Bending Behavior of Z SectionIsrar MuhammadNo ratings yet

- Transportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreDocument3 pagesTransportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreIsrar MuhammadNo ratings yet

- Transportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreDocument3 pagesTransportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreIsrar MuhammadNo ratings yet

- Experiment No. 1 Determination of Standard Consistency of Hydraulic CementDocument4 pagesExperiment No. 1 Determination of Standard Consistency of Hydraulic CementIsrar MuhammadNo ratings yet

- Transportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreDocument3 pagesTransportation Planning (MS372) : Department of Civil Engineering University of Management and Technology LahoreIsrar MuhammadNo ratings yet

- Experiment No 1Document20 pagesExperiment No 1Israr MuhammadNo ratings yet

- Hydrology and Water Resources ManagementDocument7 pagesHydrology and Water Resources ManagementIsrar MuhammadNo ratings yet

- Resource Person: H M Osaid UMT, LahoreDocument47 pagesResource Person: H M Osaid UMT, LahoreIsrar MuhammadNo ratings yet

- Basic Concepts in EthicsDocument36 pagesBasic Concepts in EthicsIsrar MuhammadNo ratings yet

- Hm-221 Social and Ethical Aspects in EngineeringDocument31 pagesHm-221 Social and Ethical Aspects in EngineeringIsrar MuhammadNo ratings yet