Professional Documents

Culture Documents

RA For Phase 1 Existing LV Panel and Cable Dismantling Work

RA For Phase 1 Existing LV Panel and Cable Dismantling Work

Uploaded by

Anandu AshokanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RA For Phase 1 Existing LV Panel and Cable Dismantling Work

RA For Phase 1 Existing LV Panel and Cable Dismantling Work

Uploaded by

Anandu AshokanCopyright:

Available Formats

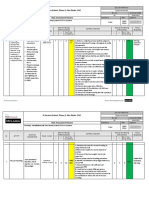

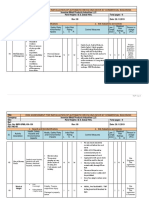

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-069

Rev. No. Assessment Date

00 26/05/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Existing Phase 1 LV Panel Removal, Cable Disconnection & Reconnection work Safety

Prabir

Officer

1

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

2

1

1) Eliminate the need for manual handling by

using mechanical aid.

2)Reduce the weight of a load to limit force

exertion

3) If unsure of the load weight, check with

supervisor.

5)Ensure proper manual handling procedure Supervisor,

musculoskeletal

Manual Handling Operatives Med 6) Identify and eliminate sharp edges before any Foreman,

1 disorders, Hand involved in work

Low

4 3 12 ium manual lift 1 3 3 Site Eng.

injuries, cut, bruises

7) Ensure adherence with sufficient and

Sharp edges

appropriate PPE.

8) Limit load carrying to 20kg per person

9) Supervisor must make sure while manual

handling load individual task and environment to

be considered to reduce the risk of manual

handling.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

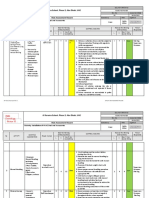

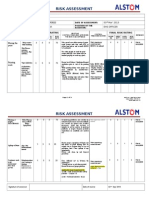

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-069

Rev. No. Assessment Date

00 26/05/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Existing Phase 1 LV Panel Removal, Cable Disconnection & Reconnection work Safety

Prabir

Officer

3

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

4

1) Ensure accesses are kept clear at all times.

2)Housekeeping to be carried out regularly

throughout the day when required

3)Supervisor to ensure operatives are stacking

material neatly and stacks are stable and in a safe

condition Supervisor,

Operatives

Slips, Trips and fall 4)Provide adequate lighting especially during

Staff/storekeeper Med Foreman,

2 Material storing Poor house keeping 3 4 12 night hours 1 4 4 Low

ium Site Eng.

5) Appropriate space is allowed around storage

areas for employees to move around safely

without the risk being trapped between stacked

materials.

6) Maintain good housekeeping.

3 Cable Slip trip fall Operatives 3 3 9 Med 1 Ensured that STARRT card briefing done by 1 3 3 Low Supervisor

dismantling re Narrow access & involved supervisor. Foreman

installation work Poor posture 2 Work areas should be clear from unwanted

Finger injury materials that are scattered everywhere

3 Always wear suitable hand gloves during cable

dismantling and re installing.

4 When the workers manually lift the cable drum

onto the jack operatives are exposed to pinch

point injury between the steel pipe and the jack

so need to take precaution to avoid hand and

finger injury.

5 Change of person to reduce continue bending

work to avoid poor posture.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

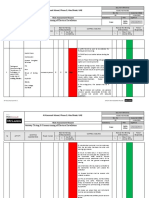

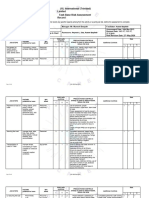

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-069

Rev. No. Assessment Date

00 26/05/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Existing Phase 1 LV Panel Removal, Cable Disconnection & Reconnection work Safety

Prabir

Officer

5

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

6

6 Avoid loose clothing and jewellery to protect

from entanglement with rotating parts

4 LV Panel Welding activity Operatives 4 4 16 High 1 If unsure of the load weight, check with 1 4 4 Low Supervisor

dismantling and musculoskeletal involved supervisor. Foreman

Fabrication of disorders, Hand 2 Ensure sufficient illumination in work place

base frame & injuries, cut, bruises 3 Identify and eliminate shape/sizes and weight

Reinstallation of Sharp edges before any manual lift

SMDB Tripping hazard 4 Ensure adherence with sufficient and

appropriate PPE.

5 Limit loads carrying to 20kg per person

6 Supervisor must make sure while manual

handling loads individual task and environment to

be considered to reduce the risk of manual

handling.

7 Ensure good house keeping

8 Ensure while manually rolling the Panel cubical

there should not be any obstruction.

9 For Hot work activity make sure Hot work

permit in place.

10 Fire Extinguisher must be in place with 3 rd

party certified active Fire watcher.

11 Fire watcher should not leave the area until

hot work activity completed and he should check

and confirmed there is no smoke or hot surface.

12 Make sure no combustible item nearby Hot

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

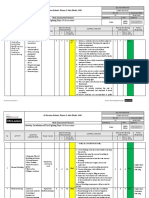

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-069

Rev. No. Assessment Date

00 26/05/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Existing Phase 1 LV Panel Removal, Cable Disconnection & Reconnection work Safety

Prabir

Officer

7

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

8

work area.

13 Housekeeping to be conduct.

1. Prepare the working area for a good working

condition.

2.All workers should wear high visibility vest and

PPE

Physical injuries,

3. Ensure that the working area is well-ventilated.

Working in poor Slips, trips & falls, Site Eng.

All personnel in Med 4.Wear goggles & face mask when working in a

5 visibility/dust Health effects – eye 3 4 12 1 4 4 Low Supervisors,

the work area ium dusty place

condition damage/respiratory Foreman

5. TBT conducted by supervisor.

diseases.

6.First aider and first aid kit available on the site

7. Ensure that work area must have proper

illumination

8. Maintain good house keeping

6 Use of power Damaged cable Operatives 3 4 12 Med 1) All portable electrical equipment must be PAT 1 4 4 Low Supervisor

tools such as, insulation, and staff tested and color coded. Make sure the test dates Foreman

Drill machine for Sockets. are visible on the equipment. Site Eng.

Glanding using Electrocution 2)Ensure all power tools 110 volt and maintained

hole saw cutter Electric shock 3) PTW to be obtained, prior to commencing the

Short circuit task

Trip/Fall 4) Damaged industrial sockets and power cables

Noise must be removed.

Hearing loss 5) Ensure the electrical cable is not damaged and

Vibration

has not been repaired with insulating tape or

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-069

Rev. No. Assessment Date

00 26/05/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Existing Phase 1 LV Panel Removal, Cable Disconnection & Reconnection work Safety

Prabir

Officer

9

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

10

unsuitable connectors.

6) Ensure cables from power tools shall be

organized so as not to present a tripping hazard

7) Only trained competent operatives to operate

the power tools.

8) Ensure proper and regular maintenance of

equipment that takes account of noise

9) Ensure proper hearing protection always.

Dust 10) Make sure people use the right tool for the

job and are trained to use it correctly

11) Ensure defective tools that require

maintenance is reported for repair or

replacement.

12) Instruct workers to keep their hands warm

and dry, and to not grip a vibrating tool too

tightly. Workers should allow the tool or machine

to do the work.

13) Ensuring proper job rotation and limiting

time operatives working with power tools and

hand tools.

14) use dust mask and ear plug.

7 Use of Hand Improper selection 3 3 9 Med 1) Hand tools should be visually inspected for 1 3 3 Low Site Eng.

tools and Testing of hand tools. Operatives/Sta ium defects, prior to use. Supervisor

kit Damaged and ff 2) Competent certified Engineer must use testing Foreman

Defective Hand kit

tools 3) Select right tools for right Job

Hand injuries 4) Ensure no Homemade or makeshift tools to be

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-069

Rev. No. Assessment Date

00 26/05/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Existing Phase 1 LV Panel Removal, Cable Disconnection & Reconnection work Safety

Prabir

Officer

11

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

12

used at site

5) All the test kit power connection must be in

good condition and no loose connection

6) Ensure Hand tools are Stored in accordance

Pinch point with the manufacturer’s instructions.

Ergonomics 7) Ensure hands are not in direct line of fire while

Repetitive strain working with hand tools.

injury 8) Ensure all the testing kits are calibrated from

authorized lab.

9) Electrical Permit need to obtain for using

Testing kit if above 110V.

10) Only authorized persons are allowed during

testing activity and area must be barricaded with

caution signage.

11) Ensure appropriate PPE always.

1) Ensure proper night work permit is obtained

2) Proper lighting system should be in place

3) Ensure proper Communication / Coordination

Poor visibility due to Operatives/staff and close supervision

Site Eng.

Working at night darkness / poor 4) Industrial safe torches to be available for

Med Supervisor

8 time illumination 3 4 12 emergency situations 1 4 4 Low

Lone worker

ium 5) High visibility Traffic Vest for personnel’s in Foreman

night shift

6) Avoid lone working and close supervision

7) Employees to be trained and understand

McLaren Crises plan.

9 Adverse weather Rain, All employee, 4 4 16 High 1 Weather report must be monitored and 1 4 4 Low Site Eng.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-069

Rev. No. Assessment Date

00 26/05/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Existing Phase 1 LV Panel Removal, Cable Disconnection & Reconnection work Safety

Prabir

Officer

13

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

14

informed to work force.

2 No activity shall be allowed during adverse

weather condition on site

3 Protect the Power tools/DB from rain water to

Sand Storm

avoid short circuit.

Fog

4 Ensure during adverse weather or Foggy

Slippery surface

weather no lifting operation and no vehicle

Risk of electrocution Supervisor

condition visitors movement.

Flying debris, Foreman

5 After clear the weather make sure all power

Slip, Tripping and

tools are safe to use.

fall

6 No work at height during high wind and rain

7 In case of emergency, call McLaren/Emergency

number

5 Approved By: Name Vishnu Mohan Position _PM________ Signature _ ________ ___________

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

6

7 RISK ASSESSMENT & CONTROL GUIDELINES

8

9 1. Executing Steps:

10 1.1. Planning

11 a) Construction and HSE team must ensure that hazard identification is complete.

12 b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks

13 have well established legal requirements, potentially high risks).

14 c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these

15 potential high risks.

16 1.2. Risk Assessment

17 Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The

18 hazard is the potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an

19 event occurring, but also the outcome will be in terms of injury, loss, damage or harm.

20 1.3. Risk Assessment Process

21 The process of carrying out a risk assessment should be as follows.

22 1. Identify the hazards.

23 2. Identify who might be harmed and how.

24 3. Evaluate the risk and implement the control measures.

25 4. Record the significant findings.

26 5. Review the assessment and update if necessary.

27 1.4. Examination of the Hazards and Risk Associated

28 Competent staff must be used in examining the risk associated with the identified hazard.

29 Competent staff should examine following aspect to determine the risk involved:

30 o Examine the existing control measures in place.

31 o Identify employees at risk.

32 o Likelihood of risk.

33 o Severity

34 o Risk level and their tolerability.

35 1.5. Evaluating the risk:

36 Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to

37 access the risks.

38 1.5.1. Risk Rating Score

39 Risk rating score is a combination of two factors.

40 The severity of the risk that could injure persons or cause damage to plant.

41 The likelihood of the risk that it could happen (Probability).

42

43 RISK RATING = LIKELIHOOD X SEVERITY

44 NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in

45 the table below. SEVERITY

46

No Injury Minor Moderate Major Catastrophic

47

(1) Injury (2) Injury (3) Injury (4) (5)

48 LIK

49 ELI 1 2 3 4 5

Rarely (1)

50 HO

51 OD Unlikely (2) 2 4 6 8 10

52 Possible (3) 3 6 9 12 15

53

54 Likely (4) 4 8 12 16 20

55 Almost

56 Certain (5)

5 10 15 20 25

57 RISK LEVEL:

Low Medium High

58

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

59

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

You might also like

- Risk Assessment For Testing & Commissioning of Electrical InstallationDocument14 pagesRisk Assessment For Testing & Commissioning of Electrical InstallationAnandu Ashokan100% (18)

- Risk Assessment For Testing & Commissioning of HVAC SystemDocument12 pagesRisk Assessment For Testing & Commissioning of HVAC SystemAnandu Ashokan75% (12)

- Risk Assessment For Pressure TestingDocument13 pagesRisk Assessment For Pressure TestingAnandu Ashokan83% (6)

- Barb Wire InstallationDocument3 pagesBarb Wire Installationzaigham naqvi100% (3)

- Risk Assessment For Hot WorksDocument4 pagesRisk Assessment For Hot Workseldho100% (2)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 pagesRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul Wasay100% (1)

- Substructure Modelling and Design As Per IRC112Document66 pagesSubstructure Modelling and Design As Per IRC112vaibhav dahiwalkar100% (1)

- AHA Roofing SystemDocument8 pagesAHA Roofing SystemLawrence adeleke Omisakin100% (2)

- Risk Assessment Form: 1 Biophysical HazardsDocument5 pagesRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- Risk Assessment For Testing & Commissioning of Fire Fighting SystemDocument17 pagesRisk Assessment For Testing & Commissioning of Fire Fighting SystemAnandu Ashokan93% (14)

- Risk Assessment For Testing & Commissioning of Fire Fighting SystemDocument17 pagesRisk Assessment For Testing & Commissioning of Fire Fighting SystemAnandu Ashokan93% (14)

- SWMS - Glass PartitionDocument11 pagesSWMS - Glass PartitionParasNo ratings yet

- Risk Assessment For Installation and Testing of ACS (RA33)Document11 pagesRisk Assessment For Installation and Testing of ACS (RA33)Anandu Ashokan100% (3)

- Risk Assessment For Water Heaters InstallationDocument6 pagesRisk Assessment For Water Heaters Installationfidgety100% (2)

- Risk Assessment For Earthing Work-R1Document3 pagesRisk Assessment For Earthing Work-R1Azhar Mushtaq83% (6)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Document12 pagesRisk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Anandu Ashokan100% (1)

- Risk Assessment - T&C For Medium Voltage SwitchgearDocument8 pagesRisk Assessment - T&C For Medium Voltage SwitchgearMuhammad IrfanNo ratings yet

- Risk Assessment For Aluminium Handrail InstallationDocument5 pagesRisk Assessment For Aluminium Handrail InstallationKalid Jmal100% (1)

- Risk Assessment For Lifting OperationDocument2 pagesRisk Assessment For Lifting OperationPrem Shiva100% (2)

- SAT of MV Cables (GEN)Document18 pagesSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- Risk Assessment For Use of Power ToolsDocument2 pagesRisk Assessment For Use of Power ToolsRicardo Dalisay100% (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Document12 pagesRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Installation of Copper Pipes and Fittings.: Barq Group Risk AssessmentDocument8 pagesInstallation of Copper Pipes and Fittings.: Barq Group Risk AssessmentYousaf Richu75% (4)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Document12 pagesRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 pagesRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (6)

- Risk Assessment - Wall & Floor Tiling: April 2010Document2 pagesRisk Assessment - Wall & Floor Tiling: April 2010wahyu nugroho100% (2)

- New Pta Complex: Jsa For Reinforcing Steel BarsDocument12 pagesNew Pta Complex: Jsa For Reinforcing Steel BarsUMUTNo ratings yet

- Installation and Testing of Structured CablingDocument38 pagesInstallation and Testing of Structured CablingAnandu AshokanNo ratings yet

- Installation of Fire Fighting SystemDocument66 pagesInstallation of Fire Fighting SystemAnandu AshokanNo ratings yet

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- Risk Assessment For Dismantling of Temporary ServicesDocument17 pagesRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNo ratings yet

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Risk Assessment For Testing and Commissioning of Water Supply Pipes Including ChlorinationDocument3 pagesRisk Assessment For Testing and Commissioning of Water Supply Pipes Including Chlorinationfidgety100% (4)

- Risk Assessment (Installation of Cables & Wires)Document6 pagesRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- Risk Assessment For Anti Termite WorksDocument7 pagesRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel Factor60% (5)

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- 18 - RA Roadworks Risk AssessmentDocument1 page18 - RA Roadworks Risk Assessmentkumar100% (1)

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh50% (2)

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- RA For Installation of Air Colled ChillersDocument8 pagesRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (2)

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- Shuttering WorksDocument3 pagesShuttering WorksAbdul GhaffarNo ratings yet

- SWMS - HVAC ShiftingDocument6 pagesSWMS - HVAC ShiftingParas100% (1)

- Risk Assessment For Installation of Automatic Sliding DoorDocument6 pagesRisk Assessment For Installation of Automatic Sliding DoorKalid Jmal100% (1)

- Ra For Fire Protection Piping Installation WorksDocument7 pagesRa For Fire Protection Piping Installation WorksprinceNo ratings yet

- Ra For Installation of Grills, Diffusers & LouversDocument8 pagesRa For Installation of Grills, Diffusers & LouversAnandu Ashokan100% (1)

- Thread-Machine Inspection Check ListDocument1 pageThread-Machine Inspection Check ListThein Myint Oo0% (1)

- Painting WorksDocument2 pagesPainting WorksAhoyAoaNo ratings yet

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment Switchgear Testing & CommissioningDocument7 pagesRisk Assessment Switchgear Testing & CommissioningguspriyNo ratings yet

- Motor Maintenance PDFDocument1 pageMotor Maintenance PDFAbdul HadiNo ratings yet

- Mobilization and Installation of CHW PipesDocument8 pagesMobilization and Installation of CHW PipesYounis KhanNo ratings yet

- Job Safety Analysis Worksheet: Tie - in For Power Cable 33 KVDocument3 pagesJob Safety Analysis Worksheet: Tie - in For Power Cable 33 KVmohammed a hseNo ratings yet

- Al Karama School, Phase 2, Abu Dhabi, UAE Risk Assessment Record ActivityDocument11 pagesAl Karama School, Phase 2, Abu Dhabi, UAE Risk Assessment Record ActivitymuradNo ratings yet

- HSE-TBRA-OP11 - Transportation of Cargo To Client Site Rev2Document4 pagesHSE-TBRA-OP11 - Transportation of Cargo To Client Site Rev2hseassistant.cgaNo ratings yet

- SAT of Earthing & Lightning Protection System (GEN)Document15 pagesSAT of Earthing & Lightning Protection System (GEN)Anandu AshokanNo ratings yet

- Ara-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Document15 pagesAra-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Anandu AshokanNo ratings yet

- Testing Commissioning of HVAC SystemDocument53 pagesTesting Commissioning of HVAC SystemAnandu Ashokan100% (4)

- SAT of MV Cables (GEN)Document1 pageSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- SAT of Final Small Power & Lighting Circuits (GEN)Document13 pagesSAT of Final Small Power & Lighting Circuits (GEN)Anandu AshokanNo ratings yet

- M1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerDocument63 pagesM1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerAnandu AshokanNo ratings yet

- Rerouting of Existing MEP Services in New SubstationDocument52 pagesRerouting of Existing MEP Services in New SubstationAnandu AshokanNo ratings yet

- Master Log - LOGDocument15 pagesMaster Log - LOGAnandu AshokanNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- Installation of VRF System FAHU DX Package Unit With Dehumidifier DX Split UnitDocument102 pagesInstallation of VRF System FAHU DX Package Unit With Dehumidifier DX Split UnitAnandu AshokanNo ratings yet

- Installation and Testing of Access Control SystemDocument36 pagesInstallation and Testing of Access Control SystemAnandu AshokanNo ratings yet

- Installation of Underground Electrical-ELV DuctDocument41 pagesInstallation of Underground Electrical-ELV DuctAnandu AshokanNo ratings yet

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Testing Commissioning of Electrical InstallationDocument39 pagesTesting Commissioning of Electrical InstallationAnandu AshokanNo ratings yet

- M1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - ADocument48 pagesM1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - AAnandu AshokanNo ratings yet

- M1492-MCL-MSS-021 Installation of UPVC Underground and Above Ground Drainage Pipes and Fittings - PDF - ADocument57 pagesM1492-MCL-MSS-021 Installation of UPVC Underground and Above Ground Drainage Pipes and Fittings - PDF - AAnandu AshokanNo ratings yet

- Installation of Light FittingsDocument38 pagesInstallation of Light FittingsAnandu AshokanNo ratings yet

- Installation and Commissioning of Fire Alarm System PAVA SystemDocument40 pagesInstallation and Commissioning of Fire Alarm System PAVA SystemAnandu AshokanNo ratings yet

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Installation and Testing of BMS (Building Management System) NSRDocument51 pagesInstallation and Testing of BMS (Building Management System) NSRAnandu Ashokan50% (2)

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- PG Provisional Offer LetterDocument1 pagePG Provisional Offer LetterkartiksharmaNo ratings yet

- Full Chapter The Zoo and Screen Media Images of Exhibition and Encounter 1St Edition Michael Lawrence PDFDocument53 pagesFull Chapter The Zoo and Screen Media Images of Exhibition and Encounter 1St Edition Michael Lawrence PDFpamela.thomas142100% (6)

- Valve Outlet VelDocument16 pagesValve Outlet VelB rgNo ratings yet

- The Bioleaching Potential of A Bacterial ConsortiumDocument8 pagesThe Bioleaching Potential of A Bacterial ConsortiumBekele OljiraNo ratings yet

- Homework Week 2 Basic Data StructuresDocument8 pagesHomework Week 2 Basic Data StructuresLe Thi Cam NhungNo ratings yet

- Personal EssayDocument2 pagesPersonal Essayapi-657919781No ratings yet

- Experiment: WE - 1 Title: Infiltration Rate and Double-Ring Infiltrometer Test Duration: 2 Hours: 1 0F 7Document6 pagesExperiment: WE - 1 Title: Infiltration Rate and Double-Ring Infiltrometer Test Duration: 2 Hours: 1 0F 7asadNo ratings yet

- Gülyüz Et Al. Multiphase Deformation, Fluid Flow and Mineralization in Epithermal Systems Inferences From Structures, Vein Textures and Breccias of The Kestanelik Epithermal Au-ADocument22 pagesGülyüz Et Al. Multiphase Deformation, Fluid Flow and Mineralization in Epithermal Systems Inferences From Structures, Vein Textures and Breccias of The Kestanelik Epithermal Au-Ahüseyin burak göktaşNo ratings yet

- Diversity and Taxonomy of Wood Rotting Fungi From Dharashiv (Osmanabad) District (M.S.) IndiaDocument8 pagesDiversity and Taxonomy of Wood Rotting Fungi From Dharashiv (Osmanabad) District (M.S.) IndiaIJAR JOURNALNo ratings yet

- DTL Summer Training ReportDocument63 pagesDTL Summer Training ReportARYAN ANo ratings yet

- ISO/IEC Directives, Part 1Document76 pagesISO/IEC Directives, Part 1Rock BandNo ratings yet

- Behaviorist and Learning Aspects of PersonalityDocument24 pagesBehaviorist and Learning Aspects of Personalitydurubelsan02No ratings yet

- Pert CPMDocument59 pagesPert CPMFunsuk VangduNo ratings yet

- Cementing Design - FinalDocument27 pagesCementing Design - FinalBIGBOAZ XX100% (1)

- Rashtrasant Tukadoji Maharaj Nagpur UniversityDocument1 pageRashtrasant Tukadoji Maharaj Nagpur UniversityAkash RautNo ratings yet

- Week 3 - 1Document11 pagesWeek 3 - 1visiting mathematicsNo ratings yet

- Hbo 1-3Document12 pagesHbo 1-3i'm lightNo ratings yet

- 7762075-Dreger and WielgusDocument15 pages7762075-Dreger and WielgusAlma KunicNo ratings yet

- Square of Binomial, Product of Sum and Diff, Square of MultinomialDocument11 pagesSquare of Binomial, Product of Sum and Diff, Square of Multinomialacechi iNo ratings yet

- Telephone Handling Techniques: Hints and Helpful InformationDocument4 pagesTelephone Handling Techniques: Hints and Helpful InformationRajmani2501No ratings yet

- GLP Lecture 8Document45 pagesGLP Lecture 8BABAR ZAFARULLAH MINHASNo ratings yet

- Đáp Án Đề Thi Tuyển Sinh Vào Lớp 10 Chuyên Môn Tiếng Anh - Hải Phòng Năm 2021-2022Document10 pagesĐáp Án Đề Thi Tuyển Sinh Vào Lớp 10 Chuyên Môn Tiếng Anh - Hải Phòng Năm 2021-2022supernhatnheoNo ratings yet

- 0001Document7 pages0001ag_f53No ratings yet

- Daikin Infrastructure Cooling SolutionDocument24 pagesDaikin Infrastructure Cooling SolutionBrian SmithNo ratings yet

- Good NotesDocument2 pagesGood NotesYousef AwartanyNo ratings yet

- Anushka Jain - MDC003 - BBADocument5 pagesAnushka Jain - MDC003 - BBAAnushka JainNo ratings yet

- David Ellen - The Scientific Examination of Documents - Methods and Techniques - Methods and Techniques-Taylor & Francis (2014)Document189 pagesDavid Ellen - The Scientific Examination of Documents - Methods and Techniques - Methods and Techniques-Taylor & Francis (2014)Daniel BolivarNo ratings yet

- CBC AssessmentDocument15 pagesCBC AssessmentStellaNo ratings yet

- 200 English Grammar Mistakes (Books-Here - Com)Document115 pages200 English Grammar Mistakes (Books-Here - Com)Mr. Sham BK100% (1)