Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

16 viewsAnnexure-I Specifications For Austenitic Stainless Steel 316L Plates

Annexure-I Specifications For Austenitic Stainless Steel 316L Plates

Uploaded by

Sharat ChandraThe document specifies the requirements for 11 types of austenitic stainless steel 316L plates in various thicknesses, widths, lengths, and quantities. The plates must conform to ASTM standards and be solution annealed to a minimum temperature of 1900°F and quenched. Certificates verifying heat treatment, chemical composition, impact strength, intergranular corrosion resistance, and grain size are required. Pre-dispatch inspection by the purchaser is also specified. Materials meeting all specifications will be accepted.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Astm A352Document5 pagesAstm A352depeche1modeNo ratings yet

- Specification of F1267Document7 pagesSpecification of F1267pLangpLingpLungNo ratings yet

- 1977Document11 pages1977Vineet Krishan67% (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- ASTM Material SpecificationsDocument6 pagesASTM Material SpecificationsLim SenglinNo ratings yet

- Astm A182Document6 pagesAstm A182Rayan AlfredNo ratings yet

- Metal Specifications PDFDocument4 pagesMetal Specifications PDFJaeup YouNo ratings yet

- Seamless and Welded Ferritic/Austenitic Stainless Steel PipeDocument6 pagesSeamless and Welded Ferritic/Austenitic Stainless Steel PipeJosé Ramón GutierrezNo ratings yet

- Astm A356Document6 pagesAstm A356Srinivasan KrishnamoorthyNo ratings yet

- Astm A485Document4 pagesAstm A485Vikash YadavNo ratings yet

- Astm A653-06a - SGCC StandardDocument13 pagesAstm A653-06a - SGCC Standardcremsky100% (1)

- 2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsDocument9 pages2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsKapa SandeepNo ratings yet

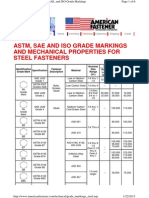

- American Fastener - ASTM, SAE, and ISO Grade Markings Bolt SpecificationDocument8 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings Bolt Specificationamir_hossein858No ratings yet

- Astm A264 (1999)Document8 pagesAstm A264 (1999)Vo Trong ThaiNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Astm A265 (1999)Document5 pagesAstm A265 (1999)P SHANKAR BABUNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99No ratings yet

- Steel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Document2 pagesSteel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Akhi IsMailNo ratings yet

- A 270 - 03 Qti3mc1sruqDocument8 pagesA 270 - 03 Qti3mc1sruqrgimiranda.engNo ratings yet

- A 814 - A 814m - 01 Qtgxnc9bode0ts1sruqDocument7 pagesA 814 - A 814m - 01 Qtgxnc9bode0ts1sruqsachinguptachdNo ratings yet

- 1 SS PP 042Document16 pages1 SS PP 042SURAJ PRSADNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersNabil RamehNo ratings yet

- ASTM A 681-08 Standard Specification For Tool Steels AlloyDocument14 pagesASTM A 681-08 Standard Specification For Tool Steels AlloyTeodoroNo ratings yet

- Materials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFDocument50 pagesMaterials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFGOUAREF SAMIRNo ratings yet

- Astm A269Document5 pagesAstm A269Jose M-hNo ratings yet

- Steel Castings, Austenitic Manganese: Standard Specification ForDocument2 pagesSteel Castings, Austenitic Manganese: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- ASTM A333 Grade 6 SpecificationDocument9 pagesASTM A333 Grade 6 SpecificationmaldonadohansNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- Stainless Chromium-Nickel Steel-Clad Plate, Sheet, and StripDocument8 pagesStainless Chromium-Nickel Steel-Clad Plate, Sheet, and StripJosé Ramón GutierrezNo ratings yet

- Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) For General ServiceDocument4 pagesSeamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) For General ServiceAlejandro GonzálezNo ratings yet

- Asme Section II A Sa-264Document8 pagesAsme Section II A Sa-264Anonymous GhPzn1xNo ratings yet

- Technical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsDocument10 pagesTechnical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsMunishNo ratings yet

- Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessDocument6 pagesSteel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessJosé Ramón GutierrezNo ratings yet

- Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0Document44 pagesPiping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0josphinvalarNo ratings yet

- A 1008 - A 1008M - 01 Qtewmdgtmdfb PDFDocument7 pagesA 1008 - A 1008M - 01 Qtewmdgtmdfb PDFTiến Lượng NguyễnNo ratings yet

- Basic Rules For Stainless Steel SpecificationDocument9 pagesBasic Rules For Stainless Steel SpecificationmutemuNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument4 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsRay CoelloNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsmameeranNo ratings yet

- Astm A514 1977Document6 pagesAstm A514 1977Elumalai Srinivasan100% (1)

- ASTM A 403/A 403M - 96: Dimensions and TolerancesDocument4 pagesASTM A 403/A 403M - 96: Dimensions and Tolerancessumit_b123No ratings yet

- A 632 - 02 Qtyzmi0wmkeDocument4 pagesA 632 - 02 Qtyzmi0wmkeLUISALBERTO06011985No ratings yet

- Valve Materials - Suitability, Performance, Applications & Cross ReferencesDocument16 pagesValve Materials - Suitability, Performance, Applications & Cross Referencesmm tradingviewNo ratings yet

- ASTM A420-Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceDocument15 pagesASTM A420-Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceN FantinNo ratings yet

- A 108 - 99 Qtewoc1sruq - PDFDocument10 pagesA 108 - 99 Qtewoc1sruq - PDFjorgesalgNo ratings yet

- Nickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForDocument5 pagesNickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Final SS Specification 18 12 2020Document10 pagesFinal SS Specification 18 12 2020Amit NG AmitNo ratings yet

- Care & Cleaning - Stainless Steel PDFDocument7 pagesCare & Cleaning - Stainless Steel PDFpsp710No ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNo ratings yet

- Practical Metal Plate Work - With Numerous Engravings and DiagramsFrom EverandPractical Metal Plate Work - With Numerous Engravings and DiagramsRating: 5 out of 5 stars5/5 (1)

- High Temperature Corrosion: Fundamentals and EngineeringFrom EverandHigh Temperature Corrosion: Fundamentals and EngineeringNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNo ratings yet

- Pressure Surge Dependence On Valve Operations in A Pipeline Loading SystemDocument10 pagesPressure Surge Dependence On Valve Operations in A Pipeline Loading SystemSharat ChandraNo ratings yet

- Finite Element Analysis On The Temperature - DependDocument11 pagesFinite Element Analysis On The Temperature - DependSharat ChandraNo ratings yet

- Design of Quick Connect-Disconnect Hydraulic CouplingDocument13 pagesDesign of Quick Connect-Disconnect Hydraulic CouplingSharat ChandraNo ratings yet

- Clinching For Sheet MaterialsDocument26 pagesClinching For Sheet MaterialsSharat ChandraNo ratings yet

- Buehler 2019 Hardness Testing Catalog CompressedDocument24 pagesBuehler 2019 Hardness Testing Catalog CompressedSharat Chandra100% (1)

- Bridge Alert Management PDFDocument18 pagesBridge Alert Management PDFbhabhasunilNo ratings yet

- 21 Problems For CB NewDocument31 pages21 Problems For CB NewNguyễn Thảo MyNo ratings yet

- Tong Hop Bai Tap So Sanh Hon Va So Sanh Nhat Co Dap AnDocument14 pagesTong Hop Bai Tap So Sanh Hon Va So Sanh Nhat Co Dap AnGia HuyNo ratings yet

- Contin Educ Anaesth Crit Care Pain-2008-Gauntlett-121-4Document4 pagesContin Educ Anaesth Crit Care Pain-2008-Gauntlett-121-4Wahyu HidayatiNo ratings yet

- Multiple MyelomaDocument8 pagesMultiple MyelomaFelipeNo ratings yet

- A Bad Workman Always Blames His ToolsDocument6 pagesA Bad Workman Always Blames His ToolsTimothy BrownNo ratings yet

- Some, No, Any, EveryDocument2 pagesSome, No, Any, Everyvivadavid100% (1)

- FNM104 Prelim ReviewerDocument8 pagesFNM104 Prelim ReviewerjelciumNo ratings yet

- PMEC Flash CardsDocument17 pagesPMEC Flash CardsHariyantoNo ratings yet

- Chapter 7 - Non Verbal CommunicationDocument7 pagesChapter 7 - Non Verbal CommunicationCarolyn NacesNo ratings yet

- BGP (Border Gateway Protocol) - Port 179: Gateway Protocols (IGP's)Document32 pagesBGP (Border Gateway Protocol) - Port 179: Gateway Protocols (IGP's)Nitesh MulukNo ratings yet

- Assignment-9 Noc18 Me61 23 PDFDocument3 pagesAssignment-9 Noc18 Me61 23 PDFvicky tNo ratings yet

- FAKRO Technical Specification DRF DU6 PDFDocument2 pagesFAKRO Technical Specification DRF DU6 PDFthomasNo ratings yet

- Jeab 1 PsDocument20 pagesJeab 1 PsDharmveer KumarNo ratings yet

- CCNA1 Mod 6Document28 pagesCCNA1 Mod 6KlokanNo ratings yet

- Lamellar TearingDocument6 pagesLamellar TearingAndreaNo ratings yet

- People vs. PradesDocument2 pagesPeople vs. PradesMayr TeruelNo ratings yet

- (1142) Grade XI Admissions 2016-17Document7 pages(1142) Grade XI Admissions 2016-17Naveen ShankarNo ratings yet

- Data Warehouse Slide3Document43 pagesData Warehouse Slide3Kai EnezhuNo ratings yet

- NOC Construction-Aero Helidromes PDFDocument14 pagesNOC Construction-Aero Helidromes PDFAnonymous AkGKYLJNo ratings yet

- Environmental ScienceDocument2 pagesEnvironmental Sciencegillianbernice.alaNo ratings yet

- The Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronDocument23 pagesThe Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronNanasaheb PatilNo ratings yet

- General Definition of Sag and Tension in Electrical Transmission LinesDocument11 pagesGeneral Definition of Sag and Tension in Electrical Transmission Linesdskymaximus67% (3)

- TDS - Masterseal 420 HBDocument2 pagesTDS - Masterseal 420 HBVenkata RaoNo ratings yet

- Teaching As A ProfessionDocument5 pagesTeaching As A Professionipinloju temitopeNo ratings yet

- SyntaxDocument9 pagesSyntaxVeronicaTurtusanNo ratings yet

- Weekly Home Learning Plan Quarter 3 Week 1 Tle Agri-6 MARCH 1-5, 2021Document1 pageWeekly Home Learning Plan Quarter 3 Week 1 Tle Agri-6 MARCH 1-5, 2021Mariano CañadaNo ratings yet

- Types of VolcanoesDocument10 pagesTypes of VolcanoesRobert MestiolaNo ratings yet

- Early DwellingsDocument33 pagesEarly DwellingsVasudha UNo ratings yet

- Increasing and Decreasing Functions, Concavity and Inflection PointsDocument17 pagesIncreasing and Decreasing Functions, Concavity and Inflection PointsAnonymous Gd16J3n7No ratings yet

Annexure-I Specifications For Austenitic Stainless Steel 316L Plates

Annexure-I Specifications For Austenitic Stainless Steel 316L Plates

Uploaded by

Sharat Chandra0 ratings0% found this document useful (0 votes)

16 views1 pageThe document specifies the requirements for 11 types of austenitic stainless steel 316L plates in various thicknesses, widths, lengths, and quantities. The plates must conform to ASTM standards and be solution annealed to a minimum temperature of 1900°F and quenched. Certificates verifying heat treatment, chemical composition, impact strength, intergranular corrosion resistance, and grain size are required. Pre-dispatch inspection by the purchaser is also specified. Materials meeting all specifications will be accepted.

Original Description:

Spec

Original Title

838spec

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document specifies the requirements for 11 types of austenitic stainless steel 316L plates in various thicknesses, widths, lengths, and quantities. The plates must conform to ASTM standards and be solution annealed to a minimum temperature of 1900°F and quenched. Certificates verifying heat treatment, chemical composition, impact strength, intergranular corrosion resistance, and grain size are required. Pre-dispatch inspection by the purchaser is also specified. Materials meeting all specifications will be accepted.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

16 views1 pageAnnexure-I Specifications For Austenitic Stainless Steel 316L Plates

Annexure-I Specifications For Austenitic Stainless Steel 316L Plates

Uploaded by

Sharat ChandraThe document specifies the requirements for 11 types of austenitic stainless steel 316L plates in various thicknesses, widths, lengths, and quantities. The plates must conform to ASTM standards and be solution annealed to a minimum temperature of 1900°F and quenched. Certificates verifying heat treatment, chemical composition, impact strength, intergranular corrosion resistance, and grain size are required. Pre-dispatch inspection by the purchaser is also specified. Materials meeting all specifications will be accepted.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Annexure-I

Specifications for Austenitic Stainless Steel 316L Plates

Austenitic Stainless steel plates, conforming to ASTM standard, of various sizes &

quantity are required as per table given below:

List of Solution Annealed SS 316L Materials

THK WIDTH LENGTH

SR.NO. DESCRIPTION QTY. Material

(mm) (mm) (mm)

1 PLATE 6.25 1250 5000 3 SS 316L

2 PLATE 8 1250 5000 2 SS 316L

3 PLATE 10 1250 5000 2 SS 316L

4 PLATE 12 1250 5000 2 SS 316L

5 PLATE 16 1250 2500 2 SS 316L

6 PLATE 20 1250 2500 2 SS 316L

7 PLATE 25 1250 2500 1 SS 316L

8 PLATE 30 1250 1250 1 SS 316L

9 PLATE 40 1250 1250 1 SS 316L

10 PLATE 50 1250 1250 1 SS 316L

11 PLATE 65 1250 1250 1 SS 316L

Essential supplementary requirements as given below:

Austenitic stainless steel Plates should conform to ASTM A240 and should be in

solution annealed condition with Cold rolled Solution annealed cleaned and polished

finish both side (No. 4 Finish).

Heat treatment: All plates shall be delivered in heat treated condition.

Solution annealing: Heating the material to a minimum temperature

of 1900 °F (1040 °C) and quenching in water or rapidly cooling by

other means. Hardness test certificate to be provided.

Material certification: Material certificates to be provided for all the material

traceable to Heat No. /lot No. of the supply & source of supply.

Impact Strength: Material should be tested for impact strength as per ASTM A370 at

-196oC. Each of the three specimens tested shall show a lateral expansion opposite

the notch of not less than 0.015 in [0.38 mm]. Transverse specimens i.e. specimen

having long axis transverse to the final rolling direction should be taken. Absorbed

energy values should also be recorded.

IGC test (Inter-granular corrosion test) shall be conducted in accordance with the

ASTM A262 Practice E on samples drawn on each lot of plates.

Grain size should be ASTM no. 5 or finer as per ASTM E112. Test certificate should be

provided for same.

Pre-dispatch inspection will be done by the purchaser’s representative, prior to

issuing shipping clearance. Samples are to be cut in presence of the purchaser’s

representative for all the test. All the tests and dimensional inspection shall be

witnessed by the purchaser’s representative.

Acceptance / Rejection Criteria: Material found to satisfy the above all requirements

shall be accepted and shipping clearance for the same will be issued after marking/

stamping of the accepted lot.

All testing charges to be included in material cost.

************

You might also like

- Astm A352Document5 pagesAstm A352depeche1modeNo ratings yet

- Specification of F1267Document7 pagesSpecification of F1267pLangpLingpLungNo ratings yet

- 1977Document11 pages1977Vineet Krishan67% (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- ASTM Material SpecificationsDocument6 pagesASTM Material SpecificationsLim SenglinNo ratings yet

- Astm A182Document6 pagesAstm A182Rayan AlfredNo ratings yet

- Metal Specifications PDFDocument4 pagesMetal Specifications PDFJaeup YouNo ratings yet

- Seamless and Welded Ferritic/Austenitic Stainless Steel PipeDocument6 pagesSeamless and Welded Ferritic/Austenitic Stainless Steel PipeJosé Ramón GutierrezNo ratings yet

- Astm A356Document6 pagesAstm A356Srinivasan KrishnamoorthyNo ratings yet

- Astm A485Document4 pagesAstm A485Vikash YadavNo ratings yet

- Astm A653-06a - SGCC StandardDocument13 pagesAstm A653-06a - SGCC Standardcremsky100% (1)

- 2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsDocument9 pages2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsKapa SandeepNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings Bolt SpecificationDocument8 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings Bolt Specificationamir_hossein858No ratings yet

- Astm A264 (1999)Document8 pagesAstm A264 (1999)Vo Trong ThaiNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Astm A265 (1999)Document5 pagesAstm A265 (1999)P SHANKAR BABUNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenershoannhuNo ratings yet

- Astm Material Summary For BoltsDocument6 pagesAstm Material Summary For Boltsangelufc99No ratings yet

- Steel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Document2 pagesSteel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Akhi IsMailNo ratings yet

- A 270 - 03 Qti3mc1sruqDocument8 pagesA 270 - 03 Qti3mc1sruqrgimiranda.engNo ratings yet

- A 814 - A 814m - 01 Qtgxnc9bode0ts1sruqDocument7 pagesA 814 - A 814m - 01 Qtgxnc9bode0ts1sruqsachinguptachdNo ratings yet

- 1 SS PP 042Document16 pages1 SS PP 042SURAJ PRSADNo ratings yet

- Astm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersDocument6 pagesAstm, Sae and Iso Grade Markings and Mechanical Properties For Steel FastenersNabil RamehNo ratings yet

- ASTM A 681-08 Standard Specification For Tool Steels AlloyDocument14 pagesASTM A 681-08 Standard Specification For Tool Steels AlloyTeodoroNo ratings yet

- Materials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFDocument50 pagesMaterials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFGOUAREF SAMIRNo ratings yet

- Astm A269Document5 pagesAstm A269Jose M-hNo ratings yet

- Steel Castings, Austenitic Manganese: Standard Specification ForDocument2 pagesSteel Castings, Austenitic Manganese: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- ASTM A333 Grade 6 SpecificationDocument9 pagesASTM A333 Grade 6 SpecificationmaldonadohansNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- Stainless Chromium-Nickel Steel-Clad Plate, Sheet, and StripDocument8 pagesStainless Chromium-Nickel Steel-Clad Plate, Sheet, and StripJosé Ramón GutierrezNo ratings yet

- Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) For General ServiceDocument4 pagesSeamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) For General ServiceAlejandro GonzálezNo ratings yet

- Asme Section II A Sa-264Document8 pagesAsme Section II A Sa-264Anonymous GhPzn1xNo ratings yet

- Technical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsDocument10 pagesTechnical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsMunishNo ratings yet

- Steel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessDocument6 pagesSteel Sheet, 55 % Aluminum-Zinc Alloy-Coated by The Hot-Dip ProcessJosé Ramón GutierrezNo ratings yet

- Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0Document44 pagesPiping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0josphinvalarNo ratings yet

- A 1008 - A 1008M - 01 Qtewmdgtmdfb PDFDocument7 pagesA 1008 - A 1008M - 01 Qtewmdgtmdfb PDFTiến Lượng NguyễnNo ratings yet

- Basic Rules For Stainless Steel SpecificationDocument9 pagesBasic Rules For Stainless Steel SpecificationmutemuNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument4 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsRay CoelloNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsmameeranNo ratings yet

- Astm A514 1977Document6 pagesAstm A514 1977Elumalai Srinivasan100% (1)

- ASTM A 403/A 403M - 96: Dimensions and TolerancesDocument4 pagesASTM A 403/A 403M - 96: Dimensions and Tolerancessumit_b123No ratings yet

- A 632 - 02 Qtyzmi0wmkeDocument4 pagesA 632 - 02 Qtyzmi0wmkeLUISALBERTO06011985No ratings yet

- Valve Materials - Suitability, Performance, Applications & Cross ReferencesDocument16 pagesValve Materials - Suitability, Performance, Applications & Cross Referencesmm tradingviewNo ratings yet

- ASTM A420-Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceDocument15 pagesASTM A420-Standard Specification For Piping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceN FantinNo ratings yet

- A 108 - 99 Qtewoc1sruq - PDFDocument10 pagesA 108 - 99 Qtewoc1sruq - PDFjorgesalgNo ratings yet

- Nickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForDocument5 pagesNickel and Nickel-Base Alloy-Clad Steel Plate: Standard Specification ForJosé Ramón GutierrezNo ratings yet

- Final SS Specification 18 12 2020Document10 pagesFinal SS Specification 18 12 2020Amit NG AmitNo ratings yet

- Care & Cleaning - Stainless Steel PDFDocument7 pagesCare & Cleaning - Stainless Steel PDFpsp710No ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNo ratings yet

- Practical Metal Plate Work - With Numerous Engravings and DiagramsFrom EverandPractical Metal Plate Work - With Numerous Engravings and DiagramsRating: 5 out of 5 stars5/5 (1)

- High Temperature Corrosion: Fundamentals and EngineeringFrom EverandHigh Temperature Corrosion: Fundamentals and EngineeringNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNo ratings yet

- Pressure Surge Dependence On Valve Operations in A Pipeline Loading SystemDocument10 pagesPressure Surge Dependence On Valve Operations in A Pipeline Loading SystemSharat ChandraNo ratings yet

- Finite Element Analysis On The Temperature - DependDocument11 pagesFinite Element Analysis On The Temperature - DependSharat ChandraNo ratings yet

- Design of Quick Connect-Disconnect Hydraulic CouplingDocument13 pagesDesign of Quick Connect-Disconnect Hydraulic CouplingSharat ChandraNo ratings yet

- Clinching For Sheet MaterialsDocument26 pagesClinching For Sheet MaterialsSharat ChandraNo ratings yet

- Buehler 2019 Hardness Testing Catalog CompressedDocument24 pagesBuehler 2019 Hardness Testing Catalog CompressedSharat Chandra100% (1)

- Bridge Alert Management PDFDocument18 pagesBridge Alert Management PDFbhabhasunilNo ratings yet

- 21 Problems For CB NewDocument31 pages21 Problems For CB NewNguyễn Thảo MyNo ratings yet

- Tong Hop Bai Tap So Sanh Hon Va So Sanh Nhat Co Dap AnDocument14 pagesTong Hop Bai Tap So Sanh Hon Va So Sanh Nhat Co Dap AnGia HuyNo ratings yet

- Contin Educ Anaesth Crit Care Pain-2008-Gauntlett-121-4Document4 pagesContin Educ Anaesth Crit Care Pain-2008-Gauntlett-121-4Wahyu HidayatiNo ratings yet

- Multiple MyelomaDocument8 pagesMultiple MyelomaFelipeNo ratings yet

- A Bad Workman Always Blames His ToolsDocument6 pagesA Bad Workman Always Blames His ToolsTimothy BrownNo ratings yet

- Some, No, Any, EveryDocument2 pagesSome, No, Any, Everyvivadavid100% (1)

- FNM104 Prelim ReviewerDocument8 pagesFNM104 Prelim ReviewerjelciumNo ratings yet

- PMEC Flash CardsDocument17 pagesPMEC Flash CardsHariyantoNo ratings yet

- Chapter 7 - Non Verbal CommunicationDocument7 pagesChapter 7 - Non Verbal CommunicationCarolyn NacesNo ratings yet

- BGP (Border Gateway Protocol) - Port 179: Gateway Protocols (IGP's)Document32 pagesBGP (Border Gateway Protocol) - Port 179: Gateway Protocols (IGP's)Nitesh MulukNo ratings yet

- Assignment-9 Noc18 Me61 23 PDFDocument3 pagesAssignment-9 Noc18 Me61 23 PDFvicky tNo ratings yet

- FAKRO Technical Specification DRF DU6 PDFDocument2 pagesFAKRO Technical Specification DRF DU6 PDFthomasNo ratings yet

- Jeab 1 PsDocument20 pagesJeab 1 PsDharmveer KumarNo ratings yet

- CCNA1 Mod 6Document28 pagesCCNA1 Mod 6KlokanNo ratings yet

- Lamellar TearingDocument6 pagesLamellar TearingAndreaNo ratings yet

- People vs. PradesDocument2 pagesPeople vs. PradesMayr TeruelNo ratings yet

- (1142) Grade XI Admissions 2016-17Document7 pages(1142) Grade XI Admissions 2016-17Naveen ShankarNo ratings yet

- Data Warehouse Slide3Document43 pagesData Warehouse Slide3Kai EnezhuNo ratings yet

- NOC Construction-Aero Helidromes PDFDocument14 pagesNOC Construction-Aero Helidromes PDFAnonymous AkGKYLJNo ratings yet

- Environmental ScienceDocument2 pagesEnvironmental Sciencegillianbernice.alaNo ratings yet

- The Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronDocument23 pagesThe Separation and Synthesis of Lipidic 1,2-And 1,3-Diols From Natural Phenolic Lipids For The Complexation and Recovery of BoronNanasaheb PatilNo ratings yet

- General Definition of Sag and Tension in Electrical Transmission LinesDocument11 pagesGeneral Definition of Sag and Tension in Electrical Transmission Linesdskymaximus67% (3)

- TDS - Masterseal 420 HBDocument2 pagesTDS - Masterseal 420 HBVenkata RaoNo ratings yet

- Teaching As A ProfessionDocument5 pagesTeaching As A Professionipinloju temitopeNo ratings yet

- SyntaxDocument9 pagesSyntaxVeronicaTurtusanNo ratings yet

- Weekly Home Learning Plan Quarter 3 Week 1 Tle Agri-6 MARCH 1-5, 2021Document1 pageWeekly Home Learning Plan Quarter 3 Week 1 Tle Agri-6 MARCH 1-5, 2021Mariano CañadaNo ratings yet

- Types of VolcanoesDocument10 pagesTypes of VolcanoesRobert MestiolaNo ratings yet

- Early DwellingsDocument33 pagesEarly DwellingsVasudha UNo ratings yet

- Increasing and Decreasing Functions, Concavity and Inflection PointsDocument17 pagesIncreasing and Decreasing Functions, Concavity and Inflection PointsAnonymous Gd16J3n7No ratings yet