Professional Documents

Culture Documents

Wk1 - No Load - DC Shunt Wound

Wk1 - No Load - DC Shunt Wound

Uploaded by

Chattha GCopyright:

Available Formats

You might also like

- 353 Laboratory Molecular Models Graded Activity Attempt ReviewDocument12 pages353 Laboratory Molecular Models Graded Activity Attempt ReviewJason Summat100% (1)

- Manolo Fortich Christian AcademyDocument10 pagesManolo Fortich Christian AcademyYan YanNo ratings yet

- Lab 1 Power Supply and Torque MeterDocument5 pagesLab 1 Power Supply and Torque Metermuhd danialNo ratings yet

- Experiment No. 1 The Separately Excited DC Shunt Generator: ObjectiveDocument12 pagesExperiment No. 1 The Separately Excited DC Shunt Generator: ObjectiveedwardNo ratings yet

- Simoreg Spare PartsDocument34 pagesSimoreg Spare Partsiyilmaz1No ratings yet

- Experiment 2: Speed Behavior of The Shunt-Wound DC Motor at Flux ShuntingDocument3 pagesExperiment 2: Speed Behavior of The Shunt-Wound DC Motor at Flux ShuntingChattha GNo ratings yet

- Lab6maquinas HampdenDocument5 pagesLab6maquinas HampdenJose Ricardo hernandezNo ratings yet

- Electrical Machines Lab 1 Electrical MacDocument153 pagesElectrical Machines Lab 1 Electrical MacOladimeji OluwaseunNo ratings yet

- Inverter StartupDocument55 pagesInverter StartupMahmoud AlaaNo ratings yet

- VR 448 ManualDocument8 pagesVR 448 ManualAbdul KhaliqNo ratings yet

- Machine - Lab Manual Merged PDFDocument14 pagesMachine - Lab Manual Merged PDFMubin LikhonNo ratings yet

- WT-3A Operation Manual (English)Document8 pagesWT-3A Operation Manual (English)Наталья100% (1)

- Terco MTR InduksiDocument51 pagesTerco MTR InduksiNovan A ImanNo ratings yet

- 2 Machine LabDocument4 pages2 Machine LabManoj GuptaNo ratings yet

- Date: Experiment - 2 To Study The Operation of Controlled Rectifier Fed Separately Excited DC Motor DriveDocument5 pagesDate: Experiment - 2 To Study The Operation of Controlled Rectifier Fed Separately Excited DC Motor DriveDaksh SharmaNo ratings yet

- Machines1 Exp 5Document6 pagesMachines1 Exp 5Lover BoyNo ratings yet

- EA448Document9 pagesEA448Orlando Velado100% (1)

- Circuit Diagram: U19Ee306 - Electrical Machines - I LaboratoryDocument16 pagesCircuit Diagram: U19Ee306 - Electrical Machines - I LaboratorySanthoshNo ratings yet

- 8 - Load Test On Im1Document9 pages8 - Load Test On Im1anitha paramasivamNo ratings yet

- Machine Based Experiments Lab Report-1 Name: Karthickeien E BY: CH - EN.U4CCE21024 Group: A TopicDocument14 pagesMachine Based Experiments Lab Report-1 Name: Karthickeien E BY: CH - EN.U4CCE21024 Group: A TopicKartheepan KaNo ratings yet

- Brake Test DC Series MotorDocument3 pagesBrake Test DC Series MotorVARAPRASADNo ratings yet

- Generator Automatic Voltage Regulator Operation Ea465 Generator Automatic VoltageDocument6 pagesGenerator Automatic Voltage Regulator Operation Ea465 Generator Automatic Voltagefahad pirzadaNo ratings yet

- External Characteristics of DC Shunt GeneratorDocument6 pagesExternal Characteristics of DC Shunt GeneratorSuyash SinghNo ratings yet

- Voltage RegulatorsDocument10 pagesVoltage Regulatorsahmed hassanNo ratings yet

- Motor Control Lab 1Document5 pagesMotor Control Lab 1Hnd FinalNo ratings yet

- EVC600C User Manual (English)Document6 pagesEVC600C User Manual (English)dhany reza100% (1)

- Swin Burns ARUNDocument6 pagesSwin Burns ARUNArun TezNo ratings yet

- Exp MachinesDocument8 pagesExp MachinesAngelina JolieNo ratings yet

- Lab # 7 - DC Machines Part 3 Separately Excited DC GeneratorDocument6 pagesLab # 7 - DC Machines Part 3 Separately Excited DC GeneratorAdeel SyedNo ratings yet

- Three-Phase Synchronous Generator AVR WT-2: VOLT - Potentiometer For Adjusting The OutputDocument3 pagesThree-Phase Synchronous Generator AVR WT-2: VOLT - Potentiometer For Adjusting The OutputBradNo ratings yet

- Beeel 1a2Document12 pagesBeeel 1a2Dr. S MuthukumarNo ratings yet

- C6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - VOLTAGE ADJUSTMENTSDocument5 pagesC6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - VOLTAGE ADJUSTMENTSsuperteffyNo ratings yet

- Jabalpur Engineering College, Jabalpur Electrical Engineering Department AC/DC Drives Lab. List of ExperimentDocument63 pagesJabalpur Engineering College, Jabalpur Electrical Engineering Department AC/DC Drives Lab. List of ExperimentSajalNo ratings yet

- R448 Leroy Somer Manual enDocument4 pagesR448 Leroy Somer Manual enJohn GarnetNo ratings yet

- Lab-4 - Name - IDDocument11 pagesLab-4 - Name - IDMOSAED MOSAED ALLOGMANINo ratings yet

- ELP332 SecCyc 23-24 1Document15 pagesELP332 SecCyc 23-24 1satyamsinghgour2002No ratings yet

- Speed Control of Squirrel Cage Induction Machine Using V/F ControlDocument33 pagesSpeed Control of Squirrel Cage Induction Machine Using V/F ControlbibiNo ratings yet

- Falt & AlarmDocument26 pagesFalt & Alarmpartha majiNo ratings yet

- Expt 6 The Cage Rotor Induction MotorDocument5 pagesExpt 6 The Cage Rotor Induction MotorRyan De GuzmanNo ratings yet

- Control System Lab ManualDocument52 pagesControl System Lab ManualMohammad Umar RehmanNo ratings yet

- SX460 Automatic Voltage Regulator PDFDocument5 pagesSX460 Automatic Voltage Regulator PDFArikson0% (1)

- Generators Control Panel: Service ManualDocument34 pagesGenerators Control Panel: Service Manualtopsi kretsNo ratings yet

- EEE 458 - Power System Protection LaboratoryDocument12 pagesEEE 458 - Power System Protection LaboratoryAbdullahNo ratings yet

- ELEC302 Lab10Document4 pagesELEC302 Lab10Ashik AhmedNo ratings yet

- Ac Servo MotorDocument14 pagesAc Servo MotorJeyanthNo ratings yet

- SS448 ManualDocument8 pagesSS448 ManualkikoNo ratings yet

- F700 Quick Set Up GuideDocument2 pagesF700 Quick Set Up GuideНебојша МитровићNo ratings yet

- Determining Motor EfficencyDocument4 pagesDetermining Motor EfficencyFaye FaigmaniNo ratings yet

- Lab 5Document7 pagesLab 5Yellow DashNo ratings yet

- Lab 3Document17 pagesLab 3Pinky EceNo ratings yet

- Maquinas de Corriente ContinuaDocument111 pagesMaquinas de Corriente ContinuaValentina Alzugaray BatallaNo ratings yet

- Experiment N O - 2 1: Efficiency and Losses of A DC Shunt Motor PurposeDocument8 pagesExperiment N O - 2 1: Efficiency and Losses of A DC Shunt Motor PurposeMiss BabyNo ratings yet

- Open Circuit Saturation Curve of An Alternator I. ObjectivesDocument4 pagesOpen Circuit Saturation Curve of An Alternator I. ObjectivesArnel Pamaos Lopiba MontañezNo ratings yet

- Ea440 T Manual enDocument4 pagesEa440 T Manual enArc HieNo ratings yet

- R220 Manual Macfarlane GeneratorsDocument7 pagesR220 Manual Macfarlane Generatorsabuzer1981No ratings yet

- Exercises On Electric Motors.Document11 pagesExercises On Electric Motors.Salman Muneer AhmedNo ratings yet

- Lab 1Document32 pagesLab 1Adhithyan KzhlmNo ratings yet

- Load Test On Single Phase TransformerDocument22 pagesLoad Test On Single Phase TransformerNamrajit Dey0% (1)

- Adobe Scan 17-Oct-2023Document5 pagesAdobe Scan 17-Oct-2023mehra familyNo ratings yet

- Stadyne GovornorDocument4 pagesStadyne GovornorM. ShaatNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Abnormal Psychology: Shiba Saeed Assistant Professor Govt. College, Township, LahoreDocument36 pagesAbnormal Psychology: Shiba Saeed Assistant Professor Govt. College, Township, LahoreM.Fizan JavedNo ratings yet

- How To Impress Someone at First MeetingDocument1 pageHow To Impress Someone at First MeetingMohammad Fahim HossainNo ratings yet

- 50420231021331792nav.2 Module 5Document2 pages50420231021331792nav.2 Module 5joeNo ratings yet

- A REVIEW OF SOIL ERODIBILITY Case Study of UGBOJU Settlement of OTURKPO Local Government Area of Benue State NigeriaDocument9 pagesA REVIEW OF SOIL ERODIBILITY Case Study of UGBOJU Settlement of OTURKPO Local Government Area of Benue State NigeriaTIZA MICHAEL B.Engr., BBS, MBA, Aff. M. ASCE, ASS.M. UACSE, M. IAENG. M.ITE.No ratings yet

- Architectural Documents For 3 Storey Residential HouseDocument26 pagesArchitectural Documents For 3 Storey Residential HouseArvin EmraNo ratings yet

- BỘ ĐỀ IELTS SPEAKING QUÝ 1-2023Document14 pagesBỘ ĐỀ IELTS SPEAKING QUÝ 1-2023phuongNo ratings yet

- OS101 ReviewerDocument3 pagesOS101 ReviewerMimi DamascoNo ratings yet

- MobilityDocument46 pagesMobilityDipen SoniNo ratings yet

- TrabDocument3 pagesTrabwilliam.123No ratings yet

- DB2 V9 Application Programming&SQL Guide Dsnapk13Document1,157 pagesDB2 V9 Application Programming&SQL Guide Dsnapk13Sergio MolinaNo ratings yet

- Abella The Tagalog Variety of Nueva EcijaDocument39 pagesAbella The Tagalog Variety of Nueva EcijaFeed Back ParNo ratings yet

- Berkeleyme - CIMA Executive ProgramDocument22 pagesBerkeleyme - CIMA Executive ProgramMuhammad NaeemNo ratings yet

- Calcul Ating T He Co ST O F CapitalDocument50 pagesCalcul Ating T He Co ST O F CapitalSyrell NaborNo ratings yet

- How To Create and Play Kahoot!Document15 pagesHow To Create and Play Kahoot!Sri Raman NairNo ratings yet

- Perbandingan Harga BhinekaDocument4 pagesPerbandingan Harga BhinekaJulio MariscalNo ratings yet

- Kao LC - Portafolio de ProductosDocument2 pagesKao LC - Portafolio de ProductosBadri Rached100% (1)

- Polymerization of Vegetable Oils and Their Uses in Printing InksDocument4 pagesPolymerization of Vegetable Oils and Their Uses in Printing InksJosé Antônio Nascimento NetoNo ratings yet

- Waves and Sound WorksheetDocument12 pagesWaves and Sound WorksheetprosenNo ratings yet

- Assignment 6 On Python: Simulations: March 6, 2018Document5 pagesAssignment 6 On Python: Simulations: March 6, 2018Vinayak Nishant Gudipaty ee19b129No ratings yet

- Horizontal Steam Sterilizer V2Document12 pagesHorizontal Steam Sterilizer V2SujiNo ratings yet

- Asme Code PresntDocument41 pagesAsme Code PresntPrasanth PadmanabhanNo ratings yet

- Design of Sequential Circuits - Example 1.3Document3 pagesDesign of Sequential Circuits - Example 1.3MD Saifuzzaman SohanNo ratings yet

- Aerospace Dynamics BrochureDocument4 pagesAerospace Dynamics BrochureAdriana Daniela SanduNo ratings yet

- Decribing Connections Between Historical EventsDocument4 pagesDecribing Connections Between Historical Eventsapi-334916201No ratings yet

- Verben Tabelle ADocument18 pagesVerben Tabelle Abechir jlaielNo ratings yet

- Almonte HistoryDocument3 pagesAlmonte HistoryAngelo ErispeNo ratings yet

- Cadence Vol 23Document38 pagesCadence Vol 23api-3709957No ratings yet

Wk1 - No Load - DC Shunt Wound

Wk1 - No Load - DC Shunt Wound

Uploaded by

Chattha GOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wk1 - No Load - DC Shunt Wound

Wk1 - No Load - DC Shunt Wound

Uploaded by

Chattha GCopyright:

Available Formats

The shunt-wound DC machine

1 Experiments with the Shunt-wound DC Motor

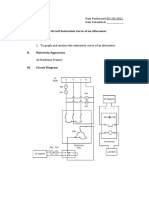

❒ Experiment 1a: Commissioning of the shunt-wound DC machine

Experimental purpose:

Operate the shunt-wound machine as a motor.

Necessary equipment:

- Shunt-wound DC Machine (Type 2701)

- Brake Unit (Type 2719)

- Control Unit (Type 2730)

- Universal Power Supply (Type 2740)

- 2 multimeters

Experimental setup:

Control Unit (Type 2 7 3 0 ) Universal Power Supply

(Type 2 7 4 0 )

armature field

0 ... 250 V 205 V

P1 P2 TK PE PE + - - +

IA A

UA

A1

PE TK PE

P1 P2

E2 E1

M

3 T M

x

Shunt-wound

DC Machine

Brake U nit (Type 2 7 1 9 ) (Ty pe 2 7 0 1 ) A2

Fig. 1.1 Experimental setup: Commissioning of the shunt-wound machine

The shunt-wound DC machine

Experimental procedure:

Observe the safety instructions! Make the following settings on the Control Unit:

Push the experimental machine onto the Brake Unit - Observe the setting of the torque attenuator. See chap-

and couple it to the braking machine. ter 2.4.

Direction for use: - speed-preselection switch to range of previously noted

Adjust the adapter feet so that the experimental ma- speed (3600 rpm)

chine and the braking machine are on one axis! - direction-of-rotation switch to direction of rotation noted

before

Fix the experimental machine by pulling the clamping

lever towards the braking machine. Check the direction of rotation of the braking machine.

R/L switch to R for right-hand rotation; LED for right-

Set up the experiment as shown in Fig. 1.1.

hand rotation must light.

Direction for use:

Direction for use:

In order to monitor the armature current and the arma-

The braking machine rotates in the opposite direction of

ture voltage it is recommendable to use an ampere-

rotation to that displayed on the Control Unit. To ensure

meter (measuring range: 10 A) and a voltmeter (meas-

that the experimental machine turns to the right direc-

uring range: 300 V DC).

tion, the braking machine must turn to the opposite di-

Set the operation mode MANUAL and ,,internal“ input rection. The direction of rotation setting on the Control Unit

on the Control Unit. always refers to the experimental machine.

Switch on the Control Unit. Start the braking machine by briefly pressing the

START/STOP key.

Check whether armature voltage, field voltage and pro-

tective-earth conductor (PE) of the Universal Power Compare the displayed speed with the previously noted

Supply are connected correctly to the experimental ma- one and adjust it if necessary with the setpoint poten-

chine. tiometer.

Turn the potentiometer for the armature voltage to the Direction for use:

left stop (0 V). For an accurate setting of speed and torque the voltage

values can be measured additionally at the jacks pro-

Switch on the Universal Power Supply and check if the

vided.

field voltage applies at the experimental machine (green

LED lights). Switch on the Universal Power Supply. The speed

should now have its rated value. Correct the speed with

Now increase the armature voltage until the rated

the setpoint potentiometer if necessary.

speed of the machine (2000 rpm) is reached.

To finish the experiment first switch off the Universal

Note the direction of rotation of the experimental ma-

Power Supply and then the Control Unit.

chine.

direction of rotation: . . .

Switch off the Universal Power Supply.

The shunt-wound DC machine

❒ Experiment 1b: No-load characteristic of the shunt-wound DC motor

Experimental purpose:

Determine the speed behavior of the separately excited shunt-wound DC motor depending on the armature voltage. To do this determine the no-load

characteristic n = f (UA).

Necessary equipment:

- Shunt-wound DC Machine (Type 2701)

- Brake Unit (Type 2719)

- Control Unit (Type 2730)

- Universal Power Supply (Type 2740)

- 2 multimeters

Experimental setup:

Control Unit (Type 2 7 3 0 ) Universal Power Supply

(Type 2 7 4 0 )

armature field

0 ... 250 V 205 V

P1 P2 TK PE PE + - - +

IA A

UA

A1

PE TK PE

P1 P2

E2 E1

M

3 T M

x

Shunt-wound

DC Machine

Brake U nit (Type 2 7 1 9 ) (Ty pe 2 7 0 1 ) A2

Fig. 1.2 Experimental setup: No-load characteristic of the shunt-wound DC motor

The shunt-wound DC machine

Experimental procedure:

Observe the safety instructions!

Attention!

Set up the experiment as shown in Fig. 1.2.

Make sure that the exciting winding is connected

Start up the system as already described in experiment 1. with the correct polarity!

Observe the setting of the torque attenuator.

Make sure that the exciting voltage is never inter-

Make sure that the field voltage is connected to the ex- rupted during operation!

citing winding.

Set the armature voltage to the left stop (0 V).

Set the armature voltages asked for in Table 1.1 and First switch off the Universal Power Supply and then

measure the speed n. the Control Unit.

Measure the armature current and the armature voltage Draw the no-load characteristic in the prepared dia-

at rated speed. gram Fig. 1.3. Determine the scale for UA yourself.

=... . . . A, U =... .V

IA A

UA / V 25 50 75 100 125 150 175 200 205

n / rpm

Table 1.1 Speed

n /rpm

2000

1500

1000

500

0 Fig. 1.3 No-load character-

U A/V istic of the shunt-wound motor

The shunt-wound DC machine

Evaluation:

Question 1: Question 2:

What do you learn from the no-load characteristic in Fig. How high is the power consumed by the armature wind-

1.3? ing at rated speed?

Answer: Calculation:

You might also like

- 353 Laboratory Molecular Models Graded Activity Attempt ReviewDocument12 pages353 Laboratory Molecular Models Graded Activity Attempt ReviewJason Summat100% (1)

- Manolo Fortich Christian AcademyDocument10 pagesManolo Fortich Christian AcademyYan YanNo ratings yet

- Lab 1 Power Supply and Torque MeterDocument5 pagesLab 1 Power Supply and Torque Metermuhd danialNo ratings yet

- Experiment No. 1 The Separately Excited DC Shunt Generator: ObjectiveDocument12 pagesExperiment No. 1 The Separately Excited DC Shunt Generator: ObjectiveedwardNo ratings yet

- Simoreg Spare PartsDocument34 pagesSimoreg Spare Partsiyilmaz1No ratings yet

- Experiment 2: Speed Behavior of The Shunt-Wound DC Motor at Flux ShuntingDocument3 pagesExperiment 2: Speed Behavior of The Shunt-Wound DC Motor at Flux ShuntingChattha GNo ratings yet

- Lab6maquinas HampdenDocument5 pagesLab6maquinas HampdenJose Ricardo hernandezNo ratings yet

- Electrical Machines Lab 1 Electrical MacDocument153 pagesElectrical Machines Lab 1 Electrical MacOladimeji OluwaseunNo ratings yet

- Inverter StartupDocument55 pagesInverter StartupMahmoud AlaaNo ratings yet

- VR 448 ManualDocument8 pagesVR 448 ManualAbdul KhaliqNo ratings yet

- Machine - Lab Manual Merged PDFDocument14 pagesMachine - Lab Manual Merged PDFMubin LikhonNo ratings yet

- WT-3A Operation Manual (English)Document8 pagesWT-3A Operation Manual (English)Наталья100% (1)

- Terco MTR InduksiDocument51 pagesTerco MTR InduksiNovan A ImanNo ratings yet

- 2 Machine LabDocument4 pages2 Machine LabManoj GuptaNo ratings yet

- Date: Experiment - 2 To Study The Operation of Controlled Rectifier Fed Separately Excited DC Motor DriveDocument5 pagesDate: Experiment - 2 To Study The Operation of Controlled Rectifier Fed Separately Excited DC Motor DriveDaksh SharmaNo ratings yet

- Machines1 Exp 5Document6 pagesMachines1 Exp 5Lover BoyNo ratings yet

- EA448Document9 pagesEA448Orlando Velado100% (1)

- Circuit Diagram: U19Ee306 - Electrical Machines - I LaboratoryDocument16 pagesCircuit Diagram: U19Ee306 - Electrical Machines - I LaboratorySanthoshNo ratings yet

- 8 - Load Test On Im1Document9 pages8 - Load Test On Im1anitha paramasivamNo ratings yet

- Machine Based Experiments Lab Report-1 Name: Karthickeien E BY: CH - EN.U4CCE21024 Group: A TopicDocument14 pagesMachine Based Experiments Lab Report-1 Name: Karthickeien E BY: CH - EN.U4CCE21024 Group: A TopicKartheepan KaNo ratings yet

- Brake Test DC Series MotorDocument3 pagesBrake Test DC Series MotorVARAPRASADNo ratings yet

- Generator Automatic Voltage Regulator Operation Ea465 Generator Automatic VoltageDocument6 pagesGenerator Automatic Voltage Regulator Operation Ea465 Generator Automatic Voltagefahad pirzadaNo ratings yet

- External Characteristics of DC Shunt GeneratorDocument6 pagesExternal Characteristics of DC Shunt GeneratorSuyash SinghNo ratings yet

- Voltage RegulatorsDocument10 pagesVoltage Regulatorsahmed hassanNo ratings yet

- Motor Control Lab 1Document5 pagesMotor Control Lab 1Hnd FinalNo ratings yet

- EVC600C User Manual (English)Document6 pagesEVC600C User Manual (English)dhany reza100% (1)

- Swin Burns ARUNDocument6 pagesSwin Burns ARUNArun TezNo ratings yet

- Exp MachinesDocument8 pagesExp MachinesAngelina JolieNo ratings yet

- Lab # 7 - DC Machines Part 3 Separately Excited DC GeneratorDocument6 pagesLab # 7 - DC Machines Part 3 Separately Excited DC GeneratorAdeel SyedNo ratings yet

- Three-Phase Synchronous Generator AVR WT-2: VOLT - Potentiometer For Adjusting The OutputDocument3 pagesThree-Phase Synchronous Generator AVR WT-2: VOLT - Potentiometer For Adjusting The OutputBradNo ratings yet

- Beeel 1a2Document12 pagesBeeel 1a2Dr. S MuthukumarNo ratings yet

- C6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - VOLTAGE ADJUSTMENTSDocument5 pagesC6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - VOLTAGE ADJUSTMENTSsuperteffyNo ratings yet

- Jabalpur Engineering College, Jabalpur Electrical Engineering Department AC/DC Drives Lab. List of ExperimentDocument63 pagesJabalpur Engineering College, Jabalpur Electrical Engineering Department AC/DC Drives Lab. List of ExperimentSajalNo ratings yet

- R448 Leroy Somer Manual enDocument4 pagesR448 Leroy Somer Manual enJohn GarnetNo ratings yet

- Lab-4 - Name - IDDocument11 pagesLab-4 - Name - IDMOSAED MOSAED ALLOGMANINo ratings yet

- ELP332 SecCyc 23-24 1Document15 pagesELP332 SecCyc 23-24 1satyamsinghgour2002No ratings yet

- Speed Control of Squirrel Cage Induction Machine Using V/F ControlDocument33 pagesSpeed Control of Squirrel Cage Induction Machine Using V/F ControlbibiNo ratings yet

- Falt & AlarmDocument26 pagesFalt & Alarmpartha majiNo ratings yet

- Expt 6 The Cage Rotor Induction MotorDocument5 pagesExpt 6 The Cage Rotor Induction MotorRyan De GuzmanNo ratings yet

- Control System Lab ManualDocument52 pagesControl System Lab ManualMohammad Umar RehmanNo ratings yet

- SX460 Automatic Voltage Regulator PDFDocument5 pagesSX460 Automatic Voltage Regulator PDFArikson0% (1)

- Generators Control Panel: Service ManualDocument34 pagesGenerators Control Panel: Service Manualtopsi kretsNo ratings yet

- EEE 458 - Power System Protection LaboratoryDocument12 pagesEEE 458 - Power System Protection LaboratoryAbdullahNo ratings yet

- ELEC302 Lab10Document4 pagesELEC302 Lab10Ashik AhmedNo ratings yet

- Ac Servo MotorDocument14 pagesAc Servo MotorJeyanthNo ratings yet

- SS448 ManualDocument8 pagesSS448 ManualkikoNo ratings yet

- F700 Quick Set Up GuideDocument2 pagesF700 Quick Set Up GuideНебојша МитровићNo ratings yet

- Determining Motor EfficencyDocument4 pagesDetermining Motor EfficencyFaye FaigmaniNo ratings yet

- Lab 5Document7 pagesLab 5Yellow DashNo ratings yet

- Lab 3Document17 pagesLab 3Pinky EceNo ratings yet

- Maquinas de Corriente ContinuaDocument111 pagesMaquinas de Corriente ContinuaValentina Alzugaray BatallaNo ratings yet

- Experiment N O - 2 1: Efficiency and Losses of A DC Shunt Motor PurposeDocument8 pagesExperiment N O - 2 1: Efficiency and Losses of A DC Shunt Motor PurposeMiss BabyNo ratings yet

- Open Circuit Saturation Curve of An Alternator I. ObjectivesDocument4 pagesOpen Circuit Saturation Curve of An Alternator I. ObjectivesArnel Pamaos Lopiba MontañezNo ratings yet

- Ea440 T Manual enDocument4 pagesEa440 T Manual enArc HieNo ratings yet

- R220 Manual Macfarlane GeneratorsDocument7 pagesR220 Manual Macfarlane Generatorsabuzer1981No ratings yet

- Exercises On Electric Motors.Document11 pagesExercises On Electric Motors.Salman Muneer AhmedNo ratings yet

- Lab 1Document32 pagesLab 1Adhithyan KzhlmNo ratings yet

- Load Test On Single Phase TransformerDocument22 pagesLoad Test On Single Phase TransformerNamrajit Dey0% (1)

- Adobe Scan 17-Oct-2023Document5 pagesAdobe Scan 17-Oct-2023mehra familyNo ratings yet

- Stadyne GovornorDocument4 pagesStadyne GovornorM. ShaatNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Abnormal Psychology: Shiba Saeed Assistant Professor Govt. College, Township, LahoreDocument36 pagesAbnormal Psychology: Shiba Saeed Assistant Professor Govt. College, Township, LahoreM.Fizan JavedNo ratings yet

- How To Impress Someone at First MeetingDocument1 pageHow To Impress Someone at First MeetingMohammad Fahim HossainNo ratings yet

- 50420231021331792nav.2 Module 5Document2 pages50420231021331792nav.2 Module 5joeNo ratings yet

- A REVIEW OF SOIL ERODIBILITY Case Study of UGBOJU Settlement of OTURKPO Local Government Area of Benue State NigeriaDocument9 pagesA REVIEW OF SOIL ERODIBILITY Case Study of UGBOJU Settlement of OTURKPO Local Government Area of Benue State NigeriaTIZA MICHAEL B.Engr., BBS, MBA, Aff. M. ASCE, ASS.M. UACSE, M. IAENG. M.ITE.No ratings yet

- Architectural Documents For 3 Storey Residential HouseDocument26 pagesArchitectural Documents For 3 Storey Residential HouseArvin EmraNo ratings yet

- BỘ ĐỀ IELTS SPEAKING QUÝ 1-2023Document14 pagesBỘ ĐỀ IELTS SPEAKING QUÝ 1-2023phuongNo ratings yet

- OS101 ReviewerDocument3 pagesOS101 ReviewerMimi DamascoNo ratings yet

- MobilityDocument46 pagesMobilityDipen SoniNo ratings yet

- TrabDocument3 pagesTrabwilliam.123No ratings yet

- DB2 V9 Application Programming&SQL Guide Dsnapk13Document1,157 pagesDB2 V9 Application Programming&SQL Guide Dsnapk13Sergio MolinaNo ratings yet

- Abella The Tagalog Variety of Nueva EcijaDocument39 pagesAbella The Tagalog Variety of Nueva EcijaFeed Back ParNo ratings yet

- Berkeleyme - CIMA Executive ProgramDocument22 pagesBerkeleyme - CIMA Executive ProgramMuhammad NaeemNo ratings yet

- Calcul Ating T He Co ST O F CapitalDocument50 pagesCalcul Ating T He Co ST O F CapitalSyrell NaborNo ratings yet

- How To Create and Play Kahoot!Document15 pagesHow To Create and Play Kahoot!Sri Raman NairNo ratings yet

- Perbandingan Harga BhinekaDocument4 pagesPerbandingan Harga BhinekaJulio MariscalNo ratings yet

- Kao LC - Portafolio de ProductosDocument2 pagesKao LC - Portafolio de ProductosBadri Rached100% (1)

- Polymerization of Vegetable Oils and Their Uses in Printing InksDocument4 pagesPolymerization of Vegetable Oils and Their Uses in Printing InksJosé Antônio Nascimento NetoNo ratings yet

- Waves and Sound WorksheetDocument12 pagesWaves and Sound WorksheetprosenNo ratings yet

- Assignment 6 On Python: Simulations: March 6, 2018Document5 pagesAssignment 6 On Python: Simulations: March 6, 2018Vinayak Nishant Gudipaty ee19b129No ratings yet

- Horizontal Steam Sterilizer V2Document12 pagesHorizontal Steam Sterilizer V2SujiNo ratings yet

- Asme Code PresntDocument41 pagesAsme Code PresntPrasanth PadmanabhanNo ratings yet

- Design of Sequential Circuits - Example 1.3Document3 pagesDesign of Sequential Circuits - Example 1.3MD Saifuzzaman SohanNo ratings yet

- Aerospace Dynamics BrochureDocument4 pagesAerospace Dynamics BrochureAdriana Daniela SanduNo ratings yet

- Decribing Connections Between Historical EventsDocument4 pagesDecribing Connections Between Historical Eventsapi-334916201No ratings yet

- Verben Tabelle ADocument18 pagesVerben Tabelle Abechir jlaielNo ratings yet

- Almonte HistoryDocument3 pagesAlmonte HistoryAngelo ErispeNo ratings yet

- Cadence Vol 23Document38 pagesCadence Vol 23api-3709957No ratings yet