Professional Documents

Culture Documents

Injection Pump Test Specifications 196000-517#

Injection Pump Test Specifications 196000-517#

Uploaded by

Edinson Ariel Chavarro QuinteroCopyright:

Available Formats

You might also like

- Parts Catalog - Option DetailDocument3 pagesParts Catalog - Option DetailEdinson Ariel Chavarro Quintero100% (2)

- HA285Document48 pagesHA285Edinson Ariel Chavarro Quintero100% (10)

- Participate in Workplace CommunicationDocument8 pagesParticipate in Workplace CommunicationArman Berina CortezNo ratings yet

- EI5501Document4 pagesEI5501aaa bbb100% (1)

- Service Manual: Pub. No. EE14E-11130Document39 pagesService Manual: Pub. No. EE14E-11130Marcelo Diesel81% (16)

- 094000-048# DespieceDocument4 pages094000-048# DespieceEdinson Ariel Chavarro QuinteroNo ratings yet

- Pump Test Specifications: InjectionDocument3 pagesPump Test Specifications: InjectionJaqueline S. S. Maicá100% (1)

- 196000-4270 - Toyota Tabela Teste PDFDocument4 pages196000-4270 - Toyota Tabela Teste PDFJaqueline S. S. Maicá100% (1)

- 3031 PDFDocument4 pages3031 PDFMihai-Eugen Popa100% (1)

- 196000-3710 TicoDocument9 pages196000-3710 TicoEdinson Ariel Chavarro Quintero100% (1)

- S5000-1-Test-Data Ui Up Bosch, DelphiDocument29 pagesS5000-1-Test-Data Ui Up Bosch, DelphiEdinson Ariel Chavarro Quintero100% (1)

- Simens Pump ibjectorDOC-20170202-WA0011Document121 pagesSimens Pump ibjectorDOC-20170202-WA0011Edinson Ariel Chavarro Quintero100% (5)

- Restricted Earth Fault (REF) ProtectionDocument8 pagesRestricted Earth Fault (REF) ProtectionNaveen Amarasinghe100% (1)

- 196000-6060 Injection Pump Test SpecificationsDocument4 pages196000-6060 Injection Pump Test SpecificationsMiguel RojasNo ratings yet

- Injection Pump Test Specifications 191000-490#Document3 pagesInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- Inj - P Ump Cal Ibration DataDocument3 pagesInj - P Ump Cal Ibration DataСергей ВладимировичNo ratings yet

- 4720Document3 pages4720Junior IungNo ratings yet

- 7030Document3 pages7030pruebaNo ratings yet

- Injection Volume Adjustment Test Conditions: 6c-59-1.tifDocument33 pagesInjection Volume Adjustment Test Conditions: 6c-59-1.tifElvis Eliud HernándezNo ratings yet

- Injection Pump Test Specifications 093000-677#Document3 pagesInjection Pump Test Specifications 093000-677#Pedro Abellan100% (1)

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsMartin Miguel Gomez SalviNo ratings yet

- Denso Bomba 092000-3690Document3 pagesDenso Bomba 092000-3690Superlativo Igv100% (1)

- 7540Document10 pages7540pruebaNo ratings yet

- Injection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxDocument3 pagesInjection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxBaytolga100% (3)

- Injection Pump Calibration Data: Assy No.: 101608-9582Document3 pagesInjection Pump Calibration Data: Assy No.: 101608-9582Elson DorigonNo ratings yet

- Injection Pump Test S Pecifications 196000-417#Document4 pagesInjection Pump Test S Pecifications 196000-417#Juan Gabriel Ochoa100% (1)

- EB8870Document2 pagesEB8870Miguel RojasNo ratings yet

- 606 9291Document2 pages606 9291Сергей ВладимировичNo ratings yet

- 101491-9530 Mazda PDFDocument10 pages101491-9530 Mazda PDFBaytolgaNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument6 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- 740 4010Document6 pages740 4010Miguel ChaconNo ratings yet

- DATODocument1 pageDATOMiguel RojasNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration Datamurillo_rodriguez8382No ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration Datamurillo_rodriguez8382No ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- Injection Pump Test Specifications: CPS21 AVM2PC-20hpDocument2 pagesInjection Pump Test Specifications: CPS21 AVM2PC-20hpDilakartikaNo ratings yet

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsBaytolgaNo ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelKevin Ttito100% (1)

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- 9322a050 - Erkunt Servet 80 TDocument6 pages9322a050 - Erkunt Servet 80 TBaytolgaNo ratings yet

- Fuel Injection Equipment For M&M 245 DI Engine: SSE-I-MML/138 12.2003Document2 pagesFuel Injection Equipment For M&M 245 DI Engine: SSE-I-MML/138 12.2003Ravikant Saini100% (1)

- 093000-1613 Hi̇no PDFDocument2 pages093000-1613 Hi̇no PDFBaytolgaNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration DataMiguel RojasNo ratings yet

- 606 9460Document2 pages606 9460Alex PakitoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)баха бахинскийNo ratings yet

- Test SheetDocument3 pagesTest SheetNemo NeoNo ratings yet

- Temp 753Document2 pagesTemp 753Neelakandan Krishnan100% (1)

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungNo ratings yet

- 9412Document3 pages9412Mihai-Eugen Popa100% (1)

- 02EN1630Document2 pages02EN1630Edinson Ariel Chavarro QuinteroNo ratings yet

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- Plano de Teste Zexel 104136-3010Document1 pagePlano de Teste Zexel 104136-3010Elson DorigonNo ratings yet

- Injection Pump Calibration Data: 1. Test ConditionsDocument3 pagesInjection Pump Calibration Data: 1. Test ConditionsElson DorigonNo ratings yet

- EE4760Document2 pagesEE4760OFFICE DANACNo ratings yet

- 104740-4734 - Test PlanDocument2 pages104740-4734 - Test PlanMihai-Eugen Popa100% (1)

- Injection Pump Test SpecificationsDocument4 pagesInjection Pump Test SpecificationsJunior IungNo ratings yet

- TSS-TS-TATA 2.95 D: For Field Service OnlyDocument2 pagesTSS-TS-TATA 2.95 D: For Field Service OnlyBest Auto TechNo ratings yet

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- STS-TS-TCL 5.88 d2: For Field Service OnlyDocument2 pagesSTS-TS-TCL 5.88 d2: For Field Service OnlyFaizul SiddiquiNo ratings yet

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Inj. Pump Calibration Data: 1. Test ConditionsDocument1 pageInj. Pump Calibration Data: 1. Test ConditionsMiguel RojasNo ratings yet

- 093400-5350 Mitsubishi PDFDocument2 pages093400-5350 Mitsubishi PDFBaytolgaNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- Test Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorDocument2 pagesTest Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorJam B100% (3)

- Dpico: Inj. Pump Calibration DataDocument3 pagesDpico: Inj. Pump Calibration DataMiguel Rojas100% (1)

- (Oto-Hui - Com) Edc Hino s05Document2 pages(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500No ratings yet

- 196000-175# 096000-175#Document4 pages196000-175# 096000-175#Junior Iung100% (1)

- Ei4060 1Document4 pagesEi4060 1Miguel RojasNo ratings yet

- 096000-352# Pump Test Specification (Plano de Teste Denso)Document4 pages096000-352# Pump Test Specification (Plano de Teste Denso)Junior IungNo ratings yet

- Core Codes and Acceptance Guidelines: May 2021 May 2021Document34 pagesCore Codes and Acceptance Guidelines: May 2021 May 2021Edinson Ariel Chavarro Quintero100% (2)

- TOYOTA I-ART Common Rail Injector G3Pi 23670-30270Document1 pageTOYOTA I-ART Common Rail Injector G3Pi 23670-30270Edinson Ariel Chavarro QuinteroNo ratings yet

- Ki T S & Component S Ki T S & Component SDocument52 pagesKi T S & Component S Ki T S & Component SEdinson Ariel Chavarro QuinteroNo ratings yet

- 196000-5172 OthersDocument1 page196000-5172 OthersEdinson Ariel Chavarro QuinteroNo ratings yet

- 196000-0990 DaihatsuDocument13 pages196000-0990 DaihatsuEdinson Ariel Chavarro QuinteroNo ratings yet

- 1960000-5172 2Document5 pages1960000-5172 2Edinson Ariel Chavarro QuinteroNo ratings yet

- 196000-5172 OthersDocument1 page196000-5172 OthersEdinson Ariel Chavarro QuinteroNo ratings yet

- 1960000-5272 2Document5 pages1960000-5272 2Edinson Ariel Chavarro QuinteroNo ratings yet

- (Dieselyturbos2) - (26-09-2018) : Parts ListDocument6 pages(Dieselyturbos2) - (26-09-2018) : Parts ListEdinson Ariel Chavarro QuinteroNo ratings yet

- DTech Catalog - 2019 PDFDocument82 pagesDTech Catalog - 2019 PDFEdinson Ariel Chavarro Quintero100% (1)

- Ee6790 PDFDocument3 pagesEe6790 PDFEdinson Ariel Chavarro Quintero100% (1)

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Ei4060 1Document4 pagesEi4060 1Miguel RojasNo ratings yet

- Parts VDO 2008Document30 pagesParts VDO 2008Edinson Ariel Chavarro QuinteroNo ratings yet

- Dpico: Inj - PumpcalibrationdataDocument2 pagesDpico: Inj - PumpcalibrationdataEdinson Ariel Chavarro Quintero100% (3)

- 0560Document4 pages0560Edinson Ariel Chavarro QuinteroNo ratings yet

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsEdinson Ariel Chavarro Quintero100% (2)

- 196000-104# List PartDocument9 pages196000-104# List PartEdinson Ariel Chavarro QuinteroNo ratings yet

- 092000-5600 Injection Pump Test SpecificationsDocument3 pages092000-5600 Injection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- DPA - 240 User'S Manual: Diesel Parts of AmericaDocument54 pagesDPA - 240 User'S Manual: Diesel Parts of AmericaEdinson Ariel Chavarro QuinteroNo ratings yet

- Lista de Precio-COMAC 2012Document41 pagesLista de Precio-COMAC 2012innopetrol0% (1)

- Integrative Programming and Technologies: Chapter TwoDocument19 pagesIntegrative Programming and Technologies: Chapter TwoDagim Fekadu AmenuNo ratings yet

- Technology That Transforms.: High-Performance Engines For Mining EquipmentDocument8 pagesTechnology That Transforms.: High-Performance Engines For Mining EquipmentJOSUE FERNANDO FERNANDEZNo ratings yet

- Saa7708h PDFDocument60 pagesSaa7708h PDFPamela Ramos SánchezNo ratings yet

- 8TH SEM PRO Ack, CertificateDocument3 pages8TH SEM PRO Ack, Certificateprinceofnation_21No ratings yet

- CPDD 17 1Document2 pagesCPDD 17 1Arthur MerilloNo ratings yet

- Dissertation Ideas Computer SecurityDocument5 pagesDissertation Ideas Computer SecurityCollegePaperWritingServiceReviewsColumbia100% (1)

- 2DOF Ball Balancer Product InformationDocument2 pages2DOF Ball Balancer Product InformationSaqib KhattakNo ratings yet

- It Companies Success and FailuresDocument5 pagesIt Companies Success and Failuresamber baigNo ratings yet

- Cos2626 2014 TL 102 2 BDocument7 pagesCos2626 2014 TL 102 2 BbibiveeNo ratings yet

- 101 Cdma BasicsDocument34 pages101 Cdma BasicsAbdul KhaderNo ratings yet

- Data Structure - Lesson 1Document4 pagesData Structure - Lesson 1Lady Marj RosarioNo ratings yet

- Sow CSP650 Oct 2023 - Feb 2024Document3 pagesSow CSP650 Oct 2023 - Feb 20242022925869No ratings yet

- Howto Configure Admin Console OIDC AzureADDocument17 pagesHowto Configure Admin Console OIDC AzureADgordacoNo ratings yet

- FM - Get - SNP - QtyDocument3 pagesFM - Get - SNP - QtymunafNo ratings yet

- E CashDocument46 pagesE CashJosephine Jebet RonohNo ratings yet

- Project Report On Shopping ApplicationDocument118 pagesProject Report On Shopping ApplicationpassionatepriyaNo ratings yet

- RTS Lecture 4 1644141180167Document21 pagesRTS Lecture 4 1644141180167Gaurav BagdeNo ratings yet

- Vishwas Haimraj (Ali Gohar & Company)Document3 pagesVishwas Haimraj (Ali Gohar & Company)VishwasNo ratings yet

- Model Set 2Document10 pagesModel Set 2AmrithaNo ratings yet

- A Group Chat Application Using Java: On Mini Project WorkDocument33 pagesA Group Chat Application Using Java: On Mini Project WorkAmar GolleNo ratings yet

- KESZ SerbiaDocument14 pagesKESZ SerbiamesipolyakNo ratings yet

- Traffic Alert Collision Avoidance System Kuchar Ja 11284Document20 pagesTraffic Alert Collision Avoidance System Kuchar Ja 11284Manchu RaiNo ratings yet

- Hitachi Unified Compute Platform RS For VMware Interoperability Matrix - 080320-BDocument3 pagesHitachi Unified Compute Platform RS For VMware Interoperability Matrix - 080320-Bstimyl_471631114No ratings yet

- Imo Safety of NavigationDocument17 pagesImo Safety of NavigationlusifadilahNo ratings yet

- Mitel 5000 CP v5.0 System Administration Diagnostics Guide PDFDocument46 pagesMitel 5000 CP v5.0 System Administration Diagnostics Guide PDFRichNo ratings yet

- Lesson Outline JBDocument3 pagesLesson Outline JBapi-241811643No ratings yet

- Practical Date SheetDocument73 pagesPractical Date SheetYashwant PatelNo ratings yet

Injection Pump Test Specifications 196000-517#

Injection Pump Test Specifications 196000-517#

Uploaded by

Edinson Ariel Chavarro QuinteroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injection Pump Test Specifications 196000-517#

Injection Pump Test Specifications 196000-517#

Uploaded by

Edinson Ariel Chavarro QuinteroCopyright:

Available Formats

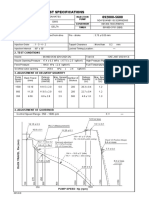

INJECTION PUMP TEST SPECIFICATIONS 196000-5170,1,2

MANUFACTURER DONGFENG CHAOYANG INJECTION 196000-517#

ENGINE TYPE QD32TI PUMP VE4/11F1800RND517

VEHICLE MODEL TRACK ROTATION Clockwise viewed from GOVERNOR TYPE All speed

drive side

RATED VOLTAGE 12V INJECTION ORDER A-B-C-D INJECTION INTERVAL 90° ± 30'

Dimension KF (mm) 6.40 ± 0.10 Dimension MS (mm) 2.00 ± 0.10

Dimension K (mm) 3.30 ± 0.15 Dimension PS (mm) 0.11 ± 0.02

1. TEST CONDITIONS

Nozzle 093400-0540 (DN12SD12A) Feed Pressure 19.6 kPa ( 0.2 kgf/cm 2)

Nozzle Opening Pressure 14.7 ± 0.5 MPa ( 150 ± 5 kgf/cm 2) High Pressure Pipe Ø2 × Ø6 × 840 mm

Test Oil SAE J967 (ISO4113) Fuel Temperature 40 - 45 °C (104 - 113°F)

NOTE : Apply 14 volts DC across the fuel cut solenoid during adjustment.

2. PRE-ADJUSTMENT Applying 0 V to T.C.V

Lever Position Pump Speed Boost Pressure Fuel Delivery Max. Spread

(deg) (rpm) in Delivery

(kPa) (mmHg) (mm3/st) (cc/200st) (mm3) (cc)

Full Load 1.5 ± 5° 1000 80.0 600 60.1 ± 0.5 12.0 ± 0.1 4.0 0.8

(Full position)

High Speed 2350 80.0 600 31.9 ± 1.5 6.4 ± 0.3 — —

3. ADJUSTMENT OF INTERNAL PRESSURE Applying 0 V to T.C.V

Lever Position Pump Speed Boost Pressure Internal Pressure Remarks

(rpm) (kPa) (mmHg) (kPa) (kgf/cm 2)

Full 1000 80.0 600 490.0 ± 70.0 5.0 ± 0.7 By the regulating valve

Less than Less than

2000 80.0 600 960.0 9.8 Applying 6 ± 0.1 V to T.C.V.

4. OVERFLOW QUANTITY CHECK Applying 0 V to T.C.V

Lever Position Pump Speed Boost Pressure Overflow Quantity Remarks

(rpm) (kPa) (mmHg) (L/h) (cc/1000st)

Full 1800 80.0 600 17.0 - 43.0 160 - 400

NOTE : The overflow valve belonging to the pump should be used checking.

5. ADJUSTMENT OF TIMER Applying 0 V to T.C.V

Lever Position Pump Speed Boost Pressure Piston Travel Remarks

(rpm) (kPa) (mmHg) (mm)

Full 1000 80.0 600 2.94 ± 0.20

1500 80.0 600 5.10 ± 0.20

1800 80.0 600 6.41 ± 0.20

NOTE : Hysteresis at each pump speed is less than 0.3 mm.

2005.11.16

196000-5170,1,2

7. ADJUSTMENT OF FUEL DELIVERY Applying 0 V to T.C.V

Lever Pump Boost Pressure Fuel Delivery Max. Spread Remarks

Speed in Delivery

Position (rpm)

(kPa) (mmHg) (mm3/st) (cc/200st) (mm3) (cc)

Full 1000 80.0 600 60.1 ± 0.5 = A 12.0 ± 0.1 = A 4.0 0.8 By full load setting screw

2350 80.0 600 31.9 ± 1.5 6.4 ± 0.3 — — By max. speed setting screw

2200 80.0 600 58.2 ± 8.0 11.6 ± 1.6 — —

Less than Less than

2600 80.0 600 3.0 0.6 — —

+ 20.0 +4.0

100 0 0 84.0 – 15.0

16.8 – 3.0 12.0 2.4 By governor sleeve plug

Less than Less than

250 0 0 50.0 10.0 — — End of fuel quantity increase

1500 80.0 600 68.7 ± 1.5 13.7 ± 0.3 — —

Less than Less than

1700 80.0 600 (B + 2.0) (B + 0.4) — —

1800 80.0 600 69.6 ± 1.5 = B 13.9 ± 0.3 = B 4.0 0.8

Less than Less than

1900 80.0 600 (B - 1.0) (B - 0.2) — —

2000 80.0 600 64.0 ± 10.0 12.8 ± 2.0 — —

2100 80.0 600 62.0 ± 10.0 12.4 ± 2.0 — —

Less than Less than

1000 100.0 750 (A + 1.0) (A + 0.2) — —

6. ADJUSTMENT OF BOOST COMPENSATOR Applying 0 V to T.C.V

Lever Pump Boost Pressure Fuel Delivery Max. Spread Remarks

Speed in Delivery

Position (rpm)

(kPa) (mmHg) (mm3/st) (cc/200st) (mm3) (cc)

Full 1000 80.0 600 60.1 ± 0.5 12.0 ± 0.1 4.0 0.8 By full load setting screw

500 0 0 44.3 ± 0.5 8.9 ± 0.1 — —

500 22.7 170 46.9 ± 0.75 9.4 ± 0.15 — —

500 29.3 220 50.6 ± 1.0 10.1 ± 0.2 — —

500 80.0 600 56.5 ± 2.0 11.3 ± 0.4 — —

8. SETTING OF LOAD SENSING TIMER Applying 0 V to T.C.V

Lever Position Pump Speed Boost Pressure Fuel Delivery Remarks

(rpm) (kPa) (mmHg) (mm3/st) (cc/200st)

Start of Load Sensing 1800 80.0 600 (B – 9.5) ± 1.5 (B – 1.9) ± 0.3 By governor shaft

End of Pressure Drop 1800 80.0 600 45.3 ± 1.5 9.1 ± 0.3 Check

Repeat Advance Angle — — — — —

Check Points 1. Piston Travel at End of Pressure Drop : 5.41 ± 0.40 mm (Pump speed 1800rpm)

2. Piston Travel at End of Pressure Drop : 5.41 ± 0.20 mm (Pump speed 1800rpm)

3. Dimension of Governor Shaft : L = 1.15 ± 0.85 mm

*1 : The point where internal pump pressure begins to rise.

196000-5170,1,2

9. SETTING OF ADJUSTING LEVER AT LOW SPEED Applying 0 V to T.C.V

Lever Pump Boost Pressure Fuel Delivery Max. Spread Remarks

Position Speed in Delivery

(deg) (rpm) (kPa) 3

(mm /st) (cc/500st) (mm3) (cc)

– 34.5 ± 5° 375 0 9.5 ± 1.0 4.8 ± 0.5 2.5 1.3 Lever setting

(Idle position)

Less than Less than

700 0 0.5 0.3 — —

10. SETTING OF ADJUSTING LEVER AT PARTIAL RANGE — : Not Applicable

Pump Speed Boost Pressure Fuel Delivery Remarks

3

(rpm) (kPa) (mmHg) (mm /st) (cc/500st)

— — — — — —

11. CHARACTERISTIC OF A.C.S.D. — : Not Applicable

Lever Pump Speed Boost Pressure Measuring Value Remarks

Position (rpm) (kPa) (mmHg)

— — — — — —

Fuel temperature : 39 - 41°C (102 - 106°F)

12. ADJUSTMENT OF T.C.V. Applying 6 ± 0.1 V to T.C.V.

Lever Position Pump Speed Boost Pressure Piston Travel Remarks

(rpm) (kPa) (mmHg) (mm)

Full 1000 80 600 4.45 ± 0.40

2000 80 600 6.90 ± 0.40 Max. advance angle

13. SETTING OF DIAPHRAGM FOR HEATER & POWER STEERING — : Not Applicable

Pump Speed Vacuum Pressure Fuel Delivery Remarks

3

(rpm) (kPa) (mmHg) (mm /st) (cc/500st)

— — — — — —

14. ADJUSTMENT OF POWER CONTROL — : Not Applicable

Lever Pump Speed Boost Pressure Fuel Delivery Remarks

Position

(rpm) (kPa) (mmHg) 3

(mm /st) (cc/200st)

— — — — — — —

196000-5170,1,2

15. ADJUSTMENT OF THROTTLE POSITION SENSOR — : Not Applicable

Lever Position Pump Speed Boost Pressure Fuel Delivery Sensor Remarks

Output

(rpm) (kPa) (mmHg) (mm3/st) (cc/500st) Voltage (V)

— — — — — — — —

16. FINAL CHECK AFTER ADJUSTMENT

1. Lever position at idle is – 34.5 ± 5° and 1.5 ± 5° at full.

2. After adgustment has been completed, delivery quantity must be 0mm3/st (0cc/200st) when

voltage at fuel cut solenoid is reduced to zero.

(Pump Speed Np = 100rpm at full lever position, Applying 6 ± 0.1 V to T.C.V.)

You might also like

- Parts Catalog - Option DetailDocument3 pagesParts Catalog - Option DetailEdinson Ariel Chavarro Quintero100% (2)

- HA285Document48 pagesHA285Edinson Ariel Chavarro Quintero100% (10)

- Participate in Workplace CommunicationDocument8 pagesParticipate in Workplace CommunicationArman Berina CortezNo ratings yet

- EI5501Document4 pagesEI5501aaa bbb100% (1)

- Service Manual: Pub. No. EE14E-11130Document39 pagesService Manual: Pub. No. EE14E-11130Marcelo Diesel81% (16)

- 094000-048# DespieceDocument4 pages094000-048# DespieceEdinson Ariel Chavarro QuinteroNo ratings yet

- Pump Test Specifications: InjectionDocument3 pagesPump Test Specifications: InjectionJaqueline S. S. Maicá100% (1)

- 196000-4270 - Toyota Tabela Teste PDFDocument4 pages196000-4270 - Toyota Tabela Teste PDFJaqueline S. S. Maicá100% (1)

- 3031 PDFDocument4 pages3031 PDFMihai-Eugen Popa100% (1)

- 196000-3710 TicoDocument9 pages196000-3710 TicoEdinson Ariel Chavarro Quintero100% (1)

- S5000-1-Test-Data Ui Up Bosch, DelphiDocument29 pagesS5000-1-Test-Data Ui Up Bosch, DelphiEdinson Ariel Chavarro Quintero100% (1)

- Simens Pump ibjectorDOC-20170202-WA0011Document121 pagesSimens Pump ibjectorDOC-20170202-WA0011Edinson Ariel Chavarro Quintero100% (5)

- Restricted Earth Fault (REF) ProtectionDocument8 pagesRestricted Earth Fault (REF) ProtectionNaveen Amarasinghe100% (1)

- 196000-6060 Injection Pump Test SpecificationsDocument4 pages196000-6060 Injection Pump Test SpecificationsMiguel RojasNo ratings yet

- Injection Pump Test Specifications 191000-490#Document3 pagesInjection Pump Test Specifications 191000-490#Miguel Rojas100% (1)

- Inj - P Ump Cal Ibration DataDocument3 pagesInj - P Ump Cal Ibration DataСергей ВладимировичNo ratings yet

- 4720Document3 pages4720Junior IungNo ratings yet

- 7030Document3 pages7030pruebaNo ratings yet

- Injection Volume Adjustment Test Conditions: 6c-59-1.tifDocument33 pagesInjection Volume Adjustment Test Conditions: 6c-59-1.tifElvis Eliud HernándezNo ratings yet

- Injection Pump Test Specifications 093000-677#Document3 pagesInjection Pump Test Specifications 093000-677#Pedro Abellan100% (1)

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsMartin Miguel Gomez SalviNo ratings yet

- Denso Bomba 092000-3690Document3 pagesDenso Bomba 092000-3690Superlativo Igv100% (1)

- 7540Document10 pages7540pruebaNo ratings yet

- Injection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxDocument3 pagesInjection Pump Testspecifications 0 9 3 0 0 0 - 5 5 5 #: ApproxBaytolga100% (3)

- Injection Pump Calibration Data: Assy No.: 101608-9582Document3 pagesInjection Pump Calibration Data: Assy No.: 101608-9582Elson DorigonNo ratings yet

- Injection Pump Test S Pecifications 196000-417#Document4 pagesInjection Pump Test S Pecifications 196000-417#Juan Gabriel Ochoa100% (1)

- EB8870Document2 pagesEB8870Miguel RojasNo ratings yet

- 606 9291Document2 pages606 9291Сергей ВладимировичNo ratings yet

- 101491-9530 Mazda PDFDocument10 pages101491-9530 Mazda PDFBaytolgaNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument6 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- 740 4010Document6 pages740 4010Miguel ChaconNo ratings yet

- DATODocument1 pageDATOMiguel RojasNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration Datamurillo_rodriguez8382No ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration Datamurillo_rodriguez8382No ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- Injection Pump Test Specifications: CPS21 AVM2PC-20hpDocument2 pagesInjection Pump Test Specifications: CPS21 AVM2PC-20hpDilakartikaNo ratings yet

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsBaytolgaNo ratings yet

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelKevin Ttito100% (1)

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- 9322a050 - Erkunt Servet 80 TDocument6 pages9322a050 - Erkunt Servet 80 TBaytolgaNo ratings yet

- Fuel Injection Equipment For M&M 245 DI Engine: SSE-I-MML/138 12.2003Document2 pagesFuel Injection Equipment For M&M 245 DI Engine: SSE-I-MML/138 12.2003Ravikant Saini100% (1)

- 093000-1613 Hi̇no PDFDocument2 pages093000-1613 Hi̇no PDFBaytolgaNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument2 pagesDpico: Inj. Pump Calibration DataMiguel RojasNo ratings yet

- 606 9460Document2 pages606 9460Alex PakitoNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document6 pagesS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)баха бахинскийNo ratings yet

- Test SheetDocument3 pagesTest SheetNemo NeoNo ratings yet

- Temp 753Document2 pagesTemp 753Neelakandan Krishnan100% (1)

- Injection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelDocument2 pagesInjection Pump Test Specifications: Manu-Facturer Engine Type Vehicle ModelJunior IungNo ratings yet

- 9412Document3 pages9412Mihai-Eugen Popa100% (1)

- 02EN1630Document2 pages02EN1630Edinson Ariel Chavarro QuinteroNo ratings yet

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- Plano de Teste Zexel 104136-3010Document1 pagePlano de Teste Zexel 104136-3010Elson DorigonNo ratings yet

- Injection Pump Calibration Data: 1. Test ConditionsDocument3 pagesInjection Pump Calibration Data: 1. Test ConditionsElson DorigonNo ratings yet

- EE4760Document2 pagesEE4760OFFICE DANACNo ratings yet

- 104740-4734 - Test PlanDocument2 pages104740-4734 - Test PlanMihai-Eugen Popa100% (1)

- Injection Pump Test SpecificationsDocument4 pagesInjection Pump Test SpecificationsJunior IungNo ratings yet

- TSS-TS-TATA 2.95 D: For Field Service OnlyDocument2 pagesTSS-TS-TATA 2.95 D: For Field Service OnlyBest Auto TechNo ratings yet

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- STS-TS-TCL 5.88 d2: For Field Service OnlyDocument2 pagesSTS-TS-TCL 5.88 d2: For Field Service OnlyFaizul SiddiquiNo ratings yet

- Injection Pump Test SpecificationsDocument2 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Inj. Pump Calibration Data: 1. Test ConditionsDocument1 pageInj. Pump Calibration Data: 1. Test ConditionsMiguel RojasNo ratings yet

- 093400-5350 Mitsubishi PDFDocument2 pages093400-5350 Mitsubishi PDFBaytolgaNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- Test Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorDocument2 pagesTest Specifications: For Field Service Only Reference No (B) Adjustment of Pump and GovernorJam B100% (3)

- Dpico: Inj. Pump Calibration DataDocument3 pagesDpico: Inj. Pump Calibration DataMiguel Rojas100% (1)

- (Oto-Hui - Com) Edc Hino s05Document2 pages(Oto-Hui - Com) Edc Hino s05ahmed_eng_1500No ratings yet

- 196000-175# 096000-175#Document4 pages196000-175# 096000-175#Junior Iung100% (1)

- Ei4060 1Document4 pagesEi4060 1Miguel RojasNo ratings yet

- 096000-352# Pump Test Specification (Plano de Teste Denso)Document4 pages096000-352# Pump Test Specification (Plano de Teste Denso)Junior IungNo ratings yet

- Core Codes and Acceptance Guidelines: May 2021 May 2021Document34 pagesCore Codes and Acceptance Guidelines: May 2021 May 2021Edinson Ariel Chavarro Quintero100% (2)

- TOYOTA I-ART Common Rail Injector G3Pi 23670-30270Document1 pageTOYOTA I-ART Common Rail Injector G3Pi 23670-30270Edinson Ariel Chavarro QuinteroNo ratings yet

- Ki T S & Component S Ki T S & Component SDocument52 pagesKi T S & Component S Ki T S & Component SEdinson Ariel Chavarro QuinteroNo ratings yet

- 196000-5172 OthersDocument1 page196000-5172 OthersEdinson Ariel Chavarro QuinteroNo ratings yet

- 196000-0990 DaihatsuDocument13 pages196000-0990 DaihatsuEdinson Ariel Chavarro QuinteroNo ratings yet

- 1960000-5172 2Document5 pages1960000-5172 2Edinson Ariel Chavarro QuinteroNo ratings yet

- 196000-5172 OthersDocument1 page196000-5172 OthersEdinson Ariel Chavarro QuinteroNo ratings yet

- 1960000-5272 2Document5 pages1960000-5272 2Edinson Ariel Chavarro QuinteroNo ratings yet

- (Dieselyturbos2) - (26-09-2018) : Parts ListDocument6 pages(Dieselyturbos2) - (26-09-2018) : Parts ListEdinson Ariel Chavarro QuinteroNo ratings yet

- DTech Catalog - 2019 PDFDocument82 pagesDTech Catalog - 2019 PDFEdinson Ariel Chavarro Quintero100% (1)

- Ee6790 PDFDocument3 pagesEe6790 PDFEdinson Ariel Chavarro Quintero100% (1)

- Injection Pump Test SpecificationsDocument3 pagesInjection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Ei4060 1Document4 pagesEi4060 1Miguel RojasNo ratings yet

- Parts VDO 2008Document30 pagesParts VDO 2008Edinson Ariel Chavarro QuinteroNo ratings yet

- Dpico: Inj - PumpcalibrationdataDocument2 pagesDpico: Inj - PumpcalibrationdataEdinson Ariel Chavarro Quintero100% (3)

- 0560Document4 pages0560Edinson Ariel Chavarro QuinteroNo ratings yet

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsEdinson Ariel Chavarro Quintero100% (2)

- 196000-104# List PartDocument9 pages196000-104# List PartEdinson Ariel Chavarro QuinteroNo ratings yet

- 092000-5600 Injection Pump Test SpecificationsDocument3 pages092000-5600 Injection Pump Test SpecificationsEdinson Ariel Chavarro QuinteroNo ratings yet

- Injection Pump Test Specifications 092000-512#Document3 pagesInjection Pump Test Specifications 092000-512#Edinson Ariel Chavarro Quintero100% (2)

- DPA - 240 User'S Manual: Diesel Parts of AmericaDocument54 pagesDPA - 240 User'S Manual: Diesel Parts of AmericaEdinson Ariel Chavarro QuinteroNo ratings yet

- Lista de Precio-COMAC 2012Document41 pagesLista de Precio-COMAC 2012innopetrol0% (1)

- Integrative Programming and Technologies: Chapter TwoDocument19 pagesIntegrative Programming and Technologies: Chapter TwoDagim Fekadu AmenuNo ratings yet

- Technology That Transforms.: High-Performance Engines For Mining EquipmentDocument8 pagesTechnology That Transforms.: High-Performance Engines For Mining EquipmentJOSUE FERNANDO FERNANDEZNo ratings yet

- Saa7708h PDFDocument60 pagesSaa7708h PDFPamela Ramos SánchezNo ratings yet

- 8TH SEM PRO Ack, CertificateDocument3 pages8TH SEM PRO Ack, Certificateprinceofnation_21No ratings yet

- CPDD 17 1Document2 pagesCPDD 17 1Arthur MerilloNo ratings yet

- Dissertation Ideas Computer SecurityDocument5 pagesDissertation Ideas Computer SecurityCollegePaperWritingServiceReviewsColumbia100% (1)

- 2DOF Ball Balancer Product InformationDocument2 pages2DOF Ball Balancer Product InformationSaqib KhattakNo ratings yet

- It Companies Success and FailuresDocument5 pagesIt Companies Success and Failuresamber baigNo ratings yet

- Cos2626 2014 TL 102 2 BDocument7 pagesCos2626 2014 TL 102 2 BbibiveeNo ratings yet

- 101 Cdma BasicsDocument34 pages101 Cdma BasicsAbdul KhaderNo ratings yet

- Data Structure - Lesson 1Document4 pagesData Structure - Lesson 1Lady Marj RosarioNo ratings yet

- Sow CSP650 Oct 2023 - Feb 2024Document3 pagesSow CSP650 Oct 2023 - Feb 20242022925869No ratings yet

- Howto Configure Admin Console OIDC AzureADDocument17 pagesHowto Configure Admin Console OIDC AzureADgordacoNo ratings yet

- FM - Get - SNP - QtyDocument3 pagesFM - Get - SNP - QtymunafNo ratings yet

- E CashDocument46 pagesE CashJosephine Jebet RonohNo ratings yet

- Project Report On Shopping ApplicationDocument118 pagesProject Report On Shopping ApplicationpassionatepriyaNo ratings yet

- RTS Lecture 4 1644141180167Document21 pagesRTS Lecture 4 1644141180167Gaurav BagdeNo ratings yet

- Vishwas Haimraj (Ali Gohar & Company)Document3 pagesVishwas Haimraj (Ali Gohar & Company)VishwasNo ratings yet

- Model Set 2Document10 pagesModel Set 2AmrithaNo ratings yet

- A Group Chat Application Using Java: On Mini Project WorkDocument33 pagesA Group Chat Application Using Java: On Mini Project WorkAmar GolleNo ratings yet

- KESZ SerbiaDocument14 pagesKESZ SerbiamesipolyakNo ratings yet

- Traffic Alert Collision Avoidance System Kuchar Ja 11284Document20 pagesTraffic Alert Collision Avoidance System Kuchar Ja 11284Manchu RaiNo ratings yet

- Hitachi Unified Compute Platform RS For VMware Interoperability Matrix - 080320-BDocument3 pagesHitachi Unified Compute Platform RS For VMware Interoperability Matrix - 080320-Bstimyl_471631114No ratings yet

- Imo Safety of NavigationDocument17 pagesImo Safety of NavigationlusifadilahNo ratings yet

- Mitel 5000 CP v5.0 System Administration Diagnostics Guide PDFDocument46 pagesMitel 5000 CP v5.0 System Administration Diagnostics Guide PDFRichNo ratings yet

- Lesson Outline JBDocument3 pagesLesson Outline JBapi-241811643No ratings yet

- Practical Date SheetDocument73 pagesPractical Date SheetYashwant PatelNo ratings yet