Professional Documents

Culture Documents

Dive Lab Dirty/Contaminated Water Diving Tips

Dive Lab Dirty/Contaminated Water Diving Tips

Uploaded by

PaulSmith89Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dive Lab Dirty/Contaminated Water Diving Tips

Dive Lab Dirty/Contaminated Water Diving Tips

Uploaded by

PaulSmith89Copyright:

Available Formats

Dive Lab, Inc.

1415 Moylan Road, Panama City Beach, FL 32407

Phone: 850-235-2715 Fax: 850-235-0858 E-mail: divelab@aol.com

Complete Support & Testing of Underwater Diving Equipment

Dirty/Contaminated Water Diving Tips

Mike Ward, July 6, 2010

Dive Lab and Kirby Morgan get a lot of inquires / questions from divers about what kind

of chemicals and contamination the KMDSI helmets can protect against, and what can be

done to minimize water exposure. The information herein primarily discusses the use of

KMDSI helmets, and gives information, and tips that will help to minimize the chances

of getting water into the helmet by explaining and identifying factors, conditions and

situations that can make water entry possible. This information is primarily for KMDSI

helmets however the concepts apply to other demand mod diving helmets.

KMDSI recommends that persons engaged in contaminated water diving be

properly trained in contaminated water diving and techniques. No diver is 100% safe

when diving in contaminated water, regardless of what brand, model, or type of helmet

and suit is being used. Besides water leakage, chemical gas permeation through the

rubber and fabric components can be a factor to deal with which can be deadly. To get a

good idea of stay times and risks, you would have to know exactly what chemicals are

present, at what concentrations, and then you would also need to know if any of the

chemicals when combined add to the hazard. Also, when it comes to permeation, gases

like phosgene and chlorine, know few boundaries. It is virtually impossible to cover all

the scenarios and combinations.

The main purpose of this paper is to educate helmet users how to best operate and use

Kirby Morgan helmets from the diver’s point of view so the diver stays dry. Simply put,

if you don’t use and dive a helmet and dry suit the right way, you are probably going to

get wet, and once wet you are exposed.

Diving in contaminated waters can pose serious health risks and requires special

equipment, procedures, and techniques. Most diving schools do not teach the detailed

specifics when it comes to how the diver must actually operate and adjust the helmet for

contaminated water diving.

For a helmeted diver to stay dry, a dry, properly maintained, good quality dry suit

attached directly to the helmet is required. For maximum protection, a helmet equipped

with a DIVEX™ (Dirty Harry) return line system is probably the best choice because it

Copyright© 2010, Dive Lab, Inc. All Rights Reserved. 1

Contaminated/Dirty Water Dive Tips July 2010

exhausts to the surface and minimizes the possibility of water entering the exhaust system

due to suspended debris and / or chemical deterioration of the exhaust system. Return

line systems have a supply and return hose and basically provide the helmet with

breathing gas, then exhausts the exhalation gas up the exhaust hose to the surface so the

exhaled breathing gas is never in contact with the water. Even a return line system is not

perfect, and getting water in the helmet and suit is still a possibility under certain

circumstances. In addition, return line systems are extremely expensive making them out

of reach for many companies because quite often the customers are not willing to pay a

diving contractor the extra money for having this type of equipment, especially if he can

get a SCUBA diver to do it with a full face mask for ¼ of the price. The competitive

nature of diving contract work, lack of labor enforcement, and prospect of saving money,

often results in safety being compromised.

Dirty Diving: For contaminated water diving, any of the Kirby Morgan helmets

equipped with the quad valve system and properly mated to a dry suit will offer a high

degree of protection from biological, chemical, and petroleum contaminated waters. Of

all the KMDSI helmets used for contaminated water diving the KM-37 and KM-77 seem

to be the helmets of choice. Regardless of the helmet model used, in order to stay dry

throughout the dive requires not only a good sealing system between the helmet, cuffs,

suit, and suit penetrations, but also a good understanding of how and why water can enter

the suit system, and how to minimize the possibility of water entering. Regardless of the

type of helmet or dry suit used, getting water into the helmet or suit is always possible if

the diver does not take precautions and / or does not operate and maintain the system

properly.

Demand Systems: Demand mode diving by the very name means the diver receives

breathing gas when he demands it. Unlike free flow helmets, which flow air into the

helmet continuously throughout the inhalation and exhalation cycle, demand mode

helmets are mainly intended to deliver air on demand during the inhalation cycle only. As

the diver starts to inhale, a negative pressure is created within the oral nasal / demand

regulator body drawing the regulator diaphragm against the inlet valve lever activating

gas flow into the oral nasal. The “Crack” or “Lift Off” is the term given to the very first

start of gas flow. The crack is brief point where the valve soft seat just starts to lift away

from the sharp edge of the inlet orifice. The force required to cause the “crack” is

normally measured and expressed in millibars (mbr) of pressure. For good breathing

performance it is essential that the “lift off” be as low as possible typically around 3-7

mbr, and remain as low as possible throughout the inhalation cycle. With all KMDSI

helmets, the cracking effort can be controlled by the diver using the regulator bias

adjustment located on the left side of the demand regulator. The bias adjustment simply

increases or decreases the amount of pressure that seals the inlet valve to the seat surface.

The actual inhalation effort required during the inhale phase of the breathing cycle is

primarily a function of the supply pressure and the bias setting, but the diver attitude also

comes into play. Keeping the inhalation effort as low as possible requires a light enough

bias setting to allow the inlet valve to lift away with minimal suck, and a supply pressure

high enough and steady enough to allow a venturi (vacuum) assist to develop to help float

the inlet valve. If the supply pressure is too low at the start of inhalation, the side block

Copyright© 2010, Dive Lab, Inc. All Rights Reserved. 2

Contaminated/Dirty Water Dive Tips July 2010

pressure will drop too far, killing the venturi action, therefore, reducing the pneumatic

assist and flow, requiring the diver to suck harder to open the inlet valve further to get

enough air. Because the diver now has to suck harder, a greater negative pressure is

created within the helmet and neck dam, which in turn is an invitation for water and

vapor permeation into the helmet.

Exhaust Valve Lift Off: Lift off is the term given to the very first start of gas flow

during exhalation. The exhaust lift off is also measured and expressed as pressure in mbr.

Typically, all KMDSI exhaust valve systems lift off between 3-5 mbr depending on the

physical attitude of the diver. The primary factors that influence exhalation effort are the

positioning of the exhaust valves, stiffness of the valves, number of valves, and the shape

and position of the exhaust (Whiskers).

Physical Attitude: Another major influence on demand regulator and helmet internal

pressure is the diver’s physical attitude. The further the demand regulator is from the

diver’s centroid, (Lung Center) the greater the inhalation effort will be. The closer the

regulator gets to the centroid, the easier the breathing will be. As an example, a helmet

diver standing on the bottom looking up at the surface will have a harder time inhaling

than he would if he was looking down at the sea floor. Normally, the easiest breathing

effort (least) overall is when the diver is in an almost face down angle. In this position,

the exhaust valves and demand diaphragm are closest to the lung centroid, requiring the

least differential pressure to make things work. A diver standing upright looking up can

back out slightly on the bias adjustment and make the inhalation easier. If the diver ends

up changing to head down position, he can simply dial in on the bias to keep the demand

regulator from free flowing.

Minimizing Water Entry: To minimize water entry into any demand mode helmet, the

two most important things the diver can do is to keep the inhalation effort as low as

possible, and avoid getting the demand regulator in a position that places the regulator

cover parallel or close to parallel to the bottom (sea floor). Cover “face down” to the

bottom is the position that the diver would be in if laying face down or attempting to

stand on his head, and in this position any water that was trapped in the exhaust body

would be directed to the demand regulator exhaust valve making it possible to get into

the regulator during exhalation. If for some reason you need to get into a weird position,

the diver should crack open the steady flow valve 1/8- 1/4 turn or so, two to three times

for about 1-2 seconds to purge out any water that has accumulated in the quad valve

plenum body. This is something divers should get in the habit of doing every few minutes

anyway to help eliminate any water that has accumulated in the exhaust system. Keep in

mind, when the valve opens, its opening in the water, the flapper is “In” the water! and it

gets water on it. When the flapper valve slams shut against the exhaust cage very small

amounts of water splash into the exhaust body and after a few minutes you have at least a

tea spoon or so of water in the dry sump of the exhaust body. The KMDSI quad valve is

is designed to minimize water build up and normal breathing will usually dispel most of

the water. Even if there was no water from outside there will be condensation forming

from the diver’s breath, and this will accumulate in the exhaust body and system. During

the inhalation phase of the breathing cycle, internal helmet pressures remain slightly less

Copyright© 2010, Dive Lab, Inc. All Rights Reserved. 3

Contaminated/Dirty Water Dive Tips July 2010

than the surrounding water pressure on average of about 3-5 mbr for light to moderate

work, (11-37rmv) 5-10 mbr for heavy work 38-54 rmv, and as high as 12-18 mbr for

extremely heavy work 62.5 rmv and above. Keep in mind, a lot of this depends on the

divers depth, and work rate, supply pressure, and bias adjustment. At shallower depths

and/or lower work rates, inhalation and exhalation pressures will be lower, significantly

reducing the risk of water intrusion.

Exhalation Effort: The primary factors that influence exhalation effort are the

positioning of the exhaust valves, stiffness of the valves, number of valves, and the shape

and position of the exhaust (Whiskers).

Inhalation Effort: The primary factors that influence inhalation resistance are supply

pressure, the bias adjustment setting of the demand regulator, and position of the

diaphragm in relation to the lung center due to the divers in water position. “Proper

Adjustment” Making sure regulator Bias Adjustment (Regulator adjustment knob) is

backed out to the lightest setting to ensure the lowest inhalation resistance for the

particular attitude the diver is working in will keep the negative pressure in the helmet as

low as possible reducing or minimizing the possibility of water entering through the

exhaust valves or small leaks in the suit or sealing surfaces.

Divers Attitude: The closer the demand valve diaphragm and exhaust valves are to the

lung center, the easier breathing will be. The further away the exhaust valves get from the

divers lung center, the greater the exhalation effort will be resulting in increased helmet

pressure. If the diver can minimize this distance, the result will be lower positive

pressure, and lower exhalation effort.

Dry Suit: It is extremely important to know how to properly use, operate, and maintain

the particular dry suit being used. It is important to minimize the negative pressure within

the suit because as the negative pressure increases so too does the possibility of water

leakage and gas permeation due to micro-pin holes, or worn or damaged seems.

Maintenance: The diver can significantly minimize or eliminate water intrusion by

knowing what conditions or circumstances can cause the water intrusion. First and

foremost, the helmet and equipment must be properly maintained. This means proper

cleaning, inspection, maintenance and pre dive testing IAW the KMDSI checklists and

operations manuals and the dry suit manufacturers’ recommendations and instructions.

Cleaning: Proper cleaning will keep the components free of corrosion and will make it

much easier to spot worn or damaged components and will help determine the

serviceability of components before failure occurs.

Petroleum and Exhaust Valves / Diaphragms: Some dives should not be made.

Making a dive inside tanks or compartments that are filled with fuel oils or chemicals

should never be attempted “period”! Even with a return line system. Fuel oils, as well as

other types of chemicals can permeate directly through the suit material and flexible

components and then it can be directly absorbed into the skin.

Copyright© 2010, Dive Lab, Inc. All Rights Reserved. 4

Contaminated/Dirty Water Dive Tips July 2010

The most vulnerable and sensitive components on the helmet are the neck dam, exhaust

valves, and diaphragm. The exhaust valves and diaphragms used on all KMDSI Helmets

are molded of high quality liquid silicone. Silicone just like rubber, will swell when it

comes in contact with high concentrations of most petroleum products such as crude oil,

diesel, gasoline, and hydraulic fluids to name a few. Once the valves swell beyond 10%,

they will not seal properly and exhaust leakage can occur. The amount of swelling

depends on the type of fluid, concentration, and exposure time. Unless the valves remain

in contact with the high concentrations for more than a minute or two, they will usually

work and hold up fairly well, however, it is safer to start off with short duration dives,

then pull, and inspect the two quad valves after each dive. If inspection of the flapper

valves reveals swelling or damage, adjustments to the dive plan will need to be made

and/or the valves and diaphragm will require frequent changing. Keep in mind that fuel

and oils will rise in water and collect on the surface. When making water entries and

exits, use a water hose if possible to make an entry and exit point for the diver reducing

exposure of the suit and helmet during entry and exit reducing high concentration

exposure. Keep in mind, dry suits are considered a consumable item and after the first use

in certain chemicals and oils, all bets are off. At $1500-$2500, many companies cannot

afford to only use the suit for one dive. Diving in high concentrations of oil and

chemicals can be extremely hazardous because gases can permeate through the suit and

polymer components. The worst case is direct exposure to high concentrations of refined

fuels like gasoline, diesel, found in retention ponds, fuel camels, and sunken barges. In

cases like this, other practices must be brought into play. This information does not just

apply to KMDSI helmets, but many other brands of helmets as well.

Dive Safe and Stay Dry.

Reminder: Please don’t hesitate to call or e-mail technical questions or problems. It is

important to include e-mails (CC) to KMDSI as well. KMDSI is interested in any and all

comments, problems and anything that can make it better for the user/maintainer.

Best Regards,

Mike Ward

Dive Lab, Inc

850-235-2715

Copyright© 2010, Dive Lab, Inc. All Rights Reserved. 5

Contaminated/Dirty Water Dive Tips July 2010

You might also like

- US Navy Diving Manual Rev 7Document991 pagesUS Navy Diving Manual Rev 7PaulSmith89100% (13)

- SINGING. An Extensive Handbook For All Singers and Their Teachers 2Document172 pagesSINGING. An Extensive Handbook For All Singers and Their Teachers 2Paul Anthony Westhead95% (20)

- Hazards of Trapped Pressure and VacuumDocument97 pagesHazards of Trapped Pressure and VacuumDucViking88% (8)

- Multigauge 3000 Underwater Thickness Gauge User ManualDocument28 pagesMultigauge 3000 Underwater Thickness Gauge User ManualPaulSmith89No ratings yet

- General Diving ProceduresDocument9 pagesGeneral Diving ProceduresAndre KrugelNo ratings yet

- IndustrialDocument30 pagesIndustrialkcontreras_79309No ratings yet

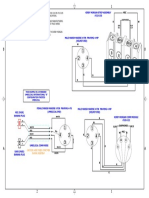

- Dive Lab - Four Wire Comms Configuration Kirby MorganDocument1 pageDive Lab - Four Wire Comms Configuration Kirby MorganPaulSmith89No ratings yet

- ADCI International Consensus Standards For Commercial Diving and Underwater Operations 6.4 EditionDocument370 pagesADCI International Consensus Standards For Commercial Diving and Underwater Operations 6.4 EditionPaulSmith89100% (1)

- Surya NamaskarDocument64 pagesSurya Namaskarsivaramv8100% (3)

- Desco Diving Hat ManualDocument14 pagesDesco Diving Hat Manualcaptain essamNo ratings yet

- Diving High Risk CH 4 8-07Document24 pagesDiving High Risk CH 4 8-07Henry ArismendiNo ratings yet

- Commercial DivingDocument53 pagesCommercial Divingtarekeee100% (4)

- Valve Manual 2012Document2 pagesValve Manual 2012António VCNo ratings yet

- SR-1053 Resilient Seated BFV Applications 2010-10Document7 pagesSR-1053 Resilient Seated BFV Applications 2010-10Carlos GutierrezNo ratings yet

- Coverstar Eclipse Pool Cover ManualDocument12 pagesCoverstar Eclipse Pool Cover Manualgrn4jdNo ratings yet

- CECA - Adsorbents Handling ProceduresDocument15 pagesCECA - Adsorbents Handling ProceduresRonald SzafirskiNo ratings yet

- Pool Closing GuideDocument4 pagesPool Closing GuideSteve CeeNo ratings yet

- August 2005Document2 pagesAugust 2005Roy NawarNo ratings yet

- Breathing From Scuba: Safety EquipmentDocument5 pagesBreathing From Scuba: Safety EquipmentZamhyrre Perral - ABE FairviewNo ratings yet

- Build Hookah 2Document12 pagesBuild Hookah 2dannyjan5080No ratings yet

- SOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Document4 pagesSOP SMB - 050.1 - Using A Rotory Evaporator DF NS 0614Kimia AsikNo ratings yet

- Scientific Diving LP 2Document4 pagesScientific Diving LP 2Keanu Denzel BolitoNo ratings yet

- Hookah Airline Owners ManualDocument161 pagesHookah Airline Owners Manualdale1238501No ratings yet

- Introduction To Maritime Safety G 12 Module LessonDocument25 pagesIntroduction To Maritime Safety G 12 Module Lessonken geornie benavente100% (1)

- History: Early Diving GearDocument6 pagesHistory: Early Diving GearIrene QuiñonesNo ratings yet

- Vacuum ContaminationDocument4 pagesVacuum Contaminationelkin manrique100% (1)

- Scuba DivingDocument12 pagesScuba DivingStefan BogosavljevićNo ratings yet

- Diver Mobility: Nitrogen Decompression Sickness NarcosisDocument6 pagesDiver Mobility: Nitrogen Decompression Sickness NarcosisZamhyrre Perral - ABE FairviewNo ratings yet

- Assignment IndividualDocument18 pagesAssignment IndividualAqil FadzilNo ratings yet

- Group 1 Scuba Diving 1Document160 pagesGroup 1 Scuba Diving 1TunelyNo ratings yet

- Basic Facts About Scuba Diving PDFDocument3 pagesBasic Facts About Scuba Diving PDFRagnesh SaijaNo ratings yet

- Uso Globos CerradosDocument2 pagesUso Globos CerradosMiguel CantóNo ratings yet

- Scuba Diving ProjDocument6 pagesScuba Diving ProjHarshNo ratings yet

- Owner'S Manual Life Preserver Survival Vest #485 (Manual) : Warnings & CautionsDocument2 pagesOwner'S Manual Life Preserver Survival Vest #485 (Manual) : Warnings & CautionsFlorin NiteNo ratings yet

- For Swimming Pools Bermuda Gunite Skimmer: Installation and User'S GuideDocument12 pagesFor Swimming Pools Bermuda Gunite Skimmer: Installation and User'S GuideKhalid RamanNo ratings yet

- Scuba BuildDocument9 pagesScuba BuildLlamarama5000No ratings yet

- SCUBA Module 1Document23 pagesSCUBA Module 1Von Genevieve LoquiasNo ratings yet

- Before Diving Make A Complete Dive Plan Together & Estimate Sea ConditionsDocument8 pagesBefore Diving Make A Complete Dive Plan Together & Estimate Sea ConditionsMike LuckyNo ratings yet

- Helicopter Pilot Egress Emergency ProcedureDocument16 pagesHelicopter Pilot Egress Emergency ProcedureORLANDO CASTILLONo ratings yet

- Manual Filtros Dynamic Series Rainbow Pentair InglesDocument2 pagesManual Filtros Dynamic Series Rainbow Pentair InglesIrvin Enrique Solano SalvadorNo ratings yet

- Orals Gravity DiscDocument33 pagesOrals Gravity DiscHARISHNo ratings yet

- SHS - HOPE4 - Week 6Document23 pagesSHS - HOPE4 - Week 6Kristian Benedict BernardoNo ratings yet

- Chapter 6 Diving and SubmersiblesDocument11 pagesChapter 6 Diving and SubmersiblesMuhamed BadawiNo ratings yet

- DuraMax Manual REV5Document20 pagesDuraMax Manual REV5CanadaPoolNo ratings yet

- InflatableLifeJacketBasics PDFDocument5 pagesInflatableLifeJacketBasics PDFAnisa Ayu RinjaniNo ratings yet

- Inflatable Lifejacket BasicsDocument5 pagesInflatable Lifejacket BasicsDaniel SetyadiNo ratings yet

- InflatableLifeJacketBasics PDFDocument5 pagesInflatableLifeJacketBasics PDFAnisa Ayu RinjaniNo ratings yet

- Dive Equipment Lesson 5Document95 pagesDive Equipment Lesson 5Stanley IdiNo ratings yet

- 09 MaintenanceDocument2 pages09 MaintenanceahikmathNo ratings yet

- Pool FilterDocument5 pagesPool FilterChris NewmanNo ratings yet

- Instructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air ValvesDocument15 pagesInstructions On Installation, Operation and Maintenance For Kirloskar Kinetic Air Valvessure_iitdNo ratings yet

- MulticycloneDocument7 pagesMulticycloneIrvin Enrique Solano SalvadorNo ratings yet

- Multicyclone ManualDocument4 pagesMulticyclone ManualPASEOS13728No ratings yet

- Aquatics Snorkeling Scuba Diving PPT Stdents CPDocument35 pagesAquatics Snorkeling Scuba Diving PPT Stdents CPMarbie MaumbasNo ratings yet

- Divator MKII Face Mask Instruction ManualDocument21 pagesDivator MKII Face Mask Instruction ManualDaniel Martinez BernalNo ratings yet

- SCUBADocument6 pagesSCUBACriselle Joy LaviñaNo ratings yet

- ةرازو يممعلا ثحبلاو يلاعلا ميمعتلا ةيمك رافلا ا عماجلا يب ة ةمحرملا ةيناثلا: Fluid flow2 ةداملا ريرقت ناونعب Butterfly valve نم بلاطلا لبق باهيا دامح ديلو فارشأب ذاتسلاا: ريملاادبع ةزمحDocument18 pagesةرازو يممعلا ثحبلاو يلاعلا ميمعتلا ةيمك رافلا ا عماجلا يب ة ةمحرملا ةيناثلا: Fluid flow2 ةداملا ريرقت ناونعب Butterfly valve نم بلاطلا لبق باهيا دامح ديلو فارشأب ذاتسلاا: ريملاادبع ةزمحHamzah A. LaftaNo ratings yet

- Mechanical Seal PresentationDocument48 pagesMechanical Seal Presentationsathesh100% (7)

- Ship Safety Bulletin: SubjectDocument4 pagesShip Safety Bulletin: SubjectAlonso OlayaNo ratings yet

- Hookah Instructions PDFDocument7 pagesHookah Instructions PDFPablito_rocketNo ratings yet

- PANAMA - Immersion SuitsDocument2 pagesPANAMA - Immersion Suitsyongmin seoNo ratings yet

- 165-Panama Circular Immersion SuitsDocument2 pages165-Panama Circular Immersion SuitsNeelakantan SankaranarayananNo ratings yet

- 55 Emerson Catalog PDFDocument82 pages55 Emerson Catalog PDF050678No ratings yet

- Lab Manual Separation Tech February 2023Document41 pagesLab Manual Separation Tech February 2023Nurhanis DayanaNo ratings yet

- DynaWave Centrifugal Pump With Integral Trap English SpanishDocument28 pagesDynaWave Centrifugal Pump With Integral Trap English SpanishsmitharsNo ratings yet

- OGP 411 2021 Recommended Practices For Diving OperationsDocument62 pagesOGP 411 2021 Recommended Practices For Diving OperationsPaulSmith89100% (1)

- Dive Lab Pipe ThreadsDocument2 pagesDive Lab Pipe ThreadsPaulSmith89No ratings yet

- Dive Lab - Kirby Morgan Helmets and Full Face Masks Differences and SimilaritiesDocument8 pagesDive Lab - Kirby Morgan Helmets and Full Face Masks Differences and SimilaritiesPaulSmith89No ratings yet

- Operator Training Guide 10-21-09-NEWDocument71 pagesOperator Training Guide 10-21-09-NEWPaulSmith89No ratings yet

- Manual DVR IPook BK-04Document30 pagesManual DVR IPook BK-04PaulSmith89No ratings yet

- TVI Lesson PlanDocument6 pagesTVI Lesson PlanRobelle RelativoNo ratings yet

- Evfuel Mccabe Gasoline Level Indicator Paste MsdsDocument9 pagesEvfuel Mccabe Gasoline Level Indicator Paste Msdsapi-525617690No ratings yet

- JUE-250 Installation Manual 7ZPSC0258 - Ver4.0 PDFDocument83 pagesJUE-250 Installation Manual 7ZPSC0258 - Ver4.0 PDFPaul Robert PredoiNo ratings yet

- Eliminating Tension and StressDocument2 pagesEliminating Tension and StressNicole HawkinsNo ratings yet

- Krylon - All Fast Dry Enamel PaintDocument4 pagesKrylon - All Fast Dry Enamel Paintjaredf@jfelectric.com100% (2)

- 7 Facial Yoga Exercises For Glowing Skin Forest EssentialsDocument1 page7 Facial Yoga Exercises For Glowing Skin Forest Essentialsswd5h6c57yNo ratings yet

- Practical 4 - Using A Simple RespirometerDocument4 pagesPractical 4 - Using A Simple RespirometerHashiniNo ratings yet

- Zoology Finals ReviewerDocument18 pagesZoology Finals ReviewerZian Lei MienNo ratings yet

- Breath Holding SpellDocument3 pagesBreath Holding SpellDimas Alphiano100% (1)

- Kerosene PoisoningDocument12 pagesKerosene PoisoningTheRHIC21No ratings yet

- Yoga Nidra PDFDocument7 pagesYoga Nidra PDFPablo Ronin100% (1)

- AsmaDocument9 pagesAsmaFegiNo ratings yet

- Administering Oxygen Therapy Powerpoint 3Document58 pagesAdministering Oxygen Therapy Powerpoint 3RajaNo ratings yet

- Trauma Coping Skills CardsDocument16 pagesTrauma Coping Skills CardsPayal KNo ratings yet

- Nasal Airway and Malocclucion / Orthodontic Courses by Indian Dental AcademyDocument35 pagesNasal Airway and Malocclucion / Orthodontic Courses by Indian Dental Academyindian dental academyNo ratings yet

- Fundamentals of MarksmanshipDocument6 pagesFundamentals of MarksmanshipGrozny GroznyNo ratings yet

- Marine Fuels: Safety Data SheetDocument33 pagesMarine Fuels: Safety Data SheetAhmad YaniNo ratings yet

- Sweeping TipsDocument3 pagesSweeping Tipssonaliforex1100% (2)

- ĐỌC 2 (Đáp Án Kèm Theo)Document10 pagesĐỌC 2 (Đáp Án Kèm Theo)Huy Hữu Ngọc LêNo ratings yet

- Safety Data SheetsDocument150 pagesSafety Data SheetsHitesh Soni0% (1)

- Nursing Manag BURNDocument34 pagesNursing Manag BURNumi margi rahayuNo ratings yet

- Simulated Exam RationalesDocument20 pagesSimulated Exam Rationalesrhymes2u100% (3)

- Aro KursDocument63 pagesAro KursFilipJovanovskiNo ratings yet

- 8465 1F QP Synergy SpecimenSet 2 v1.0 PDFDocument34 pages8465 1F QP Synergy SpecimenSet 2 v1.0 PDFK's Gaming0% (1)

- Discharge Planning ASTHMADocument4 pagesDischarge Planning ASTHMANadja JamilahNo ratings yet

- Salitair Salt Air Inhaler - Salt Therapy in Your Own Home!Document4 pagesSalitair Salt Air Inhaler - Salt Therapy in Your Own Home!saltairinhalerNo ratings yet

- Vol.13 Human Performance and LimitationsDocument222 pagesVol.13 Human Performance and LimitationsMostafa MohsenNo ratings yet

- Respiratory System Concept MapDocument1 pageRespiratory System Concept MapsamNo ratings yet