Professional Documents

Culture Documents

Characteristics Specifications: Aterborne Raffic Arking Aint

Characteristics Specifications: Aterborne Raffic Arking Aint

Uploaded by

umuhuza salomonCopyright:

Available Formats

You might also like

- CIT-CON-01-CMT-MTS-000..-V0.. Method Statement For Construction Work at Night ShiftDocument13 pagesCIT-CON-01-CMT-MTS-000..-V0.. Method Statement For Construction Work at Night Shiftumuhuza salomon100% (1)

- PurifierDocument26 pagesPurifierAbhishek Kumar100% (1)

- Envirolastic AR 425 Data PageDocument4 pagesEnvirolastic AR 425 Data PageYsmael Steel TeklaNo ratings yet

- Checklist Site InspectionDocument29 pagesChecklist Site Inspectionthanzawtun198191% (11)

- Penguard Topcoat: Technical Data SheetDocument4 pagesPenguard Topcoat: Technical Data SheetQuoc VinhNo ratings yet

- PVC DatasheetDocument2 pagesPVC DatasheetvikrantNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Electrodeposition Andreas Tolz PPGDocument14 pagesElectrodeposition Andreas Tolz PPGAndi MusdalifahNo ratings yet

- WATCHDOG Waterproofing Features and BenefitsDocument2 pagesWATCHDOG Waterproofing Features and BenefitsappuramuvichuNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- DEGALAN® For PVC Finishes (English) PDFDocument2 pagesDEGALAN® For PVC Finishes (English) PDFslantsyhimNo ratings yet

- 2306 TDS Epoxy Antiskid CoatingDocument4 pages2306 TDS Epoxy Antiskid CoatingMeet NaikNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Jotafloor EP SLDocument4 pagesJotafloor EP SLEduardo Vera portocarreroNo ratings yet

- Protective & Marine Coatings: Sher-Clear™Document4 pagesProtective & Marine Coatings: Sher-Clear™Ana CabreraNo ratings yet

- Macal® 8200 Pro: Technical Data SheetDocument2 pagesMacal® 8200 Pro: Technical Data SheetMOHAMEDNo ratings yet

- WB Paint PDS 1952EF TY II Fast Dry Final 1222 MWDocument2 pagesWB Paint PDS 1952EF TY II Fast Dry Final 1222 MWAngga PratamaNo ratings yet

- Jotamastic 80: Technical Data SheetDocument14 pagesJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- WB Paint PDS 1952F TY II Fast Dry Final 210303 DADocument2 pagesWB Paint PDS 1952F TY II Fast Dry Final 210303 DALuis Barrios ArandaNo ratings yet

- Source Approval Kataline Part 2Document13 pagesSource Approval Kataline Part 2Arun KumarNo ratings yet

- Dow Corning 732 Multi-Purpose Sealant: Product InformationDocument2 pagesDow Corning 732 Multi-Purpose Sealant: Product InformationProject Sales CorpNo ratings yet

- Fluide at 42Document3 pagesFluide at 42Clodoaldo De Melo PereiraNo ratings yet

- Tankguard SF: Technical Data SheetDocument5 pagesTankguard SF: Technical Data SheetRifki ArifinNo ratings yet

- Raylene Ashless Multi-Vis Hydraulic Oil - 11Document3 pagesRaylene Ashless Multi-Vis Hydraulic Oil - 11aditNo ratings yet

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocument3 pagesSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosNo ratings yet

- Road Marking Paint SB AcrylicDocument4 pagesRoad Marking Paint SB AcrylicAngga PratamaNo ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- Tankguard 412: Technical Data SheetDocument6 pagesTankguard 412: Technical Data SheetMuneer ahmedNo ratings yet

- Flowcrete Asia Mondéco Crystal May2020 TdsDocument2 pagesFlowcrete Asia Mondéco Crystal May2020 TdsQuoc AnNo ratings yet

- Targuard PDFDocument4 pagesTarguard PDFsofian juniardiNo ratings yet

- TarguardDocument4 pagesTarguardMariela Tabata Calizaya ChipanaNo ratings yet

- Carboguard 1340 PDSDocument4 pagesCarboguard 1340 PDSSaefuddin OrtegaNo ratings yet

- TDS - 372 - SeaQuantum Plus - Eng - USDocument4 pagesTDS - 372 - SeaQuantum Plus - Eng - UShendra.siskal001No ratings yet

- TDS - 373 - SeaQuantum Ultra - Eng - USDocument4 pagesTDS - 373 - SeaQuantum Ultra - Eng - UShendra.siskal001No ratings yet

- TDS 2063 Tankguard 412 Euk GBDocument6 pagesTDS 2063 Tankguard 412 Euk GBSrimathi VijayakumarNo ratings yet

- Jotaguard 100: Technical Data SheetDocument6 pagesJotaguard 100: Technical Data SheetHector MacavilcaNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Fomblin Y45: Perfl UoropolyetherDocument1 pageFomblin Y45: Perfl UoropolyetheryatheendravarmaNo ratings yet

- PDS en-GB 45751Document2 pagesPDS en-GB 45751Anuar SalehNo ratings yet

- Jotamastic 80: Technical Data SheetDocument5 pagesJotamastic 80: Technical Data SheetArif dwi prasetyoNo ratings yet

- Interior Fluid Resistant Epoxy Primer: Technical Data SheetDocument5 pagesInterior Fluid Resistant Epoxy Primer: Technical Data SheetPannha LangNo ratings yet

- Jotatemp 1000 Ceramic: Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic: Technical Data Sheetebastien2No ratings yet

- Tankguard DW Jotun PaintDocument6 pagesTankguard DW Jotun PaintGurdeep Sungh AroraNo ratings yet

- Lexan Margard HLG5 2021Document3 pagesLexan Margard HLG5 2021Jessica RamosNo ratings yet

- Datasheet Jotun-Tankguard StorageDocument5 pagesDatasheet Jotun-Tankguard Storagebudi handoyoNo ratings yet

- Astm Specs Villa OroDocument2 pagesAstm Specs Villa OroAngel VegaNo ratings yet

- MolykoteDocument2 pagesMolykoteRafael FrançaNo ratings yet

- Pittseal CW Sealant: 1. Description and Area of ApplicationDocument3 pagesPittseal CW Sealant: 1. Description and Area of ApplicationElie AouadNo ratings yet

- Carboguard 891: Selection & Specification DataDocument4 pagesCarboguard 891: Selection & Specification DataPrakashNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBassam AljiffryNo ratings yet

- Kwer 1001-55BR (TDS)Document4 pagesKwer 1001-55BR (TDS)NganNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- CMP Liner Blue: CMP LNR BL CMP LNR BL CMP LNR BL CMP LNR BLDocument2 pagesCMP Liner Blue: CMP LNR BL CMP LNR BL CMP LNR BL CMP LNR BLRiki AkbarNo ratings yet

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 pagesPDS Hempadur Multi-Strength 45753 en-GBJosip LasanNo ratings yet

- Epofine 138 - Finehard 998Document3 pagesEpofine 138 - Finehard 998Karishma PrabhuNo ratings yet

- Product Data: HEMPADUR 37620Document2 pagesProduct Data: HEMPADUR 37620Juanda Mardohar Dantec SitompulNo ratings yet

- Mariseal 400 Aqua Version18Document2 pagesMariseal 400 Aqua Version18Chetal BholeNo ratings yet

- Jotamastic 80: Technical Data SheetDocument5 pagesJotamastic 80: Technical Data SheetSafinahNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- 2023年10月份PK24保安工资Document2 pages2023年10月份PK24保安工资umuhuza salomonNo ratings yet

- 2360007745Document5 pages2360007745umuhuza salomonNo ratings yet

- 02frontier Theory and Development of Project ManagementDocument149 pages02frontier Theory and Development of Project Managementumuhuza salomonNo ratings yet

- Painting Spraying OperationsDocument3 pagesPainting Spraying Operationsumuhuza salomonNo ratings yet

- CIT CON 01 CMT MTS 0040 V00 Method Statement For Repairing PaintingDocument25 pagesCIT CON 01 CMT MTS 0040 V00 Method Statement For Repairing Paintingumuhuza salomonNo ratings yet

- Method Statement For Paint Repair Procedure For Piping PDF FreeDocument16 pagesMethod Statement For Paint Repair Procedure For Piping PDF Freeumuhuza salomonNo ratings yet

- Newton Form of The Interpolation PolynomialDocument11 pagesNewton Form of The Interpolation Polynomialumuhuza salomonNo ratings yet

- W-13 Solving The Linear Equation Systems by Iteration MethodDocument24 pagesW-13 Solving The Linear Equation Systems by Iteration Methodumuhuza salomonNo ratings yet

- Transmittal: China Harbour Engineering Company LimitedDocument34 pagesTransmittal: China Harbour Engineering Company Limitedumuhuza salomonNo ratings yet

- The Reference For More Than .: Quality 50 YearsDocument6 pagesThe Reference For More Than .: Quality 50 Yearsumuhuza salomonNo ratings yet

- P6 Programme113Document1 pageP6 Programme113umuhuza salomonNo ratings yet

- 6.4.2 Daily Returns: Second Container TerminalDocument2 pages6.4.2 Daily Returns: Second Container Terminalumuhuza salomonNo ratings yet

- The Role of Pinyin Proficiency in The Ac PDFDocument66 pagesThe Role of Pinyin Proficiency in The Ac PDFumuhuza salomonNo ratings yet

- Curriculum Vitae (Summary)Document5 pagesCurriculum Vitae (Summary)umuhuza salomonNo ratings yet

- Ap P Lication For M For Chinese Gover Nment Scholar ShipDocument5 pagesAp P Lication For M For Chinese Gover Nment Scholar Shipumuhuza salomonNo ratings yet

- Perform Routine Manual Metal Arc Welding: (MEM5.12C)Document27 pagesPerform Routine Manual Metal Arc Welding: (MEM5.12C)umuhuza salomonNo ratings yet

- Buses Best Practices FinalDocument26 pagesBuses Best Practices FinalpioneeringcompNo ratings yet

- Aisi 5160 Alloy Steel (Uns g51600)Document4 pagesAisi 5160 Alloy Steel (Uns g51600)Rizki RiantoniNo ratings yet

- Basic EE PrelimDocument3 pagesBasic EE PrelimJohnCris B. FornilosNo ratings yet

- 1520412369part2 2Document261 pages1520412369part2 2Jothimanikkam SomasundaramNo ratings yet

- Aircraft Communication SystemsDocument31 pagesAircraft Communication SystemsAhmedShah75% (4)

- Manual On The Creation of Accretion and Erosion Map Using Arcgis and Digital Shoreline Assessment System (DSAS)Document75 pagesManual On The Creation of Accretion and Erosion Map Using Arcgis and Digital Shoreline Assessment System (DSAS)Rojelon Vic AmataNo ratings yet

- Bemco BrochureDocument19 pagesBemco BrochurelightsonsNo ratings yet

- Mathcad CMU WallDocument23 pagesMathcad CMU WallqimingzengNo ratings yet

- Project Scheduling: Precedence Diagram MethodDocument61 pagesProject Scheduling: Precedence Diagram MethodJacob LusterioNo ratings yet

- Proposal Defence - Farah Wahida Corrected Ss 2Document19 pagesProposal Defence - Farah Wahida Corrected Ss 2Farah Wahida JusohNo ratings yet

- Hazard Identification, Risk Assessment & Risk Control (Hirarc)Document26 pagesHazard Identification, Risk Assessment & Risk Control (Hirarc)Satrio ReksoNo ratings yet

- Trumpet Manual PDFDocument24 pagesTrumpet Manual PDFEslam Hossny100% (1)

- Isometric Layout Drawing Isometric Offsets Calculating Isometric Offsets Isometric Dimensioning & LabelingDocument18 pagesIsometric Layout Drawing Isometric Offsets Calculating Isometric Offsets Isometric Dimensioning & LabelingSuresh Ram RNo ratings yet

- Technical Data YKK400-4WF1-315KW 6KV 50HZ IP55 IC611Document1 pageTechnical Data YKK400-4WF1-315KW 6KV 50HZ IP55 IC611tanviryNo ratings yet

- 1 Home Base Work March 19-MRCH 31Document3 pages1 Home Base Work March 19-MRCH 31Celso AmotoNo ratings yet

- API 674 Positive Displacement PumpsDocument67 pagesAPI 674 Positive Displacement PumpsFrancisco Pérez ChaniqueNo ratings yet

- Dyeing of Polyamide FibersDocument19 pagesDyeing of Polyamide FibersrajdewaanNo ratings yet

- EPE 2010 Brochure LowDocument71 pagesEPE 2010 Brochure LowNicoleNo ratings yet

- CX20 SpecificationsDocument1 pageCX20 SpecificationsDaniel Trovao SimoesNo ratings yet

- Tutorial Exercises For Chapter 3: Human Resources Capacity PlanningDocument2 pagesTutorial Exercises For Chapter 3: Human Resources Capacity PlanningDHARSHININo ratings yet

- Dial Indicators and Digital Indicators: Mounting A Dial IndicatorDocument1 pageDial Indicators and Digital Indicators: Mounting A Dial IndicatorozanNo ratings yet

- Project and Production Management Prof. Arun Kanda Department of Mechanical Engineering Indian Institute of Technology, Delhi Lecture - 40 Material Requirements PlanningDocument25 pagesProject and Production Management Prof. Arun Kanda Department of Mechanical Engineering Indian Institute of Technology, Delhi Lecture - 40 Material Requirements PlanningManish Kumar ChaudharyNo ratings yet

- Airborne Antenna Product Range 20-03-12Document5 pagesAirborne Antenna Product Range 20-03-12PeterNo ratings yet

- Undergraduate Studies Calendar - University of WaterlooDocument4 pagesUndergraduate Studies Calendar - University of WaterlooBrandin RoveloNo ratings yet

- Benchmark Functions PDFDocument47 pagesBenchmark Functions PDFshdotcom11004No ratings yet

- GATE 2014 Exam Admit Card: Examination Centre (7003)Document1 pageGATE 2014 Exam Admit Card: Examination Centre (7003)Hemanth JNo ratings yet

- Samsung-Cw21z503 21z453Document4 pagesSamsung-Cw21z503 21z453Anonymous 4aChpF1hZNo ratings yet

- Worksheet Science 2 º Unit 5Document20 pagesWorksheet Science 2 º Unit 5Kyo Toey0% (1)

Characteristics Specifications: Aterborne Raffic Arking Aint

Characteristics Specifications: Aterborne Raffic Arking Aint

Uploaded by

umuhuza salomonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Characteristics Specifications: Aterborne Raffic Arking Aint

Characteristics Specifications: Aterborne Raffic Arking Aint

Uploaded by

umuhuza salomonCopyright:

Available Formats

113.

80

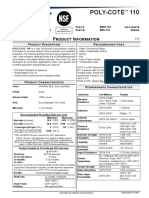

PRO-PARK™

WATERBORNE

TRAFFIC MARKING PAINT

B97 SERIES

As of 03/01/2013, Complies with:

OTC Yes LEED® 09 CI Yes

SCAQMD Yes LEED® 09 NC Yes

CARB Yes LEED® 09 CS Yes

CARB SCM 2007 Yes LEED® 09 H No

MPI # 97 NGBS Yes

CHARACTERISTICS SPECIFICATIONS

PRO-PARK TRAFFIC MARKING PAINT Finish: Flat

is a premium quality waterborne acrylic Colors: White, Yellow, Blue, Red, Black

alkyd traffic marking paint. It has excel- Volume Solids: 62 ± 2% (White)

lent chemical and dirt pickup resistance. Weight Solids: 77 ± 2% (White)

Pro-Park delivers the performance ex- VOC : <50 g/L; <0.42 lb/gal

As per 40 CFR 59.406 and SOR/2009-264, s.12

pected by the most discerning contractor,

property manager or national retail chain. Recommended Spreading Rate per coat:

Approximately 330 lineal feet of standard 4" stripe per gallon

Wet mils (microns) 15.0 / 375

Apartments Communities

Dry mils (microns) 9.0 / 225

Shopping Centers

Coverage sq ft/gal (m2/L) 108 / 2.7

Schools and Universities

Municipalities Drying Schedule @ 15.0 mils / 375 microns wet, @ 77°F / 25°C, @ 50% RH:

Property Managers Dry-no-pickup: 30 minutes

Asphalt Seal Contractors Dry to recoat: 60 minutes

Pavement Stripers Open to heavy traffic: 120 minutes

Drying time is temperature, humidity, and film thickness dependent.

The coating may be made into reflective Shelf Life: 12 months, unopened

paint by dropping on glass beads while Store indoors at 40°F / 4.5°C to 100°F / 38°C

the paint is still wet. Flash Point: 150°F / 65°C, PMCC

Reducer: Water

Can be used with stencils (Available

through Sherwin-Williams) for street and Spreading rates are calculated on volume solids and do not include an application

parking lot marking: loss factor due to surface profile, roughness or porosity of the surface, method of

application, surface irregularities, over-thinning, climatic conditions, and excessive

Directional Arrows film build.

STOP

YIELD Cured Asphalt, Concrete, and Brick:

Numbers 1 ct. Pro-Park Traffic Marking Paint

Pedestrian Crossing @ 330 lineal feet of standard 4" stripe per gallon

Handicap Markings

White B97WD2434 Abrasion Resistance (falling sand) Dry Opacity (Contrast Ratio)

Yellow B97YD2467 Method: ASTM D968 Method: Fed. Met. 141C at 5 mils (125

Firelane Red B97RD2012 Result: 150 liters microns) wet

Blue B97LD2022 Result: 0.95 (white)

Black B97BD2021 Bleed Resistance

Method: ASTM D969 Flexibility

Result: >0.95 over seal coat Method: ASTM D522, 1/2" mandrel

Result: Pass

Color (yellow)

Method: Fed. Std. 595 #33538 Reflectance (white)

Result: Pass Method: ASTM-E97

Result: 85% minimum

Dry-No-Pickup

Method: ASTM D711 Scrub Resistance

Result: <30 minutes @ 77°F/25°C Method: ASTM D2486

Result: 500 cycles minimum

3/2013 www.sherwin-williams.com continued on back

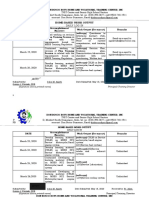

PRO-PARK™

WATERBORNE TRAFFIC MARKING PAINT

SURFACE PREPARATION APPLICATION

WARNING! Removal of old paint by sanding, scraping or other means may generate Temperature:

dust or fumes that contain lead. Exposure to lead dust or fumes may cause brain minimum 40°F / 4.5°C

damage or other adverse health effects, especially in children or pregnant women. maximum 110°F / 43°C

Controlling exposure to lead or other hazardous substances requires the use of air, surface, and material

proper protective equipment, such as a properly fitted respirator (NIOSH approved) At least 5°F / 2.8°C above dew point

and proper containment and cleanup. For more information, call the National Lead Relative humidity: 85% maximum

Information Center at 1-800-424-LEAD (in US) or contact your local health authority.

The following is a guide. Changes in

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, pressures and tip sizes may be needed

loose rust, and other foreign material to ensure adequate adhesion. for proper spray characteristics. Always

Surfaces should be clean and dry and free from loose or peeling paint. Do not apply purge spray equipment before use with

when air or surface temperatures are below 40°F (4.5°C), or when the relative hu- listed reducer. Any reduction must be

midity exceeds 85%, or when the temperature falls below the dew point. compatible with the existing environ-

mental and application conditions.

The presence of concrete sealers or efflorescence on new concrete may interfere

with adhesion and should be removed by extended weathering, etching, or abrasive Reducer Water

blasting. As needed up to 25% by volume

Most previously painted lines may be repainted without additional surface prepara- Airless Spray Line Striper

tion, provided the old paint is still tightly adhered to the surface. However, multiple Pressure .......................... 1800-2700 psi

layers of paint will eventually peel and require removal. Hose ................................... 1/4" - 3/8" ID

Tip ...................................... .015" - .017"

New asphalt surfaces should ideally be allowed to age several months before strip- Filter ......................................... 60 mesh

ing. Exceeding the recommended film thickness will increase the tendency to cause

asphalt lifting. Placing an inconspicuous test stripe to determine if a new asphalt sur- Conventional Spray Line Striper

face has cured sufficiently to paint is recommended. Gun ........................... Binks 21 (Bleeder)

Fluid Nozzle...................................... #68

If it is necessary to paint new asphalt surfaces, do not exceed an application rate of 8 Air Nozzle ................... Internal mix, #709

mils (200 microns) wet (approximately 200 sq ft/gal / 4.9 m2/L). Special care should Atomization Pressure .............. 45-80 psi

be given to laps and edges of stencils to prevent excessive film thickness. Fluid Pressure ......................... 40-70 psi

NOTE: Fluid and atomization pressures

Asphalt surfaces generally require aging prior to painting. are dependent on environmental condi-

tions. Use the lowest pressures neces-

If the asphalt is insufficiently cured, applying a thin coat (approximately 1/2 the rec- sary to achieve a “flat line”.

ommended dft) generally reduces the extent of lifting and cracking. Brush Natural bristle

Roller Cover 3/8" woven

Painted surfaces can become slippery when wet. Zone Marking paints are not in- with solvent resistant core

tended for use as floor paints, and should not be used to paint large areas subject to

pedestrian traffic. For instance, painting an entire traffic stall is not recommended. If specific application equipment is listed

above, equivalent equipment may be

Do not paint on wet surfaces. substituted.

Check adhesion by applying a test strip to determine the readiness for painting.

CLEANUP INFORMATION

Slip Resistance

Some surfaces may require a slip resistant additive for safety. Add H&C SharkGrip® Clean spills and spatters immediately

Slip Resistant Additive to the final coat applied following label directions. Sand may with soap and warm water. Clean hands

also be broadcast onto the wet paint or incorporated in the final coat. These additives and tools immediately after use with soap

should not be used in place of a non-skid finish. and warm water. After cleaning, flush

spray equipment with VM&P Naphtha to

prevent rusting of the equipment. Use

VM&P Naphtha for overspray or dry paint

clean up.

Follow manufacturer’s safety recommen-

dations when using any solvent.

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommen-

dations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your Sherwin-Williams representative to obtain the most recent Product Data

Information and Application Bulletin. The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control proce-

dures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-

Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHER-

WISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

You might also like

- CIT-CON-01-CMT-MTS-000..-V0.. Method Statement For Construction Work at Night ShiftDocument13 pagesCIT-CON-01-CMT-MTS-000..-V0.. Method Statement For Construction Work at Night Shiftumuhuza salomon100% (1)

- PurifierDocument26 pagesPurifierAbhishek Kumar100% (1)

- Envirolastic AR 425 Data PageDocument4 pagesEnvirolastic AR 425 Data PageYsmael Steel TeklaNo ratings yet

- Checklist Site InspectionDocument29 pagesChecklist Site Inspectionthanzawtun198191% (11)

- Penguard Topcoat: Technical Data SheetDocument4 pagesPenguard Topcoat: Technical Data SheetQuoc VinhNo ratings yet

- PVC DatasheetDocument2 pagesPVC DatasheetvikrantNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Electrodeposition Andreas Tolz PPGDocument14 pagesElectrodeposition Andreas Tolz PPGAndi MusdalifahNo ratings yet

- WATCHDOG Waterproofing Features and BenefitsDocument2 pagesWATCHDOG Waterproofing Features and BenefitsappuramuvichuNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- DEGALAN® For PVC Finishes (English) PDFDocument2 pagesDEGALAN® For PVC Finishes (English) PDFslantsyhimNo ratings yet

- 2306 TDS Epoxy Antiskid CoatingDocument4 pages2306 TDS Epoxy Antiskid CoatingMeet NaikNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Jotafloor EP SLDocument4 pagesJotafloor EP SLEduardo Vera portocarreroNo ratings yet

- Protective & Marine Coatings: Sher-Clear™Document4 pagesProtective & Marine Coatings: Sher-Clear™Ana CabreraNo ratings yet

- Macal® 8200 Pro: Technical Data SheetDocument2 pagesMacal® 8200 Pro: Technical Data SheetMOHAMEDNo ratings yet

- WB Paint PDS 1952EF TY II Fast Dry Final 1222 MWDocument2 pagesWB Paint PDS 1952EF TY II Fast Dry Final 1222 MWAngga PratamaNo ratings yet

- Jotamastic 80: Technical Data SheetDocument14 pagesJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- WB Paint PDS 1952F TY II Fast Dry Final 210303 DADocument2 pagesWB Paint PDS 1952F TY II Fast Dry Final 210303 DALuis Barrios ArandaNo ratings yet

- Source Approval Kataline Part 2Document13 pagesSource Approval Kataline Part 2Arun KumarNo ratings yet

- Dow Corning 732 Multi-Purpose Sealant: Product InformationDocument2 pagesDow Corning 732 Multi-Purpose Sealant: Product InformationProject Sales CorpNo ratings yet

- Fluide at 42Document3 pagesFluide at 42Clodoaldo De Melo PereiraNo ratings yet

- Tankguard SF: Technical Data SheetDocument5 pagesTankguard SF: Technical Data SheetRifki ArifinNo ratings yet

- Raylene Ashless Multi-Vis Hydraulic Oil - 11Document3 pagesRaylene Ashless Multi-Vis Hydraulic Oil - 11aditNo ratings yet

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocument3 pagesSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosNo ratings yet

- Road Marking Paint SB AcrylicDocument4 pagesRoad Marking Paint SB AcrylicAngga PratamaNo ratings yet

- 5.1 Sumatane HSDocument4 pages5.1 Sumatane HSjnu6mnju6njNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- Tankguard 412: Technical Data SheetDocument6 pagesTankguard 412: Technical Data SheetMuneer ahmedNo ratings yet

- Flowcrete Asia Mondéco Crystal May2020 TdsDocument2 pagesFlowcrete Asia Mondéco Crystal May2020 TdsQuoc AnNo ratings yet

- Targuard PDFDocument4 pagesTarguard PDFsofian juniardiNo ratings yet

- TarguardDocument4 pagesTarguardMariela Tabata Calizaya ChipanaNo ratings yet

- Carboguard 1340 PDSDocument4 pagesCarboguard 1340 PDSSaefuddin OrtegaNo ratings yet

- TDS - 372 - SeaQuantum Plus - Eng - USDocument4 pagesTDS - 372 - SeaQuantum Plus - Eng - UShendra.siskal001No ratings yet

- TDS - 373 - SeaQuantum Ultra - Eng - USDocument4 pagesTDS - 373 - SeaQuantum Ultra - Eng - UShendra.siskal001No ratings yet

- TDS 2063 Tankguard 412 Euk GBDocument6 pagesTDS 2063 Tankguard 412 Euk GBSrimathi VijayakumarNo ratings yet

- Jotaguard 100: Technical Data SheetDocument6 pagesJotaguard 100: Technical Data SheetHector MacavilcaNo ratings yet

- NC-558 TDS enDocument2 pagesNC-558 TDS enniteshacharya100% (1)

- Fomblin Y45: Perfl UoropolyetherDocument1 pageFomblin Y45: Perfl UoropolyetheryatheendravarmaNo ratings yet

- PDS en-GB 45751Document2 pagesPDS en-GB 45751Anuar SalehNo ratings yet

- Jotamastic 80: Technical Data SheetDocument5 pagesJotamastic 80: Technical Data SheetArif dwi prasetyoNo ratings yet

- Interior Fluid Resistant Epoxy Primer: Technical Data SheetDocument5 pagesInterior Fluid Resistant Epoxy Primer: Technical Data SheetPannha LangNo ratings yet

- Jotatemp 1000 Ceramic: Technical Data SheetDocument5 pagesJotatemp 1000 Ceramic: Technical Data Sheetebastien2No ratings yet

- Tankguard DW Jotun PaintDocument6 pagesTankguard DW Jotun PaintGurdeep Sungh AroraNo ratings yet

- Lexan Margard HLG5 2021Document3 pagesLexan Margard HLG5 2021Jessica RamosNo ratings yet

- Datasheet Jotun-Tankguard StorageDocument5 pagesDatasheet Jotun-Tankguard Storagebudi handoyoNo ratings yet

- Astm Specs Villa OroDocument2 pagesAstm Specs Villa OroAngel VegaNo ratings yet

- MolykoteDocument2 pagesMolykoteRafael FrançaNo ratings yet

- Pittseal CW Sealant: 1. Description and Area of ApplicationDocument3 pagesPittseal CW Sealant: 1. Description and Area of ApplicationElie AouadNo ratings yet

- Carboguard 891: Selection & Specification DataDocument4 pagesCarboguard 891: Selection & Specification DataPrakashNo ratings yet

- Gulf FidelityDocument1 pageGulf FidelityBassam AljiffryNo ratings yet

- Kwer 1001-55BR (TDS)Document4 pagesKwer 1001-55BR (TDS)NganNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- CMP Liner Blue: CMP LNR BL CMP LNR BL CMP LNR BL CMP LNR BLDocument2 pagesCMP Liner Blue: CMP LNR BL CMP LNR BL CMP LNR BL CMP LNR BLRiki AkbarNo ratings yet

- PDS Hempadur Multi-Strength 45753 en-GBDocument2 pagesPDS Hempadur Multi-Strength 45753 en-GBJosip LasanNo ratings yet

- Epofine 138 - Finehard 998Document3 pagesEpofine 138 - Finehard 998Karishma PrabhuNo ratings yet

- Product Data: HEMPADUR 37620Document2 pagesProduct Data: HEMPADUR 37620Juanda Mardohar Dantec SitompulNo ratings yet

- Mariseal 400 Aqua Version18Document2 pagesMariseal 400 Aqua Version18Chetal BholeNo ratings yet

- Jotamastic 80: Technical Data SheetDocument5 pagesJotamastic 80: Technical Data SheetSafinahNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- 2023年10月份PK24保安工资Document2 pages2023年10月份PK24保安工资umuhuza salomonNo ratings yet

- 2360007745Document5 pages2360007745umuhuza salomonNo ratings yet

- 02frontier Theory and Development of Project ManagementDocument149 pages02frontier Theory and Development of Project Managementumuhuza salomonNo ratings yet

- Painting Spraying OperationsDocument3 pagesPainting Spraying Operationsumuhuza salomonNo ratings yet

- CIT CON 01 CMT MTS 0040 V00 Method Statement For Repairing PaintingDocument25 pagesCIT CON 01 CMT MTS 0040 V00 Method Statement For Repairing Paintingumuhuza salomonNo ratings yet

- Method Statement For Paint Repair Procedure For Piping PDF FreeDocument16 pagesMethod Statement For Paint Repair Procedure For Piping PDF Freeumuhuza salomonNo ratings yet

- Newton Form of The Interpolation PolynomialDocument11 pagesNewton Form of The Interpolation Polynomialumuhuza salomonNo ratings yet

- W-13 Solving The Linear Equation Systems by Iteration MethodDocument24 pagesW-13 Solving The Linear Equation Systems by Iteration Methodumuhuza salomonNo ratings yet

- Transmittal: China Harbour Engineering Company LimitedDocument34 pagesTransmittal: China Harbour Engineering Company Limitedumuhuza salomonNo ratings yet

- The Reference For More Than .: Quality 50 YearsDocument6 pagesThe Reference For More Than .: Quality 50 Yearsumuhuza salomonNo ratings yet

- P6 Programme113Document1 pageP6 Programme113umuhuza salomonNo ratings yet

- 6.4.2 Daily Returns: Second Container TerminalDocument2 pages6.4.2 Daily Returns: Second Container Terminalumuhuza salomonNo ratings yet

- The Role of Pinyin Proficiency in The Ac PDFDocument66 pagesThe Role of Pinyin Proficiency in The Ac PDFumuhuza salomonNo ratings yet

- Curriculum Vitae (Summary)Document5 pagesCurriculum Vitae (Summary)umuhuza salomonNo ratings yet

- Ap P Lication For M For Chinese Gover Nment Scholar ShipDocument5 pagesAp P Lication For M For Chinese Gover Nment Scholar Shipumuhuza salomonNo ratings yet

- Perform Routine Manual Metal Arc Welding: (MEM5.12C)Document27 pagesPerform Routine Manual Metal Arc Welding: (MEM5.12C)umuhuza salomonNo ratings yet

- Buses Best Practices FinalDocument26 pagesBuses Best Practices FinalpioneeringcompNo ratings yet

- Aisi 5160 Alloy Steel (Uns g51600)Document4 pagesAisi 5160 Alloy Steel (Uns g51600)Rizki RiantoniNo ratings yet

- Basic EE PrelimDocument3 pagesBasic EE PrelimJohnCris B. FornilosNo ratings yet

- 1520412369part2 2Document261 pages1520412369part2 2Jothimanikkam SomasundaramNo ratings yet

- Aircraft Communication SystemsDocument31 pagesAircraft Communication SystemsAhmedShah75% (4)

- Manual On The Creation of Accretion and Erosion Map Using Arcgis and Digital Shoreline Assessment System (DSAS)Document75 pagesManual On The Creation of Accretion and Erosion Map Using Arcgis and Digital Shoreline Assessment System (DSAS)Rojelon Vic AmataNo ratings yet

- Bemco BrochureDocument19 pagesBemco BrochurelightsonsNo ratings yet

- Mathcad CMU WallDocument23 pagesMathcad CMU WallqimingzengNo ratings yet

- Project Scheduling: Precedence Diagram MethodDocument61 pagesProject Scheduling: Precedence Diagram MethodJacob LusterioNo ratings yet

- Proposal Defence - Farah Wahida Corrected Ss 2Document19 pagesProposal Defence - Farah Wahida Corrected Ss 2Farah Wahida JusohNo ratings yet

- Hazard Identification, Risk Assessment & Risk Control (Hirarc)Document26 pagesHazard Identification, Risk Assessment & Risk Control (Hirarc)Satrio ReksoNo ratings yet

- Trumpet Manual PDFDocument24 pagesTrumpet Manual PDFEslam Hossny100% (1)

- Isometric Layout Drawing Isometric Offsets Calculating Isometric Offsets Isometric Dimensioning & LabelingDocument18 pagesIsometric Layout Drawing Isometric Offsets Calculating Isometric Offsets Isometric Dimensioning & LabelingSuresh Ram RNo ratings yet

- Technical Data YKK400-4WF1-315KW 6KV 50HZ IP55 IC611Document1 pageTechnical Data YKK400-4WF1-315KW 6KV 50HZ IP55 IC611tanviryNo ratings yet

- 1 Home Base Work March 19-MRCH 31Document3 pages1 Home Base Work March 19-MRCH 31Celso AmotoNo ratings yet

- API 674 Positive Displacement PumpsDocument67 pagesAPI 674 Positive Displacement PumpsFrancisco Pérez ChaniqueNo ratings yet

- Dyeing of Polyamide FibersDocument19 pagesDyeing of Polyamide FibersrajdewaanNo ratings yet

- EPE 2010 Brochure LowDocument71 pagesEPE 2010 Brochure LowNicoleNo ratings yet

- CX20 SpecificationsDocument1 pageCX20 SpecificationsDaniel Trovao SimoesNo ratings yet

- Tutorial Exercises For Chapter 3: Human Resources Capacity PlanningDocument2 pagesTutorial Exercises For Chapter 3: Human Resources Capacity PlanningDHARSHININo ratings yet

- Dial Indicators and Digital Indicators: Mounting A Dial IndicatorDocument1 pageDial Indicators and Digital Indicators: Mounting A Dial IndicatorozanNo ratings yet

- Project and Production Management Prof. Arun Kanda Department of Mechanical Engineering Indian Institute of Technology, Delhi Lecture - 40 Material Requirements PlanningDocument25 pagesProject and Production Management Prof. Arun Kanda Department of Mechanical Engineering Indian Institute of Technology, Delhi Lecture - 40 Material Requirements PlanningManish Kumar ChaudharyNo ratings yet

- Airborne Antenna Product Range 20-03-12Document5 pagesAirborne Antenna Product Range 20-03-12PeterNo ratings yet

- Undergraduate Studies Calendar - University of WaterlooDocument4 pagesUndergraduate Studies Calendar - University of WaterlooBrandin RoveloNo ratings yet

- Benchmark Functions PDFDocument47 pagesBenchmark Functions PDFshdotcom11004No ratings yet

- GATE 2014 Exam Admit Card: Examination Centre (7003)Document1 pageGATE 2014 Exam Admit Card: Examination Centre (7003)Hemanth JNo ratings yet

- Samsung-Cw21z503 21z453Document4 pagesSamsung-Cw21z503 21z453Anonymous 4aChpF1hZNo ratings yet

- Worksheet Science 2 º Unit 5Document20 pagesWorksheet Science 2 º Unit 5Kyo Toey0% (1)