Professional Documents

Culture Documents

FW Offer No. 61702.03.2020 - Sun Valve Company Syrian Arab Republic

FW Offer No. 61702.03.2020 - Sun Valve Company Syrian Arab Republic

Uploaded by

Jawad ChamsouOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FW Offer No. 61702.03.2020 - Sun Valve Company Syrian Arab Republic

FW Offer No. 61702.03.2020 - Sun Valve Company Syrian Arab Republic

Uploaded by

Jawad ChamsouCopyright:

Available Formats

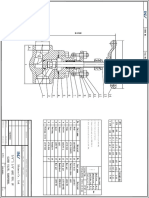

Cast Steel Gate Valves Cast Steel Gate Valves

W

Table 1

No. Description Material

12

12 Handwheel A 216 WCB

11

11 Yoke sleeve A 439 D2

10 Packing Graphite

Symbol Class Size Working Temperature 9 Backseat A 182 F 6

RSP-OT 150 2” ... 24” -29 °C ... +427°C 8 Studs A 193 B7

H

RSP-OT 300 2" ... 12" -29 °C ... +427°C 7 Bonnet A 216 WCB

Low carbon steel / Low carbon steel

6 Gasket platted with graphite for 24"

Application 5 Nuts A 194 - 2H

These valves are used as passing or stop valves in installations for water, steam, gas, 4 Stem A 182 F 6a

petroleum products or for other similar fluids with low corrosive action, except hydrogen,

6”- 24” A 216 WCB

hydrogen and hydrocarbons mixtures, aggressive agents containing sulphur, hydrogen

D1

3 Wedge

sulphide etc. 2”- 4” A 105

D

2 Seat ring 13% Cr / 13% Cr

Service and Tests for carbon steel A 216 WCB nxD2

1 Body A 216 WCB

b

L

Max. Working temperature Test Pressure Fig. 1

Class

working ( ° F) -20...100 200 300 400 500 600 700 800 Table 2

pressure Class 150

pressure ( ° C) -29...38 93 149 204 260 316 371 427 Size inch

Shell Seat (air)

OVERALL DIMENSIONS

2" 2 1/2” 3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24”

mm 50 65 80 100 150 200 250 300 350 400 450 500 600

psig 285 260 230 200 170 140 110 80 450 60 -100 inch 7.00 7.50 8.00 9.00 10.50 11.50 13.00 14.00 15.00 16.00 17.00 18.00 20.00

150 L

bar 19.6 17.9 15.8 13.7 11.7 9.6 7.5 5.5 mm 178 190 203 229 267 292 330 355 381 406 432 457 508

31 4-7

inch 14.29 14.57 16.93 19.68 25.00 29.84 35.55 42.24 46.90 52.60 58.97 66.50 77.40

psig 740 675 655 635 600 550 535 410 1125 60 - 100 H

mm 363 370 430 500 635 758 903 1073 1192 1336 1498 1690 1966

300

bar 51 46.5 45.1 43.7 41.3 37.9 36.8 28.2 78 4-7 inch 7.88 7.88 9.75 9.75 11.88 14.00 15.88 17.88 19.50 23.38 23.38 26.75 30.00

W

mm 200 200 248 248 302 355 404 454 496 594 594 680 762

Constructive and functional characteristics inch 6.00 7.00 7.50 9.00 11.00 13.50 16.00 19.00 21.00 23.50 25.00 27.50 32.00

CONNECTION FLANGES

D

mm 152 178 190 229 279 343 406 483 533 597 635 698 812.8

type: bolted bonnet, outside screw and yoke;

inch 4.75 5.50 6.00 7.50 9.50 11.75 14.25 17.00 18.75 21.25 22.75 25.00 29.50

flexible wedge; D1

rising stem with top sealing (backseat); mm 120.5 139.5 152.5 190.5 241.5 298.5 362 432 476 539.5 578 635 749.3

full bore; inch 4 x 0.75 4 x 0.75 4 x 0.75 8 x 0.75 8 x 0.88 8 x 0.88 12 x 1.00 12 x 1.00 12 x 1.12 16 x 1.12 16 x 1.25 20 x 1.25 20 x 1.37

flanged ends; n x D2

mm 4 x 19 4 x 19 4 x 19 8 x 19 8 x 22 8 x 22 12 x 25 12 x 25 12 x 29 16 x 29 16 x 32 20 x 32 20 x 35

shutting-off: by rotating the handwheel in clockwise direction;

inch 0.62 0.69 0.75 0.94 1.00 1.12 1.19 1.25 1.38 1.44 1.56 1.69 1.88

mounting position: any. b

mm 16 17.5 19 24 25.4 28.5 30 32 35 36.6 39.7 42.9 48

Execution NET lbs 46.3 59.5 81.5 119 185 275.6 431 598 804 1090 1433 1896 2688

WEIGHT

basic design according to API 600; kg 21 27 37 54 84 125 198 272 364 490 650 860 1200

face to face according to ANSI B 16.10;

flanges according to ANSI B 16.5;

flange facings: 0,06" raised face;

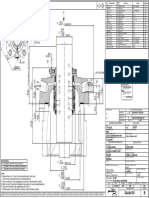

pressure - temperature ratings according to ASME B 16.34; Class 300 Table 3

Size inch 2” 2 1/2” 3” 4” 6” 8” 10” 12”

sheel wall thickness according to API 600;

OVERALL DIMESIONS

mm 50 65 80 100 150 200 250 300

testing according to API 598;

inch 8.50 9.51 11.14 12.01 15.87 16.50 17.99 19.76

trim standard: no. 1 main sealing 13% Cr / 13% Cr. L

mm 216 241.5 283 305 403 419 457 502

On request inch 15.03 15.55 17.70 20.15 25.70 31.96 38.18 44.88

H

other basic design according to API 6 D; mm 382 395 450 512 653 812 970 1140

other sheel materials (see table 2, page 25); inch 7.88 7.88 9.75 9.75 14.00 15.88 17.88 19.50

other trim (see table 5, page 27); W

mm 200 200 248 248 355 404 454 496

other flange facings according to ANSI B 16.5;

other type gasket body - bonnet (see table 6 page 27); inch 6.50 7.50 8.25 10.00 12.50 15.00 17.50 20.50

CONNECTION FLANGES

D

lantern ring for class 300; mm 165 190 210 254 318 381 445 521

drain tappings; inch 5.00 5.88 6.62 7.88 10.62 13.00 15.25 17.75

by-pass; D1

mm 127 149 168 200 270 330 387.5 451

open and shut indicator;

gear operation; inch 8 x 0.75 8 x 0.88 8 x 0.88 8 x 0.88 12 x 0.88 12 x 1.00 16 x 1.12 16 x 1.25

n x D2

electric motor operation; mm 8 x 19 8 x 22 8 x 22 8 x 22 12 x 22 12 x 25 16 x 29 16 x 32

manufactured according to specification NACE MR 0175 for hydrogen sulphide and sour gas inch 0.88 1.00 1.12 1.25 1.44 1.62 1.88 2.00

service (see table 10, page 29) b

mm 22 25.4 28.5 32 36.5 41.5 48 51

Ed. 2010 NET lbs 62 88 115 168 328 504 728 1025 Ed. 2010

9 WEIGHT kg 28 40 52 76 149 228 330 465 10

You might also like

- 6505 MHDocument10 pages6505 MHJulio Güissa57% (7)

- B&K Amp Service ManualDocument16 pagesB&K Amp Service ManualPhantom GoatlordNo ratings yet

- Chapter 6 Microscopic ExaminationDocument8 pagesChapter 6 Microscopic ExaminationNicole EncinaresNo ratings yet

- Chemistry of Environmental SystemsDocument579 pagesChemistry of Environmental SystemsNikhil Pimpare100% (1)

- 630 Kva - Private b62Document1 page630 Kva - Private b62Kris JokowiNo ratings yet

- Carvin 8 BusDocument1 pageCarvin 8 BusRobby AhyanaNo ratings yet

- 008 01 SCV BW 600 WCC-ModelDocument1 page008 01 SCV BW 600 WCC-ModelTasneemNo ratings yet

- Forged Steel Globe Valve Cl300 1.2-2 v1 (103464)Document1 pageForged Steel Globe Valve Cl300 1.2-2 v1 (103464)enginenauticaNo ratings yet

- La213x.ca100v-111 R01-CLGDocument1 pageLa213x.ca100v-111 R01-CLGRicardo TurinNo ratings yet

- DWO-P-05-76 - Intalasi + Layout TOH 200 VDCDocument2 pagesDWO-P-05-76 - Intalasi + Layout TOH 200 VDCMuhamad Shofiyuddin EsteNo ratings yet

- Front BrakeDocument1 pageFront BrakeManuel MoralesNo ratings yet

- Series 14b - Type HD: High-Performance Control and Shut-Off Butterfly ValveDocument8 pagesSeries 14b - Type HD: High-Performance Control and Shut-Off Butterfly ValveMostafa ShipishlyNo ratings yet

- CW505Document1 pageCW505Mina AzmiNo ratings yet

- Precambering 5mm: Am/V 71,7 (1/m) Critical Temperature 600 CDocument1 pagePrecambering 5mm: Am/V 71,7 (1/m) Critical Temperature 600 CBercea GeorgeDoruNo ratings yet

- Siemens: ASK DDocument1 pageSiemens: ASK DMurilo MonteiroNo ratings yet

- Đ NG Cơ NgangDocument34 pagesĐ NG Cơ NgangPhong FuujinNo ratings yet

- AssemblyDocument1 pageAssemblyEdwin FuentesNo ratings yet

- SS-0150-TJR-DWG-ELE-004 - Auxiliary Single Line Diagram (Along With UPS) - PV1-IS01Document1 pageSS-0150-TJR-DWG-ELE-004 - Auxiliary Single Line Diagram (Along With UPS) - PV1-IS01tukaram.pawarNo ratings yet

- Part No. (2pcs) Part No. (4pcs) : 2. All Plate Minimum 6mm or AboveDocument1 pagePart No. (2pcs) Part No. (4pcs) : 2. All Plate Minimum 6mm or AboveIwan AbdurahmanNo ratings yet

- Materials Api 610, 10Th Edition S-6 (M) : Item No. Description Material Qty. Item No. Description Material QtyDocument1 pageMaterials Api 610, 10Th Edition S-6 (M) : Item No. Description Material Qty. Item No. Description Material QtyAditya PrajasNo ratings yet

- Ins PT003Document1 pageIns PT003faisal hajjNo ratings yet

- Forged Steel Globe Valve 800 15NB To 50NBDocument1 pageForged Steel Globe Valve 800 15NB To 50NBpriyanka GNo ratings yet

- Electrical Power Socket: Issue 1 Sheet 2 en-GBDocument1 pageElectrical Power Socket: Issue 1 Sheet 2 en-GBRuanNo ratings yet

- V1141 - EN-Gate ValveDocument1 pageV1141 - EN-Gate ValveHai PhanNo ratings yet

- Flue Gas Outlet DamperDocument1 pageFlue Gas Outlet Damperprth valveNo ratings yet

- FM638 & FM639: Fully Lugged Butterfly Valve PN25Document1 pageFM638 & FM639: Fully Lugged Butterfly Valve PN25RonaldNo ratings yet

- Section B-B Section C-C: 0-8936-2 Golden Triangle Polymers Company LLCDocument1 pageSection B-B Section C-C: 0-8936-2 Golden Triangle Polymers Company LLCLester MuscaNo ratings yet

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocument1 pagePesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNo ratings yet

- CSP MILL-Model3Document1 pageCSP MILL-Model3Mitul PatelNo ratings yet

- PSLF800A03SDocument4 pagesPSLF800A03SGabriel Latiu100% (1)

- Aoc 078Document1 pageAoc 078Luong LeNo ratings yet

- Pile Centerline DrawingDocument1 pagePile Centerline DrawingbujjiNo ratings yet

- Globe Valve W BellowDocument1 pageGlobe Valve W BellowIvan TijerinaNo ratings yet

- Layout Plan 132kV SubstationDocument1 pageLayout Plan 132kV SubstationShuhan Mohammad Ariful Hoque0% (1)

- La233r1.ca100v-000 R03Document1 pageLa233r1.ca100v-000 R03Ricardo TurinNo ratings yet

- 2023 GR Corolla WiringDocument344 pages2023 GR Corolla WiringpavsimsNo ratings yet

- Ems e 0066 001 01 06Document2 pagesEms e 0066 001 01 06Luong LeNo ratings yet

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Schneider 1mva 3 Phase Oltc Distribution TransformerDocument8 pagesSchneider 1mva 3 Phase Oltc Distribution TransformerRavindra AngalNo ratings yet

- 3-1 Circuito HidraulicoDocument1 page3-1 Circuito Hidraulicolevinton jose tobias genesNo ratings yet

- La253x.ca100v-008 R02Document2 pagesLa253x.ca100v-008 R02Ricardo TurinNo ratings yet

- FL3B-434-M-2070-0.0 (434T007) EOP Filtrate TankDocument1 pageFL3B-434-M-2070-0.0 (434T007) EOP Filtrate TanknyaptoNo ratings yet

- SB 13006 01Document192 pagesSB 13006 01soorajsundaran93No ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- SAR200 258 - LISBON PTS BDocument1 pageSAR200 258 - LISBON PTS BOktovianus TeguhNo ratings yet

- Detail Z (1: 5) : Rabigh 3 Independent Water ProjectDocument1 pageDetail Z (1: 5) : Rabigh 3 Independent Water ProjectrenjithyesodharanNo ratings yet

- RH-SA-02-60 R1 Alkali ScrubberDocument1 pageRH-SA-02-60 R1 Alkali Scrubberkaushal100% (1)

- Tolerances: Drawing Third Angle Projection REV MillimetersDocument1 pageTolerances: Drawing Third Angle Projection REV Millimetersasnopolar12No ratings yet

- WWW .Absfir E.it: High Flow Discharge ValveDocument2 pagesWWW .Absfir E.it: High Flow Discharge Valvehamdy nabawyNo ratings yet

- Forged Steel Gate Valve 800 15NB To 50NBDocument1 pageForged Steel Gate Valve 800 15NB To 50NBArsag Tech PharmaNo ratings yet

- 7.629193.R 002 01Document1 page7.629193.R 002 01rajitkumar.3005No ratings yet

- Modulador Class D RV3.Document1 pageModulador Class D RV3.Edgar MamaniNo ratings yet

- Hyundai H-LCDVD2001 Schematics DiagramDocument40 pagesHyundai H-LCDVD2001 Schematics DiagramGeovanny SanJuanNo ratings yet

- P4059zor 62 22 1 T1001 017 001 - ADocument1 pageP4059zor 62 22 1 T1001 017 001 - Ashravan.office11No ratings yet

- J3BGDF02BR012 01 05Document1 pageJ3BGDF02BR012 01 05Naheed AkhtarNo ratings yet

- R1 Dibujos Tecnicos Q24409 Enquiry E24155Document3 pagesR1 Dibujos Tecnicos Q24409 Enquiry E24155Lenin MagañaNo ratings yet

- Corrosion Loops Example 2 - Pumps Template2Document1 pageCorrosion Loops Example 2 - Pumps Template2Christian JoseNo ratings yet

- Drawing Mech SealDocument1 pageDrawing Mech Sealjohndoe100198No ratings yet

- 8997 6217 00 Diagrams and Drawings MT6020MKII PDFDocument127 pages8997 6217 00 Diagrams and Drawings MT6020MKII PDFFrancisco Rojas100% (1)

- Ss023a x10 Schematic Diagram2Document1 pageSs023a x10 Schematic Diagram2cattia0% (1)

- Arvin: Vintage 50Document14 pagesArvin: Vintage 50rodrigoNo ratings yet

- Metallic Sealing - Short Face-To-Face Length - Stainless Steel - With HandwheelDocument3 pagesMetallic Sealing - Short Face-To-Face Length - Stainless Steel - With HandwheelJawad ChamsouNo ratings yet

- PipeDocument1 pagePipeJawad ChamsouNo ratings yet

- 33 Level D March 29 - April 2 Language Pages110-113Document2 pages33 Level D March 29 - April 2 Language Pages110-113Jawad ChamsouNo ratings yet

- Tpco Catalogue (2013)Document14 pagesTpco Catalogue (2013)Jawad ChamsouNo ratings yet

- Apsa 80Document1 pageApsa 80rejiiboNo ratings yet

- Campbell PPT Ch21 Fall 2020Document69 pagesCampbell PPT Ch21 Fall 2020Tommy RamazzottoNo ratings yet

- Chemical Reaction WorksheetDocument2 pagesChemical Reaction WorksheetTrinity Marie HablanNo ratings yet

- 700E EUTECTRODEUS-en144710Document8 pages700E EUTECTRODEUS-en144710Juan LondonoNo ratings yet

- CHT Tubicoat A 71 I TDSDocument2 pagesCHT Tubicoat A 71 I TDSUtpalNo ratings yet

- MSTS SG - Course Calendar 2020Document30 pagesMSTS SG - Course Calendar 2020Siti MstsNo ratings yet

- Daftar Nama Pembimbimg Praktek Kerja Industri (Prakerin) TAHUN AJARAN 2020/2021Document2 pagesDaftar Nama Pembimbimg Praktek Kerja Industri (Prakerin) TAHUN AJARAN 2020/2021A Ming MingNo ratings yet

- Atomic StrucutreDocument41 pagesAtomic Strucutreganeshdhembare89No ratings yet

- Chris Brooks - Storage Tanks Inspection, Maintenance and FailureDocument43 pagesChris Brooks - Storage Tanks Inspection, Maintenance and FailureAnderson ReyesNo ratings yet

- 13 - ElectrochemistryDocument2 pages13 - Electrochemistrysuppalerk janechaijitravanitNo ratings yet

- Science 9 Quarter 2Document12 pagesScience 9 Quarter 2Catherine Yorong PedranoNo ratings yet

- 5090 s10 QP 11Document20 pages5090 s10 QP 11DKFBNo ratings yet

- Roto Foodgrade Certificat NSF 2021Document1 pageRoto Foodgrade Certificat NSF 2021Erwan Le GuenNo ratings yet

- Gtu Dissertation Topics M.pharmDocument4 pagesGtu Dissertation Topics M.pharmOnlinePaperWritingServiceUK100% (1)

- Toxic Substances Containment TankDocument272 pagesToxic Substances Containment Tanktobeykim1No ratings yet

- Guideline For Cargo Hold CleaningDocument6 pagesGuideline For Cargo Hold CleaningtrivediarjunNo ratings yet

- Controlled Release Pellets: An Effective Tool in Chronic TherapyDocument26 pagesControlled Release Pellets: An Effective Tool in Chronic TherapyfakhriNo ratings yet

- Phytochemical, Fluorescence and GC-MS Analysis of Methanolic Extract of Sterculia Foetida L. SeedsDocument8 pagesPhytochemical, Fluorescence and GC-MS Analysis of Methanolic Extract of Sterculia Foetida L. SeedsIJEAB JournalNo ratings yet

- English - FISPQ - Mobil SHC 634Document10 pagesEnglish - FISPQ - Mobil SHC 634MagnoNo ratings yet

- Is 2362 1993Document14 pagesIs 2362 1993qcNo ratings yet

- Calibration Curve: Concentration Absorbance (MG/L) F (X) 0.0374290909x R 0.9996352674 AbsorbanceDocument16 pagesCalibration Curve: Concentration Absorbance (MG/L) F (X) 0.0374290909x R 0.9996352674 Absorbanceprmahajan18No ratings yet

- Pharmacokinetics: The Absorption, Distribution, and Excretion of DrugsDocument14 pagesPharmacokinetics: The Absorption, Distribution, and Excretion of DrugsAriiNo ratings yet

- Handouts 3. Narcotic Identities, Influences, Causes and EffectsDocument5 pagesHandouts 3. Narcotic Identities, Influences, Causes and EffectsMjay MedinaNo ratings yet

- A PreethiDocument26 pagesA PreethiShanmuga PrabhuNo ratings yet

- - N = 2 D Sinθ: Bragg EquationDocument35 pages- N = 2 D Sinθ: Bragg EquationdkaurNo ratings yet

- Unit 7 Assignment 4 P6 P8 M3Document6 pagesUnit 7 Assignment 4 P6 P8 M3oliversmithsignify1No ratings yet

- Api 570 315-498Document56 pagesApi 570 315-498nancyNo ratings yet

- MAN Flexmethanol-EngDocument2 pagesMAN Flexmethanol-EngRoberto Carlos LuciaNo ratings yet