Professional Documents

Culture Documents

Pont Bras de La Pleine La Reunion

Pont Bras de La Pleine La Reunion

Uploaded by

Tamaduianu IoanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pont Bras de La Pleine La Reunion

Pont Bras de La Pleine La Reunion

Uploaded by

Tamaduianu IoanCopyright:

Available Formats

Bras de la Plaine Bridge, Reunion Island, France

Jean-Marc Tanis, General Dir., Jean Muller International, France

Introduction

The Bras de la Plaine Bridge, situated

in the south of Reunion island, is a

single 280 m long span embedded in

counterweight abutments. The deck is

a composite truss structure compris-

ing two concrete slabs linked by two

planes of steel diagonals. The bridge

structure is a single 280 m long span

embedded in counterweight abutments.

The deck is a composite truss structure

comprising two concrete slabs linked

by two planes of steel diagonals.

After a restricted European tender

during the first half of 1999, the Bras

de la Plaine Bridge was awarded to a

Fig. 1: Bridge under completion

joint venture consortium.

– a 6 m wide bi-directional carriageway Structural Characteristics

In its bid, the Consortium eliminated

– two pedestrian pavements each 1,35 m

the articulation at the key included in Background Information

wide

the basic design and made the upper

– two cycle-paths each 1,10 m wide The structure designed to cross the

slab continuous after horizontal jack-

Bras de la Plaine ravine comprises a

ing. The connection of the steel diago- and standard BN4-type lateral safety

single 280 m long span embedded at

nals to the upper and lower slabs was barriers.

both ends in huge abutments (Fig. 3).

completely modified. The prestress in

The deck cross section is roof-shaped: At the key, only the upper slab is con-

the diagonals can be replaced. In addi-

each side slopes down with a 2,5% gra- tinuous.

tion, the abutments were reduced due to

dient (Fig. 2).

the effect of the horizontal jacking at the The deck has a constant width of

key before stitching the two halves to- Vertical Alignment 11,90 m and a depth ranging from

gether. Construction began in December 17,60 m on the abutment to 4 m at the

The vertical alignment is a convex

1999 and ended in December 2001 (Fig. 1). key. It is a composite prestressed con-

parabola with a 1500 m radius. It

crete and steel truss structure compris-

slopes down to the right bank abut-

ing:

Structure Description ment with a 1,013% gradient and to

the left bank abutment with a 5,017% – an upper slab with a constant section

Functional Characteristics and gradient. in high-performance prestressed con-

Geometry crete

Plane Alignment – a lower slab with a variable section in

Functional Cross Section The Bras de la Plaine Bridge is situat- high-performance concrete

The bridge’s functional cross section ed on a straight alignment over the – 2 planes of steel tubes arranged in

has a useful width (between the safety ravine and slightly overlaps on either V-shaped triangulation inclined at

devices) of 10,90 m which comprises: bank. about 6° off vertical.

Fig. 3: Longitudinal section

Structural Engineering International 4/2003 IABSE Outstanding Structure Award 259

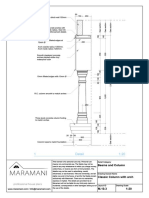

11,900 m Upper anchorage

Jacks

0,270

0,250

0,812

2,5%

0,775

Var. 17,386 a 4,050

0,735

0,850

0,

04

100

0

Var. 1,650

à 0,200

Var. 1,650

à 0,650

10 Plate

HA32 ou HA40

routing with compensated

shrinkage

0,450

Lower anchorage Plate planer view

Threaded rod, galvanized disc and nut

Fig. 4: Cross section Plate Longitudinal axis

0, Coupling

04 0,610

0

The truss mesh is a constant 12,70 m Grouting with

along the whole structure. The deck compensated HA32 ou HA40

intrados is a parabola with a radius of shrinkage

0,730

661 m (Fig. 4). Diagonal

thicknes 14,2

Abutments

The abutments consist of a reinforced

concrete box-shaped structure about 0,850

45 m long, 11,90 m wide and between

18 m and 21 m in height. This structure

has 2 compartments: Fig. 7: Prestressed diagonals connected to the slabs

– a back compartment 11 m long, filled

with ballast

The slab formwork is constant for the anchoring points. These cables are an-

– a hollow front compartment.

whole structure except around the key chored just in front of the diagonals

The invert (bottom slab) has a con- where a transverse beam enables the nodes:

stant thickness of 1 m. The side walls structure to be jacked apart (6000 t

– because, first, of the cantilevered

of the front compartment are 0,70 m horizontally at the key) before stitch-

method

thick. The side walls of the back com- ing the two cantilevers. The slabs for

– also, to equilibrate the horizontal

partment are 1 m thick. The upper slab either side will be cast successively in

tension effort transmitted by the di-

has an average thickness of 0,60 m 12,70 m long segments.

agonals on the bottom slab.

(Figs. 5 and 6).

Prestress: Lower Slab:

Deck The upper slabs of each half are pre- Like the upper slab, the lower slab is in

stressed using 12 or 19T15 super ten- B60 high-performance concrete. The

Upper Slab:

dons with an elastic strength of 1860 intrados is a parabola with a 661 m ra-

The slab is built in B60 high-perfor-

MPa. This cantilever prestressing can dius. The lower slab has variable width

mance concrete (60 MPa characteristic

be divided into internal and external and thickness so as to both:

strength at 28 days). Its total width is

prestressing.

11,90 m. The slab is of varying thick- – adapt to the transverse interval be-

ness as follows: On the deck side, the tendons are an- tween the ends of the diagonals which

chored in groups of four at the end of is variable

– 0.270 m for the cantilevers which are

each segment and then at the back of – accompany the increase in compres-

1,7 m long

the abutment. The tendons are ten- sion effort of the key towards the

– a constant 0.250 m for the central

sioned at both ends. They are disposed abutment.

part, 3,8 m long

in a plane alignment like fish bones

– 0,810 m at the ribs which are 0,850 m

and there is no vertical undulation in The section on the abutment is rectan-

wide edged by 2 gussets 0,735 m and

the slab except locally, near the deck gular: 4,120 m wide and 1,700 m high.

0,775 m wide.

Elevation

B-B section B-B section Elevation

SAPHIR water pipe

C26

C 32,973 B Construction 11,900

C27

B A

0,600 3,0132% 0,500 5,950 5,950 11,900 35,973

joint SAPHIR waterpipe

5,950 5,950 3,0119% 0,500 0,600

Struts

LEST

Struts

22,158

1000

19,794

700

1000

700 4000 LEST

4000

Construction joint

44,337

45,347

Fig. 5: Abutment C26 Fig. 6: Abutment C27

260 IABSE Outstanding Structure Award Structural Engineering International 4/2003

As it nears the key, the lower slab has The tensioned diagonals are prestressed pression efforts in the lower slab of the

the shape of an inverted cradle. The by a pair of tendons comprising be- beam and in the upper slab at the key.

section near the key is 0,200 m thick tween 10 and 17 strands. The prestress- Where the beam is embedded in the

with ribbing 0,650 m high. The lower ing anchors are situated in the upper abutments, traction efforts are gener-

slab is cast in place in 12,70 m long sec- and lower slabs (Fig. 7). ated in the upper slab.

tions (pours).

Diagonals: General Stability

The diagonals are comprised of S355

Structural Behaviour

The structure’s stability is achieved at

steel tubes. A single range of tubes

each abutment by using ballast weigh-

with an external diameter of 610 mm General Behaviour

ing 7500 t. The deadweight of the abut-

is used. Their thickness ranges from

Apart from the aesthetic aspect which ment is 7250 t whereas the deck weighs

28 mm to 36 mm for the compressed

is visible in the original architectural 4400 t on each bank (deadweight 3000 t,

diagonals and is a constant 14,2 mm

design, the new bridge over the Bras equipment 800 t, extra loads 600 t). The

for the tensioned diagonals. The dia-

de la Plaine river is an exceptional safety coefficient against overturning

gonals are welded on to rectangular

bridge structurally speaking. The struc- is 2.1 in Service Limit States and 1.6 in

plates between 55 mm and 65 mm thick.

ture functions like a variable depth War- Ultimate Limit States.

Around the upper nodes, the meeting

ren beam whose upper and lower slabs

point of the diagonals is situated at the

are the heart of an arch effect after hori- Efforts in Deck

neutral axis. The plates are fixed on to

zontal jacking and stitching at the key.

the concrete by means of screws whose Diagonals

As the arch, or lower slab, is not con-

number varies depending on whether

tinuous at the key, the positive flexion Due to the curve of the lower slab, the

the diagonals are tensioned or com-

moment in mid-span generates com- normal efforts in the diagonals are

pressed.

View B-B

In addition, the standard phasing for building a segment Elevation Cross beam back tie

(upper slab and lower slab) is: A Cross beam

Front tie

front tie

Phase 1:

Placing compressed diagonals in segment Vn.

Phase 2 :

temporary

pile frame

Reinforcing and concreting segment Vn top slab.

View A-A Temporary

B

Phase 3 : Front tie pile frame

Back tie

Connecting the compressed diagonals of segment Vn with A

concrete slabs. B

Phase 4 :

Fig. 8: Concreting of an upper slab segment

Tensioning the first pair of cantilever tendons in segment Vn.

Phase 5:

Elevation

Removing the top slab formwork of segment Vn. Cross beam Cross beam

front tie back tie Cross section

Phase 6:

Tensioning the second pair of cantilever tendons in

segment Vn.

Phase 7:

Moving the travelling form to prepare for casting the

bottom slab of segment Vn.

Phase 8:

Placing tensioned diagonals of segment Vn.

Phase 9:

Reinforcing and concreting the bottom slab of Vn segment. Fig. 9: Concreting of a lower slab segment

Phase 10:

Connecting the tensioned diagonals of segment Vn with

concrete slabs. Elevation

Cross beam Cross beam

front tie back tie

Phase 11: Truss tie

Removing the bottom slab formwork of segment Vn. Formwork tie

Phase 12:

Moving the travelling form to prepare casting of top slab of

Cross section

segment Vn+1.

Temporary

Phase 13: hanger

Prestressing the tensioned diagonals of segment Vn.

Phase 14:

Back tie

Placing compressed diagonals of segment Vn+1.

Table 1: Segment construction phase Fig. 10: Move of the bottom travelling form

Structural Engineering International 4/2003 IABSE Outstanding Structure Award 261

Fig. 11: Travelling form Fig. 12: Aerial view of bridge under construction

Deck Construction

Abutments Deck

To build the deck, two sets of travel-

B35 concrete 5437 m3 B60 concrete 2395 m 3 ling forms were designed, one for each

B60 concrete 318 m3 Average thickness 0,72 m side, each weighing 150 t. Each set of

Reinforcement 910 t Reinforcement 530 t forms casts 12,70 m of upper deck,

Ratio 158 kg/m 3

Ratio 221 kg/m3 then 12,70 m of lower deck as shown in

Figs. 8 and 9.

Internal longitudinal prestressing 158 t

External longitudinal prestressing 49 t The travelling forms are moved as fol-

lows:

Prestressing for diagonals 15 t

Steel for diagonals 201 t – upper part: drawer-like system with

Steel plates 45 t the formwork and the steel structure

successively resting on the concrete

Table 2: Principal quantities upper slab already built (Fig. 8)

– lower part: the steel structure and

the lower framework are moved as

similar in both the compressed diago- Building the Bridge indicated in Fig. 9.

nals and in the prestressed tensioned

diagonals. The compressed diagonals

bear an average effort of 600 t whereas General Site Organisation

the tensioned diagonals always remain

As access from the right bank is diffi- SEI Data Block

compressed in Static Limit States due

cult, the site was set up mainly on the

to their prestressing and the residual

left bank with a batching plant to Owner:

compression is 150 t on average. The Réunion Department, Sainte Clotilde,

produce the B35 concrete for the two

diagonals prestressing varies between France

abutments and the B60 concrete for

500 and 600 t.

the deck. Project manager

Deck (design and construction supervision):

For material supplies and concrete for

Under the effect of live loads (3.5 t/m), the right band, an elevated cableway Jean Muller International/Scetauroute,

Guyancourt, France

the arch effect of the stitched deck de- crane was set up between the two

velops the following efforts: banks. Its spans between the two py- Owner’s engineering consultancy:

lons is 415 m. The two pylons are 40 m Jean Muller International, France

– compression at the key: 570 t

high and can be inclined ±10° which Architect:

– traction of the upper slab where em-

corresponds to a horizontal movement A. Amedeo, J. Padlewski & Assoc.,

bedded at the abutment: 760 t

at the top of ±7 m. The elevated cable- Marseille, France

– compression of the lower slab where

way crane loading capacity is 8 t. Contractors:

embedded at the abutment: 1300 t.

Bouygues TP / DTP

Deflection at the key is 83 mm. Under Building the Abutments Terrassements, St-Quentin-en

the effect of the deck dilating 20°, the Yvelines, France

The walls were built in sections 6 m

structure moves vertically 214 mm at Final designs:

high and 10 m long. The upper slab

the key resulting in compression of Bouygues TP Design

was built using sacrificial slabs resting

2850 t in the upper slab and tension of Office, St-Quentin-en Yvelines, France

on a temporary support half way along

up to 300 t in the lower slab near the Sub-contractor:

the transverse span.

abutments. VSL (Prestressing), Montigny-le-

Bretonneux, France

Total cost (EUR millions): 21

Service date: 2001

262 IABSE Outstanding Structure Award Structural Engineering International 4/2003

You might also like

- Installation Manual RockfallDocument38 pagesInstallation Manual RockfallJonas Kañombi MukwatuNo ratings yet

- M50 - Design of Integral BridgesDocument7 pagesM50 - Design of Integral BridgeslovehackinggalsNo ratings yet

- Falsework CheckingDocument8 pagesFalsework Checkingdineshsirasat100% (1)

- Two Storey Hotel Building - ZafraDocument4 pagesTwo Storey Hotel Building - ZafraMonica Ann Louise IntongNo ratings yet

- CSCTC-Chapter 3Document30 pagesCSCTC-Chapter 3MộcNo ratings yet

- 142966.70 Kgs KG/SQFT KG/SQM (A) + (B) + (C) TOTAL WEIGHT: Kalinda Technical Services and Consultancy® KTSC-PROGRAM-V14.2Document1 page142966.70 Kgs KG/SQFT KG/SQM (A) + (B) + (C) TOTAL WEIGHT: Kalinda Technical Services and Consultancy® KTSC-PROGRAM-V14.2Sudhanshu PalNo ratings yet

- Comparative Study For Overead and Intze TankDocument6 pagesComparative Study For Overead and Intze TankASHOK ARJUNRAO TAYADENo ratings yet

- 01 - Connessione Beam To BeamDocument8 pages01 - Connessione Beam To BeamGinoNo ratings yet

- Behaviour of Reinforced Concrete Cantilever Slabs With OpeningDocument15 pagesBehaviour of Reinforced Concrete Cantilever Slabs With Openingلا للظلمNo ratings yet

- TALAT Lecture 2701: Bridge DeckDocument8 pagesTALAT Lecture 2701: Bridge DeckCORE MaterialsNo ratings yet

- Walif ConstructionDocument3 pagesWalif ConstructiontofikkemalNo ratings yet

- ROB PIER Open Foundation at 3 M DepthDocument51 pagesROB PIER Open Foundation at 3 M DepthSangram keshari bejaNo ratings yet

- Structural ExamDocument3 pagesStructural ExamJohnStaCruzNo ratings yet

- Design and Steel Fixing of SlabDocument5 pagesDesign and Steel Fixing of SlabErastus Kagwe Tyson Jnr100% (2)

- Hydraulic Cylinder BucklingDocument3 pagesHydraulic Cylinder Bucklingprajakt_pie100% (1)

- Restoration of A Damaged Box CulvertDocument5 pagesRestoration of A Damaged Box CulvertMalayKumarDebNo ratings yet

- I-Introduction: This System Is One of The Most Traditional System in Acrow Form Work Because It Is Multiuse SystemDocument59 pagesI-Introduction: This System Is One of The Most Traditional System in Acrow Form Work Because It Is Multiuse SystemanilNo ratings yet

- Tensile Behavior of Rubber Bearing On Bridge Models Using Proposed Model Based On Tensile Fracture ExperimentsDocument7 pagesTensile Behavior of Rubber Bearing On Bridge Models Using Proposed Model Based On Tensile Fracture ExperimentsFrancisco GoFlesNo ratings yet

- Bahar & FriendsDocument11 pagesBahar & FriendstofikkemalNo ratings yet

- Urji ConstructionDocument9 pagesUrji ConstructiontofikkemalNo ratings yet

- Narganj HP2N X 1000Document4 pagesNarganj HP2N X 1000marsplanning108No ratings yet

- Defects in Tunnel Causes and Rectification: by Chief engineer/C/North Northern RailwayDocument27 pagesDefects in Tunnel Causes and Rectification: by Chief engineer/C/North Northern RailwaySangrah MauryaNo ratings yet

- Proposed Residential For MR GitauDocument30 pagesProposed Residential For MR GitauBob MbuguaNo ratings yet

- M.10.3 Classic Column With ArchDocument1 pageM.10.3 Classic Column With ArchGkou DojkuNo ratings yet

- SIDE ARM CHARGER Design-R0 PDFDocument8 pagesSIDE ARM CHARGER Design-R0 PDFSripara Krishna100% (1)

- Sayfa Aviator 021 Abseil AnchorsDocument17 pagesSayfa Aviator 021 Abseil AnchorsCharles FernandesNo ratings yet

- Developing Reinforced Concrete Slotted Beam Structures To Reduce Earthquake Damage and To Enhance Seismic Structural PerformanceDocument10 pagesDeveloping Reinforced Concrete Slotted Beam Structures To Reduce Earthquake Damage and To Enhance Seismic Structural PerformanceAnandhuHaridasNo ratings yet

- Experimental Study On Four-Span Rahmen Bridge With Sliding-Type Seismic Isolation FoundationDocument8 pagesExperimental Study On Four-Span Rahmen Bridge With Sliding-Type Seismic Isolation FoundationLê KhánhNo ratings yet

- A SITE VISIT To Hollow ClaypotDocument9 pagesA SITE VISIT To Hollow ClaypotAyodele Oluwaseyi Dina100% (1)

- Ijbe Special Issue 2017 Diclelimilani 79 97Document20 pagesIjbe Special Issue 2017 Diclelimilani 79 97dpaulNo ratings yet

- Design: Data 12MDocument7 pagesDesign: Data 12Moz_1990No ratings yet

- Inelastic Response of Shear Links With Axial Restraints: Numerical vs. Analytical ResultsDocument6 pagesInelastic Response of Shear Links With Axial Restraints: Numerical vs. Analytical ResultsEugen MosnoiNo ratings yet

- Bridge in Cala GaldanaDocument4 pagesBridge in Cala GaldananagaNo ratings yet

- Behavior of Lap Splice Reinforcement Bars in Light Weight ConcreteDocument13 pagesBehavior of Lap Splice Reinforcement Bars in Light Weight ConcreteIdrus zlnNo ratings yet

- StaircaseDocument9 pagesStaircaseubhutada100% (2)

- Simple Way of Constructing Road BridgesDocument83 pagesSimple Way of Constructing Road BridgesJakka LakshmikanthNo ratings yet

- Hutchinson and Diederichs - 1996 Cablebolting HandbookDocument5 pagesHutchinson and Diederichs - 1996 Cablebolting HandbookOciel Silva MartinezNo ratings yet

- Bill of Quantities Riyadh - An Nakheel General Requirements Item No. Description Unit QTY Unit Price Amount SRDocument34 pagesBill of Quantities Riyadh - An Nakheel General Requirements Item No. Description Unit QTY Unit Price Amount SRmahmoud sayedNo ratings yet

- 015hara - Edited - NEWDocument6 pages015hara - Edited - NEWFilip Van den AbeeleNo ratings yet

- V08 Ketfi WEH BrdigeDocument10 pagesV08 Ketfi WEH BrdigeMutanga ShemnyNo ratings yet

- Thogoto Vocation BQDocument13 pagesThogoto Vocation BQJuancy LemaiyanNo ratings yet

- Measured Works - August - 2019 - RevisedDocument34 pagesMeasured Works - August - 2019 - RevisedFelistaNo ratings yet

- BFC 35503 - Contract & Estimation Section 4 CQI: Submission Date: 20 July 2022Document5 pagesBFC 35503 - Contract & Estimation Section 4 CQI: Submission Date: 20 July 2022yukilimNo ratings yet

- Ijciet 09 06 0241333996618920847855 PDFDocument7 pagesIjciet 09 06 0241333996618920847855 PDFYe Yeint AungNo ratings yet

- Ijciet 09 06 0241333996618920847855 PDFDocument7 pagesIjciet 09 06 0241333996618920847855 PDFYe Yeint AungNo ratings yet

- Archive of SID: Optimum Dimensions of Waffle Slab For Medium Size FloorsDocument16 pagesArchive of SID: Optimum Dimensions of Waffle Slab For Medium Size FloorsAli El AzzaouiNo ratings yet

- Geotechnical Solutions For Unstable Rock Mass at Sg. Buloh AreaDocument8 pagesGeotechnical Solutions For Unstable Rock Mass at Sg. Buloh Areajinwook75No ratings yet

- Naf 2 Bed Boq OnlyDocument22 pagesNaf 2 Bed Boq Onlyuche ekeNo ratings yet

- Percentage Boq: Validate Print HelpDocument18 pagesPercentage Boq: Validate Print HelpASRAR AHMED KHANNo ratings yet

- The Behaviour of RCC Column in A Multistorey Building 15.02.2015Document6 pagesThe Behaviour of RCC Column in A Multistorey Building 15.02.2015Ahmad AnasNo ratings yet

- 3 BemeDocument32 pages3 BemeFaroukNo ratings yet

- Section A: (Attached: BS 8110/1 CL 3.6 BS 8110/2 CL 4.2)Document21 pagesSection A: (Attached: BS 8110/1 CL 3.6 BS 8110/2 CL 4.2)Puneetkumar GargNo ratings yet

- QL Design 111 14A & 24A Spec Sheet 1980Document2 pagesQL Design 111 14A & 24A Spec Sheet 1980Alan MastersNo ratings yet

- Finite Element Analysis of Spreader Bar by Utilizing The Arrangement and Connection of PadeyesDocument21 pagesFinite Element Analysis of Spreader Bar by Utilizing The Arrangement and Connection of PadeyesrahulNo ratings yet

- A C B A C B: General NotesDocument1 pageA C B A C B: General Notesflor johnNo ratings yet

- Design&Drawing of StaircaseDocument76 pagesDesign&Drawing of Staircasepankaj DNo ratings yet

- T150mm - Beam and Blocks PDFDocument2 pagesT150mm - Beam and Blocks PDFErnie ErnieNo ratings yet

- BQ Wall Samburu - ExelDocument25 pagesBQ Wall Samburu - ExelsatejaNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Shear Variable Angle InfluenceDocument10 pagesShear Variable Angle InfluenceTamaduianu IoanNo ratings yet

- Evaluation of Nonlinear Static Procedure NSP To Estimate Seismic DeformationDocument9 pagesEvaluation of Nonlinear Static Procedure NSP To Estimate Seismic DeformationTamaduianu IoanNo ratings yet

- 15 Joetsu Shinkansen Frame ViaductDocument1 page15 Joetsu Shinkansen Frame ViaductTamaduianu IoanNo ratings yet

- Stress Distributions in Girder-Arch-Pier Connections of Long-Span Continuous Rigid Frame Arch Railway BridgesDocument7 pagesStress Distributions in Girder-Arch-Pier Connections of Long-Span Continuous Rigid Frame Arch Railway BridgesTamaduianu IoanNo ratings yet

- Balanced Cantilever Shear of SegmentsDocument10 pagesBalanced Cantilever Shear of SegmentsTamaduianu IoanNo ratings yet

- Dry Joint of Precast Bridges FEM ModelDocument12 pagesDry Joint of Precast Bridges FEM ModelTamaduianu IoanNo ratings yet

- Dry Joint Shear Key Segments Under Temperature DifferencesDocument6 pagesDry Joint Shear Key Segments Under Temperature DifferencesTamaduianu IoanNo ratings yet

- Technical Approval For MAURER Girder Grid JointsDocument42 pagesTechnical Approval For MAURER Girder Grid JointsTamaduianu IoanNo ratings yet

- Shear Strength of Dry Joints in Precast UHPC Segmental Bridges: Experimental and Theoretical ResearchDocument19 pagesShear Strength of Dry Joints in Precast UHPC Segmental Bridges: Experimental and Theoretical ResearchTamaduianu IoanNo ratings yet

- Prestressed - Structures - Basic Rules For DimensioningDocument17 pagesPrestressed - Structures - Basic Rules For DimensioningTamaduianu IoanNo ratings yet

- Catalog Precomprimare TENSACCIAIDocument40 pagesCatalog Precomprimare TENSACCIAITamaduianu IoanNo ratings yet

- Long-Span Continuous Rigid Frame Bridge Construction ControlDocument5 pagesLong-Span Continuous Rigid Frame Bridge Construction ControlTamaduianu IoanNo ratings yet

- A New Post Tensioned Continuity Detail For Super Tees BGE David MolloyDocument11 pagesA New Post Tensioned Continuity Detail For Super Tees BGE David MolloyTamaduianu IoanNo ratings yet

- Swivel Joist-Expansion Joints: (With/without Noise Reduction)Document48 pagesSwivel Joist-Expansion Joints: (With/without Noise Reduction)Tamaduianu IoanNo ratings yet

- Two-Year Deflections of The Confederation BridgeDocument11 pagesTwo-Year Deflections of The Confederation BridgeTamaduianu IoanNo ratings yet

- Reston Pendulum BearingsDocument4 pagesReston Pendulum BearingsTamaduianu IoanNo ratings yet

- Balanced Cantilever Form-Traveller Huada-Heavy-Industry ChinaDocument4 pagesBalanced Cantilever Form-Traveller Huada-Heavy-Industry ChinaTamaduianu IoanNo ratings yet

- BST500 Reinforcement Steel AgreementDocument12 pagesBST500 Reinforcement Steel AgreementTamaduianu IoanNo ratings yet

- ULMA Bridge FormworkDocument25 pagesULMA Bridge FormworkTamaduianu IoanNo ratings yet

- Oil and Natural Gas Corporation Western Offshore, Mumbai RegionDocument2 pagesOil and Natural Gas Corporation Western Offshore, Mumbai RegionVarun GuptaNo ratings yet

- Problem Set No.2 - Ultimate Stress Design (USD)Document1 pageProblem Set No.2 - Ultimate Stress Design (USD)Catherine Shaina O. PasionNo ratings yet

- 2016 Mini Buggy GK005Document1 page2016 Mini Buggy GK005clauuss81No ratings yet

- RuntechTURBO EngDocument20 pagesRuntechTURBO Engvemanreddy29No ratings yet

- Course File PagesDocument20 pagesCourse File PagesrajivNo ratings yet

- Presentation Pavement Failures 1507355219 83810Document26 pagesPresentation Pavement Failures 1507355219 83810suraj shetNo ratings yet

- Concepts of Metrology and Importance of CalibrationDocument19 pagesConcepts of Metrology and Importance of CalibrationDhruv PrajapatiNo ratings yet

- CFD 2 MidDocument2 pagesCFD 2 MidBhavani GujjariNo ratings yet

- Cargo: C3E 100R C3E 130R C3E 150RDocument224 pagesCargo: C3E 100R C3E 130R C3E 150RalexsandrNo ratings yet

- Relays and SwitchesDocument5 pagesRelays and SwitchesBattinapati ShivaNo ratings yet

- Free FallDocument7 pagesFree FallFatin Naqiya Roslan50% (2)

- MCQ PGTDocument17 pagesMCQ PGTmahajanpb2012No ratings yet

- Hoover Xarion Pro - Manual de InstruçõesDocument66 pagesHoover Xarion Pro - Manual de InstruçõesHjac CarvalhoNo ratings yet

- Spare Parts: Gun, LS373Document2 pagesSpare Parts: Gun, LS373Pandel LucianNo ratings yet

- Beltone Turn PDFDocument9 pagesBeltone Turn PDFvangelchNo ratings yet

- Rencana Anggaran Biaya (Rab) : Pekerjaan Musholla, Kanopi Curah Dari Finish Bin, Paving Block Dan Sumur TradisionalDocument10 pagesRencana Anggaran Biaya (Rab) : Pekerjaan Musholla, Kanopi Curah Dari Finish Bin, Paving Block Dan Sumur TradisionalWillie SudhantaNo ratings yet

- R E C Y C L E Purging With ReactionDocument7 pagesR E C Y C L E Purging With ReactionJoSaNo ratings yet

- Chilled Water1Document2 pagesChilled Water1lhhjklll0% (1)

- Standard Specification FOR Casing Insulators and End SealsDocument9 pagesStandard Specification FOR Casing Insulators and End Sealsresp-ectNo ratings yet

- Hoja Tecnica QJ341Document2 pagesHoja Tecnica QJ341Guillermo PaisNo ratings yet

- BZY97C12 FagorElectronicComponentsDocument5 pagesBZY97C12 FagorElectronicComponentssuppoNo ratings yet

- Deep Groove Ball BearingsDocument14 pagesDeep Groove Ball BearingsImam SuhartoNo ratings yet

- Coen445 Lab4 Socket ProgrammingDocument10 pagesCoen445 Lab4 Socket ProgrammingBansIa ShobhitNo ratings yet

- Accedian TE DatasheetDocument2 pagesAccedian TE Datasheetgates2010No ratings yet

- Phy450 ReferencesDocument40 pagesPhy450 ReferencesGiovanni Andrew DaltonNo ratings yet

- 750 - 404 Data SheetDocument1 page750 - 404 Data SheetBin MulyadinNo ratings yet

- Raspberry Pi CNC Machine - 8 Steps (With Pictures)Document12 pagesRaspberry Pi CNC Machine - 8 Steps (With Pictures)Everton Klinger Sousa SilvaNo ratings yet

- Veritas Volume ManagerDocument10 pagesVeritas Volume ManageranimeshdocNo ratings yet

- BS 5750 PDFDocument6 pagesBS 5750 PDFMZeeshanAkramNo ratings yet

- NewFunctions enDocument3 pagesNewFunctions enGeo PuiuNo ratings yet