Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

6 viewsSL

SL

Uploaded by

amonCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PARTS LIST FOR MANITOU MT 1840 SERIES (00000002)Document3 pagesPARTS LIST FOR MANITOU MT 1840 SERIES (00000002)amonNo ratings yet

- Automotive Lamp Guide – BulbAmericaDocument1 pageAutomotive Lamp Guide – BulbAmericaamonNo ratings yet

- Poulie Fte MA SPZDocument3 pagesPoulie Fte MA SPZamonNo ratings yet

- Dustite LR Dtlry22Document2 pagesDustite LR Dtlry22amonNo ratings yet

- Dustite LR Dtlry17Document2 pagesDustite LR Dtlry17amonNo ratings yet

- PT Parts - VBeltsDocument25 pagesPT Parts - VBeltsamonNo ratings yet

- Gsw415v 2011 (Alt.m) Acp FrameDocument4 pagesGsw415v 2011 (Alt.m) Acp FrameamonNo ratings yet

- Wa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)Document2 pagesWa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)amonNo ratings yet

- IC Stock Inventory Control 8566 V1Document7 pagesIC Stock Inventory Control 8566 V1amonNo ratings yet

- CRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARDocument3 pagesCRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARamonNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- Section 2 - General: 2-8 - JLG Lift - 3121290Document1 pageSection 2 - General: 2-8 - JLG Lift - 3121290amonNo ratings yet

- Instructions Concernant L'Entretien: Options Cat® en Libre-ServiceDocument40 pagesInstructions Concernant L'Entretien: Options Cat® en Libre-ServiceamonNo ratings yet

- Datasheet - HK pm24024-110 4671240Document2 pagesDatasheet - HK pm24024-110 4671240amonNo ratings yet

- Caterpillar Preventive Maintenance Products For On-Highway Engines and TransmissionsDocument3 pagesCaterpillar Preventive Maintenance Products For On-Highway Engines and Transmissionsamon100% (1)

- 692734Document44 pages692734amonNo ratings yet

- Sinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDDocument10 pagesSinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDamonNo ratings yet

SL

SL

Uploaded by

amon0 ratings0% found this document useful (0 votes)

6 views2 pagesOriginal Title

sl

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views2 pagesSL

SL

Uploaded by

amonCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

SECTION 2 - GENERAL

2.6 PREVENTIVE MAINTENANCE AND

INSPECTION SCHEDULE

‘The preventive maintenance and inspection checks are

listed and defined in the following table. This table is,

divided into two basic parts, the "AREA" to be inspected

and the "INTERVAL’ at which the inspection is to take

plage. Under the “AREA” portion of the tablo, the various

systems along with the components that make up that

‘system are listed. The “INTERVAL” portion of the table is

divided into five columns representing the various inspec-

tion time periods. The numbers listed within the interval

column represent the applicable inspection code for

which that component is to be checked.

‘The checks and services listed in this schedule are not

intended to replace any local or regional regulations that

may pertain to this type of equipment nor should the lsts|

be considered as all inclusive. Variances in interval times

may occur due to climate and/or conditions and depend:

ing on the location and use of the machine.

Denes

JLG INDUSTRIES REQUIRES THAT A COMPLETE ANNUAL,

INSPECTION BE PERFORMED IN ACCORDANCE WITH THE

“ANNUAL MACHINE INSPECTION REPORT” FORM.

26 = JLG Lit

This machine requires periodic safety and mainto-

‘nance inspections by a JLG Dealer. Noiiy dealer it

inspection is overdue,

‘The inspection and maintenance code numbers are as fol

lows:

1. Check for proper and secure installation.

2. Check for visible damage and legibility

3. Check for proper fluid evel

4. Check for any structural damage; cracked or broken

welds; bent or warped surfaces.

5. Check for leakage,

6 Check for prasance of excessive ditt or forsign

material

7. Check for proper operation and freedom of move-

ment.

8. Check for excessive wear or damage.

98. Check for proper tightness and adjustment.

40. Drain, clean and rofl

11, Check for proper operation while pumpimotor is

running.

12. Check for proper lubrication.

418, Check for evidence of scratches, nicks or rust and

for straightness of rod

14, Check for condition of element, replace as neces:

sary,

18. Check for proper inflation,

3121166

SECTION 2 - GENERAL

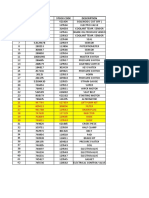

‘Table 2-3. Preventive Maintenance and Safely Inspection

Daily

Weekly

00 Hours

(3 Months)

7200 Hours

(6 Months)

400 Hours

(year)

PLATFORM

Tarver

tat

2 Switches

tat

3-Plaardsand Decals

12

4 ControlTags

12

5 Hosesand Cables

6. WearPads

aie

7. Handrail and Chains

CHASSIS

‘Batley

2. HyeraulePump

a.Vaves

4 Hydraulic Filler

"ANNUAL

5. yeraule Hoses end Tubing

6. HyéauloOi Tank

34

8.UiRCylnder

7

3618

Limit wich

W

0. TitAlarm Switch

a7

1. Pacards and Decals

2

72 Wheeland Tire Assembles

38

13. Drive Motors

156

14. Drive Brakes

16

5. Drive Torque Hubs

1356

16 SieerGyinder

5613

{7-Sieer Components

46

1. Wheel Bearings

19.SdissorArms |

14

2

20.SaletyProps

14

2 Sing Wear Pads

ai

22.ProtPins!Bos

1

78

23. Switches, Ground Control

tat

24. Cont Tags

12

3121166

VLG Lit

27

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PARTS LIST FOR MANITOU MT 1840 SERIES (00000002)Document3 pagesPARTS LIST FOR MANITOU MT 1840 SERIES (00000002)amonNo ratings yet

- Automotive Lamp Guide – BulbAmericaDocument1 pageAutomotive Lamp Guide – BulbAmericaamonNo ratings yet

- Poulie Fte MA SPZDocument3 pagesPoulie Fte MA SPZamonNo ratings yet

- Dustite LR Dtlry22Document2 pagesDustite LR Dtlry22amonNo ratings yet

- Dustite LR Dtlry17Document2 pagesDustite LR Dtlry17amonNo ratings yet

- PT Parts - VBeltsDocument25 pagesPT Parts - VBeltsamonNo ratings yet

- Gsw415v 2011 (Alt.m) Acp FrameDocument4 pagesGsw415v 2011 (Alt.m) Acp FrameamonNo ratings yet

- Wa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)Document2 pagesWa320-5 S - N 60001-Up - Air Conditioner (Mounting and Piping)amonNo ratings yet

- IC Stock Inventory Control 8566 V1Document7 pagesIC Stock Inventory Control 8566 V1amonNo ratings yet

- CRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARDocument3 pagesCRITICAL PARTS LIST OF GENERATING SET 80KVA CATERPILLARamonNo ratings yet

- Critical Spare For Manitou MT X1840 New ManitouDocument3 pagesCritical Spare For Manitou MT X1840 New ManitouamonNo ratings yet

- Section 2 - General: 2-8 - JLG Lift - 3121290Document1 pageSection 2 - General: 2-8 - JLG Lift - 3121290amonNo ratings yet

- Instructions Concernant L'Entretien: Options Cat® en Libre-ServiceDocument40 pagesInstructions Concernant L'Entretien: Options Cat® en Libre-ServiceamonNo ratings yet

- Datasheet - HK pm24024-110 4671240Document2 pagesDatasheet - HK pm24024-110 4671240amonNo ratings yet

- Caterpillar Preventive Maintenance Products For On-Highway Engines and TransmissionsDocument3 pagesCaterpillar Preventive Maintenance Products For On-Highway Engines and Transmissionsamon100% (1)

- 692734Document44 pages692734amonNo ratings yet

- Sinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDDocument10 pagesSinotruk Maintenance Manual-SINOTRUK-China National Heavy Duty Truck Group Co., LTDamonNo ratings yet