Professional Documents

Culture Documents

JGS 320 GS-B.L: Technical Description Genset

JGS 320 GS-B.L: Technical Description Genset

Uploaded by

Amir QayyumOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JGS 320 GS-B.L: Technical Description Genset

JGS 320 GS-B.L: Technical Description Genset

Uploaded by

Amir QayyumCopyright:

Available Formats

Technical Description

Genset

JGS 320 GS-B.L

dyn. Gridcode BDEW (DEU, DNK, AUT, BEL, GBR, ITA, FRA)

AB Energy – ECOMAX® 10 BIO

Electrical output 999 kW el.

Emission values

NOx < 500 mg/Nm³ (5% O2)

(C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 1/11

0.01 Technical Data (at genset) 3

Main dimensions and weights (at genset) 4

Connections 4

Output / fuel consumption 4

0.02 Technical data of engine 5

Thermal energy balance 5

Exhaust gas data 5

Combustion air data 5

Sound pressure level 6

Sound power level 6

0.03 Technical data of generator 7

Reactance and time constants (saturated) 7

connection variant 1K 8

0.05 Cooling water circuit 9

Oil - heat (Engine jacket water cooling circuit) 9

Engine jacket water - heat (Engine jacket water cooling circuit) 9

Mixture Intercooler (1st stage) (Engine jacket water cooling circuit) 9

Mixture Intercooler (2nd stage) (Low temperature circuit) 9

0.10 Technical parameters 10

(C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 2/11

0.01 Technical Data (at genset)

Data at: Full Part Load

load

Fuel gas LHV kWh/Nm³ 4,5

100% 75% min.

Energy input kW [2] 2.454 1.891 1.414

Gas volume Nm³/h *) 545 420 314

Mechanical output kW [1] 1.026 769 548

Electrical output kW el. [4] 999 747 529

Heat to be dissipated [5]

~ Intercooler 1st stage (Engine jacket water cooling circuit) kW 148

~ Intercooler 2nd stage (Low temperature circuit) kW 84

~ Lube oil (Engine jacket water cooling circuit) kW 119

~ Jacket water kW 341

~ Surface heat ca. kW [7] 82

Spec. fuel consumption of engine electric kWh/kWel.h [2] 2,46 2,53 2,67

Spec. fuel consumption of engine kWh/kWh [2] 2,39 2,46 2,58

Lube oil consumption ca. kg/h [3] 0,33 ~ ~

Electrical efficiency % 40,7% 39,5% 37,4%

*) approximate value for pipework dimensioning

[_] Explanations: see 0.10 - Technical parameters

All heat data is based on standard conditions according to attachment 0.10. Deviations from the standard conditions can result in a

change of values within the heat balance, and must be taken into consideration in the layout of the cooling circuit/equipment

(intercooler; emergency cooling; ...). In the specifications in addition to the general tolerance of ±8 % on the thermal output a further

reserve of +5 % is recommended for the dimensioning of the cooling requirements.

(C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 3/11

Main dimensions and weights (at genset)

Length mm ~ 5.700

Width mm ~ 1.700

Height mm ~ 2.300

Weight empty kg ~ 13.100

Weight filled kg ~ 13.600

Connections

Jacket water inlet and outlet DN/PN 80/10

Exhaust gas outlet DN/PN 250/10

Fuel Gas (at genset) DN/PN 80/16

Water drain ISO 228 G ½''

Condensate drain mm 18

Safety valve - jacket water ISO 228 DN/PN 1½''/2,5

Lube oil replenishing (pipe) mm 28

Lube oil drain (pipe) mm 28

Jacket water - filling (flex pipe) mm 13

Intercooler water-Inlet/Outlet 1st stage DN/PN 80/10

Intercooler water-Inlet/Outlet 2nd stage DN/PN 65/10

Output / fuel consumption

ISO standard fuel stop power ICFN kW 1.026

Mean effe. press. at stand. power and nom. speed bar 16,87

Fuel gas type Biogas

Based on methane number | Min. methane number MZ d) 135 | 100

Compression ratio Epsilon 12,5

Min./Max. fuel gas pressure at inlet to gas train mbar 80 - 200 c)

Allowed Fluctuation of fuel gas pressure % ± 10

Max. rate of gas pressure fluctuation mbar/sec 10

Maximum Intercooler 2nd stage inlet water temperature °C 50

Spec. fuel consumption of engine kWh/kWh 2,39

Specific lube oil consumption g/kWh 0,30

Max. Oil temperature °C 90

Jacket-water temperature max. °C 95

Filling capacity lube oil (refill) lit ~ 342

c) Lower gas pressures upon inquiry

d) based on methane number calculation software AVL 3.1

(C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 4/11

0.02 Technical data of engine

Manufacturer GE Jenbacher

Engine type J 320 GS-D25

Working principle 4-Stroke

Configuration V 70°

No. of cylinders 20

Bore mm 135

Stroke mm 170

Piston displacement lit 48,67

Nominal speed rpm 1.500

Mean piston speed m/s 8,50

Length mm 3.320

Width mm 1.358

Height mm 2.065

Weight dry kg 5.200

Weight filled kg 5.700

Moment of inertia kgm² 8,61

Direction of rotation (from flywheel view) left

Radio interference level to VDE 0875 N

Starter motor output kW 7

Starter motor voltage V 24

Thermal energy balance

Energy input kW 2.454

Intercooler kW 232

Lube oil kW 119

Jacket water kW 341

Exhaust gas cooled to 180 °C kW 486

Exhaust gas cooled to 100 °C kW 612

Surface heat kW 47

Exhaust gas data

Exhaust gas temperature at full load °C [8] 473

Exhaust gas temperature at bmep= 13,5 [bar] °C ~ 494

Exhaust gas temperature at bmep= 9 [bar] °C ~ 512

Exhaust gas mass flow rate, wet kg/h 5.277

Exhaust gas mass flow rate, dry kg/h 4.900

Exhaust gas volume, wet Nm³/h 4.123

Exhaust gas volume, dry Nm³/h 3.653

Max.admissible exhaust back pressure after engine mbar 60

Combustion air data

Combustion air mass flow rate kg/h 4.861

Combustion air volume Nm³/h 3.762

(C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 5/11

Sound pressure level

Aggregate b) dB(A) re 20µPa 96

31,5 Hz dB 78

63 Hz dB 90

125 Hz dB 92

250 Hz dB 89

500 Hz dB 92

1000 Hz dB 90

2000 Hz dB 89

4000 Hz dB 87

8000 Hz dB 90

Exhaust gas a) dB(A) re 20µPa 122

31,5 Hz dB 97

63 Hz dB 108

125 Hz dB 118

250 Hz dB 110

500 Hz dB 113

1000 Hz dB 114

2000 Hz dB 117

4000 Hz dB 115

8000 Hz dB 114

Sound power level

Aggregate dB(A) re 1pW 117

Measurement surface m² 109

Exhaust gas dB(A) re 1pW 130

Measurement surface m² 6,28

a) average sound pressure level on measurement surface in a distance of 1m according to DIN 45635, precision class 2.

b) average sound pressure level on measurement surface in a distance of 1m (converted to free field) according to DIN 45635,

precision class 3.

The spectra are valid for aggregates up to bmep=18 bar. (for higher bmep add safety margin of 1dB to all values per increase of 1

bar pressure).

For operation with 1200 rpm see above values, for operation with 1800 rpm add 3 dB to the above values.

Engine tolerance ± 3 dB

(C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 6/11

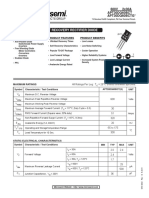

0.03 Technical data of generator

Manufacturer STAMFORD e)

Type PI 734 B e)

Type rating kVA 1.400

Driving power kW 1.026

Ratings at p.f. = 1,0 kW 999

Ratings at p.f. = 0,8 kW 991

Rated output at p.f. = 0,8 kVA 1.249

Rated reactive power at p.f. = 0,8 kVar 743

Rated current at p.f. = 0,8 A 1.803

Frequency Hz 50

Voltage V 400

Speed rpm 1.500

Permissible overspeed rpm 1.800

Power factor (lagging - leading) 0,8 - 0,95

Efficiency at p.f. = 1,0 % 96,8%

Efficiency at p.f. = 0,8 % 95,3%

Moment of inertia kgm² 44,50

Mass kg 3.506

Radio interference level to EN 55011 Class A (EN 61000-6-4) N

Construction B3/B14

Protection Class IP 23

Insulation class H

Temperature (rise at driving power) H

Maximum ambient temperature °C 40

Reactance and time constants (saturated)

xd direct axis synchronous reactance p.u. 3,26

xd' direct axis transient reactance p.u. 0,20

xd'' direct axis sub transient reactance p.u. 0,15

x2 negative sequence reactance p.u. 0,21

Td'' sub transient reactance time constant ms 130

Ta Time constant direct-current ms 20

Tdo' open circuit field time constant s 2,14

e) GE Jenbacher reserves the right to change the generator supplier and the generator type. The contractual data of the

generator may thereby change slightly. The contractual produced electrical power will not change.

(C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 7/11

connection variant 1K

established by authorized sales provider from GE Jenbacher GmbH & Co OG

0.05 Cooling water circuit

Oil - heat (Engine jacket water cooling circuit)

Nominal output kW 119

Max. Oil temperature °C 90

Loss of nominal pressure of engine jacket water bar 0,20

Safety valve - max press. set point bar 2,50

Engine jacket water - heat (Engine jacket water cooling circuit)

Nominal output kW 341

Max. engine jacket water temperature (outlet engine) °C 93

Engine jacket water flow rate m³/h 30,8

Safety valve - max press. set point bar 2,50

Mixture Intercooler (1st stage) (Engine jacket water cooling circuit)

Nominal output kW 148

Max. inlet cooling water temp. (intercooler) °C 77,7

Nominal pressure of cooling water / (max. operating pressure) PN 10

Loss of nominal pressure of engine jacket water bar 0,40

Safety valve - max press. set point bar 2,50

Mixture Intercooler (2nd stage) (Low temperature circuit)

Nominal output kW 84

Max. inlet cooling water temp. (intercooler) °C 50

Aftercooler water flow rate m³/h 25,0

Nominal pressure of cooling water / (max. operating pressure) PN 10

Intercooler water pressure drop bar 0,20

Safety valve - max press. set point bar 2,50

The final pressure drop will be given after final order clarification and must be taken from the P&ID order documentation.

19.01.2015/MF (C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 9/11

0.10 Technical parameters

All data in the technical specification are based on engine full load (unless stated otherwise) at specified

temperatures and the methane number and subject to technical development and modifications.

All pressure indications are to be measured and read with pressure gauges (psi.g.).

(1) At nominal speed and standard reference conditions ICFN according to DIN-ISO 3046 and DIN 6271,

respectively

(2) According to DIN-ISO 3046 and DIN 6271, respectively, with a tolerance of +5 %.

Efficiency performance is based on a new unit (immediately upon commissioning).Effects of

degradation during normal operation can be mitigated through regular service and maintenance work;

reference value --> 65%CH4

(3) Average value between oil change intervals according to maintenance schedule, without oil change

amount

(4) At p. f. = 1.0 according to VDE 0530 REM / IEC 34.1 with relative tolerances

(5) Total output with a tolerance of ±8 %

(6) According to above parameters (1) through (5)

(7) Only valid for engine and generator; module and peripheral equipment not considered (at p. f. = 0,8)

(8) Exhaust temperature with a tolerance of ±8 %

Radio interference level

The ignition system of the gas engines complies the radio interference levels of CISPR 12 and EN 55011

class B, (30-75 MHz, 75-400 MHz, 400-1000 MHz) and (30-230 MHz, 230-1000 MHz), respectively.

Definition of output

• ISO-ICFN continuous rated power:

Net break power that the engine manufacturer declares an engine is capable of delivering continuously,

at stated speed, between the normal maintenance intervals and overhauls as required by the

manufacturer. Power determined under the operating conditions of the manufacturer’s test bench and

adjusted to the standard reference conditions.

• Standard reference conditions:

Barometric pressure: 1000 mbar (14.5 psi) or 100 m (328 ft) above sea level

Air temperature: 25°C (77°F) or 298 K

Relative humidity: 30 %

• Volume values at standard conditions (fuel gas, combustion air, exhaust gas)

Pressure: 1013 mbar (14.7 psi)

Temperature: 0°C (32°F) or 273 K

Output adjustment for turbo charged engines

Standard rating of the engines is for an installation at an altitude ≤ 500 m and an air intake

temperature ≤ 30 °C (T1)

Maximum room temperature: 50°C (T2) -> engine stop

19.01.2015/MF (C6FF) JGS 320 D25 999 EUR - INGLESE

established by authorized sales provider from GE Jenbacher GmbH & Co OG 10/11

If the actual methane number is lower than the specified, the knock control responds. First the ignition

timing is changed at full rated power. Secondly the rated power is reduced. These functions are carried

out by the engine management system.

Exceedance of the voltage and frequency limits for generators according to IEC 60034-1 Zone A will lead

to a derate in output.

Parameters for the operation of GE Jenbacher gas engines

The genset fulfills the limits for mechanical vibrations according to ISO 8528-9.

The following "Technical Instruction of GE JENBACHER" forms an integral part of a contract and must be

strictly observed: TI 1100-0110, TI 1100-0111 and TI 1100-0112.

If possible, railway trucks must not be used for transport (TI 1000-0046).

Parameters for the operation of control unit and the electrical equipment

Relative humidity 50% by maximum temperature of 40°C.

Altitude up to 2000m above the sea level.

Parameters for using a gas compressor

The gas quantity indicated under the technical data refers to standard conditions with the given calorific

value. The actual volume flow (under operating conditions) has to be considered for dimensioning the gas

compressor and each gas feeding component – it will be affected by:

• Actual gas temperature (limiting temperature according to TI 1000-0300)

• Gas humidity (limiting value according to TI 1000-0300)

• Gas Pressure

• Calorific value variations (can be equated with methane (CH4) variations in the case of biogas)

• The gas compressor is designed for a max. relative under pressure of 15 mbar(g) (0.22 psi) and a inlet

temperature of 40°C (104°F) , if within scope of supply GE Jenbacher

Page No.: 11/11

GE Proprietary Information: CONFIDENTIAL! Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

You might also like

- Jenbacher: 1. Power Shift Diagrams Type 6 Engines in Compliance With ISO 8528, Part 5: - 2Document4 pagesJenbacher: 1. Power Shift Diagrams Type 6 Engines in Compliance With ISO 8528, Part 5: - 2ArîfNo ratings yet

- JMS 616 GS-N.L: Technical SpecificationDocument4 pagesJMS 616 GS-N.L: Technical SpecificationMartin KratkyNo ratings yet

- Lean Burn or Rich Burn?: It Depends On What Meets The Customer's Application NeedsDocument4 pagesLean Burn or Rich Burn?: It Depends On What Meets The Customer's Application Needsciprian_dalvaruNo ratings yet

- 1000-1109 - Index 17 GE Jenbacher Gas EnginesDocument14 pages1000-1109 - Index 17 GE Jenbacher Gas EnginesDavid PomaNo ratings yet

- ST-030 Correct Installation and Handling of Connecting Rods PDFDocument7 pagesST-030 Correct Installation and Handling of Connecting Rods PDFPopa MihaiNo ratings yet

- Ge Jenbacher - Jgs 616dsDocument4 pagesGe Jenbacher - Jgs 616dsabdulkidwai2009No ratings yet

- Jenbacher Start UpDocument3 pagesJenbacher Start UpJamil AhmedNo ratings yet

- Jenbacher: 1902-0228E Screwing and Tightening Torque J 6..GS-EDocument6 pagesJenbacher: 1902-0228E Screwing and Tightening Torque J 6..GS-EArîf100% (2)

- Component OverviewDocument20 pagesComponent OverviewAndronic Cosmin0% (1)

- Technical Diagram enDocument4 pagesTechnical Diagram enJamil Ahmed100% (2)

- Jen Bacher Gas EngineDocument4 pagesJen Bacher Gas Enginedannymay9575% (4)

- JGS 420 GS-S.L: Low Methane - Coal Mine MethaneDocument34 pagesJGS 420 GS-S.L: Low Methane - Coal Mine MethaneDexterous EngineeringNo ratings yet

- JGS 420 B05 - 1500 KW (Nox - 500)Document11 pagesJGS 420 B05 - 1500 KW (Nox - 500)Ibrahim Ahmed FarrukhNo ratings yet

- GERMANY - Engineering JGS620Document40 pagesGERMANY - Engineering JGS620Ali Ramezani KhoozestaniNo ratings yet

- TS - 2023 - JMS 624K 101 - 11KV - 4496kW - 40C - 250m - ICWT60C - LS - 70-95CDocument16 pagesTS - 2023 - JMS 624K 101 - 11KV - 4496kW - 40C - 250m - ICWT60C - LS - 70-95Chipobo8255No ratings yet

- JGS620Document40 pagesJGS620Vik KarNo ratings yet

- Especificação Técnica - TD 20729-0Document39 pagesEspecificação Técnica - TD 20729-0Geovane FonsecNo ratings yet

- Iil C249Document206 pagesIil C249Khalid RafiqNo ratings yet

- GE - 200802 - Technical Specs Jenbacher Type 6 PDFDocument2 pagesGE - 200802 - Technical Specs Jenbacher Type 6 PDFsakthivelNo ratings yet

- J312V02 enDocument4 pagesJ312V02 enMartin KratkyNo ratings yet

- Deutz, TBG 616 K (323 - 700 KW)Document4 pagesDeutz, TBG 616 K (323 - 700 KW)Dexterous EngineeringNo ratings yet

- Technical Specifiaction of Control SystemDocument34 pagesTechnical Specifiaction of Control SystemLidef SellenrofNo ratings yet

- Amjad Textile JH827 - 2196246 - 258Document279 pagesAmjad Textile JH827 - 2196246 - 258Shahzad AhmadNo ratings yet

- W 8050m6 - Crankshaft Main Bearings PDFDocument6 pagesW 8050m6 - Crankshaft Main Bearings PDFPopa MihaiNo ratings yet

- Fuel SystemDocument1 pageFuel SystemJamil Ahmed50% (2)

- 320Document61 pages320Rashid Mahmood JaatNo ratings yet

- 1 X Jgs 420-Bl-BopDocument25 pages1 X Jgs 420-Bl-Bophaji atinNo ratings yet

- Jenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Document14 pagesJenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Jamil Ahmed100% (1)

- JMS 612 GS-N.L: Jenbacher Gas EnginesDocument4 pagesJMS 612 GS-N.L: Jenbacher Gas EngineshadNo ratings yet

- Jenbacher: 1. Engine Oil System: - 1Document1 pageJenbacher: 1. Engine Oil System: - 1Jamil AhmedNo ratings yet

- Expt 6 The Split Phase MotorDocument4 pagesExpt 6 The Split Phase MotorCapalar KyleNo ratings yet

- J616V01 enDocument4 pagesJ616V01 enMartin KratkyNo ratings yet

- Tedom Handbook For Designers 2008Document57 pagesTedom Handbook For Designers 2008ManretyNo ratings yet

- J616V21 enDocument4 pagesJ616V21 enMartin KratkyNo ratings yet

- Jenbacher Type 6 Fs en Metric 2016Document2 pagesJenbacher Type 6 Fs en Metric 2016laiquz zamanNo ratings yet

- TBG616K PDFDocument4 pagesTBG616K PDFTyler GoodwinNo ratings yet

- ST-124 New Gear Train PDFDocument21 pagesST-124 New Gear Train PDFPopa MihaiNo ratings yet

- J624 G01 6300VDocument5 pagesJ624 G01 6300VJajap TanudjajaNo ratings yet

- ManualDocument4 pagesManualmuhammad arif67% (3)

- GE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLDocument24 pagesGE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLSerg MarushkoNo ratings yet

- Jenbacher Gasm BHKW enDocument28 pagesJenbacher Gasm BHKW ensaniterm100% (1)

- Jgs616 Ds Preliminary DataDocument4 pagesJgs616 Ds Preliminary DataEdutamNo ratings yet

- Boundary Conditions Engines Installation 1100-0110 enDocument19 pagesBoundary Conditions Engines Installation 1100-0110 enAndronic Cosmin50% (2)

- ST-117 Trenul de Roti Distributie Seria 6-23.oct.2017 PDFDocument6 pagesST-117 Trenul de Roti Distributie Seria 6-23.oct.2017 PDFPopa MihaiNo ratings yet

- (PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressDocument5 pages(PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressArie AozNo ratings yet

- 5 1 1 B J320C enDocument12 pages5 1 1 B J320C enAdnan Yousaf67% (3)

- 624 JGS-NL-electric Wiring Diagram PDFDocument617 pages624 JGS-NL-electric Wiring Diagram PDFPopa MihaiNo ratings yet

- W 0700m6 - Gas Mixer PDFDocument5 pagesW 0700m6 - Gas Mixer PDFPopa MihaiNo ratings yet

- JMS 320 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 320 GS-B.L: Jenbacher Gas EnginesSergioNo ratings yet

- Emissions Monitoring: Technical InstructionDocument16 pagesEmissions Monitoring: Technical InstructionJuly E. Maldonado M.No ratings yet

- Operating InstructionsDocument161 pagesOperating Instructionsfares bellNo ratings yet

- Main Engine DetailDocument9 pagesMain Engine DetailRashid Mahmood JaatNo ratings yet

- Jenbacher Engine DetailsDocument2 pagesJenbacher Engine DetailsAmin HunzaiNo ratings yet

- 1502-0068 MorisDocument52 pages1502-0068 MorisLuis PupialesNo ratings yet

- Checklist For Alarm MessagesDocument43 pagesChecklist For Alarm MessagesHamid HpNo ratings yet

- GE's Jenbacher Gas Engines - Advantage Austria (PDFDrive)Document23 pagesGE's Jenbacher Gas Engines - Advantage Austria (PDFDrive)saman karbasiNo ratings yet

- 1b Technical Description - JMS 320C47 11barDocument11 pages1b Technical Description - JMS 320C47 11barRyan Meta PratamaNo ratings yet

- Technical Description: Cogeneration UnitDocument12 pagesTechnical Description: Cogeneration UnitDexterous Engineering100% (1)

- 320 D105 - 400V - 1000kW - 45°C - 250m - ICWT50°CDocument11 pages320 D105 - 400V - 1000kW - 45°C - 250m - ICWT50°CIbrahim Ahmed FarrukhNo ratings yet

- TS J420 E900 at BMEP 12bar, Pure H2Document12 pagesTS J420 E900 at BMEP 12bar, Pure H2d_macuraNo ratings yet

- TS JGS 420 B11 400V 50Hz New 2018Document12 pagesTS JGS 420 B11 400V 50Hz New 2018veljal6317100% (2)

- Manual Inversor Cargador Solar Ica 8k 48pDocument72 pagesManual Inversor Cargador Solar Ica 8k 48pAmir QayyumNo ratings yet

- Solubility of Stearic Acid in Various Organic SolvDocument5 pagesSolubility of Stearic Acid in Various Organic SolvAmir QayyumNo ratings yet

- Ultrafast Soft Recovery Rectifier Diode: 600V 2x30a APT30DQ60BCT APT30DQ60BCTGDocument4 pagesUltrafast Soft Recovery Rectifier Diode: 600V 2x30a APT30DQ60BCT APT30DQ60BCTGAmir QayyumNo ratings yet

- Catalog 01 PD5-1Document2 pagesCatalog 01 PD5-1Amir QayyumNo ratings yet

- ECA450 User Manual N.AmericaEnglishDocument86 pagesECA450 User Manual N.AmericaEnglishAmir QayyumNo ratings yet

- FBL Client List (July 2021) SDocument11 pagesFBL Client List (July 2021) SAmir QayyumNo ratings yet

- Microprocessor Reset Circuits ADM1810-ADM1813/ADM1815-ADM1818Document17 pagesMicroprocessor Reset Circuits ADM1810-ADM1813/ADM1815-ADM1818Amir QayyumNo ratings yet

- Adjustable Precision Shunt Regulators: NC AnodeDocument15 pagesAdjustable Precision Shunt Regulators: NC AnodeAmir QayyumNo ratings yet

- IT-DS Manual Rev 0Document43 pagesIT-DS Manual Rev 0Amir QayyumNo ratings yet

- PG NaturalGas S4000 BrochureDocument9 pagesPG NaturalGas S4000 BrochureAmir QayyumNo ratings yet

- Proxel GXL Antimicrobial: Arch® BiocidesDocument4 pagesProxel GXL Antimicrobial: Arch® BiocidesAmir QayyumNo ratings yet

- Saudi Industrial Resins Limited: HETRON 922Document3 pagesSaudi Industrial Resins Limited: HETRON 922Amir QayyumNo ratings yet

- Environmental Metrics GuideDocument18 pagesEnvironmental Metrics GuideAmir QayyumNo ratings yet

- 289 Booklet ProductsandApplicationsHSDocument13 pages289 Booklet ProductsandApplicationsHStelo khentirNo ratings yet

- Gas Engine JenbacherDocument19 pagesGas Engine JenbacherceroandoneNo ratings yet

- HTTP WWW - Niigata-Power - Com English Products Gasengines IndexDocument6 pagesHTTP WWW - Niigata-Power - Com English Products Gasengines IndexSeong Ju KangNo ratings yet

- Shell Mysella Family BrochureDocument2 pagesShell Mysella Family BrochureVictor R PeñarandaNo ratings yet

- Shell Mysella S3 N 40: Performance, Features & BenefitsDocument2 pagesShell Mysella S3 N 40: Performance, Features & Benefitsfaraz24No ratings yet

- Gas Engine Site Specific Technical DataDocument4 pagesGas Engine Site Specific Technical Datavlcmstne04No ratings yet

- Retrofit of Reciprocating Compressors - Hoerbiger ElectricDocument22 pagesRetrofit of Reciprocating Compressors - Hoerbiger ElectricRadu BabauNo ratings yet

- Gas DM8670 06 GS Epg e 31090256Document5 pagesGas DM8670 06 GS Epg e 31090256Suresh kumar ChockalingamNo ratings yet

- 616 Diesel BrochureDocument2 pages616 Diesel Brochurer.eddie.cookeNo ratings yet

- Catalog 52122 PDFDocument46 pagesCatalog 52122 PDFpartha majiNo ratings yet

- GE's Jenbacher Gas Engines - Advantage Austria (PDFDrive)Document23 pagesGE's Jenbacher Gas Engines - Advantage Austria (PDFDrive)saman karbasiNo ratings yet

- (CIBSE Applications Manuals AM12) - Combined Heat and Power For Buildings-Chartered Institution of Building Services Engineers (2013)Document90 pages(CIBSE Applications Manuals AM12) - Combined Heat and Power For Buildings-Chartered Institution of Building Services Engineers (2013)zukchuNo ratings yet

- Shell Mysella S5 N 40Document2 pagesShell Mysella S5 N 40Muhammad SaputraNo ratings yet

- SFGLD360Document2 pagesSFGLD360Pankaj KambleNo ratings yet

- Bergen Engines Roadshow Poland 2013Document44 pagesBergen Engines Roadshow Poland 2013Sylvek91No ratings yet

- Wärtsilä 50Sg Gas Engine Generating Set: Key FeaturesDocument2 pagesWärtsilä 50Sg Gas Engine Generating Set: Key FeaturesJarvi Al habibiNo ratings yet

- PTS Gas Driven Compressor300807Document114 pagesPTS Gas Driven Compressor300807sumit kumarNo ratings yet

- Marine Products and Systems Catalogue - RR PDFDocument202 pagesMarine Products and Systems Catalogue - RR PDFLiladhar Ganesh Dhoble100% (3)

- Electricity Generation From BiogasDocument18 pagesElectricity Generation From BiogasDaniyal AliNo ratings yet

- GE Lubricating Oil For Type 2, 3, 4 and 6 1000-1109 - enDocument16 pagesGE Lubricating Oil For Type 2, 3, 4 and 6 1000-1109 - enBARCODE SPANo ratings yet

- Perkins 4006 23TRS12 Gas PN1850 Soecification SheetDocument2 pagesPerkins 4006 23TRS12 Gas PN1850 Soecification SheetAbdul Latif KhanNo ratings yet

- J416V06 enDocument4 pagesJ416V06 enMartin Kratky100% (1)

- Product Description: Mobil Pegasus™ 805Document4 pagesProduct Description: Mobil Pegasus™ 805MONJURUL KARIMNo ratings yet

- CarivendorDocument19 pagesCarivendorslamet haryadiNo ratings yet

- Jenbacher: 1. Leanox® Controller: - 1Document3 pagesJenbacher: 1. Leanox® Controller: - 1ArîfNo ratings yet

- Summary Value Map of Palm OilDocument5 pagesSummary Value Map of Palm OilAlia100% (3)

- Peak Shaving - Using Natural Gas ChillersDocument8 pagesPeak Shaving - Using Natural Gas ChillersAnton WorkNo ratings yet

- Servicio Nacional de Aprendizaje SenaDocument4 pagesServicio Nacional de Aprendizaje SenaAbnner GabrielNo ratings yet

- E2842E - V12 Gas Engine For CHPDocument4 pagesE2842E - V12 Gas Engine For CHPFlo MarineNo ratings yet