Professional Documents

Culture Documents

Risk Assessment For Pressure Testing

Risk Assessment For Pressure Testing

Uploaded by

Anandu AshokanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment For Pressure Testing

Risk Assessment For Pressure Testing

Uploaded by

Anandu AshokanCopyright:

Available Formats

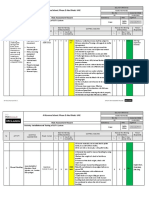

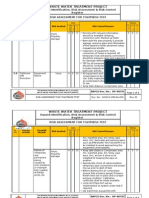

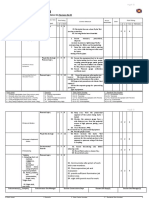

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

1

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

2

1

1 Delivering, Plant and Traffic Operatives 3 4 12 Medi 1) Delivery/ collection drivers shall be subject to 1 4 4 Low Site Engr

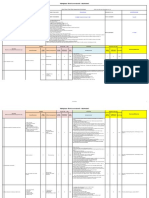

unloading and movement Staff/visitors um McLaren induction/Training with regards to traffic Supervisor

storing of Pressure management. Foreman

test equipment’s

Run over by 2)Ensure exclusion zone is set up around the

using pickup van

vehicles/plants preparation work area and all plant movement

and unloading by

manual handling Hit by reversing and checked by supervisor

and shifting by equipment 3) Always use the pedestrian access provided

using pallet trolley Overhead 4) Traffic light batons shall be provided for banks

obstructions man at night

Vehicle break 5) All plant to have a fully trained banks man

down present all times.

Property damage 6) No plant to reverse without banks man.

Collision with 7) Ensure access route are sufficient and safe to

other vehicles use.

Personal injury 8) Do not take rest in or under vehicles

Accident due to 9) Proper barricade and safety signboard

poor lighting and provided on open excavation

visibility (operation 10) All vehicles must be fitted with reverse

at night) alarm / Flashing light.

11) The work place and all access to be well

illuminated.

12) Ensure close supervision, Effective

Communication & Coordination with McLaren

13) Enforce Speed limit

14) Ensure all vehicles entering the site is

properly maintained and reported if found any

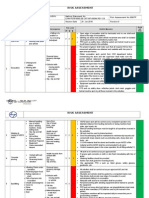

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

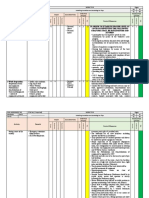

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

3

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

4

defect

15) Ensure materials are secured/tied in pallet

trolley to avoid fall from trolley.

16) Do not ride or horse play with pallet trolley.

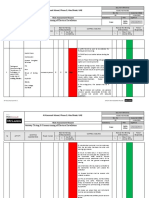

1) Eliminate the need for manual handling by

using mechanical aid.

2)Reduce the weight of a load to limit force

exertion

3) If unsure of the load weight, check with

supervisor.

5)Ensure proper manual handling procedure Supervisor,

musculoskeletal

Manual Handling Operatives Med 6) Identify and eliminate sharp edges before any Foreman,

2 disorders, Hand involved in work

Low

4 3 12 ium manual lift 1 3 3 Site Eng.

injuries, cut, bruises

7) Ensure adherence with sufficient and

Sharp edges

appropriate PPE.

8) Limit load carrying to 20kg per person

9) Supervisor must make sure while manual

handling load individual task and environment to

be considered to reduce the risk of manual

handling.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

5

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

6

1) Ensure accesses are kept clear at all times.

2)Housekeeping to be carried out regularly

throughout the day when required

3)Supervisor to ensure operatives are stacking

material neatly and stacks are stable and in a safe

condition Supervisor,

Operatives

Slips, Trips and fall 4)Provide adequate lighting especially during

Staff/storekeeper Med Foreman,

3 Material storing Poor house keeping 3 4 12 night hours 1 4 4 Low

ium Site Eng.

5) Appropriate space is allowed around storage

areas for employees to move around safely

without the risk being trapped between stacked

materials.

6) Maintain good housekeeping.

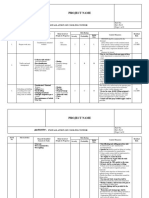

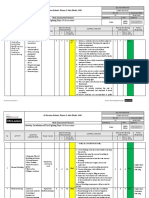

4 All operatives 4 4 16 High 1 Risk assessment must brief to the operatives. 1 4 4 Low Site eng

High-pressure leak involved in 2 Ensure permit obtained for pressure test. Supervisor

of water & Flooding work 3 All pressure tests must be conducted with due Foreman

Explosion regard for the safety of life and property.

Failure of test pump 4 Area must be barricaded with caution signage.

Electric shock with Precautions should be taken to see that people

Motor not directly engaged in the testing operations

Electrocution remain out of the test area during the test period.

Unintended release 5 Check that all high points have a tap or vent to

of stored energy. facilitate removal of air during filling and that

these are all closed.

6 Blank, plug or seal any open ends and close all

valves at the limits of the test section of the

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

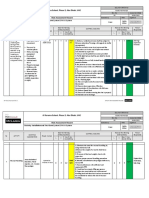

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

7

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

8

piping.

Pressure Testing 7 Start to fill the piping and then ‘walk’ the route

of the piping under test, continuously visually

checking for leaks and by listening for the sound

of escaping air

8 Release air from all the high points

systematically through the system to completely

fill it with water

9 Check that the test gauge is functioning

correctly has been calibrated and has the correct

range of the test pump.

10 Check that a suitable hose is available for

draining the system

11 Before attempting test, Supervisor will review

the test specifications and procedures with the

Test Inspector and any other relevant personnel

to be certain that all equipment is adequate, and

duties are organized and understood

12 All the electric live service must be temporary

isolate to avoid electric shock and electrocution

13 All test connectors are subject to cyclic

loading, both from the pressure test application

and from tightening torque loadings. Fatigue is a

factor that must be addressed when test

connectors are being inspected and assessed for

continued use. Some signs of fatigue are clearly

visible and measurable (deformed threads), and

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

9

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

10

some are not

14 PPE must in use with face shield

15 Ensure proper grounding and earthling After

completion of the pressure test, release the

water and disconnect all the temporary

connections and close both ends

16 Exclusion zone must be removing and remove

the danger signage after completion of pressure

test.

17 Operatives must be wear necessary PPE.

18 At the end of the Fire Hose reel test, the hose

reel is cleaned and rewound. Make sure before

leave the site area must be cleaned and tidy.

19 During Fire hose reel testing make sure

caution signage in visible with Pressure rate.

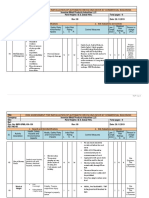

5 Spillage/ soil Operatives 3 4 12 Med 1 Ensure that all chemical substances have a 1 4 4 Low Supervisors

contamination using solvent ium COSHH assessment Foreman,

2 Refer SDS prior to any handling of hazardous Site Eng.

Burns substances and ensure SDS is easily accessible at

Contact with skin site while working with chemicals.

3 Ensure chemicals are properly stacked.

Acute/Chronic 4 Ensure all chemical containers are properly

adverse heath labeled.

effect. 5 Spill kits to be available at site.

Fire 6 Ensured all COSHH waste must be dispose in

designated waste bin.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

11

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

12

7 Competent person to oversee the storage, use

Use of and disposal of hazardous materials.

Glue/Paint 8 Ensure that correct welfare/first aid facilities

Solvent, are available in the area i.e. washing facility/eye

(Hazardous wash.

Substance) 9 Proper and adequate PPE to be used always

10 Ensure all chemical containers are properly

labeled.

11 Adjust work schedules so that workers are not

overexposed to a hazardous chemical.

12 Ensure proper and adequate PPE to be used

always.

13 Ensure smoking is prohibited

14 Ensure appropriate Firefighting equipment’s

are in place and easily accessible

6 Working in poor Physical injuries, All personnel in 3 4 12 Med 1. Prepare the working area for a good working 1 4 4 Low Site Eng.

visibility/dust Slips, trips & falls, the work area ium condition. Supervisors,

condition Health effects – eye 2.All workers should wear high visibility vest and Foreman

damage/respiratory PPE

diseases. 3. Ensure that the working area is well-ventilated.

4.Wear goggles & face mask when working in a

dusty place

5. TBT conducted by supervisor.

6.First aider and first aid kit available on the site

7. Ensure that work area must have proper

illumination

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

13

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

14

8. Maintain good house keeping

7 Falling from height All involved in 3 4 12 Med 1 Only light work, off short duration and work in 1 4 4 Low Supervisor

Collapse of ladder work ium which the operative can maintain secure hand Foreman,

Working on and foot hold can be undertaken form a ladder Site Eng.

ladder 2 Never try to overreach with any ladders

3 Check the ladder is of suitable quality for

industrial use and is in good condition

4 Check the inclination of the ladder conforms to

the one-in-four rule.

5 Maintain a minimum of 3 points of contact with

stepladders always (feet/thighs/hands)

6 If possible avoid the use of stepladders at a

working height of 2 meters and more.

7Check the ladder legs (and stays) are fully

deployed or locked (depending on type) to

maintain maximum base dimensions and the step

ladder is orientated to provide maximum

stability.

8 Ensure that during using ladder from the top 2

steps is blocked to avoid climb on that.

9 The ladder securely fixed to prevent slipping

outwards or sideways or securely footed at all

times.

10 Person must hold the ladder while another

operative working on it

11 Materials should not be placed above the

thread of ladders/step ladders

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

15

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

16

12 Ensure using podium type ladder to reduce the

risk.

8 Use of power Damaged cable Operatives 3 4 12 Med 1) All portable electrical equipment must be PAT 1 4 4 Low Supervisor

tools such as, insulation, and staff tested and color coded. Make sure the test dates Foreman

Drill machine, Sockets. are visible on the equipment. Site Eng.

Electrocution 2)Ensure all power tools 110 volt and maintained

Electric shock 3) PTW to be obtained, prior to commencing the

Short circuit task

Trip/Fall 4) Damaged industrial sockets and power cables

Noise must be removed.

Hearing loss 5) Ensure the electrical cable is not damaged and

Vibration

has not been repaired with insulating tape or

Dust

unsuitable connectors.

6) Ensure cables from power tools shall be

organized so as not to present a tripping hazard

7) Only trained competent operatives to operate

the power tools.

8) Ensure proper and regular maintenance of

equipment that takes account of noise

9) Ensure proper hearing protection always.

10) Make sure people use the right tool for the

job and are trained to use it correctly

11) Ensure defective tools that require

maintenance is reported for repair or

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

17

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

18

replacement.

12) Instruct workers to keep their hands warm

and dry, and to not grip a vibrating tool too

tightly. Workers should allow the tool or machine

to do the work.

13) Ensuring proper job rotation and limiting

time operatives working with power tools and

hand tools.

14) use dust mask

9 Use of Hand Improper selection 3 3 9 Med 1) Hand tools should be visually inspected for 1 3 3 Low Site Eng.

tools and Testing of hand tools. Operatives/Sta ium defects, prior to use. Supervisor

kit Damaged and ff 2) Competent certified Engineer must use testing Foreman

Defective Hand kit

tools 3) Select right tools for right Job

Hand injuries 4) Ensure no Homemade or makeshift tools to be

Pinch point used at site

Ergonomics 5) All the test kit power connection must be in

Repetitive strain good condition and no loose connection

injury 6) Ensure Hand tools are Stored in accordance

with the manufacturer’s instructions.

7) Ensure hands are not in direct line of fire while

working with hand tools.

8) Ensure all the testing kits are calibrated from

authorized lab.

9) Electrical Permit need to obtain for using

Testing kit if above 110V.

10) Only authorized persons are allowed during

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

19

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

20

testing activity and area must be barricaded with

caution signage.

11) Ensure appropriate PPE always.

1) Ensure proper night work permit is obtained

2) Proper lighting system should be in place

3) Ensure proper Communication / Coordination

Poor visibility due to Operatives/staff and close supervision

Site Eng.

Working at night darkness / poor 4) Industrial safe torches to be available for

Med Supervisor

10 time illumination 3 4 12 emergency situations 1 4 4 Low

Lone worker

ium 5) High visibility Traffic Vest for personnel’s in Foreman

night shift

6) Avoid lone working and close supervision

7) Employees to be trained and understand

McLaren Crises plan.

11 Adverse weather Rain, All employee, 4 4 16 High 1 Weather report must be monitored and 1 4 4 Low Site Eng.

condition Sand Storm visitors informed to work force. Supervisor

Fog 2 No activity shall be allowed during adverse Foreman

Slippery surface weather condition on site

Risk of electrocution 3 Protect the Power tools/DB from rain water to

Flying debris, avoid short circuit.

Slip, Tripping and 4 Ensure during adverse weather or Foggy

fall weather no lifting operation and no vehicle

movement.

5 After clear the weather make sure all power

tools are safe to use.

6 No work at height during high wind and rain

7 In case of emergency, call McLaren/Emergency

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

Al Karama School, Phase 2, Abu Dhabi, UAE M1492-HSE-RA-042

Rev. No. Assessment Date

00 06/06/2020

Risk Assessment Record Assessed by Titile Signature

Activity: Pressure Testing Safety

Prabir

Officer

21

Base Risk Ranking Residual Risk Ranking Person

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Responsible

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk

L S L S

Score Rating Score Rating

22

number

5 Approved By: Name Vishnu Mohan Position _PM________ Signature _ ________ ___________

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

6

7 RISK ASSESSMENT & CONTROL GUIDELINES

8

9 1. Executing Steps:

10 1.1. Planning

11 a) Construction and HSE team must ensure that hazard identification is complete.

12 b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks

13 have well established legal requirements, potentially high risks).

14 c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these

15 potential high risks.

16 1.2. Risk Assessment

17 Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The

18 hazard is the potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an

19 event occurring, but also the outcome will be in terms of injury, loss, damage or harm.

20 1.3. Risk Assessment Process

21 The process of carrying out a risk assessment should be as follows.

22 1. Identify the hazards.

23 2. Identify who might be harmed and how.

24 3. Evaluate the risk and implement the control measures.

25 4. Record the significant findings.

26 5. Review the assessment and update if necessary.

27 1.4. Examination of the Hazards and Risk Associated

28 Competent staff must be used in examining the risk associated with the identified hazard.

29 Competent staff should examine following aspect to determine the risk involved:

30 o Examine the existing control measures in place.

31 o Identify employees at risk.

32 o Likelihood of risk.

33 o Severity

34 o Risk level and their tolerability.

35 1.5. Evaluating the risk:

36 Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to

37 access the risks.

38 1.5.1. Risk Rating Score

39 Risk rating score is a combination of two factors.

40 The severity of the risk that could injure persons or cause damage to plant.

41 The likelihood of the risk that it could happen (Probability).

42

43 RISK RATING = LIKELIHOOD X SEVERITY

44 NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in

45 the table below. SEVERITY

46

No Injury Minor Moderate Major Catastrophic

47

(1) Injury (2) Injury (3) Injury (4) (5)

48 LIK

49 ELI 1 2 3 4 5

Rarely (1)

50 HO

51 OD Unlikely (2) 2 4 6 8 10

52 Possible (3) 3 6 9 12 15

53

54 Likely (4) 4 8 12 16 20

55 Almost

56 Certain (5)

5 10 15 20 25

57 RISK LEVEL:

Low Medium High

58

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

59

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

You might also like

- Risk Assessment For Testing & Commissioning of Electrical InstallationDocument14 pagesRisk Assessment For Testing & Commissioning of Electrical InstallationAnandu Ashokan100% (16)

- Risk Assessment For Testing & Commissioning of Electrical InstallationDocument14 pagesRisk Assessment For Testing & Commissioning of Electrical InstallationAnandu Ashokan100% (16)

- Risk Assessment For Installation of Fire Fighting SystemDocument20 pagesRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan91% (35)

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan86% (14)

- Risk Assessment For Testing & Commissioning of HVAC SystemDocument12 pagesRisk Assessment For Testing & Commissioning of HVAC SystemAnandu Ashokan75% (12)

- Risk Assessment For Structured CablingDocument7 pagesRisk Assessment For Structured CablingAnandu Ashokan75% (8)

- Risk Assessment For Installation of Light FittingsDocument11 pagesRisk Assessment For Installation of Light FittingsAnandu Ashokan89% (9)

- RISK ASSESSMENT For Installation of HDPE Pipes and Fittings...Document21 pagesRISK ASSESSMENT For Installation of HDPE Pipes and Fittings...721917114 4763% (8)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument7 pagesRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (3)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 pagesRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan95% (19)

- Risk Assessment For Testing and Commissioning of Electrical SystemDocument8 pagesRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (8)

- 08 Cable Termination Risk AssessmentDocument2 pages08 Cable Termination Risk AssessmentBaranidaranRavi74% (19)

- Risk Assessment For Installation and Testing of CCTVDocument11 pagesRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (5)

- Risk Assessment For MEP Isolation WorksDocument8 pagesRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (6)

- Johnstone 2015Document13 pagesJohnstone 2015Siti MinartiNo ratings yet

- Risk Assessment For Installation & Testing Commissioning of PumpsDocument17 pagesRisk Assessment For Installation & Testing Commissioning of PumpsAnandu Ashokan82% (11)

- Risk Assessment For InsulationDocument9 pagesRisk Assessment For InsulationSaleem Akhtar75% (8)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 pagesRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment For Installation & Testing of BMS UnitDocument15 pagesRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of Fan Coil UnitsDocument18 pagesRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan83% (6)

- Porta Cabins Shifting Risk AssessmentDocument8 pagesPorta Cabins Shifting Risk AssessmentAsad Raza100% (3)

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul Wasay100% (1)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan82% (11)

- Risk Assessment For Tightness TestDocument8 pagesRisk Assessment For Tightness TestAriel Dela Cruz100% (1)

- Risk Assessment For Air BlowingDocument8 pagesRisk Assessment For Air BlowingAriel Dela Cruz100% (5)

- Hse Risk Assessment - 006 Ra - Hdpe Duct LayingDocument7 pagesHse Risk Assessment - 006 Ra - Hdpe Duct Layingbinunalukandam83% (12)

- Risk Assessment For Installation of Cooling TowersDocument9 pagesRisk Assessment For Installation of Cooling TowersGirithar M Sundaram100% (2)

- Method Statement For External Stone Cladding (Marble and Granite)Document7 pagesMethod Statement For External Stone Cladding (Marble and Granite)Muthukumar Jayaveerapandian100% (1)

- Robot Programming: A Practical Guide to Behavior-Based RoboticsFrom EverandRobot Programming: A Practical Guide to Behavior-Based RoboticsRating: 4.5 out of 5 stars4.5/5 (1)

- Risk Assessment For Testing & Commissioning of Fire Fighting SystemDocument17 pagesRisk Assessment For Testing & Commissioning of Fire Fighting SystemAnandu Ashokan92% (13)

- Risk Assessment For Flushing of Chilled Water PipingDocument9 pagesRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanNo ratings yet

- Risk Assessment For Testing & Commissioning of Fire Fighting SystemDocument17 pagesRisk Assessment For Testing & Commissioning of Fire Fighting SystemAnandu Ashokan92% (13)

- Alicia F. Lieberman, Patricia Van Horn - Psychotherapy With Infants and Young Children - Repairing The Effects of Stress and Trauma On Early Attachment (2008)Document385 pagesAlicia F. Lieberman, Patricia Van Horn - Psychotherapy With Infants and Young Children - Repairing The Effects of Stress and Trauma On Early Attachment (2008)alina chiritescu100% (1)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- R-A CP2H NIGHT SHIFT ACTIVITY NewDocument16 pagesR-A CP2H NIGHT SHIFT ACTIVITY Newthomson100% (1)

- Hydro Test Risk Assessment CS TankDocument3 pagesHydro Test Risk Assessment CS TankAvinash Rai100% (3)

- MH-Diesel-Generator-Hazard-Assessment - PDF Master Hire PDFDocument6 pagesMH-Diesel-Generator-Hazard-Assessment - PDF Master Hire PDFRajesh gp100% (1)

- Risk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Document12 pagesRisk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Anandu Ashokan100% (1)

- Risk Assessment - All ActivityDocument42 pagesRisk Assessment - All Activityمحمد عمر حسين100% (4)

- SAT of MV Cables (GEN)Document18 pagesSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- Risk Assessment - Installation of Air-Cooled ChillersDocument4 pagesRisk Assessment - Installation of Air-Cooled ChillersBabar Shehzad100% (1)

- Feedwater LCA Statement of ComplianceDocument5 pagesFeedwater LCA Statement of ComplianceTarundeep Singh100% (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDocument15 pagesRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Document15 pagesRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Fighting SystemDocument14 pagesRisk Assessment For Installation of Fire Fighting SystemMohamed Elhadad100% (5)

- Risk Assessment For Installation and Testing of ACS (RA33)Document11 pagesRisk Assessment For Installation and Testing of ACS (RA33)Anandu Ashokan100% (3)

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Document12 pagesRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Document12 pagesRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Amc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineDocument8 pagesAmc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineEm Niax100% (1)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDocument9 pagesRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument8 pagesRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- Hazard Identification and Risk Assessment For Pipe LoweringDocument4 pagesHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- Installation and Testing of Structured CablingDocument38 pagesInstallation and Testing of Structured CablingAnandu AshokanNo ratings yet

- Installation of Fire Fighting SystemDocument66 pagesInstallation of Fire Fighting SystemAnandu AshokanNo ratings yet

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDocument11 pagesRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Document12 pagesRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Surgical Procedure Manual Surgical Procedure ManualDocument76 pagesSurgical Procedure Manual Surgical Procedure ManualCariti91100% (2)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Document12 pagesRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNo ratings yet

- Risk Assessment For Dismantling of Temporary ServicesDocument17 pagesRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNo ratings yet

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment For Testing and Commissioning of Water Supply Pipes Including ChlorinationDocument3 pagesRisk Assessment For Testing and Commissioning of Water Supply Pipes Including Chlorinationfidgety100% (4)

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- 2.risk Assessment of Working at HeightDocument7 pages2.risk Assessment of Working at HeightRisal Sinu67% (3)

- Risk Assessment Welding & Radiography of Chilled Water PipeDocument11 pagesRisk Assessment Welding & Radiography of Chilled Water PipeAldrin78% (9)

- Risk Assessment - Fire Pump SetDocument8 pagesRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasNo ratings yet

- Risk Assessment For .Testing and Commissioning of Fire Rated Bus DuctDocument13 pagesRisk Assessment For .Testing and Commissioning of Fire Rated Bus Ductarun kurlan100% (1)

- 63 Risk Assesments Testing and Pre-Commissioning WorksDocument18 pages63 Risk Assesments Testing and Pre-Commissioning WorksEngr.Syed Amjad100% (3)

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- SAT of Final Small Power & Lighting Circuits (GEN)Document13 pagesSAT of Final Small Power & Lighting Circuits (GEN)Anandu AshokanNo ratings yet

- Ara-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Document15 pagesAra-Dc-Ms-Ele-0030 Sat of LV Cables (Gen)Anandu AshokanNo ratings yet

- SAT of Earthing & Lightning Protection System (GEN)Document15 pagesSAT of Earthing & Lightning Protection System (GEN)Anandu AshokanNo ratings yet

- Master Log - LOGDocument15 pagesMaster Log - LOGAnandu AshokanNo ratings yet

- Installation of Underground Electrical-ELV DuctDocument41 pagesInstallation of Underground Electrical-ELV DuctAnandu AshokanNo ratings yet

- Pressure TestingDocument45 pagesPressure TestingAnandu AshokanNo ratings yet

- SAT of MV Cables (GEN)Document1 pageSAT of MV Cables (GEN)Anandu AshokanNo ratings yet

- Testing Commissioning of HVAC SystemDocument53 pagesTesting Commissioning of HVAC SystemAnandu Ashokan100% (4)

- Rerouting of Existing MEP Services in New SubstationDocument52 pagesRerouting of Existing MEP Services in New SubstationAnandu AshokanNo ratings yet

- M1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerDocument63 pagesM1439-GHD-MCL-MSS-032 Rev. 01 Installation of TransformerAnandu AshokanNo ratings yet

- Installation and Testing of Access Control SystemDocument36 pagesInstallation and Testing of Access Control SystemAnandu AshokanNo ratings yet

- Installation of VRF System FAHU DX Package Unit With Dehumidifier DX Split UnitDocument102 pagesInstallation of VRF System FAHU DX Package Unit With Dehumidifier DX Split UnitAnandu AshokanNo ratings yet

- Installation and Commissioning of Fire Alarm System PAVA SystemDocument40 pagesInstallation and Commissioning of Fire Alarm System PAVA SystemAnandu AshokanNo ratings yet

- M1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - ADocument48 pagesM1492-MCL-MSS-024 Wiring Cable Pulling Installation of Wiring Accessories - PDF - AAnandu AshokanNo ratings yet

- Installation of Light FittingsDocument38 pagesInstallation of Light FittingsAnandu AshokanNo ratings yet

- M1492-MCL-MSS-021 Installation of UPVC Underground and Above Ground Drainage Pipes and Fittings - PDF - ADocument57 pagesM1492-MCL-MSS-021 Installation of UPVC Underground and Above Ground Drainage Pipes and Fittings - PDF - AAnandu AshokanNo ratings yet

- Testing Commissioning of Electrical InstallationDocument39 pagesTesting Commissioning of Electrical InstallationAnandu AshokanNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Installation and Testing of BMS (Building Management System) NSRDocument51 pagesInstallation and Testing of BMS (Building Management System) NSRAnandu Ashokan50% (2)

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDocument17 pagesRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- 4th Grade MathDocument3 pages4th Grade Mathapi-373647228No ratings yet

- Toward A Drugs and Crime Research Agenda For The 21st Century-US DoJDocument203 pagesToward A Drugs and Crime Research Agenda For The 21st Century-US DoJsylodhiNo ratings yet

- Personal Development Exam: Feedback Your Answer Is CorrectDocument35 pagesPersonal Development Exam: Feedback Your Answer Is Correctsinigang bengbeng82% (17)

- CV (Dr. Mayada Farag)Document3 pagesCV (Dr. Mayada Farag)ABC XYZNo ratings yet

- RCA CompleteDocument68 pagesRCA CompleteRakhmad Sucahyo100% (1)

- PDF Health Assessment For Nursing Practice Susan F Wilson Ebook Full ChapterDocument53 pagesPDF Health Assessment For Nursing Practice Susan F Wilson Ebook Full Chapterhelen.rama903100% (2)

- G10 DepEd Masterlist Template On COVID 19 Vaccination Ages 12 17 Years Old 2Document72 pagesG10 DepEd Masterlist Template On COVID 19 Vaccination Ages 12 17 Years Old 2Donna joy ManaloNo ratings yet

- Federal Public & Community Defenders Legislative CommitteeDocument11 pagesFederal Public & Community Defenders Legislative CommitteeWalt PavloNo ratings yet

- Aphasia Notes by Dr. Santhosh (PW Med Ed)Document4 pagesAphasia Notes by Dr. Santhosh (PW Med Ed)Stella ParkerNo ratings yet

- Barcode UnileverDocument31 pagesBarcode UnileverDidi MardiyantoNo ratings yet

- Performance Evaluation Checklist: Republic of The Philippines Isabela State University Echague, IsabelaDocument20 pagesPerformance Evaluation Checklist: Republic of The Philippines Isabela State University Echague, IsabelaAngel CauilanNo ratings yet

- TPS 3 Pengetahuan & Pemahaman UmumDocument7 pagesTPS 3 Pengetahuan & Pemahaman UmumMedia VideoNo ratings yet

- Cover Letter For Porter Without ExperienceDocument6 pagesCover Letter For Porter Without Experienceafjwftijfbwmen100% (2)

- Sikapronto 19: Easy-To-Use, High Molecular Weight Methacrylate, Crack Healer/Penetrating SealerDocument2 pagesSikapronto 19: Easy-To-Use, High Molecular Weight Methacrylate, Crack Healer/Penetrating SealerBruno AlfanoNo ratings yet

- Final Paper - Tylenol Murders Case StudyDocument16 pagesFinal Paper - Tylenol Murders Case StudyGeorgiana TerzoglouNo ratings yet

- LP Tle RVM FormatDocument3 pagesLP Tle RVM FormatXaviery Boss EdadesNo ratings yet

- The Effects of Lack of Sex Education That Leads To Teenage Pregnancy in TVL HE E and FDocument2 pagesThe Effects of Lack of Sex Education That Leads To Teenage Pregnancy in TVL HE E and FAbra BolandoNo ratings yet

- Books 201304Document35 pagesBooks 201304Achmad HakeemNo ratings yet

- Evaluation - of - Safety - and - Health - Performance - On - Con KulaDocument11 pagesEvaluation - of - Safety - and - Health - Performance - On - Con KulaabdirahmanNo ratings yet

- Drug Name Mechanism of Action Indication / Contraindication Adverse Effect Nursing Responsibilities Indications: CnsDocument1 pageDrug Name Mechanism of Action Indication / Contraindication Adverse Effect Nursing Responsibilities Indications: CnsSeno HyeonNo ratings yet

- Mathematics: Quarter 3 - Module 4: Mutually and Non-Mutually Exclusive EventsDocument23 pagesMathematics: Quarter 3 - Module 4: Mutually and Non-Mutually Exclusive EventsSpades Of BlueNo ratings yet

- Development of An Intelligent Vital Sign Monitoring Robot SystemDocument21 pagesDevelopment of An Intelligent Vital Sign Monitoring Robot SystemAdam HansenNo ratings yet

- MSDSMaterial Safety Data Sheet Melamine Faced Boards MFF 10032015 EDocument3 pagesMSDSMaterial Safety Data Sheet Melamine Faced Boards MFF 10032015 EγNo ratings yet

- Amoxillin Glimepirid Amoxillin Metronidazol Metformin: Ambroxol Tablet Ambroxol TabletDocument10 pagesAmoxillin Glimepirid Amoxillin Metronidazol Metformin: Ambroxol Tablet Ambroxol TabletSeptia MonalisaNo ratings yet

- Lcp-Mapeh 7Document4 pagesLcp-Mapeh 7Jzaninna SolNo ratings yet