Professional Documents

Culture Documents

Crankshaft Position Sensor - Remove and Install (RENR9705) C13

Crankshaft Position Sensor - Remove and Install (RENR9705) C13

Uploaded by

Allan LariosaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Crankshaft Position Sensor - Remove and Install (RENR9705) C13

Crankshaft Position Sensor - Remove and Install (RENR9705) C13

Uploaded by

Allan LariosaCopyright:

Available Formats

2006/04/10 Crankshaft Position Sensor - Remove and Install (RENR9705)

SMCS - 1912 i02531273

Removal Procedure

Note: Put identification marks on all hoses, on all hose assemblies, on all wires, and on all tube assemblies for installation purposes. Plug all hose

assemblies and all tube assemblies. This helps to prevent fluid loss, and this helps to keep contaminants from entering the system.

Note: Cleanliness is an important factor. Before you begin the removal procedure, the exterior of the components should be thoroughly cleaned.

This will help to prevent dirt from entering the internal mechanism.

NOTICE

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and

repair of the product. Be prepared to collect the fluid with

suitable containers before opening any compartment or

disassembling any component containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Dealer

Service Tool Catalog" for tools and supplies suitable to collect

and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

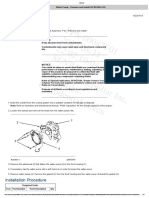

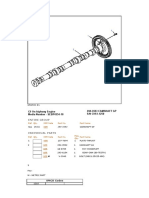

Illustration 1 g01266363

1. Disconnect harness assembly (1). Remove bolt (2) and crankshaft position sensor (3) .

Installation Procedure

Note: Cleanliness is an important factor. Before assembly, thoroughly clean all parts in cleaning fluid. Allow the parts to air dry. Do not use wiping

cloths or rags to dry parts. Lint may be deposited on the parts which may cause trouble. Inspect all parts. If any parts are worn or damaged, use

new parts for replacement. Dirt and other contaminants can damage the precision component. Perform assembly procedures on a clean work

surface. Keep components covered and protected at all times.

Note: Check the O-ring seals, the gaskets, and the seals for wear or for damage. Replace the components, if necessary.

NOTICE

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and

repair of the product. Be prepared to collect the fluid with

suitable containers before opening any compartment or

disassembling any component containing fluids.

Refer to Special Publication, NENG2500, "Caterpillar Dealer

Service Tool Catalog" for tools and supplies suitable to collect

and contain fluids on Caterpillar products.

Dispose of all fluids according to local regulations and

mandates.

Illustration 2 g01266363

1. Install crankshaft position sensor (3). Make sure that crankshaft position sensor (3) is fully seated in the bore. Install bolt (2). Connect harness

assembly (1) .

PPI-0004826A

2021/06/11

01:53:55+08:00

i02531273

© 2021 Caterpillar Inc.

Caterpillar:

Confidential Green

You might also like

- 3114 3116 3126 Disassembly and Assemblypdf PDFDocument253 pages3114 3116 3126 Disassembly and Assemblypdf PDFGeorge Guerrero100% (9)

- John S. Tjia - Building Financial Models, Third Edition - The Complete Guide To Designing, Building, and Applying Projection ModelsDocument379 pagesJohn S. Tjia - Building Financial Models, Third Edition - The Complete Guide To Designing, Building, and Applying Projection ModelsSec ok100% (3)

- Caterpillar Cat 247 MULTI TERRAIN LOADER (Prefix CML) Service Repair Manual (CML00001 and Up)Document22 pagesCaterpillar Cat 247 MULTI TERRAIN LOADER (Prefix CML) Service Repair Manual (CML00001 and Up)rpoy93966150% (1)

- 6WG1 e 01 (2 - 2)Document266 pages6WG1 e 01 (2 - 2)mohan100% (8)

- Pinion and Carrier Group - Disassemble - In-ChassisDocument4 pagesPinion and Carrier Group - Disassemble - In-ChassisNidya Wardah JuhanaNo ratings yet

- C13 Camshaft Position Sensor - Remove and Install (RENR9705)Document2 pagesC13 Camshaft Position Sensor - Remove and Install (RENR9705)Allan LariosaNo ratings yet

- Engine Oil Pressure Sensor - Remove and Install - Intake Valve Actuator (RENR9705) C13Document2 pagesEngine Oil Pressure Sensor - Remove and Install - Intake Valve Actuator (RENR9705) C13Allan LariosaNo ratings yet

- Remove Turbo 9zrDocument3 pagesRemove Turbo 9zrPRISMA WPNo ratings yet

- Removal Procedure: NoticeDocument2 pagesRemoval Procedure: Noticerakhikishore143No ratings yet

- 3406e MARINE Disassembly AssemblyDocument337 pages3406e MARINE Disassembly AssemblypremierrepairNo ratings yet

- Fuel System Filter-ReplaceDocument3 pagesFuel System Filter-ReplaceFiza IlmiNo ratings yet

- Sis 2.0Document3 pagesSis 2.0Mly ObrequeNo ratings yet

- Sis 2.0Document2 pagesSis 2.0Tomi Ananda PradistyNo ratings yet

- Cilindro de Direccion - 4Document13 pagesCilindro de Direccion - 4agarlab02No ratings yet

- Inyect OreDocument2 pagesInyect OreBrayan Sánchez ParedesNo ratings yet

- Fuel Transfer Pump - Remove (SENR1126-36)Document2 pagesFuel Transfer Pump - Remove (SENR1126-36)redminote12pro.5garNo ratings yet

- Bomba Aceite Motor RemocionDocument3 pagesBomba Aceite Motor RemocionCRIATHIANNo ratings yet

- Caterpillar Cat 235B EXCAVATOR (Prefix 9PC) Service Repair Manual (9PC00001-UP)Document23 pagesCaterpillar Cat 235B EXCAVATOR (Prefix 9PC) Service Repair Manual (9PC00001-UP)rpoy9396615No ratings yet

- Turbocharger - Install (SENR1126-36)Document3 pagesTurbocharger - Install (SENR1126-36)redminote12pro.5garNo ratings yet

- Water Pump - Remove (SENR1126-36)Document5 pagesWater Pump - Remove (SENR1126-36)redminote12pro.5garNo ratings yet

- Caterpillar Cat 229 EXCAVATOR (Prefix 1AG) Service Repair Manual (1AG00001 and Up)Document36 pagesCaterpillar Cat 229 EXCAVATOR (Prefix 1AG) Service Repair Manual (1AG00001 and Up)rpoy9396615No ratings yet

- Water Pump - RemoveDocument3 pagesWater Pump - RemoveAlexander LauraNo ratings yet

- 14H Motor Grader Rear Chassis Support RemoveDocument9 pages14H Motor Grader Rear Chassis Support RemoveMahmoud SamerNo ratings yet

- Fuel Filter Base - RemoveDocument2 pagesFuel Filter Base - RemoveYUDI WAHYUDI 17249No ratings yet

- 33 Crankshaft Rear Seal - RemoveDocument2 pages33 Crankshaft Rear Seal - RemovegwahyudinnNo ratings yet

- Turbocharger - Remove (SENR1126-36)Document3 pagesTurbocharger - Remove (SENR1126-36)redminote12pro.5garNo ratings yet

- 312C & 312C L Excavators FDS00301-UP (MACHINE) POWERED BY 3064 Engine (SEBP3833 - 38) - Documentation PDFDocument3 pages312C & 312C L Excavators FDS00301-UP (MACHINE) POWERED BY 3064 Engine (SEBP3833 - 38) - Documentation PDFRaul RodriguezNo ratings yet

- 312C & 312C L Excavators FDS00301-UP (MACHINE) POWERED BY 3064 Engine (SEBP3833 - 38) - DocumentationDocument3 pages312C & 312C L Excavators FDS00301-UP (MACHINE) POWERED BY 3064 Engine (SEBP3833 - 38) - DocumentationRaul RodriguezNo ratings yet

- Fuel Priming Pump - Remove and Install (SENR1126-36)Document3 pagesFuel Priming Pump - Remove and Install (SENR1126-36)redminote12pro.5garNo ratings yet

- Cylinder Liner RemoveSMCS 1216 011Document2 pagesCylinder Liner RemoveSMCS 1216 011andi yusufNo ratings yet

- Protector de Tren de PotenciaDocument3 pagesProtector de Tren de PotenciaElford Yalico vargasNo ratings yet

- Water Temperature Regulators - Remove (SENR1126-36)Document3 pagesWater Temperature Regulators - Remove (SENR1126-36)redminote12pro.5garNo ratings yet

- 320C, 320C L, 320C LN Excavator: Service Repair ManualDocument23 pages320C, 320C L, 320C LN Excavator: Service Repair ManualPatricio OrdóñezNo ratings yet

- Supply Pump RemoveDocument6 pagesSupply Pump Removeeshopmanual EnamNo ratings yet

- Pistion and Connetion Rod removeSMCS - 1225 - 011Document2 pagesPistion and Connetion Rod removeSMCS - 1225 - 011ZakNo ratings yet

- Transmission Pressures - Test (SENR9159-10)Document3 pagesTransmission Pressures - Test (SENR9159-10)Anderson Oliveira SilvaNo ratings yet

- PSP-000B669A 2024/03/02 04:19:16+07:00 KENR8106 © 2024 Caterpillar IncDocument3 pagesPSP-000B669A 2024/03/02 04:19:16+07:00 KENR8106 © 2024 Caterpillar IncFiza IlmiNo ratings yet

- KM 6WG1 e 02 (2 - 2) PDFDocument272 pagesKM 6WG1 e 02 (2 - 2) PDFDick Gii100% (2)

- Turbocharger - Remove (SENR1126-36)Document4 pagesTurbocharger - Remove (SENR1126-36)redminote12pro.5garNo ratings yet

- Valtek Spring Cylinder Rotary Actuators: General InformationDocument8 pagesValtek Spring Cylinder Rotary Actuators: General InformationJUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Section 8 Maintenance and Repair: Safety Storing ComponentsDocument22 pagesSection 8 Maintenance and Repair: Safety Storing ComponentsJonathanDavidDeLosSantosAdornoNo ratings yet

- Procedimiento Suspencion 740Document6 pagesProcedimiento Suspencion 740Mauricio AlejandroNo ratings yet

- Accumulator Discharging and Charging ProceduresDocument25 pagesAccumulator Discharging and Charging Proceduresbenjir shuvoNo ratings yet

- Remove Brake Valve - Brake RelayDocument3 pagesRemove Brake Valve - Brake Relaysuwardiwardi307No ratings yet

- 330D-336D Testing and Adjusting (RENR9585-11) PDFDocument176 pages330D-336D Testing and Adjusting (RENR9585-11) PDFDiego Alonso Huaraca Baleriano100% (3)

- Using The 362-3555 Connector Repair Kit To Service Harnesses With Ampseal 16 Connectors (0685, 1408)Document37 pagesUsing The 362-3555 Connector Repair Kit To Service Harnesses With Ampseal 16 Connectors (0685, 1408)Rajan MullappillyNo ratings yet

- Turbocharger - Remove - Turbocharger Top Mounted (KENR6081-15)Document4 pagesTurbocharger - Remove - Turbocharger Top Mounted (KENR6081-15)Anderson Oliveira SilvaNo ratings yet

- Caterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U03765 and UP)Document28 pagesCaterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U03765 and UP)rpoy9396615No ratings yet

- Scrren Now Uses Cooling Lines 777GDocument3 pagesScrren Now Uses Cooling Lines 777GJUAN PABLONo ratings yet

- SM47576Document7 pagesSM47576Edison CorderoNo ratings yet

- KM 4HK1 - 6HK1 e 03 (20170310)Document365 pagesKM 4HK1 - 6HK1 e 03 (20170310)Rio SetiawanNo ratings yet

- Hitachi 4hk1 6hk1 Engine SMDocument20 pagesHitachi 4hk1 6hk1 Engine SMwillie100% (66)

- Engine Oil Cooler Bypass Valve - Remove and Install: Shutdown SISDocument4 pagesEngine Oil Cooler Bypass Valve - Remove and Install: Shutdown SISMbahdiro KolenxNo ratings yet

- Caterpillar Cat 320C L 320CL Excavator (Prefix GLA) Service Repair Manual (GLA00001 and Up)Document30 pagesCaterpillar Cat 320C L 320CL Excavator (Prefix GLA) Service Repair Manual (GLA00001 and Up)rpoy9396615No ratings yet

- Piloto Acumulador420eDocument2 pagesPiloto Acumulador420eWuagner MontoyaNo ratings yet

- Crankshaft RemoveDocument2 pagesCrankshaft RemoveFiza IlmiNo ratings yet

- Water Pump Removal 3500 EnginesDocument3 pagesWater Pump Removal 3500 EnginesIbrahim Shaaban AliNo ratings yet

- Volvo D12 - Manutenção 4Document10 pagesVolvo D12 - Manutenção 4UNICARGAS SU, Lda.No ratings yet

- 225 Excavator: Service Repair ManualDocument26 pages225 Excavator: Service Repair ManualAmel AlidraNo ratings yet

- 15904746-Isuzu Engine 4lb1 4lc1 4le1 Workshop Service Repair ManualDocument210 pages15904746-Isuzu Engine 4lb1 4lc1 4le1 Workshop Service Repair Manual張家豪No ratings yet

- Graphic Color CodesDocument2 pagesGraphic Color CodesAllan LariosaNo ratings yet

- Engine Oil Pressure Sensor - Remove and Install - Intake Valve Actuator (RENR9705) C13Document2 pagesEngine Oil Pressure Sensor - Remove and Install - Intake Valve Actuator (RENR9705) C13Allan LariosaNo ratings yet

- Caterpillar Machines With Acert Technology: For More Information VisitDocument4 pagesCaterpillar Machines With Acert Technology: For More Information VisitAllan LariosaNo ratings yet

- Competitive Bulletin: Caterpillar ACERT™ vs. Volvo V-ACT Tier 3 EnginesDocument12 pagesCompetitive Bulletin: Caterpillar ACERT™ vs. Volvo V-ACT Tier 3 EnginesAllan LariosaNo ratings yet

- Cucumber Nutrition Facts and Health BenefitsDocument3 pagesCucumber Nutrition Facts and Health BenefitsAllan LariosaNo ratings yet

- 14m Hydraulic Fan SystemDocument1 page14m Hydraulic Fan SystemAllan LariosaNo ratings yet

- Coconut Water Nutrition Facts and Health BenefitsDocument3 pagesCoconut Water Nutrition Facts and Health BenefitsAllan LariosaNo ratings yet

- Cauliflower Nutrition Facts and Health BenefitsDocument3 pagesCauliflower Nutrition Facts and Health BenefitsAllan LariosaNo ratings yet

- Asparagus Nutrition Facts and Health BenefitsDocument3 pagesAsparagus Nutrition Facts and Health BenefitsAllan LariosaNo ratings yet

- Automotive Lighting System SimulatorDocument14 pagesAutomotive Lighting System SimulatorAllan LariosaNo ratings yet

- Electrical Fundamentals: Learning ObjectivesDocument18 pagesElectrical Fundamentals: Learning ObjectivesAllan LariosaNo ratings yet

- Diesel Fuel System Electronics - Topic 1Document3 pagesDiesel Fuel System Electronics - Topic 1Allan LariosaNo ratings yet

- Diesel Fuel System - Topic 1Document3 pagesDiesel Fuel System - Topic 1Allan LariosaNo ratings yet

- Click On The Region You Would Like To Review..Document20 pagesClick On The Region You Would Like To Review..Allan LariosaNo ratings yet

- Camshaft: C9 On-Highway Engine Media Number - SEBP4354-18 S/N C9S1-1250Document1 pageCamshaft: C9 On-Highway Engine Media Number - SEBP4354-18 S/N C9S1-1250Allan LariosaNo ratings yet

- Pragnesh Black Book 18Document77 pagesPragnesh Black Book 18Pragnesh PawarNo ratings yet

- Module 4 Chapter 3 3. Business CommunicationDocument14 pagesModule 4 Chapter 3 3. Business CommunicationAlian BarrogaNo ratings yet

- Summary About NetworkingDocument7 pagesSummary About Networkingdon dali100% (1)

- PSR IiDocument62 pagesPSR IiRizqy AgungNo ratings yet

- Aggregate Lab Internal Audit Practice AidDocument8 pagesAggregate Lab Internal Audit Practice AidTesfuNo ratings yet

- Build Hat Serial ProtocolDocument17 pagesBuild Hat Serial ProtocolDozer KamilNo ratings yet

- Q Mix Tmix 8-16-30 UsermanualDocument146 pagesQ Mix Tmix 8-16-30 UsermanualJonathan BayonaNo ratings yet

- Class 12 Complete Book of Informatics PracticesDocument220 pagesClass 12 Complete Book of Informatics PracticesSuraj RajNo ratings yet

- IOT, Sumaiya KhanDocument22 pagesIOT, Sumaiya Khanshashank kumarNo ratings yet

- DOP 107EV DOP-107CV: Instruction SheetDocument2 pagesDOP 107EV DOP-107CV: Instruction Sheetbhoo100% (1)

- Lecture01 IntroDocument45 pagesLecture01 Introali-AlshattiNo ratings yet

- ISO 15189:2003 - FROM THEORY INTO PRACTICE David BurnettDocument5 pagesISO 15189:2003 - FROM THEORY INTO PRACTICE David Burnettofusandeep100% (1)

- Humminbird Wide Optic ManualDocument32 pagesHumminbird Wide Optic ManualLaurent Chandezon50% (2)

- Manual Zodiac D-One BT - 18.08.23Document31 pagesManual Zodiac D-One BT - 18.08.23martonbiro07No ratings yet

- Lecture 5, 6, 7 & 8 Database Systems: Comsats University Islamabad, Wah CampusDocument59 pagesLecture 5, 6, 7 & 8 Database Systems: Comsats University Islamabad, Wah CampusSyed IrtazaNo ratings yet

- Adham 2 C.V 2016Document5 pagesAdham 2 C.V 2016Hazem MohamedNo ratings yet

- 032 - Performance - AnswersDocument139 pages032 - Performance - AnswersEASA ATPL Question BankNo ratings yet

- Volatile Matter in The Analysis of Particulate Wood Fuels: Standard Test Method ForDocument3 pagesVolatile Matter in The Analysis of Particulate Wood Fuels: Standard Test Method Foranna curatoloNo ratings yet

- New Microsoft Excel WorksheetDocument6 pagesNew Microsoft Excel WorksheetArvind HarikrishnanNo ratings yet

- B320 Series: Rugged and Dependable Bevel Gear Operators For Manual or Motorized Valve Control ApplicationsDocument12 pagesB320 Series: Rugged and Dependable Bevel Gear Operators For Manual or Motorized Valve Control ApplicationsThái Mai ĐìnhNo ratings yet

- Arif Ihtisham CVDocument2 pagesArif Ihtisham CVIHTISHAM ARIFNo ratings yet

- Api 653 Tank Inspection, Tank Maintenance, AND Causes of Tank FailureDocument43 pagesApi 653 Tank Inspection, Tank Maintenance, AND Causes of Tank FailureArif PriyadiNo ratings yet

- 5 Natiora MahagagaDocument13 pages5 Natiora MahagagaSafidiniaina Lahatra RasamoelinaNo ratings yet

- Grade 7 Week 2 Weekly Plan 2 5769Document6 pagesGrade 7 Week 2 Weekly Plan 2 5769amnakamran126No ratings yet

- Eke 2018 - EnglishDocument60 pagesEke 2018 - EnglishMauro GonzalezNo ratings yet

- Profile of Dr. K. KanagalakshmiDocument3 pagesProfile of Dr. K. KanagalakshmiBALAKUMAR CNo ratings yet

- Compression Test and Analysis of Tpu Material Using Utm & FeaDocument7 pagesCompression Test and Analysis of Tpu Material Using Utm & Feaci_balaNo ratings yet

- API 579 & a.S.M.E FFS-2 (2009) Fitness For Service - Example Problem ManualDocument4 pagesAPI 579 & a.S.M.E FFS-2 (2009) Fitness For Service - Example Problem ManualFarahat67% (3)

- (Research Paper) The Needs and Challenges of Adopting Business Intelligence in SME - Rasmey HeangDocument11 pages(Research Paper) The Needs and Challenges of Adopting Business Intelligence in SME - Rasmey HeangRasmey HeangNo ratings yet