Professional Documents

Culture Documents

Zinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product Information

Zinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product Information

Uploaded by

Thennarasu VelloreOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product Information

Zinc Clad Iii HS: Organic Zinc-Rich Epoxy Primer Industrial & Marine Coatings Product Information

Uploaded by

Thennarasu VelloreCopyright:

Available Formats

Module 10: Navigating Coating Specifications

Industrial 6.07

& ZINC CLAD® III HS

Marine ORGANIC ZINC-RICH EPOXY PRIMER

Coatings PART A

PART B

B69A100

B69V100

BASE

HARDENER

PART F B69D11 ZINC DUST

PRODUCT INFORMATION Revised 6/05

PRODUCT DESCRIPTION RECOMMENDED USES

ZINC CLAD III HS is a three-component, polyamide epoxy, For use over properly prepared blasted steel.

zinc-rich coating. It has a low VOC level and contains 90.5% • Fabrication Shops

by weight of zinc dust pigment in its dried film. • Bridge and Highway Structures

• Meets Class B requirements for Slip Coefficient and Creep • Stadiums and Sports Complexes

Resistance, .52 • Drilling Rigs

• Provides cathodic protection • Piping

• Damaged film exhibits "self-healing" properties • Refineries

• Fast Recoat Time • Barges and Ships

• Shop or Field Applications

• Not recommended for immersion service.

PRODUCT CHARACTERISTICS PERFORMANCE CHARACTERISTICS

Finish: Flat System Tested: (unless otherwise indicated)

Substrate: Steel

Color: Gray-green

Surface Preparation: SSPC-SP10

Volume Solids: 60% ± 2%, mixed 1 ct. Zinc Clad III HS @ 5.0 mils dft

1 ct. Macropoxy 646 @ 5.0-10.0 mils dft

Weight Solids: 90% ± 2%, mixed 1 ct. Acrolon 218 HS @ 5.0 mils dft

VOC (EPA Method 24): Unreduced: <340 g/L; 2.80 lb/gal

mixed Reduced 5%: <360 g/L; 3.00 lb/gal

Adhesion:

Method: ASTM D4541

Zinc Content in Dry Film: 90.5% by weight Result: 975 psi

Mix Ratio: 3 components, premeasured Corrosion Weathering

3.25 gallons total

Method: ASTM D5894, 13 cycles, 2016 hours

Recommended Spreading Rate per coat: Result: Rating 10 per ASTM D610 for rusting

Wet mils: 5.0 - 8.0 Rating 10 per ASTM D714 for blistering

Dry mils: 3.0 - 5.0

Coverage: 190 - 320 sq ft/gal approximate Dry Heat Resistance, zinc only:

Note: Brush application is for stripe coating and small areas only. Method: ASTM D2485

Drying Schedule @ 5.0 mils wet @ 50% RH: Result: 300°F

@ 40°F @ 77°F @ 120°F

To touch: 45 minutes 30 minutes 10 minutes Moisture Condensation Resistance:

To handle: 2 hours 1 hour 30 minutes Method: ASTM D4585, 100°F, 4000 hours

To recoat*: Result: Rating 10 per ASTM D610 for rusting

minimum: 4 hours 2 hours 1 hour

maximum: 1 year 1 year 1 year Rating 10 per ASTM D714 for blistering

To cure: 10 days 7 days 7 days

Pot Life: 6 hours 4 hours 2 hours Pencil Hardness, zinc only:

Sweat-in-Time: 1 hour 30 minutes 15 minutes Method: ASTM D3363

Result: 2H

Drying time is temperature, humidity, and film thickness dependent.

*NOTE: Film must be free of solvent, hard and firm. When rubbed with

the face of a coin or knife the film should polish but not flake or chip. Salt Fog Resistance:

Method: ASTM B117, 4500 hours

Shelf Life: Parts A, B, & F - 24 months, unopened Result: Rating 10 per ASTM D610 for rusting

Store indoors at 40°F to 100°F Rating 10 per ASTM D714 for blistering

Flash Point: 58°F, Seta Flash, mixed

Slip Coefficient, zinc only:

Reducer/Clean Up: Method: AISC Specification for Structural Joints Using

Below 80°F: MEK, R6K10 ASTM A325 or ASTM A490 Bolts

Above 80°F: Reducer #58 (R7K58) or Result: Class B, 0.52

MEK (R6K10)

Zinc Rich 6.07 continued on back

Protective Coatings Inspector Training

©2013 SSPC W10-11

Module 10: Navigating Coating Specifications

Industrial 6.07

& ZINC CLAD® III HS

Marine ORGANIC ZINC-RICH EPOXY PRIMER

PART A B69A100 BASE

Coatings PART B B69V100 HARDENER

PART F B69D11 ZINC DUST

PRODUCT INFORMATION

RECOMMENDED SYSTEMS SURFACE PREPARATION

Steel, polyurethane topcoat: Surface must be clean, dry, and in sound condition. Remove

1 ct. Zinc Clad III HS @ 3.0 - 5.0 mils dft all oil, dust, grease, dirt, loose rust, and other foreign material

1-2 cts. Acrolon 218 HS @ 3.0 - 6.0 mils dft/ct to ensure adequate adhesion.

Steel, catalyzed epoxy topcoat: Refer to product Application Bulletin for detailed surface prepa-

ration information.

1 ct. Zinc Clad III HS @ 3.0 - 5.0 mils dft

1-2 cts. Macropoxy 646 @ 5.0 - 10.0 mils dft/ct

Minimum recommended surface preparation:

Iron & Steel: SSPC-SP6/NACE 3, 2 mil

Steel, catalyzed epoxy topcoat: profile

1 ct. Zinc Clad III HS @ 3.0 - 5.0 mils dft Galvanizing: SSPC-SP7

1-2 cts. Tile-Clad HS @ 2.5 - 4.0 mils dft Weathered Zinc Rich Primer: Clean, dry, sound

Steel, acrylic topcoat: TINTING

1 ct. Zinc Clad III HS @ 3.0 - 5.0 mils dft

2 cts. DTM Acrylic Coating @ 2.5 - 4.0 mils dft/ct Do not tint.

or

1 ct. Fast Clad HB Acrylic @ 5.0 - 8.0 mils dft APPLICATION CONDITIONS

Temperature: 40°F minimum, 120°F maximum

Steel, water based epoxy topcoat: (air, surface, and material)

1 ct. Zinc Clad III HS @ 3.0 - 5.0 mils dft At least 5°F above dew point

2 cts. Waterbased Tile-Clad Epoxy @ 2.0 - 4.0 mils dft/ct Relative humidity: 85% maximum

Steel, water-based polyurethane topcoat: Refer to product Application Bulletin for detailed application

1 ct. Zinc Clad III HS @ 3.0 - 5.0 mils dft information.

1 ct. Waterbased Tile-Clad Epoxy @ 2.0 - 4.0 mils dft ORDERING INFORMATION

1-2 cts. Centurion WB Urethane @ 2.0 - 3.0 mils dft/ct

or Packaging: 3.25 gallons mixed

1-2 cts. Hydrogloss@ 2.0-4.0 mills dft/ct Part A 1 gallon

Part B 1 gallon

Steel, Class B Compliant System: Part F 73 lb Zinc Dust

1 ct Zinc Clad III HS @ 3.0-5.0 mils dft

Weight per gallon: 27.63 ± 0.2 lb, mixed

1 ct Steel Spec Epoxy Primer (red) @4.0-6.0 mils dft

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use.

The systems listed above are representative of the product's Published technical data and instructions are subject to

use. Other systems may be appropriate. change without notice. Contact your Sherwin-Williams repre-

sentative for additional technical data and instructions.

DISCLAIMER WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufactur-

The information and recommendations set forth in this Product Data Sheet are ing defects in accord with applicable Sherwin-Williams quality control procedures.

based upon tests conducted by or on behalf of The Sherwin-Williams Company. Liability for products proven defective, if any, is limited to replacement of the

Such information and recommendations set forth herein are subject to change defective product or the refund of the purchase price paid for the defective

and pertain to the product offered at the time of publication. Consult your product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUAR-

Sherwin-Williams representative to obtain the most recent Product Data Infor- ANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR

mation and Application Bulletin. IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUD-

ING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Protective Coatings Inspector Training

©2013 SSPC W10-12

Module 10: Navigating Coating Specifications

Industrial 6.07A

& ZINC CLAD® III HS

Marine ORGANIC ZINC-RICH EPOXY PRIMER

Coatings PART A

PART B

B69A100

B69V100

BASE

HARDENER

PART F B69D11 ZINC DUST

APPLICATION BULLETIN Revised 6/05

SURFACE PREPARATION APPLICATION CONDITIONS

Zinc rich coatings require direct contact between the zinc pig- Temperature: 40°F minimum, 120°F maximum

ment in the coating and the metal substrate for optimum per- (air, surface, and material)

formance. Surface must be dry, free from oil, dirt, dust, mill At least 5°F above dew point

scale or other contaminants to ensure adequate adhesion.

Relative humidity: 85% maximum

Iron & Steel (atmospheric service)

Remove all oil and grease from surface by Solvent Cleaning

per SSPC-SP1. Minimum surface preparation is Commercial APPLICATION EQUIPMENT

Blast Cleaning per SSPC-SP6/NACE 3. For better perform-

ance, use Near White Metal Blast Cleaning per SSPC-SP10/ The following is a guide. Changes in pressures and tip sizes

NACE 2. Blast clean all surfaces using a sharp, angular abra- may be needed for proper spray characteristics. Always purge

sive for optimum surface profile (2 mils). Coat any bare steel spray equipment before use with listed reducer. Any reduc-

the same day as it is cleaned or before flash rusting occurs. tion must be compliant with existing VOC regulations and

compatible with the existing environmental and application

Galvanized Steel conditions.

Allow to weather a minimum of six months prior to coating.

Solvent Clean per SSPC-SP1 (recommended solvent is VM&P Reducer/Clean Up

Naphtha). When weathering is not possible, or the surface has Below 80°F ................... MEK, R6K10

been treated with chromates or silicates, first Solvent Clean Above 80°F ................... Reducer #58, R7K58 or

per SSPC-SP1 and apply a test patch. Allow paint to dry at MEK, R6K10

least one week before testing adhesion. If adhesion is poor, Airless Spray

brush blasting per SSPC-SP7 is necessary to remove these (use Teflon packings and continuous agitation)

treatments. Rusty galvanizing requires a minimum of Hand Tool Pressure ....................... 2000 - 2300 psi

Cleaning per SSPC-SP2, prime the area the same day as Hose ............................. 3/8" ID

cleaned or before flash rusting occurs. Tip ................................ .019"

Filter ............................. none

Weathered Zinc-Rich Primer Reduction ..................... As needed up to 5% by volume

Remove zinc salts by either high pressure water washing and

scrubbing with stiff bristle brush or sweep blast followed by Conventional Spray

water flush. Allow to dry. (continuous agitation required)

Gun ............................... Binks 95

Note: If blast cleaning with steel media is used, an appropri- Fluid Nozzle .................. 68

ate amount of steel grit blast media may be incorporated into Air Nozzle ..................... 68P

the work mix to render a dense, angular 1.5 - 2.0 mil surface Atomization Pressure .. 50 psi

profile. This method may result in improved adhesion and per- Fluid Pressure .............. 10 - 20 psi

formance. Reduction ..................... As needed up to 5% by volume

Keep pressure pot at level of applicator to avoid blocking of

fluid line due to weight of material. Blow back coating in fluid

line at intermittent shutdowns, but continue agitation at pres-

sure pot.

Brush

Brush ............................ Small areas only; natural bristle

Reduction ..................... Not recommended

If specific application equipment is not listed above, equiva-

lent equipment may be substituted.

Zinc Rich 6.07A continued on back

Protective Coatings Inspector Training

©2013 SSPC W10-13

Module 10: Navigating Coating Specifications

Industrial 6.07A

& ZINC CLAD® III HS

Marine ORGANIC ZINC-RICH EPOXY PRIMER

PART A B69A100 BASE

Coatings PART B B69V100 HARDENER

PART F B69D11 ZINC DUST

APPLICATION BULLETIN

APPLICATION PROCEDURES PERFORMANCE TIPS

Surface preparation must be completed as indicated. Stripe coat all crevices, welds, and sharp angles to prevent

Zinc Clad III HS comes in 3 premeasured containers which early failure in these areas.

when mixed provides 3.25 gallons of ready-to-apply material.

Mixing Instructions: When using spray application, use a 50% overlap with each

Mix contents of component A and B thoroughly with power pass of the gun to avoid holidays, bare areas, and pinholes. If

agitator. Make certain no pigment remains on the bottom of necessary, cross spray at a right angle.

the can. Then combine 1 part by volume of Part A with 1 part by

volume of Part B, then add Part F (73 lb zinc dust). Thoroughly Spreading rates are calculated on volume solids and do not

agitate the mixture with power agitation. After mixing, pour include an application loss factor due to surface profile, rough-

through a 30-60 mesh screen. Allow the material to sweat-in ness or porosity of the surface, skill and technique of the ap-

as indicated. Re-stir before using. plicator, method of application, various surface irregularities,

If reducer solvent is used, add only after components have material lost during mixing, spillage, overthinning, climatic

been thoroughly mixed, after sweat-in. conditions, and excessive film build.

Continuous agitation of mixture during application is required,

otherwise zinc dust will quickly settle out. Excessive reduction of material can affect film build, appear-

Apply paint at the recommended film thickness and spread- ance, and performance.

ing rate as indicated below:

Recommended Spreading Rate per coat: Do not mix previously catalyzed material with new.

Wet mils: 5.0 - 8.0

Dry mils: 3.0 - 5.0 Do not apply the material beyond recommended pot life.

Coverage: 190 - 320 sq ft/gal approximate

Note: Brush application is for stripe coating and small areas only. In order to avoid blockage of spray equipment, clean equip-

ment before use or before periods of extended downtime with

Drying Schedule @ 5.0 mils wet @ 50% RH: MEK, R6K10.

@ 40°F @ 77°F @ 120°F

To touch: 45 minutes 30 minutes 10 minutes Keep pressure pot at level of applicator to avoid blocking of

To handle: 2 hours 1 hour 30 minutes fluid line due to weight of material. Blow back coating in fluid

To recoat*: line at intermittent shutdowns, but continue agitation at pres-

minimum: 4 hours 2 hours 1 hour sure pot.

maximum: 1 year 1 year 1 year

To cure: 10 days 7 days 7 days Application above recommended film thickness may result in

Pot Life: 6 hours 4 hours 2 hours mud cracking.

Sweat-in-Time: 1 hour 30 minutes 15 minutes

Refer to Product Information sheet for additional performance

Drying time is temperature, humidity, and film thickness dependent. characteristics and properties.

*NOTE: Film must be free of solvent, hard and firm. When rubbed with

the face of a coin or knife the film should polish but not flake or chip.

Application of coating above maximum or below minimum

recommended spreading rate may adversely affect coating

performance.

CLEAN UP INSTRUCTIONS SAFETY PRECAUTIONS

Clean spills and spatters immediately with MEK, R6K10. Clean Refer to the MSDS sheet before use.

tools immediately after use with MEK, R6K10. Follow

manufacturer's safety recommendations when using any sol- Published technical data and instructions are subject to

vent. change without notice. Contact your Sherwin-Williams repre-

sentative for additional technical data and instructions.

DISCLAIMER WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufactur-

The information and recommendations set forth in this Product Data Sheet are ing defects in accord with applicable Sherwin-Williams quality control procedures.

based upon tests conducted by or on behalf of The Sherwin-Williams Company. Liability for products proven defective, if any, is limited to replacement of the

Such information and recommendations set forth herein are subject to change defective product or the refund of the purchase price paid for the defective

and pertain to the product offered at the time of publication. Consult your product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUAR-

Sherwin-Williams representative to obtain the most recent Product Data Infor- ANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR

mation and Application Bulletin. IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUD-

ING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Protective Coatings Inspector Training

©2013 SSPC W10-14

Module 10: Navigating Coating Specifications

Industrial 4.53

& MACROPOXY® 646

Marine FAST CURE EPOXY

Coatings PART A B58-600 SERIES

PART B B58V600 HARDENER

PRODUCT INFORMATION Revised 8/05

PRODUCT DESCRIPTION RECOMMENDED USES

MACROPOXY 646 FAST CURE EPOXY is a high solids, high • Marine applications

build, fast drying, polyamide epoxy designed to protect steel • Fabrication shops • Refineries

and concrete in industrial exposures. Ideal for maintenance • Pulp and paper mills • Chemical plants

painting and fabrication shop applications. The high solids • Power plants • Tank exteriors

content ensures adequate protection of sharp edges, corners, • Offshore platforms • Water treatment plants

and welds. This product can be applied directly to marginally • Mill White and Black are acceptable for immersion use for

prepared steel surfaces. salt water and fresh water, not acceptable for potable water

• Low VOC • Chemical resistant • Suitable for use in USDA inspected facilities

• Low odor • Abrasion resistant

Conforms to AWWA D102-03 OCS #5

PRODUCT CHARACTERISTICS PERFORMANCE CHARACTERISTICS

Finish: Semi-Gloss System Tested: (unless otherwise indicated)

Substrate: Steel

Surface Preparation: SSPC-SP10

Color: Mill White, Black and a wide range

1 ct. Macropoxy 646 Fast Cure @ 6.0 mils dft

of colors available through tinting Abrasion Resistance:

Method: ASTM D4060, CS17 wheel, 1000 cycles, 1 kg load

Volume Solids: 72% ± 2%, mixed Result: 84 mg loss

Mill White Accelerated Weathering - QUV, Zinc Clad II Plus Primer:

Weight Solids: 85% ± 2%, mixed Method: ASTM D4587, QUV-A, 12,000 hours

Mill White Results: passes

VOC (EPA Method 24): Unreduced: <250 g/L; 2.08 lb/gal Adhesion:

mixed Reduced 10%: <300 g/L; 2.50 lb/gal Method: ASTM D4541

Result: 1,037 psi

Mix Ratio: 1:1 by volume Corrosion Weathering, Zinc Clad II Plus Primer:

Method: ASTM D5894, 36 cycles, 12,000 hours

Recommended Spreading Rate per coat: Result: Rating 10 per ASTM D714 for blistering

Wet mils: 7.0 - 13.5 Rating 9 per ASTM D610 for rusting

Dry mils: 5.0 - 10.0* Direct Impact Resistance:

Coverage: 116 - 232 sq ft/gal approximate Method: ASTM D2794

Result: 30 in. lb.

NOTE: Brush or roll application may require multiple coats to achieve Dry Heat Resistance:

maximum film thickness and uniformity of appearance. Method: ASTM D2485

* See Recommended Systems Result: 250°F

Exterior Durability:

Drying Schedule @ 7.0 mils wet and 50% RH: Method: 1 year at 45° South

@ 40°F @ 77°F @ 100°F Result: Excellent, chalks

To touch: 4-5 hours 2 hours 1½ hours Flexibility:

To handle: 48 hours 8 hours 4½ hours Method: ASTM D522, 180° bend, 3/4" mandrel

To recoat: Result: Passes

minimum: 48 hours 8 hours 4½ hours Immersion:

maximum: 3 months 3 months 3 months Method: 1 year fresh and salt water

Cure for Result: Passes, no rusting, blistering, or loss of adhesion

service: 10 days 7 days 4 days Irradiation-Effects on Coatings used in Nuclear Power Plants

immersion: 14 days 7 days 4 days Method: ANSI 5.12 / ASTM D4082-89

If maximum recoat time is exceeded, abrade surface before recoating. Result: Passes

Drying time is temperature, humidity and film thickness dependent. Pencil Hardness:

Method: ASTM D3363

Pot Life: 10 hours 4 hours 2 hours Result: 3H

Permeability Rating:

Sweat-in-time: 30 minutes 30 minutes 15 minutes Method: ASTM D1653

Result: 0.154 mg/cm²

Shelf Life: 36 months, unopened Salt Fog Resistance, Zinc Clad II Plus Primer::

Store indoors at 40°F to 100°F. Method: ASTM B117, 6,500 hours

Result: Rating 10 per ASTM D610 for rusting

Flash Point: 60°F, TCC, mixed Rating 9 per ASTM D1654 for corrosion

Slip Coefficient, Mill White:

Method: AISC Specification for Structural Joints Using ASTM A325

Reducer/Clean Up: Reducer, R7K15 or ASTM A490 Bolts

In California: Reducer R7K111 or Oxsol 100 Result: Class A, 0.36

Epoxy coatings may darken or discolor following application and curing.

Epoxy 4.53 continued on back

Protective Coatings Inspector Training

©2013 SSPC W10-15

Module 10: Navigating Coating Specifications

Industrial 4.53

& MACROPOXY® 646

Marine FAST CURE EPOXY

Coatings PART A B58-600 SERIES

PART B B58V600 HARDENER

PRODUCT INFORMATION

RECOMMENDED SYSTEMS SURFACE PREPARATION

Immersion and atmospheric: Surface must be clean, dry, and in sound condition. Remove all oil,

dust, grease, dirt, loose rust, and other foreign material to ensure

Steel: good adhesion.

2 cts. Macropoxy 646 @ 5.0 - 10.0 mils dft/ct Refer to product Application Bulletin for detailed surface preparation

information.

Concrete/Masonry, smooth: Minimum recommended surface preparation:

2 cts. Macropoxy 646 @ 5.0 - 10.0 mils dft/ct Iron & Steel

Atmospheric: SSPC-SP2/3

Concrete Block:

1 ct. Kem Cati-Coat HS Epoxy Filler/Sealer Immersion: SSPC-SP10/NACE 2, 2-3 mil profile

@ 10.0 - 20.0 mils dft, as needed to fill voids and provide Aluminum: SSPC-SP1

a continuous substrate. Galvanizing: SSPC-SP1

2 cts. Macropoxy 646 @ 5.0 - 10.0 mils dft/ct Concrete & Masonry

Atmospheric: SSPC-SP13/NACE 6, or ICRI 03732, CSP

1-3

Atmospheric: Immersion: SSPC-SP13/NACE 6-4.3.1 or 4.3.2, or

*Steel: ICRI 03732, CSP 1-3

(Shop applied system, new construction, AWWA D102-03, can also

be used at 3 mils minimum dft when used as an intermediate coat TINTING

as part of a multi-coat system)

1 ct. Macropoxy 646 Fast Cure Epoxy Tint Part Awith 844 Colorants at 150% strength. Five minutes minimum

@ 3.0 - 6.0 mils dft mixing on a mechanical shaker is required for complete mixing of

1-2 cts. of recommended topcoat color.

Steel:

1 ct. Recoatable Epoxy Primer @ 4.0 - 6.0 mils dft Tinting is not recommended for immersion service.

2 cts. Macropoxy 646 @ 5.0 - 10.0 mils dft/ct

APPLICATION CONDITIONS

*Steel:

1 ct. Macropoxy 646 @ 4.0 - 6.0 mils dft Temperature: 40°F minimum, 140°F maximum

1-2 cts. Acrolon 218 Polyurethane @ 3.0 - 6.0 mils dft/ct (air, surface, and material)

or Hi-Solids Polyurethane @ 3.0 - 5.0 mils dft/ct At least 5°F above dew point

or SherThane 2K Urethane @ 2.0 - 4.0 mils dft/ct Relative humidity: 85% maximum

Steel:

2 cts. Macropoxy 646 @ 5.0 - 10.0 mils dft/ct Refer to product Application Bulletin for detailed application informa-

1-2 cts. Tile-Clad HS Epoxy @ 2.5 - 4.0 mils dft/ct tion.

Steel: ORDERING INFORMATION

1 ct. Zinc Clad II Plus @ 3.0 - 6.0 mils dft

1 ct. Macropoxy 646 @ 5.0 - 10.0 mils dft Packaging:

1-2 cts. Acrolon 218 Polyurethane @ 3.0 - 6.0 mils dft/ct Part A: 1 and 5 gallon containers

Steel: Part B: 1 and 5 gallon containers

1 ct. Zinc Clad III HS @ 3.0 - 5.0 mils dft

or Zinc Clad IV @ 3.0 - 5.0 mils dft Weight per gallon: 12.7 ± 0.2 lb

1 ct. Macropoxy 646 @ 5.0 - 10.0 mils dft mixed, may vary by color

1-2 cts. Acrolon 218 Polyurethane @ 3.0 - 6.0 mils dft/ct

SAFETY PRECAUTIONS

Aluminum:

2 cts. Macropoxy 646 @ 5.0 - 10.0 mils dft/ct Refer to the MSDS sheet before use.

Galvanizing:

2 cts. Macropoxy 646 @ 5.0 - 10.0 mils dft/ct Published technical data and instructions are subject to change with-

out notice. Contact your Sherwin-Williams representative for addi-

tional technical data and instructions.

The systems listed above are representative of the product's use.

Other systems may be appropriate.

DISCLAIMER WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufactur-

The information and recommendations set forth in this Product Data Sheet are ing defects in accord with applicable Sherwin-Williams quality control procedures.

based upon tests conducted by or on behalf of The Sherwin-Williams Company. Liability for products proven defective, if any, is limited to replacement of the

Such information and recommendations set forth herein are subject to change defective product or the refund of the purchase price paid for the defective

and pertain to the product offered at the time of publication. Consult your product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUAR-

Sherwin-Williams representative to obtain the most recent Product Data Infor- ANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR

mation and Application Bulletin. IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUD-

ING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Protective Coatings Inspector Training

©2013 SSPC W10-16

Module 10: Navigating Coating Specifications

Industrial 4.53A

& MACROPOXY® 646

Marine FAST CURE EPOXY

Coatings PART A B58-600 SERIES

PART B B58V600 HARDENER

APPLICATION BULLETIN Revised 8/05

SURFACE PREPARATION APPLICATION CONDITIONS

Surface must be clean, dry, and in sound condition. Remove all oil, Temperature: 40°F minimum, 140°F maximum

dust, grease, dirt, loose rust, and other foreign material to ensure (air, surface, and material)

adequate adhesion. At least 5°F above dew point

Iron & Steel, Atmospheric Service:

Minimum surface preparation is Hand Tool Clean per SSPC-SP2. Re- Relative humidity: 85% maximum

move all oil and grease from surface by Solvent Cleaning per SSPC-

SP1. For better performance, use Commercial Blast Cleaning per SSPC-

SP6/NACE 3, blast clean all surfaces using a sharp, angular abrasive

for optimum surface profile (2 mils). Prime any bare steel within 8

hours or before flash rusting occurs.

Iron & Steel, Immersion Service:

APPLICATION EQUIPMENT

Remove all oil and grease from surface by Solvent Cleaning per SSPC-

The following is a guide. Changes in pressures and tip sizes

SP1. Minimum surface preparation is Near White Metal Blast Cleaning

may be needed for proper spray characteristics. Always purge

per SSPC-SP10/NACE 2. Blast clean all surfaces using a sharp, angu-

spray equipment before use with listed reducer. Any reduction

lar abrasive for optimum surface profile (2-3 mils). Remove all weld

spatter and round all sharp edges by grinding. Prime any bare steel must be compliant with existing VOC regulations and com-

the same day as it is cleaned. patible with the existing environmental and application condi-

Aluminum tions.

Remove all oil, grease, dirt, oxide and other foreign material by Solvent

Cleaning per SSPC-SP1. Reducer/Clean Up ........... Reducer R7K15

Galvanized Steel In California .................. Reducer R7K111

Allow to weather a minimum of six months prior to coating. Solvent

Clean per SSPC-SP1 (recommended solvent is VM&P Naphtha). When Airless Spray

weathering is not possible, or the surface has been treated with Pump ............................ 30:1

chromates or silicates, first Solvent Clean per SSPC-SP1 and apply a Pressure ...................... 2800 - 3000 psi

test patch. Allow paint to dry at least one week before testing adhe- Hose ............................ 1/4" ID

sion. If adhesion is poor, brush blasting per SSPC-SP7 is necessary to Tip ................................ .017" - .023"

remove these treatments. Rusty galvanizing requires a minimum of Filter ............................. 60 mesh

Hand Tool Cleaning per SSPC-SP2, prime the area the same day as Reduction ..................... As needed up to 10% by volume

cleaned.

Concrete and Masonry, Atmospheric Service:

Conventional Spray

For surface preparation, refer to NACE 6/SSPC-SP13, or ICRI 03732,

Gun ............................... DeVilbiss MBC-510

CSP 1-3. Surfaces should be thoroughly clean and dry. Concrete and

Fluid Tip ....................... E

mortar must be cured at least 28 days @ 75°F. Remove all loose

mortar and foreign material. Surface must be free of laitance, con- Air Nozzle ...................... 704

crete dust, dirt, form release agents, moisture curing membranes, Atomization Pressure .. 60-65 psi

loose cement and hardeners. Fill bug holes, air pockets and other Fluid Pressure ............. 10-20 psi

voids with a cement patching compound. Weathered masonry and Reduction ..................... As needed up to 10% by volume

soft or porous cement board must be brush blasted or power tool Requires oil and moisture separators

cleaned to remove loosely adhering contamination and to get to a

hard, firm surface. Laitance must be removed by etching with a 10% Brush

muriatic acid solution and thoroughly neutralized with water. Brush ............................ Nylon/Polyester or Natural Bristle

Concrete and Masonry, Immersion Service: Reduction ..................... Not recommended

For surface preparation, refer to SSPC-SP13/NACE 6, Section 4.3.1

or 4.3.2, or ICRI 03732, CSP 1-3. Roller

Previously Painted Surfaces Cover ............................ 3/8" woven with phenolic core

If in sound condition, clean the surface of all foreign material. Smooth, Reduction ..................... Not recommended

hard or glossy coatings and surfaces should be dulled by abrading

the surface. Apply a test area, allowing paint to dry one week before If specific application equipment is listed above, equivalent

testing adhesion. If adhesion is poor, or if this product attacks the equipment may be substituted.

previous finish, removal of the previous coating may be necessary. If

paint is peeling or badly weathered, clean surface to sound substrate

and treat as a new surface as above.

Epoxy 4.53A continued on back

Protective Coatings Inspector Training

©2013 SSPC W10-17

Module 10: Navigating Coating Specifications

Industrial 4.53A

& MACROPOXY® 646

Marine FAST CURE EPOXY

Coatings PART A B58-600 SERIES

PART B B58V600 HARDENER

APPLICATION BULLETIN

APPLICATION PROCEDURES PERFORMANCE TIPS

Surface preparation must be completed as indicated. Stripe coat all crevices, welds, and sharp angles to prevent

early failure in these areas.

Mix contents of each component thoroughly with power agita-

tion. Make certain no pigment remains on the bottom of the When using spray application, use a 50% overlap with each

can. Then combine one part by volume of Part A with one part pass of the gun to avoid holidays, bare areas, and pinholes. If

by volume of Part B. Thoroughly agitate the mixture with power necessary, cross spray at a right angle

agitation. Allow the material to sweat-in as indicated prior to

application. Re-stir before using. Spreading rates are calculated on volume solids and do not

include an application loss factor due to surface profile, rough-

If reducer solvent is used, add only after both components ness or porosity of the surface, skill and technique of the ap-

have been thoroughly mixed, after sweat-in. plicator, method of application, various surface irregularities,

material lost during mixing, spillage, overthinning, climatic con-

Apply paint to the recommended film thickness and spreading ditions, and excessive film build.

rate as indicated below:

Recommended Spreading Rate per coat: Excessive reduction of material can affect film build, appear-

Wet mils: 7.0 - 13.5 ance, and adhesion.

Dry mils: 5.0 - 10.0*

Coverage: 116 - 232 sq ft/gal approximate Do not mix previously catalyzed material with new.

NOTE: Brush or roll application may require multiple coats to achieve

maximum film thickness and uniformity of appearance.

Do not apply the material beyond recommended pot life.

* See Recommended Systems

In order to avoid blockage of spray equipment, clean equip-

Drying Schedule @ 7.0 mils wet and 50% RH:

@ 40°F @ 77°F @ 100°F ment before use or before periods of extended downtime with

To touch: 4-5 hours 2 hours 1½ hours Reducer R7K15. In California use Reducer R7K111.

To handle: 48 hours 8 hours 4½ hours

To recoat: Tinting is not recommended for immersion service.

minimum: 48 hours 8 hours 4½ hours

maximum: 3 months 3 months 3 months Use only Mil White and Black for immersion service.

Cure for

service: 10 days 7 days 4 days

immersion: 14 days 7 days 4 days Quik-Kick Epoxy Accelerator is acceptable for use. See data

If maximum recoat time is exceeded, abrade surface before recoating. page 4.99 for details.

Drying time is temperature, humidity and film thickness dependent.

Refer to Product Information sheet for additional performance

Pot Life: 10 hours 4 hours 2 hours characteristics and properties.

Sweat-in-time: 30 minutes 30 minutes 15 minutes

Application of coating above maximum or below minimum rec-

ommended spreading rate may adversely affect coating per-

formance.

CLEAN UP INSTRUCTIONS SAFETY PRECAUTIONS

Clean spills and spatters immediately with Reducer R7K15. Refer to the MSDS sheet before use.

Clean tools immediately after use with Reducer R7K15. In

California use Reducer R7K111. Follow manufacturer's safety Published technical data and instructions are subject to change

recommendations when using any solvent. without notice. Contact your Sherwin-Williams representative

for additional technical data and instructions.

Protective Coatings Inspector Training

©2013 SSPC W10-18

You might also like

- Heat-Flex HI-TEMP 1200: Protective & Marine CoatingsDocument4 pagesHeat-Flex HI-TEMP 1200: Protective & Marine CoatingsAna CabreraNo ratings yet

- Linuxintro LEFE 4.33 PDFDocument307 pagesLinuxintro LEFE 4.33 PDFR00t D1rNo ratings yet

- Informatica Deployment ChecklistDocument9 pagesInformatica Deployment Checklisttajsmart1No ratings yet

- Targuard PDFDocument4 pagesTarguard PDFsofian juniardiNo ratings yet

- TarguardDocument4 pagesTarguardMariela Tabata Calizaya ChipanaNo ratings yet

- Protective & Marine Coatings: Zinc Clad XIDocument4 pagesProtective & Marine Coatings: Zinc Clad XIfdpc1987No ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- Macropoxy 646 FF 2022Document4 pagesMacropoxy 646 FF 2022nellyNo ratings yet

- Dura-Plate Uhs Primer NSF: Protective & Marine CoatingsDocument4 pagesDura-Plate Uhs Primer NSF: Protective & Marine CoatingscerorideNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocument4 pagesFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Pintura 7000 - System - Cold - Galvanizing - Compound - RO65 - GDH585 - 0622Document2 pagesPintura 7000 - System - Cold - Galvanizing - Compound - RO65 - GDH585 - 0622Carmen CespedesNo ratings yet

- HO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)Document2 pagesHO PLUS 32-PLUS 46 - Hydraulic Oil (HEES)azimchemNo ratings yet

- Carbozinc 11: Selection & Specification DataDocument5 pagesCarbozinc 11: Selection & Specification DataQuy RomNo ratings yet

- 113.007 - Zinc Clad Xi WB BR PDFDocument2 pages113.007 - Zinc Clad Xi WB BR PDFFernando VittoNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- Indium10.8hf Pbfree Solder Paste 99040 A4 r9Document2 pagesIndium10.8hf Pbfree Solder Paste 99040 A4 r9rigoberto solNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Cor Cote HTDocument4 pagesCor Cote HTlovaldes62No ratings yet

- Sher-Tile HS - SHERWIN WILLIAMSDocument4 pagesSher-Tile HS - SHERWIN WILLIAMSJoão Gilberto Vedana JúniorNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Q8 El Greco 220 - enDocument1 pageQ8 El Greco 220 - enDeepak YadavNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Fast Clad Er Epoxy: Protective & Marine CoatingsDocument4 pagesFast Clad Er Epoxy: Protective & Marine CoatingsCarlangasPardoNo ratings yet

- 1A-Acrolon 890Document2 pages1A-Acrolon 890Stuart PhamNo ratings yet

- Product Specification - Apcoshield Py905sg Grey Ral 7016 20kgDocument1 pageProduct Specification - Apcoshield Py905sg Grey Ral 7016 20kgVenkatraman SubramaniamNo ratings yet

- Carboguard 193: Selection & Specification DataDocument4 pagesCarboguard 193: Selection & Specification DataGraciele SantosNo ratings yet

- 450F HsdviDocument2 pages450F HsdviJoJo kNo ratings yet

- Elite Evolution ECO F 5W-20: LubricantsDocument1 pageElite Evolution ECO F 5W-20: Lubricantstehnicar1No ratings yet

- Jotun - Technical Data Sheet - Tankguard Storage - 09.2019Document5 pagesJotun - Technical Data Sheet - Tankguard Storage - 09.2019Victor PomboNo ratings yet

- Exceed™ S 9272ML: Performance PolymerDocument2 pagesExceed™ S 9272ML: Performance PolymerMaram YasserNo ratings yet

- Product Information: Megol Motorenoel New Generation SAE 5W-30Document1 pageProduct Information: Megol Motorenoel New Generation SAE 5W-30Valeriy ValkovetsNo ratings yet

- Carbozinc 11 PDSDocument5 pagesCarbozinc 11 PDSSUBODHNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Protective & Marine Coatings: Zinc Clad Ii PlusDocument4 pagesProtective & Marine Coatings: Zinc Clad Ii Plusbhanu.kiranNo ratings yet

- Gear Compound Plus Iso - 68 - enDocument1 pageGear Compound Plus Iso - 68 - enSedin MurtićNo ratings yet

- Repsol Merak VDL PDFDocument1 pageRepsol Merak VDL PDFrandiNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Mystik TetrimolyDocument1 pageMystik TetrimolyBanti SidhiwalaNo ratings yet

- Carboweld 11P PDSDocument4 pagesCarboweld 11P PDS이선엽No ratings yet

- P003998 Special Tec F 0W 30 33 en - GBDocument1 pageP003998 Special Tec F 0W 30 33 en - GBAXIS LUBRIFICANTESNo ratings yet

- Carbozinc 858 (3K)Document4 pagesCarbozinc 858 (3K)DuongthithuydungNo ratings yet

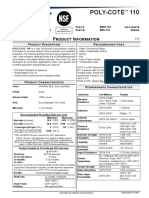

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- SSPC Protective Coatings Inspector (Pci) Training Module 6 QuizDocument2 pagesSSPC Protective Coatings Inspector (Pci) Training Module 6 QuizThennarasu VelloreNo ratings yet

- Module 5 Inspection Case Study: Coating and Lining Installation of The Sun Spree Township Elevated Potable Water Storage TankDocument28 pagesModule 5 Inspection Case Study: Coating and Lining Installation of The Sun Spree Township Elevated Potable Water Storage TankThennarasu VelloreNo ratings yet

- C% MN% Si% P% Max S% Max: The Ladle Analysis of The Steel Shall Be Given As BelowDocument2 pagesC% MN% Si% P% Max S% Max: The Ladle Analysis of The Steel Shall Be Given As BelowThennarasu VelloreNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- ICE STEEL 1 Private Limited (S14) : Liquid Penetrant Inspection ReportDocument28 pagesICE STEEL 1 Private Limited (S14) : Liquid Penetrant Inspection ReportThennarasu VelloreNo ratings yet

- TC PLC Lib Controller ToolboxDocument180 pagesTC PLC Lib Controller ToolboxPedro VieiraNo ratings yet

- Manual de Instruções Philips HeartStart XL M4735A (304 Páginas)Document2 pagesManual de Instruções Philips HeartStart XL M4735A (304 Páginas)JeffersonsgueirosNo ratings yet

- Pengaruh Laju Erosi Terhadap Umur PipaDocument6 pagesPengaruh Laju Erosi Terhadap Umur PipaDede Si Engghe SurenggheNo ratings yet

- Eco NicalDocument13 pagesEco Nicalluizfellipe95No ratings yet

- Stress in Boiler DrumDocument8 pagesStress in Boiler DrummuhdjusriNo ratings yet

- Presented by - ASHUTOSH SINGHAL (1312231041)Document21 pagesPresented by - ASHUTOSH SINGHAL (1312231041)askarNo ratings yet

- Engineering Mechanics ProblemDocument71 pagesEngineering Mechanics ProblemEu Aumentado0% (1)

- New9 Page MSO B.E. Chem. Engg. Sem. VIIIDocument9 pagesNew9 Page MSO B.E. Chem. Engg. Sem. VIIIAakashNo ratings yet

- CHP - V Geometric Design of Highways - 5.2.3 ODocument5 pagesCHP - V Geometric Design of Highways - 5.2.3 Odisasa abebeNo ratings yet

- Fundamental of Smart GridDocument3 pagesFundamental of Smart GridGhayas Ud-din DarNo ratings yet

- Kishore Kumar Pabbisetty It - 33Document5 pagesKishore Kumar Pabbisetty It - 33Sathya MunukutlaNo ratings yet

- New Progress in Senior Mathematics Compulsory Part SolutionDocument2 pagesNew Progress in Senior Mathematics Compulsory Part Solutioninvincibilitized abdominizerNo ratings yet

- 737 Air Systems SummaryDocument10 pages737 Air Systems SummaryAhmed RefNo ratings yet

- DCS - Interlocks DH JHDDocument23 pagesDCS - Interlocks DH JHDPrdptiwariNo ratings yet

- Chapter 5: The Project Life Cycle: Just Enough Structured AnalysisDocument28 pagesChapter 5: The Project Life Cycle: Just Enough Structured AnalysisMarcelo RojasNo ratings yet

- Aluminum Crust BreakerDocument8 pagesAluminum Crust BreakersenamotoNo ratings yet

- Solar Powered Airplane Literature ReviewDocument25 pagesSolar Powered Airplane Literature Reviewali67% (3)

- Service ManualDocument45 pagesService ManualStoneAge1No ratings yet

- Zam 180Document2 pagesZam 180Orlando SantofimioNo ratings yet

- SiemensDocument74 pagesSiemenskazishahNo ratings yet

- UPVC Product: Type of Color and SeriesDocument4 pagesUPVC Product: Type of Color and SeriesJefri Andhika PNo ratings yet

- VWR Standard 1000 Orbital Shaker Instruction ManualDocument73 pagesVWR Standard 1000 Orbital Shaker Instruction ManualWai YanNo ratings yet

- Dräger Polytron 5000 Junction Box: Assembly InstructionsDocument12 pagesDräger Polytron 5000 Junction Box: Assembly InstructionsSanti AgoNo ratings yet

- Rev A (731000FH and 771000FH) Racor FTGDocument8 pagesRev A (731000FH and 771000FH) Racor FTGBarsbold AvirmedNo ratings yet

- N5 Graphic-Communication QP 2014Document21 pagesN5 Graphic-Communication QP 2014alexhqmondNo ratings yet

- Value Chain AnalysisDocument33 pagesValue Chain AnalysisM ManjunathNo ratings yet