Professional Documents

Culture Documents

QAP For Painting Works

QAP For Painting Works

Uploaded by

Ranjan KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QAP For Painting Works

QAP For Painting Works

Uploaded by

Ranjan KumarCopyright:

Available Formats

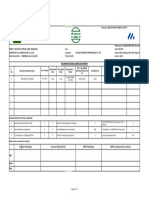

NARMADA OFFSHORE CONSTRUCTIONS PVT.

LTD

CLIENT: IDEMITSU LUBE INDIA PVT LTD.

QUALITY ASSURANCE PLAN FOR STRUCTURAL & PIPING PAINTING WORKS

DOCUMENT NO.:W467-NOCPL-SPP-QAP-001

VERIFYING

S.NO. ACTIVITY COVERAGE CONTROL REQUIREMENTS SUB-CONTRACTOR NOCPL ILIN REMARKS

DOCUMENT

1 SCAFFOLDING :

* Pipes Shall in good condition.

* Red Oxide shall be applied on all pipes.

a. Inspection of Scaffolding Pipes Physical Inspection IR P P W

* Clamps shall be checked and shall be good

condition.

Thickness Verification of Verification with * Thickness verification by Vernier Caliper.

b. IR P P W

Scaffolding Pipes. Vernier Caliper * Thickness of Pipes shall be in acceptable limit.

* Installation shall be done as per HSE Norms &

c. Installation of Scaffolding Pipes IR P P W

ILIN Specification.

Inspection of Scaffolding & Physical Inspection, * Scaffolding Inspection shall be done by NOCPL HSE

d. Scaffolding tagging (Green, Inspection Report, officer and subsequently by ILIN HSE TAGGING P P W

Yellow or Red) Checklist & Tagging Officer.Accordingly Tagging shall be done.

* TC of Material shall be verified.

Material Test

2 Raw Material Inspection * Batch No.or Sr. No. of Material shall match with nos. MTC P P W

Certificates

mentioned on TC.

3 Site Identification Physical Identification * Area for Painting works to be Identified. W W P

4 Water Jetting Pump

* PRV shall be in good condition and shall have valid Calibration

a. Pressure Relief Valve Document Verification P P R

calibration certificate. Certificate

* Hydrostatic Test Report shall submitted to ILIN for Hydrostatic

b. Flexible Hose Document Verification P P R

review & approval. Test Report

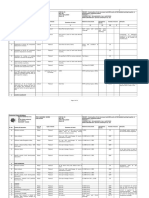

NARMADA OFFSHORE CONSTRUCTIONS PVT. LTD

CLIENT: IDEMITSU LUBE INDIA PVT LTD.

QUALITY ASSURANCE PLAN FOR STRUCTURAL & PIPING PAINTING WORKS

DOCUMENT NO.:W467-NOCPL-SPP-QAP-001

VERIFYING

S.NO. ACTIVITY COVERAGE CONTROL REQUIREMENTS SUB-CONTRACTOR NOCPL ILIN REMARKS

DOCUMENT

* Fitness Certificate for Water Jetting Pump shall be Fitness

c. Water Jetting Pump Document Verification P P R

submitted to ILIN. Certificate

Physical

d. Water Jetting Operation * Shall be done at a pressure of 2000-5000 PSI. P P RW

Verification

5 Painting

* Solvent Cleaning to remove oil from surface(if

required). OR

* St2- Manual Cleaning by Emry Paper. OR

a. Surface Preparation Physical Verification * St3- Power Tool cleaning by Grinding M/c (Using IR P P RW

Buffing Wheel )

* Area shall be free for dust, oil, grease or any other

contamination.

6 Water Jetting Operation

Water Jetting for cleaning of

a. Physical Verification * Water Jetting for all structural steel & Piping. IR P P RW

structural steel & Piping

* Location where water jetting is not possible water

b. Water Mopping Physical Verification IR P P RW

mopping shall be done.

* Shall be done when humidity is less than 85% only

Primer Application

b. Physical Verification * During application WFT shall be checked. IR P P RW

(Sigmacover 620)

* WFT Shall be in between 125-150microns.

* Surface abrading shall be done with emry paper to

Intermediate Coat remove contaminants.

c. Physical Verification IR P P RW

(Sigmacover 620) * Cotton waste shall be used to remove dust particles.

* WFT Shall be in between 140-150 microns.

* Surface abrading shall be done with emry paper to

Final Coat

d. Physical Verification remove overspray, foreign particles & contaminants. IR P P RW

(Sigmadur 550)

* WFT Shall be in between 95-102 microns.

NARMADA OFFSHORE CONSTRUCTIONS PVT. LTD

CLIENT: IDEMITSU LUBE INDIA PVT LTD.

QUALITY ASSURANCE PLAN FOR STRUCTURAL & PIPING PAINTING WORKS

DOCUMENT NO.:W467-NOCPL-SPP-QAP-001

VERIFYING

S.NO. ACTIVITY COVERAGE CONTROL REQUIREMENTS SUB-CONTRACTOR NOCPL ILIN REMARKS

DOCUMENT

* Visual Inspection of Painting

* Colour Shade verification

* Dust Particles shall be removed by using cotton

e. Final Inspection of Painting Physical Verification IR P P RW

waste.

* DFT shall be checked after drying of final coat &

thickness range shall be in between 220-260microns.

LEGENDS :

MTC : Material Test Certificate R : Review

IR : Inspection Report RW : Random Witness

P : Perform WFT : Wet Film Thickness

W : Witness DFT : Dry Film Thickness

FOR NOCPL FOR ILIN

SIGN: SIGN:

NAME: NAME:

DATE: DATE:

You might also like

- Packing Procedure (STEEL STRUCTURE)Document20 pagesPacking Procedure (STEEL STRUCTURE)Abdulrahman AlnasharNo ratings yet

- Dimensional Inspection ProcedureDocument3 pagesDimensional Inspection ProcedureWalter Unabia Rendon100% (5)

- ANSI ISA-88.00.03-2003, Batch Control Part 3.en PDFDocument82 pagesANSI ISA-88.00.03-2003, Batch Control Part 3.en PDFVulcan. LinNo ratings yet

- Audit Checklist - Blasting Painting1Document6 pagesAudit Checklist - Blasting Painting1Angel Angeleye100% (4)

- Itp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Document24 pagesItp For Aboveground Piping Metallic (Fabrication, Erection, Installation and Pressure Testing)Rakhesh Rajeevan100% (3)

- QIR 121 Bolts Torque ReportDocument1 pageQIR 121 Bolts Torque ReportSamer BayatiNo ratings yet

- Painting RecordDocument1 pagePainting RecordHimawan Setyarso100% (1)

- Zinc Plating Reports 01Document2 pagesZinc Plating Reports 01Amandeep Singh100% (2)

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- Welders Continuity Log: Name Welder ID ProcessDocument4 pagesWelders Continuity Log: Name Welder ID ProcessMacelNo ratings yet

- 000-A-Ee-0190470 Rev1 Painting Repair ProcedureDocument34 pages000-A-Ee-0190470 Rev1 Painting Repair Procedureonur gunes100% (2)

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Joint Coating Application & Pipe Coating Procedure-009-RappDocument8 pagesJoint Coating Application & Pipe Coating Procedure-009-Rappgst ajahNo ratings yet

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriNo ratings yet

- Equipment Data Record Analyzer Transmitter: AIT-100 VRU 100 H2S DetectionDocument57 pagesEquipment Data Record Analyzer Transmitter: AIT-100 VRU 100 H2S DetectionFedilino P. Fornolles100% (1)

- Software Testing Class 2Document34 pagesSoftware Testing Class 2mujahadahNo ratings yet

- Project Quality PlanDocument55 pagesProject Quality Plansamer8saif80% (5)

- MDSAP AU P0002.004 Audit Model PDFDocument81 pagesMDSAP AU P0002.004 Audit Model PDFCarolina MolfinoNo ratings yet

- Painting Procedure GlobalDocument15 pagesPainting Procedure GlobalUbed KudachiNo ratings yet

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDocument3 pagesBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNo ratings yet

- 07blasting and Painting ReportDocument2 pages07blasting and Painting ReportVenkateswaraRaoNo ratings yet

- Daily Paint ReportDocument2 pagesDaily Paint Reportcarey stewart100% (3)

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- QA-R-12 Calibration History CardDocument1 pageQA-R-12 Calibration History CardRaja DuraiNo ratings yet

- Peneterant Testing For NDT Procedure Details LatestDocument7 pagesPeneterant Testing For NDT Procedure Details LatestAlam MD SazidNo ratings yet

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryNo ratings yet

- Paint Coating Stainless SteelsDocument2 pagesPaint Coating Stainless SteelsSilva NumaNo ratings yet

- Fit-Up Inspection ReportDocument27 pagesFit-Up Inspection ReportAlfian ImaduddinNo ratings yet

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- ITP Blasting Painting.Document2 pagesITP Blasting Painting.mohd as shahiddin jafri100% (5)

- Audit Checklist Blasting PaintingDocument4 pagesAudit Checklist Blasting PaintingEyoh EffiongNo ratings yet

- Painting Report TemplateDocument1 pagePainting Report TemplateFrancisco Ona Amponin Jr.0% (1)

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel Ndifon100% (1)

- PP1-2M90-1043-007 - B - Inspection Test Procedure - CODE BDocument11 pagesPP1-2M90-1043-007 - B - Inspection Test Procedure - CODE Bfreeman11072000No ratings yet

- External Pipe Wrapping - Inspection and Test Plan: Description of LocationDocument2 pagesExternal Pipe Wrapping - Inspection and Test Plan: Description of LocationDavidNo ratings yet

- BIX - RT ProcedureDocument36 pagesBIX - RT ProcedureEduard Abastillas100% (1)

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- F-Qa-03 Material Inspection ReportDocument2 pagesF-Qa-03 Material Inspection ReportHilal mohamedNo ratings yet

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- Ins-P-021, Long Seam Set UpDocument4 pagesIns-P-021, Long Seam Set UpDeepak100% (1)

- Painting Inspection ReportDocument1 pagePainting Inspection Reportعبداللة العبداللةNo ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- SSE-QC-ELE - 500 - Incoming Material Inspection Report PDFDocument1 pageSSE-QC-ELE - 500 - Incoming Material Inspection Report PDFBhalsingh JangraNo ratings yet

- Pt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesDocument0 pagesPt. Alfa Valves Indonesia: Production General Process Flow Chart of ValvesZoebairNo ratings yet

- Blasting & Painting ProcedureDocument10 pagesBlasting & Painting ProcedurepraksahNo ratings yet

- FQP GeneralDocument21 pagesFQP GeneralgaladrialNo ratings yet

- SA MP LE: Company NameDocument4 pagesSA MP LE: Company NameAnonymous P8XHEXyIZLNo ratings yet

- Pickling and Passivation ProcedureDocument4 pagesPickling and Passivation ProcedureJaroslaw Konieczny0% (1)

- Scope: Painting ProcedureDocument2 pagesScope: Painting Procedureคุณพ่อน้อง บิ๊กบอสNo ratings yet

- FM-16 Material Verification RecordDocument1 pageFM-16 Material Verification RecordBleep NewsNo ratings yet

- Inar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaDocument14 pagesInar Profiles Pvt. LTD., Kotturu, Industrial Area, Visakhapatnam, Andhrapradesh, IndiaSreedhar Patnaik.MNo ratings yet

- Blasting & Painting Ops ProcedureDocument12 pagesBlasting & Painting Ops ProcedurekolaaruNo ratings yet

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- Painting Report - FormatDocument1 pagePainting Report - FormatSenthil Kumaran100% (1)

- Procedure For Wrapping & Coating Rev2Document4 pagesProcedure For Wrapping & Coating Rev2Alpesh100% (5)

- Material Rejection ReportDocument4 pagesMaterial Rejection ReportMunazar HussainNo ratings yet

- Attachment D (SAEP 316)Document1 pageAttachment D (SAEP 316)imtiazNo ratings yet

- Tightening BoltDocument10 pagesTightening Boltdoan gunawan100% (1)

- Corrective and Preventive Action On High Rejection RateDocument1 pageCorrective and Preventive Action On High Rejection RateRakeshNo ratings yet

- QC-GF-002 - Material Inspection ReportDocument2 pagesQC-GF-002 - Material Inspection ReportDarrel Espino Aranas100% (1)

- Surface Preparation & Coating Application RecordDocument2 pagesSurface Preparation & Coating Application RecordANIL PLAMOOTTILNo ratings yet

- Mfjo694 MRB 0001 IndexDocument2 pagesMfjo694 MRB 0001 IndexAkhtar Ansari100% (1)

- Qcpi 10Document2 pagesQcpi 10Hausland Const. Corp.No ratings yet

- Itp For Ug PipelineDocument3 pagesItp For Ug PipelineJustin Alwar100% (1)

- Inspection of Test Plan: Rotating EquipmentDocument7 pagesInspection of Test Plan: Rotating Equipmentzvlcar nainNo ratings yet

- Equipment ListDocument1 pageEquipment ListRanjan KumarNo ratings yet

- EPF-PPT - BenifitsDocument12 pagesEPF-PPT - BenifitsRanjan KumarNo ratings yet

- ESIC - Benifits PresentationDocument30 pagesESIC - Benifits PresentationRanjan KumarNo ratings yet

- NCC DPR Format - 090324Document7 pagesNCC DPR Format - 090324Ranjan KumarNo ratings yet

- TMT Bars TestingDocument1 pageTMT Bars TestingRanjan KumarNo ratings yet

- Mobilization - Manpower, Equip. & ConsDocument10 pagesMobilization - Manpower, Equip. & ConsRanjan KumarNo ratings yet

- ITP For ValvesDocument4 pagesITP For ValvesRanjan KumarNo ratings yet

- NCC DPR Format - 090324Document7 pagesNCC DPR Format - 090324Ranjan KumarNo ratings yet

- Instrument Cable ScheduleDocument9 pagesInstrument Cable ScheduleRanjan KumarNo ratings yet

- Minimum Key Construction Equipments Tools & Tackles To Be DeployedDocument3 pagesMinimum Key Construction Equipments Tools & Tackles To Be DeployedRanjan KumarNo ratings yet

- No Dues Certificate - 230320 - 214619Document2 pagesNo Dues Certificate - 230320 - 214619Ranjan KumarNo ratings yet

- Vijay Prasad Singh - DocumentsDocument17 pagesVijay Prasad Singh - DocumentsRanjan KumarNo ratings yet

- Gail VSPL Reroute PTC Scope of WorkDocument33 pagesGail VSPL Reroute PTC Scope of WorkRanjan KumarNo ratings yet

- PTR Narmada Offshore Oct 2020Document5 pagesPTR Narmada Offshore Oct 2020Ranjan KumarNo ratings yet

- Career Averages: Format Mat Inns NO Runs HS Ave BF SR Test 15921 ODI 18426 T20I 10 FC 25396 List A 21999 T20 2797Document66 pagesCareer Averages: Format Mat Inns NO Runs HS Ave BF SR Test 15921 ODI 18426 T20I 10 FC 25396 List A 21999 T20 2797Ranjan KumarNo ratings yet

- SafetyDocument313 pagesSafetyRanjan KumarNo ratings yet

- 2023 Calendar - NOCPLDocument1 page2023 Calendar - NOCPLRanjan KumarNo ratings yet

- Pipe Schedule ChartDocument1 pagePipe Schedule ChartRanjan KumarNo ratings yet

- Oswal Infrastructure Ltd.Document48 pagesOswal Infrastructure Ltd.Ranjan KumarNo ratings yet

- 26 - I - Form Gratuity Appln by Emp. Who Appointed After 10Document2 pages26 - I - Form Gratuity Appln by Emp. Who Appointed After 10Ranjan KumarNo ratings yet

- Appendix-Vii To SCC Schedule of Labour Rates: 15963-000-PP-ITT-0069Document2 pagesAppendix-Vii To SCC Schedule of Labour Rates: 15963-000-PP-ITT-0069Ranjan KumarNo ratings yet

- Procedure For Radiography TestingDocument18 pagesProcedure For Radiography TestingRanjan KumarNo ratings yet

- Procedure For Ultrasonic TestDocument13 pagesProcedure For Ultrasonic TestRanjan Kumar100% (1)

- Your Test Result: ICMR Registration Number: COREG001Document1 pageYour Test Result: ICMR Registration Number: COREG001Ranjan KumarNo ratings yet

- TECHNICALVOLUMEIIAOFIIDocument216 pagesTECHNICALVOLUMEIIAOFIIRanjan KumarNo ratings yet

- Procedure For Liquid Penetrant TestDocument6 pagesProcedure For Liquid Penetrant TestRanjan Kumar100% (1)

- SR No Approved Make - Sub-Vendor List: Civil Reinforcement SteelDocument49 pagesSR No Approved Make - Sub-Vendor List: Civil Reinforcement SteelRanjan KumarNo ratings yet

- Laying and Associated Works For Replacement of Various Pipelines in KG BasinDocument44 pagesLaying and Associated Works For Replacement of Various Pipelines in KG BasinRanjan KumarNo ratings yet

- Technical Volume I I Go FiiDocument375 pagesTechnical Volume I I Go FiiRanjan KumarNo ratings yet

- General Specification For Pipeline Field Welding & NDTDocument77 pagesGeneral Specification For Pipeline Field Welding & NDTRanjan KumarNo ratings yet

- Design History Files - Design Control Documentation: Compliant, Effective, EfficientDocument7 pagesDesign History Files - Design Control Documentation: Compliant, Effective, EfficientBilal ÇetinerNo ratings yet

- COM 324 Software EngineeringDocument44 pagesCOM 324 Software EngineeringAdesoji Elewode67% (3)

- Audiovisual Systems Design and Coordination Components Performance Standard DS1 Public ReviewDocument29 pagesAudiovisual Systems Design and Coordination Components Performance Standard DS1 Public Reviewdimlou1100% (1)

- Validation of Arc Welding Equipment - Revision of BS7570 (May 2001)Document2 pagesValidation of Arc Welding Equipment - Revision of BS7570 (May 2001)Elias KapaNo ratings yet

- Wayahead System ValidationDocument41 pagesWayahead System Validationpate malabananNo ratings yet

- ManikantaDocument4 pagesManikantaSingree GowdaNo ratings yet

- PMI ProcedureDocument9 pagesPMI ProcedureKarrar TalibNo ratings yet

- Ispe Connecting A World of Pharmacutical KnowledgeDocument12 pagesIspe Connecting A World of Pharmacutical KnowledgeSunil Murkikar (GM - PMI Quality Operations)No ratings yet

- Guidelines On Certification of Containers - Rev 0 - April 2021Document60 pagesGuidelines On Certification of Containers - Rev 0 - April 2021Sagar PanditNo ratings yet

- (Pub) AdvaMed - Software in Medical Devices - Module 1 Regulations, Guidance, Standards, and Terminology, PlanningDocument54 pages(Pub) AdvaMed - Software in Medical Devices - Module 1 Regulations, Guidance, Standards, and Terminology, PlanningAufar Rahadiandy100% (1)

- Commissioning Start UpDocument22 pagesCommissioning Start UpFranci George100% (8)

- Profile Supplier Connect Responsible-V3Document4 pagesProfile Supplier Connect Responsible-V3Hồ Cường KaizenNo ratings yet

- Geomembrane MQA ManualDocument17 pagesGeomembrane MQA ManualPiere Salas HerreraNo ratings yet

- IQ、OQ、PQ- RV022002Document30 pagesIQ、OQ、PQ- RV022002Nur Nabi RashedNo ratings yet

- What Is The Measuring Instruments Directive (MID) ?Document4 pagesWhat Is The Measuring Instruments Directive (MID) ?ZbigNo ratings yet

- 2006-04-04 - 05603 - SOW - 2300 - L - 0029 - Rev BDocument18 pages2006-04-04 - 05603 - SOW - 2300 - L - 0029 - Rev BawscobieNo ratings yet

- IT Infrastructure Recovery Plan TemplateDocument10 pagesIT Infrastructure Recovery Plan Templaterhianne_lhen5824No ratings yet

- Bidding FormsDocument26 pagesBidding FormsPERT, INC. KAREN VARQUEZNo ratings yet

- 2 & 16 Mark Questions and AnswersDocument27 pages2 & 16 Mark Questions and Answersprasath_676303No ratings yet

- Sans347 2012Document51 pagesSans347 2012cocorruoNo ratings yet

- Unit Iii: Software Testing and MaintenanceDocument34 pagesUnit Iii: Software Testing and MaintenanceKrishna KishorNo ratings yet

- IRIS Guideline 6 2014 SPECIAL PROCESSESDocument12 pagesIRIS Guideline 6 2014 SPECIAL PROCESSESmnmlNo ratings yet

- CP8Document37 pagesCP8Pradeepta MohantyNo ratings yet

- Process Discipline Equipment List Checklist: Jacobs Logo - Blue - SmallDocument5 pagesProcess Discipline Equipment List Checklist: Jacobs Logo - Blue - SmallShubham CholeNo ratings yet

- UntitledDocument15 pagesUntitledMarcelo PerettiNo ratings yet