Professional Documents

Culture Documents

Nevoeiro Salino AutomotiveUpdate4-806CCT

Nevoeiro Salino AutomotiveUpdate4-806CCT

Uploaded by

Miguel QueirosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nevoeiro Salino AutomotiveUpdate4-806CCT

Nevoeiro Salino AutomotiveUpdate4-806CCT

Uploaded by

Miguel QueirosCopyright:

Available Formats

Cyclic Corrosion Testing

Neutral Salt Spray Testing

Neutral salt spray (NSS) testing has been used for over sixty years to evaluate corrosion performance. The testing was

originally utilized for testing painted automotive body panels, however over time, its application has expanded to include

other surface finishes and base materials. The primary criticism of NSS testing is that it is a static test, whereas there is

the lack of correlation to service conditions, or even vehicle testing.

The Benefits of Cyclic Corrosion Testing

Cyclic corrosion testing simulates actual environmental conditions by alternating exposure to salt spray, humidity, heat,

and cold. Studies have been conducted on the correlation of specific laboratory cyclic test schedules to field exposure.

Even though the accelerated test will never duplicate actual atmospheric conditions, the correlation between cyclic

corrosion testing and environmental exposure is a significant improvement over NSS testing.

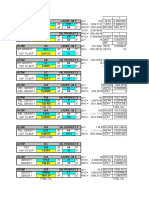

OEM Acceptance of Cyclic Corrosion Testing

Most OEMs have adopted cyclic corrosion testing in addition to NSS testing. Additionally, each OEM has developed its

own version. Some of the more common cyclic corrosion tests are provided in the chart below.

Laboratory Cyclic Corrosion Test Schedules*

Ford Dust Salt Immersion Drain & Dry Humidity

APG Koalin; 1x only 23ºC;15 min. 23ºC; 3 hrs. 50ºC, 85% - 90% RH

20 hrs., 45 min.

General Motors Salt Mist Application Humidity Dry

GM9540P 4x 8 hours 50ºC, 95% RH; 8 hours 60ºC, 25% RH; 8 hrs.

Honda Humidity Salt Spray Dry Humidity

40ºC, 95% RH; 2 hrs. 35ºC; 2 hrs. 60ºC; 1 hr. 50ºC, 95% RH; 6 hrs.

Dry Humidity Dry Dry

60ºC; 2 hrs. 50ºC, 95% RH; 6 hrs. 60ºC; 2 hrs. 20ºC; 3 hrs.

Nissan Salt Spraying Dry Moistening

CCT-I 35ºC; 4 hrs. 60ºC, <30% RH; 2 hrs. 50ºC, 95% RH; 2 hrs.

Toyota Salt Spray Dry Humidity Chill Dry

35ºC; 8 hrs. 70ºC; 2 hrs. 50ºC, 95% RH; 2 hrs. -20ºC; 2 hrs. RT; 10 hrs.

SAE J2334 Humidity Salt Application Dry

50ºC, 100% RH; 6 hrs. 25ºC, 15 min. 60ºC, 50% RH; 17 hrs., 45 min.

VDA Salt Mist (DIN 50021 SS) Humidity (DIN 50017 KFW) Dry, Room Temp. (DIN 50014-23/15-2)

VDA 621-415 24 hrs. 4 x 24 hrs. 2 x 24 hrs.

Volkswagen Salt Mist (DIN 50021 SS) Dry (DIN 50014-23/15-2) Humidity (DIN 50017 KK)

VW PV 1210 4 hours 4 hours 16 hrs.

Sequence is repeated 5 times and then: Dry, Room Temp. (DIN 50014-23/15-2) for 48 hrs.

Volvo Salt Application Humidity Dry

STD 10.27, 1375 1 hr. 35ºC, 90% RH; 7 hrs. 35ºC, 45% RH; 12 hrs.

(VICT)

Scania

STD 4233

* Refer to each OEM standard for details and other test options.

AMERICAS Enthone Inc. • 350 Frontage Road, West Haven, CT 06516 USA • Tel: 203-934-8611 • Fax: 203-799-1513

ASIA Cookson Electronics Ltd. – Enthone • 1/F, Block A, 21 Tung Yuen Street, Yau Tong Bay, Kowloon, Hong Kong • Tel: 852-2499-7299 • Fax: 852-2415-2225

EUROPE Enthone GmbH • Elisabeth-Selbert-Straβe 4, 40764 Langenfeld, Germany • Tel: 49-2173-8490-0 • Fax: 49-2173-8490-200

Issued: 08/06

Supersedes: New

2006, Enthone Inc.

® Registered Trademark of Enthone Inc.

EnthoneAutoUp-4

You might also like

- Worldwide Engineering Standards: Material Specification Finish GMW4700Document4 pagesWorldwide Engineering Standards: Material Specification Finish GMW4700Miguel Queiros100% (4)

- My Beautiful Religion According To The Hanafi School 1Document242 pagesMy Beautiful Religion According To The Hanafi School 1islamic books100% (3)

- Fiat 9.57409 - 2007-04 - ZINC - NICKEL ALLOY ELECTROLYTICDocument13 pagesFiat 9.57409 - 2007-04 - ZINC - NICKEL ALLOY ELECTROLYTICMiguel QueirosNo ratings yet

- Din 6928Document2 pagesDin 6928Miguel QueirosNo ratings yet

- Din 6928Document2 pagesDin 6928Miguel QueirosNo ratings yet

- ASTM TablesDocument29 pagesASTM TablesStemo100% (1)

- Din 7500 (1995)Document10 pagesDin 7500 (1995)JonahtanNo ratings yet

- KAMAX - Bolt and Screw CompendiumDocument60 pagesKAMAX - Bolt and Screw Compendiumjzaw65No ratings yet

- Product Data Sheet: Mobil Jet Oil IIDocument2 pagesProduct Data Sheet: Mobil Jet Oil IIGiang NguyenNo ratings yet

- RefractoryDocument38 pagesRefractoryDucNo ratings yet

- International Intertuf 262Document4 pagesInternational Intertuf 262shunanlatheefNo ratings yet

- Interzone 954 enDocument4 pagesInterzone 954 engrootwNo ratings yet

- Macropoxy 646: Fast Cure Epoxy MasticDocument2 pagesMacropoxy 646: Fast Cure Epoxy MasticANA CABRERANo ratings yet

- Cloverdale - (Data Sheet) Clovaprimer h20-0020Document3 pagesCloverdale - (Data Sheet) Clovaprimer h20-0020PubcrawlNo ratings yet

- Sikafloor®-161: Product Data SheetDocument5 pagesSikafloor®-161: Product Data SheetashayshaNo ratings yet

- CA9311 Desothane HS Advanced Performance CoatingsDocument7 pagesCA9311 Desothane HS Advanced Performance CoatingsAbhinandan JainNo ratings yet

- Sea Grandprix 880Document2 pagesSea Grandprix 880Rifat AzadNo ratings yet

- NovaguardDocument6 pagesNovaguardManuel DueñasNo ratings yet

- SigmaCover-300 DataDocument7 pagesSigmaCover-300 DataFaisal FaizNo ratings yet

- Macropoxy 646 - 2023Document2 pagesMacropoxy 646 - 2023nellyNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - A4 - 20150204Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - A4 - 20150204Zainal ArifinNo ratings yet

- 134 TDS Updated Feb 2016 78-8141-8528-2 Rev ADocument6 pages134 TDS Updated Feb 2016 78-8141-8528-2 Rev AUriel GarciaNo ratings yet

- Phenicon HS: Epoxy Novolac Phenolic Tank LiningDocument2 pagesPhenicon HS: Epoxy Novolac Phenolic Tank Liningapply19842371No ratings yet

- Interzone 5140: Epoxy PrimerDocument4 pagesInterzone 5140: Epoxy PrimerTrịnh Minh KhoaNo ratings yet

- Macropoxy 646Document2 pagesMacropoxy 646Isabel CutireNo ratings yet

- MC250 Urethane Clearcoat: BackgroundDocument3 pagesMC250 Urethane Clearcoat: BackgroundWayne LundNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519ValentinNo ratings yet

- Gelshield 200 Eng A4 20190924Document2 pagesGelshield 200 Eng A4 20190924Lin LinNo ratings yet

- Macropoxy 646: Fast Cure Epoxy MasticDocument2 pagesMacropoxy 646: Fast Cure Epoxy MasticsidneidecarvalhoNo ratings yet

- Specification Sheet: Project: AreaDocument15 pagesSpecification Sheet: Project: AreaWildan RNo ratings yet

- Armorite Soft Natural Rubber: Technical Data SheetDocument2 pagesArmorite Soft Natural Rubber: Technical Data SheetSantosh JayasavalNo ratings yet

- Technical Data: Three Bond 1104 Liquid GasketDocument4 pagesTechnical Data: Three Bond 1104 Liquid GasketMochammad irhamNo ratings yet

- Tnemec (Data Sheet) 46h-413Document2 pagesTnemec (Data Sheet) 46h-413PubcrawlNo ratings yet

- PPG PDS Amercoat 450HDocument6 pagesPPG PDS Amercoat 450HsanguripNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- Sigmacover™ 300: Product Data SheetDocument6 pagesSigmacover™ 300: Product Data SheetinnovativekarthiNo ratings yet

- RN86638218Document10 pagesRN86638218eli rezekiNo ratings yet

- Infinity Turbine Oil 32 46 BR180104-2Document4 pagesInfinity Turbine Oil 32 46 BR180104-2Ahmad ButtNo ratings yet

- Methods of Compound Corrosion Test: Nissan Engineering StandardDocument9 pagesMethods of Compound Corrosion Test: Nissan Engineering StandardJose BresciaNo ratings yet

- Dura-Plate UHS: Protective & Marine CoatingsDocument2 pagesDura-Plate UHS: Protective & Marine CoatingsABIMAELNo ratings yet

- Amtech - RMA-223 Rev 0510Document2 pagesAmtech - RMA-223 Rev 0510Mohammed AbbariNo ratings yet

- Intergard 361 EPA' EngDocument4 pagesIntergard 361 EPA' Engwgr1216No ratings yet

- Technical News: Low Smoke JacketsDocument3 pagesTechnical News: Low Smoke JacketsFelipe GustavoNo ratings yet

- Sigmacover 280 (Primer) For HDG SurfaceDocument6 pagesSigmacover 280 (Primer) For HDG SurfaceRauf AliyevNo ratings yet

- Plasite 4310 PDS 1-06Document2 pagesPlasite 4310 PDS 1-06Gerardo FloresNo ratings yet

- SikaAnchorFix3001 PdsDocument4 pagesSikaAnchorFix3001 PdssaulolmNo ratings yet

- Phenicon HS PDSDocument2 pagesPhenicon HS PDSJose MachadoNo ratings yet

- Ventana 04Document2 pagesVentana 04Anonymous hQ6z6OBwNo ratings yet

- 256 UkDocument4 pages256 UkBùi Văn TấnNo ratings yet

- Sunmide X-2000-TDSDocument2 pagesSunmide X-2000-TDSTerrence LaiNo ratings yet

- Intershield803 MDSDocument4 pagesIntershield803 MDSSahanNo ratings yet

- Interline MSDSDocument4 pagesInterline MSDSUtomoNo ratings yet

- Amercoat 450H PDSDocument7 pagesAmercoat 450H PDSNnamdi AmadiNo ratings yet

- 3M Urethane TDS - 08609Document5 pages3M Urethane TDS - 08609Oscar DazaNo ratings yet

- Methods of Compound Corrosion Test: Nissan Engineering StandardDocument7 pagesMethods of Compound Corrosion Test: Nissan Engineering StandardPushparajNo ratings yet

- RTM6 GlobalDocument4 pagesRTM6 GlobalRosa BarrancoNo ratings yet

- Ceilcote 242 Flakeline Eng A4 20180219Document4 pagesCeilcote 242 Flakeline Eng A4 20180219Cuong Nguyen ManhNo ratings yet

- 1056 HTDocument2 pages1056 HTSantosh JayasavalNo ratings yet

- 02Y040A Yellow Epoxy Primer: Product DescriptionDocument6 pages02Y040A Yellow Epoxy Primer: Product DescriptionBoris KundačinaNo ratings yet

- Intergard 269 PDFDocument4 pagesIntergard 269 PDFAdi SeptiNo ratings yet

- Celcote 242Document4 pagesCelcote 242Anwar MdNo ratings yet

- Sea Grandprix 1000l (1409)Document2 pagesSea Grandprix 1000l (1409)Trịnh Minh KhoaNo ratings yet

- Duraplate 8200Document4 pagesDuraplate 8200Carlos VillacrizNo ratings yet

- Hysol Ea 9309Document5 pagesHysol Ea 9309edgmtNo ratings yet

- en-US 6832Document5 pagesen-US 6832ROGER ENRIQUE JARA ALFARONo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Din 2510-3Document6 pagesDin 2510-3Miguel QueirosNo ratings yet

- Tightening TorqueDocument2 pagesTightening TorqueMiguel QueirosNo ratings yet

- Hole Sizes MetricDocument1 pageHole Sizes MetricMiguel QueirosNo ratings yet

- GC CatalogDocument30 pagesGC CatalogMiguel QueirosNo ratings yet

- DIN-EN-ISO-10666-2000-propiedades MecanicasDocument10 pagesDIN-EN-ISO-10666-2000-propiedades MecanicasMiguel Queiros100% (1)

- En 24015-1991 (DIN) Paraf HexDocument9 pagesEn 24015-1991 (DIN) Paraf HexMiguel QueirosNo ratings yet

- Din 7513Document5 pagesDin 7513Miguel QueirosNo ratings yet

- Din 967Document4 pagesDin 967Miguel QueirosNo ratings yet

- Tpping Screws - Chapter 4Document13 pagesTpping Screws - Chapter 4Miguel QueirosNo ratings yet

- Bits PZ PhilipsDocument5 pagesBits PZ PhilipsMiguel QueirosNo ratings yet

- Section 10 Useful Information: General Information - Stainless Steel FastenersDocument1 pageSection 10 Useful Information: General Information - Stainless Steel FastenersMiguel QueirosNo ratings yet

- Section 10 Useful Information: General Information - Plastic FastenersDocument1 pageSection 10 Useful Information: General Information - Plastic FastenersMiguel QueirosNo ratings yet

- Parafusos Com Gargantachapter 3Document7 pagesParafusos Com Gargantachapter 3Miguel QueirosNo ratings yet

- PERDEV-Module-quarter 2 - Week 7Document12 pagesPERDEV-Module-quarter 2 - Week 7erica lamsen0% (1)

- Schools of VedantaDocument21 pagesSchools of VedantaManthena Charan RajNo ratings yet

- 00 Set 1 B2 08.06 Paper Cover (20 Files Merged)Document69 pages00 Set 1 B2 08.06 Paper Cover (20 Files Merged)Ferenc CsizovszkyNo ratings yet

- Introduction Materials For 15 Companies Participating in The Internship ProgramDocument16 pagesIntroduction Materials For 15 Companies Participating in The Internship ProgramAqua BlueNo ratings yet

- TCS Beats Estimates With 16.2% Q1 Revenue Growth: Real Growth Not Possible Without Inclusiveness: PMDocument18 pagesTCS Beats Estimates With 16.2% Q1 Revenue Growth: Real Growth Not Possible Without Inclusiveness: PMf20213093No ratings yet

- BSM311 OperationsManagement ZaracasestudyDocument24 pagesBSM311 OperationsManagement ZaracasestudyFadekemi Adelabu100% (1)

- Huawei OceanStor T Series Technical White PaperDocument38 pagesHuawei OceanStor T Series Technical White PaperHelios De CreisquerNo ratings yet

- 82 - Amber ReportDocument5 pages82 - Amber ReportSaloniPatilNo ratings yet

- Christopher S. Campbell Craig W. Greene Benedict F. Neubauer Jean M. HigginsDocument8 pagesChristopher S. Campbell Craig W. Greene Benedict F. Neubauer Jean M. HigginsВоја ВојводаNo ratings yet

- The Tragic Drama of Doctor FaustusDocument12 pagesThe Tragic Drama of Doctor FaustustigerpiecesNo ratings yet

- Pharmacology and The Nursing ProcessDocument28 pagesPharmacology and The Nursing ProcessEdralyn MatalangNo ratings yet

- CROSSWORDDocument4 pagesCROSSWORDMartyneJohnNo ratings yet

- Sree Sakthi Paper MillsDocument68 pagesSree Sakthi Paper MillsMohammed AnamNo ratings yet

- Et 5050RTB 333WDocument12 pagesEt 5050RTB 333WLaurentiu IacobNo ratings yet

- VTU Connect App Download Now From Google Play Store For Notes, QP'S, Previous Sem Result and Lot MoreDocument8 pagesVTU Connect App Download Now From Google Play Store For Notes, QP'S, Previous Sem Result and Lot MoreHanumant ChikuNo ratings yet

- Evidence Notes Mere Denial and Alibi Are WeakDocument4 pagesEvidence Notes Mere Denial and Alibi Are WeakJulius Carmona GregoNo ratings yet

- Damon Leff - A Pagan Witches TouchStone Witchcraft and Witch Hunts in Cd6 Id1460283060 Size308Document65 pagesDamon Leff - A Pagan Witches TouchStone Witchcraft and Witch Hunts in Cd6 Id1460283060 Size308Roberto BrasilNo ratings yet

- Production of Low Cost Self Compacting Concrete Using Bagasse AshDocument10 pagesProduction of Low Cost Self Compacting Concrete Using Bagasse AshENgřMuhăɱɱadRiǺzAhɱadNo ratings yet

- Simple Present Vs Present ProgressiveDocument5 pagesSimple Present Vs Present ProgressiveSalomeNo ratings yet

- Character Sketch of Elizabeth BennetDocument2 pagesCharacter Sketch of Elizabeth BennetAiman Abdullah100% (2)

- PricelistDocument57 pagesPricelistalex guzmanNo ratings yet

- Application of Gypsum Sheathing: Standard Specification ForDocument3 pagesApplication of Gypsum Sheathing: Standard Specification ForAlejandroNo ratings yet

- Water Flow in Saturated Soils Darcy's Law: CE/ENVE 320 - Vadose Zone Hydrology/Soil Physics Spring 2004Document41 pagesWater Flow in Saturated Soils Darcy's Law: CE/ENVE 320 - Vadose Zone Hydrology/Soil Physics Spring 2004joo12345678910No ratings yet

- COMP538: Introduction To Bayesian NetworksDocument53 pagesCOMP538: Introduction To Bayesian NetworksMUHAMMAD HAFIZUDDIN ZAMRINo ratings yet

- Sabic® PP 49Mk45: Polypropylene Impact Copolymer For Injection MoldingDocument2 pagesSabic® PP 49Mk45: Polypropylene Impact Copolymer For Injection Moldingnhan leNo ratings yet

- Erytropoiesis Part 1&2 Ninja Nerd ScienceDocument2 pagesErytropoiesis Part 1&2 Ninja Nerd Sciencewati100% (4)

- Studies - (Chapter - 3) Environment, BST Class 12Document23 pagesStudies - (Chapter - 3) Environment, BST Class 12Manish NagdevNo ratings yet

- Shendage Et Al. (2016)Document8 pagesShendage Et Al. (2016)Reddy ReddyNo ratings yet

- Differential Equation - Module 1Document5 pagesDifferential Equation - Module 1Bonsay 23No ratings yet