Professional Documents

Culture Documents

Inverse Four Domain Twisted Nematic Liquid Crystal Mode Generated by Photo-Alignment Method

Inverse Four Domain Twisted Nematic Liquid Crystal Mode Generated by Photo-Alignment Method

Uploaded by

陳建宏Copyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Detailed Lesson Plan in Science 10Document6 pagesA Detailed Lesson Plan in Science 10Roldan Ormilla96% (50)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Soalan Tugasan Jan 2023Document19 pagesSoalan Tugasan Jan 2023NURUL AIN BINTI RAPIAN STUDENTNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shared Reading:: The Great EightDocument1 pageShared Reading:: The Great EightursulaNo ratings yet

- A Persuasive Speech On Limiting The Production and Use of PlasticDocument2 pagesA Persuasive Speech On Limiting The Production and Use of PlasticKemberly Semaña Penton100% (1)

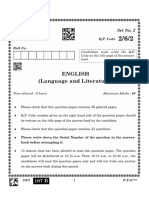

- 2 6 2 English L - LDocument16 pages2 6 2 English L - LAyush RajNo ratings yet

- KTG UpdatedDocument5 pagesKTG Updateddeejam123No ratings yet

- Maastricht University Sbe ThesisDocument5 pagesMaastricht University Sbe Thesisafknoaabc100% (2)

- Electronic Equipment 3Document4 pagesElectronic Equipment 3Dulce DeNo ratings yet

- Cambridge Mathematical Tripos 2012-2013 SchedulesDocument42 pagesCambridge Mathematical Tripos 2012-2013 SchedulesBenjaminWongNo ratings yet

- 450-Article Text-1408-1-10-20210324Document8 pages450-Article Text-1408-1-10-20210324noitoloh24No ratings yet

- The Minimum Mean Dominating Energy of GraphsDocument5 pagesThe Minimum Mean Dominating Energy of GraphsiirNo ratings yet

- REXNORD Link Belt CatalogoDocument51 pagesREXNORD Link Belt CatalogoALEXANDER FERREIRA ARENASNo ratings yet

- Pre Test in Earth and Life Science Answer KeydocxDocument2 pagesPre Test in Earth and Life Science Answer KeydocxJake UrbiNo ratings yet

- Sidiq Subandriyanto Setyawan: Statement of ParticipationDocument2 pagesSidiq Subandriyanto Setyawan: Statement of Participationsetyawan punkNo ratings yet

- Delhi Public School Secunderabad Mahendra Hills/ Nacharam / Nadergul Nursery Log Sheet-March/April 2019-2020Document3 pagesDelhi Public School Secunderabad Mahendra Hills/ Nacharam / Nadergul Nursery Log Sheet-March/April 2019-2020Khushal ChoudharyNo ratings yet

- 00 SP01 PDFDocument148 pages00 SP01 PDFAble KuriakoseNo ratings yet

- Qday7: CastorDocument1 pageQday7: CastorLiteratura esotericaNo ratings yet

- Đ1ko ĐáDocument4 pagesĐ1ko ĐábestspadNo ratings yet

- Pie Chart by Skill CountDocument3 pagesPie Chart by Skill CountHồng Thắm Nguyễn ThịNo ratings yet

- Lesson 6 Minerals and Rocks S11 12ES Ia 9Document8 pagesLesson 6 Minerals and Rocks S11 12ES Ia 9Christine CayosaNo ratings yet

- Manual Instruction For Propeller Fan (APL-APN)Document4 pagesManual Instruction For Propeller Fan (APL-APN)Adi HardiansyahNo ratings yet

- Lecture 4 - Impression MaterialsDocument44 pagesLecture 4 - Impression MaterialsMichelle Lorraine Bayan TanNo ratings yet

- Cellules À ConcentrationDocument12 pagesCellules À Concentrationmohamed ikbalNo ratings yet

- Department of Education: Republic of The PhilippinesDocument19 pagesDepartment of Education: Republic of The PhilippinesMark Nathaniel RevillaNo ratings yet

- Csc271 Exam 9Document5 pagesCsc271 Exam 9NabiLNo ratings yet

- Tech NewsletterDocument43 pagesTech NewsletterTaha AhmedNo ratings yet

- Assignment-1 CE40 NOC20 - NewDocument10 pagesAssignment-1 CE40 NOC20 - Newjayadeep ksNo ratings yet

- FST Cbse Class-X 2022-23 - Term-2 PlannerDocument2 pagesFST Cbse Class-X 2022-23 - Term-2 PlannerAbhinav KrishNo ratings yet

- QTMS Final Assessment (Spring 2020) PDFDocument6 pagesQTMS Final Assessment (Spring 2020) PDFAbdul RafayNo ratings yet

- Chapter 1 Digital Systems and Binary NumbersDocument100 pagesChapter 1 Digital Systems and Binary NumbersVandana JoshiNo ratings yet

Inverse Four Domain Twisted Nematic Liquid Crystal Mode Generated by Photo-Alignment Method

Inverse Four Domain Twisted Nematic Liquid Crystal Mode Generated by Photo-Alignment Method

Uploaded by

陳建宏Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inverse Four Domain Twisted Nematic Liquid Crystal Mode Generated by Photo-Alignment Method

Inverse Four Domain Twisted Nematic Liquid Crystal Mode Generated by Photo-Alignment Method

Uploaded by

陳建宏Copyright:

Available Formats

P-100 / S. G.

Lee

Inverse Four Domain Twisted Nematic Liquid Crystal Mode

Generated by Photo-Alignment Method

Seul Gee Lee*, Soo In Jo**, Jae-Hong Park***, Hyeokjin Lee***, Sung-Tae Shin***, You-Jin Lee*,

Chang-Jae Yu*,**, and Jae-Hoon Kim*, **

1

Department of Information Display Engineering, Hanyang University, Seoul 133-791, Korea

2

Department of Electronics and Computer Engineering, Hanyang University, Seoul 133-791, Korea

3

LCD Research Center, Samsung Electronics, Yongin, Gyeonggi 446-711, Korea

Abstract mask. So currently, non-contact techniques for LC

We fabricated an inverse four domain twisted nematic alignment are needed for application of the IFDTN mode.

(IFDTN) mode using a stacked photo-alignment layer Recently, UV2A mode is developed by K. Miyazaki and

enhancing the azimuthal anchoring energy. The strong adopted in mass production (Gen 10) using photo

anchoring energy generates the stable 4D twist structures alignment technique [4]. Similar concept was used in both

under an applying voltage. High transmittance and UV2A and IFDTN mode. However, UV2A mode shows the

contrast device is achieved without complex rubbing IFDECB structure when the electric field is on state due to

processes. the weak anchoring energy of the surface.

In this paper, we attempt to obtain IFDTN mode using

Author Keywords photo-alignment method which is non-contact technique

Twist nematic, four domain, liquid crystal display, azimuthal similar to the UV2A mode. Using stacked photo alignment

anchoring energy materials, we can increase the azimuthal anchoring energy

and thus obtain the twist structure under electric field same

1. Introduction as conventional IFDTN mode. Our device shows the high

Nowadays, liquid crystal display (LCD) has been front transmittance and wide viewing angle characteristics.

leading device among the various display devices due to its

light weight, low driving voltage, high resolution and low

fabrication cost. A lot of researches have been introduced

to overcome problems such as narrow viewing angle and

low transmittance. The twisted nematic (TN) mode is most

widely used with high transmittance, fast response time,

and low fabrication cost [1]. However, TN mode is merely

used in large size display application due to the asymmetric

viewing angle caused by the uni-directional director in

mid-plane and low contrast ratio because of strong

anchored LC molecules near the surface. For achieving the

complete dark state, Patel and Cohen reported the inverse

twisted nematic (ITN) mode using initially vertical

alignment state using chiral dopant to generate the twist

structure under electric field [2].

Multi-domain inverse TN mode is expected to be best

for obtaining not only the contrast ratio but also wide

viewing angle characteristics. In our previous research, Figure 1. The schematic diagrams of (a) initially vertical

inverse four domain TN (IFDTN) mode was proposed by alignment state, (b) IFDECB mode with weak

increasing the azimuthal anchoring energy using stacked azimuthal anchoring energy and (c) IFDTN mode with

alignment layer system as shown in Fig. 1(c) [3]. We also strong azimuthal anchoring energy

reported that the IFDTN mode shows the higher

transmittance than that of IFD electrically controlled

birefringence (IFDECB) mode due to the sharp boundary at

2. Experimental

the edge of the sub-pixel. However, we used the rubbing To obtain the photo-aligned IFDTN structure, we have to

method to generate the two different pretilt angles and this increase the surface azimuthal anchoring energy with

method is difficult to be applied to large panel fabrication stacking two different photo-alignment materials (Chisso

process due to the limitation in rubbing roller and shadow Inc.) as reported in our previous research [5]. First, planar

photo-alignment layer was deposited using spin-coating

ISSN 0097-966X/12/4303-1439-$1.00 © 2012 SID SID 2012 DIGEST • 1439

P-100 / S. G. Lee

method and baked at 210 °C for 1 h. Then, O2 plasma Figure 3 shows the measured voltage-transmittance

treatment was followed to enhance the coating property characteristics and polarized microscopic textures for

between two photo-alignment materials. After that, diluted IFDECB and IFDTN cell. The IFDECB and IFDTN cells

vertical photo-alignment layer was spin-coated onto the were obtained using only vertical photo alignment layer

planar photo-alignment layer. After full imidization, the and stacked photo alignment layers, respectively.

substrate stacked by two photo-alignment materials was

exposed to non-polarized ultra-violet (NPUV) as shown in

Fig. 2 for 30 min. The intensity of NPUV was 18 mW/cm2

at the wavelength of 365 nm. During the UV exposure

process, the substrate was tilted 45 degree from the ground

for defining the azimuthal direction by generating the

pretilt angle. As shown in Fig. 2, we used shadow mask

shifting method to generate two different domains and size

of the sub-pixel was 150 150 μm. Two substrates were

assembled in perpendicular direction which is similar to the

conventional FDTN mode [6]. The cell gap is 5.5 μm and

the MLC-6608 (E. Merck) which has negative dielectric

anisotropy was injected into the sandwiched cell at

isotropic phase.

Figure 2. The schematic diagrams of fabrication process

of the photo-aligned IFDTN mode. Red arrows and Figure 3. (a) Measured voltage-transmittance

dashed white arrows inside the figure indicate the characteristics for IFDECB and IFDTN mode. And

azimuthal direction of the LC molecules in the surface microscopic textures of the (b) IFDTN mode and (c)

IFDECB mode and (d) λ/4 plate introduced IFDTN

3. Results mode

As we already reported, sufficient surface azimuthal

anchoring energy is needed to maintain the twist structure

The transmittance of IFDECB mode using vertical

by overcoming the twist deformation energy of the LC

photo-alignment material is lower than that of IFDTN

layer with electric field. Therefore, we control the thickness

mode using stacked photo-alignment system about 19 %

of the vertical alignment layer to increase the surface

due to the splay deformation at the boundary of the sub-

azimuthal anchoring energy. And, we found that the

pixel. And, we can see the twist structure of the IFDTN

inverse twist structure was obtained at the thickness of the

cell by rotating the LC cell about 45 deg under crossed

diluted vertical photo-alignment layer below the 50 nm. We

polarizers. In this situation, the azimuthal direction of

think that azimuthal anchoring energy is increased by

the LC molecules is parallel to the one polarizer in case

decreasing the thickness of the second layer because of the

of the IFDECB cell and it shows the dark state under the

screen effect of the first layer.

crossed polarizers. However, in case of IFDTN cell, the

1440 • SID 2012 DIGEST

P-100 / S. G. Lee

transmittance characteristics are always white by 6. References

rotating the cell. And, by adopting the λ/4 plate, two [1] M. Schadt and W. Helfrich, “Voltage-dependent

different chiralities at one sub-pixel can be shown in optical activivty of a twisted nematic liquid crystal,”

Fig. 3(d). Appl. Phys. Lett. 18, 4 (1971).

[2] J. S. Patel and G. B. Cohen, “Inverse twisted nematic

4. Conclusions liquid-crystal device,” Appl. Phys. Lett. 68, 25 (1996).

We fabricated the IFDTN mode by enhancing the surface [3] S. I. Jo, S.-W. Choi, Y.-J. Lee, Y.-K. Moon, Y.-C.

azimuthal anchoring energy using staked photo-alignment Yang, C.-J. Yu, and J.-H. Kim, “Inverse four-domain

layer system. The strong azimuthal anchoring energy twisted nematic liquid crystal display fabricated by the

makes possible to generate twist structure of LCs under enhancement of azimuthal anchoring energy,” J. Appl.

applied voltage without chiral dopant and rubbing Phys. 109, 084501 (2011).

process. The fabricated IFDTN cell shows the high [4] K. Miyachi, K. Kobayashi, Y. Yamada and S.

transmittance and widely uniform viewing angle at any Mizushima, “The world’s first photo alignment LCD

direction due to the foudr domain structure. Also, using technology applied to generation ten factory,” SID 10

photo-alignment method, our proposed method is Digest 41, 579 (2010).

expected to expand to the mass-production with easy and [5] Y-J. Lee, J. S. Gwag, Y.-K. Kim, S. I. Jo, S.-G. Kang,

simple fabrication process. Y. R. Park and J.-H. Kim, “Control of liquid crystal

pretilt angle by anchoring competition of the stacked

5. Acknowledgements alignment layers,” Appl. Phys. Lett. 94, 041113 (2009).

This research was supported by a grant from Samsung [6] M. Schadt, H. Seiberle & A. Schuster, “Optical

Electronics, Co. Ltd. patterning of multi-domain liquid-crystal displays with

wide viewing angles,” Nature 381, 16 (1996).

SID 2012 DIGEST • 1441

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Detailed Lesson Plan in Science 10Document6 pagesA Detailed Lesson Plan in Science 10Roldan Ormilla96% (50)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Soalan Tugasan Jan 2023Document19 pagesSoalan Tugasan Jan 2023NURUL AIN BINTI RAPIAN STUDENTNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shared Reading:: The Great EightDocument1 pageShared Reading:: The Great EightursulaNo ratings yet

- A Persuasive Speech On Limiting The Production and Use of PlasticDocument2 pagesA Persuasive Speech On Limiting The Production and Use of PlasticKemberly Semaña Penton100% (1)

- 2 6 2 English L - LDocument16 pages2 6 2 English L - LAyush RajNo ratings yet

- KTG UpdatedDocument5 pagesKTG Updateddeejam123No ratings yet

- Maastricht University Sbe ThesisDocument5 pagesMaastricht University Sbe Thesisafknoaabc100% (2)

- Electronic Equipment 3Document4 pagesElectronic Equipment 3Dulce DeNo ratings yet

- Cambridge Mathematical Tripos 2012-2013 SchedulesDocument42 pagesCambridge Mathematical Tripos 2012-2013 SchedulesBenjaminWongNo ratings yet

- 450-Article Text-1408-1-10-20210324Document8 pages450-Article Text-1408-1-10-20210324noitoloh24No ratings yet

- The Minimum Mean Dominating Energy of GraphsDocument5 pagesThe Minimum Mean Dominating Energy of GraphsiirNo ratings yet

- REXNORD Link Belt CatalogoDocument51 pagesREXNORD Link Belt CatalogoALEXANDER FERREIRA ARENASNo ratings yet

- Pre Test in Earth and Life Science Answer KeydocxDocument2 pagesPre Test in Earth and Life Science Answer KeydocxJake UrbiNo ratings yet

- Sidiq Subandriyanto Setyawan: Statement of ParticipationDocument2 pagesSidiq Subandriyanto Setyawan: Statement of Participationsetyawan punkNo ratings yet

- Delhi Public School Secunderabad Mahendra Hills/ Nacharam / Nadergul Nursery Log Sheet-March/April 2019-2020Document3 pagesDelhi Public School Secunderabad Mahendra Hills/ Nacharam / Nadergul Nursery Log Sheet-March/April 2019-2020Khushal ChoudharyNo ratings yet

- 00 SP01 PDFDocument148 pages00 SP01 PDFAble KuriakoseNo ratings yet

- Qday7: CastorDocument1 pageQday7: CastorLiteratura esotericaNo ratings yet

- Đ1ko ĐáDocument4 pagesĐ1ko ĐábestspadNo ratings yet

- Pie Chart by Skill CountDocument3 pagesPie Chart by Skill CountHồng Thắm Nguyễn ThịNo ratings yet

- Lesson 6 Minerals and Rocks S11 12ES Ia 9Document8 pagesLesson 6 Minerals and Rocks S11 12ES Ia 9Christine CayosaNo ratings yet

- Manual Instruction For Propeller Fan (APL-APN)Document4 pagesManual Instruction For Propeller Fan (APL-APN)Adi HardiansyahNo ratings yet

- Lecture 4 - Impression MaterialsDocument44 pagesLecture 4 - Impression MaterialsMichelle Lorraine Bayan TanNo ratings yet

- Cellules À ConcentrationDocument12 pagesCellules À Concentrationmohamed ikbalNo ratings yet

- Department of Education: Republic of The PhilippinesDocument19 pagesDepartment of Education: Republic of The PhilippinesMark Nathaniel RevillaNo ratings yet

- Csc271 Exam 9Document5 pagesCsc271 Exam 9NabiLNo ratings yet

- Tech NewsletterDocument43 pagesTech NewsletterTaha AhmedNo ratings yet

- Assignment-1 CE40 NOC20 - NewDocument10 pagesAssignment-1 CE40 NOC20 - Newjayadeep ksNo ratings yet

- FST Cbse Class-X 2022-23 - Term-2 PlannerDocument2 pagesFST Cbse Class-X 2022-23 - Term-2 PlannerAbhinav KrishNo ratings yet

- QTMS Final Assessment (Spring 2020) PDFDocument6 pagesQTMS Final Assessment (Spring 2020) PDFAbdul RafayNo ratings yet

- Chapter 1 Digital Systems and Binary NumbersDocument100 pagesChapter 1 Digital Systems and Binary NumbersVandana JoshiNo ratings yet