Professional Documents

Culture Documents

Data Sheet: para Light Electronics Co., LTD

Data Sheet: para Light Electronics Co., LTD

Uploaded by

muaadhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet: para Light Electronics Co., LTD

Data Sheet: para Light Electronics Co., LTD

Uploaded by

muaadhCopyright:

Available Formats

PARA LIGHT ELECTRONICS CO., LTD.

4F, No.1, Lane 93, Chien Yi Road, Chung Ho City, Taipei, Taiwan

Tel: 886-2-2225-3733 Fax: 886-2-2225-4800

E-mail: para@para.com.tw http://www.para.com.tw

DATA SHEET

PART NO.: L-S110LGCT

REV: B / 4

CUSTOMER’S APPROVAL : _______________ DCC : ____________

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 1 of 14

PARA-FOR-065

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

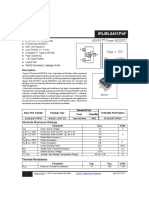

z PACKAGE OUTLINE DIMENSIONS

P .C .B O A R D

R E IN F O R C IN G P IN

(N O N E L E C T R O D E )

LE D D IC E

Notes:

1. All dimensions are in millimeters.

2. Tolerance is ± 0.1mm (.004") unless otherwise noted.

z Features

½ Top view, wide view angle, single color Chip LED.

½ Package in 8mm tape on 7" diameter reels.

½ Compatible with automatic Pick & Place equipment.

½ Compatible with Infrared and Wave soldering reflow solder processes.

½ EIA STD package.

½ I.C. compatible.

½ Pb free product.

½ Meet RoHS Green Product.

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 2 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z Chip Materials

½ Dice Material : InGaN

½ Light Color : Super Green

½ Lens Color : Water Clear

z Absolute Maximum Ratings(Ta=25℃)

Symbol Parameter Rating Unit

PD Power Dissipation 100 mW

Peak Forward Current

IPF 100 mA

(1/10 Duty Cycle, 0.1ms Pulse Width)

IF Continuous Forward Current 25 mA

- De-rating Linear From 25℃ 0.25 mA/℃

VR Reverse Voltage 5 V

Note A

ESD Electrostatic Discharge Threshold(HBM) 150 V

Topr Operating Temperature Range -40 ~ +85 ℃

Tstg Storage Temperature Range -40 ~ +85 ℃

Note A :

HBM : Human Body Model. Seller gives no other assurances regarding the ability of to

withstand ESD.

z Electro-Optical Characteristics(Ta=25℃)

Parameter Symbol Min. Typ. Max. Unit Test Condition

Luminous Intensity IV 160.0 300.0 mcd IF=20mA

Viewing Angle 2θ1/2 130 deg Note 2

Peak Emission

λp 518 nm Measurement @Peak

Wavelength

Dominant Wavelength λd 525 nm IF=20mA

Spectral Line

Δλ 15 nm

Half-Width

Forward Voltage VF 3.1 3.6 V IF =20mA

Reverse Current IR 10 μA VR = 5V

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 3 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z Bin Code List

Luminous Intensity(IV), Unit:mcd@20mA Forward Voltage(VF), Unit:V@20mA

Bin Code Min Max Bin Code Min Max

S 180.0 280.0 K8 2.80 2.95

T 280.0 450.0 K9 2.95 3.10

K10 3.10 3.25

K11 3.25 3.40

Tolerance of each bin are±15% Tolerance of each bin are±0.1Volt

Dominant Wavelength (Hue),Unit: nm@20mA

Bin Code Min Max

AP 520 525

AQ 525 530

Tolerance of each bin are±1nm

Notes:

1. Luminous intensity is measured with a light sensor and filter combination that

proximities the CIE eye-response curve.

2. θ1/2 is the off-axis angle at which the luminous intensity is half the axial luminous

intensity.

3. The dominant wavelength λd is derived from the CIE chromaticity diagram and

represents the single wavelength which defines the color of the device.

4. Caution in ESD :

Static Electricity and surge damages the LED. It is recommended use a wrist band or

anti-electrostatic glove when handling the LED. All devices, equipment and machinery

must be properly grounded.

5. Major standard testing equipment by “Instrument System” Model : CAS140B Compact

Array Spectrometer and “KEITHLEY” Source Meter Model : 2400.

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 4 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z Typical Electro-Optical Characteristics Curves

(25℃Ambient Temperature Unless Otherwise Noted)

Fig.2 Forward Current vs.Forward Voltage Luminous lntensity(mcd)

Fig.3 Luminous Intensity vs.Forward Current

1000

Relative Luminous lntensity

Relative luminous intensity(%)

Normalized of 20mA

100

10

1

-60 -40 -20 -0 20 40 60 80 100

Ambient Temperature Ta(℃)

Fig.4 Relative Luminous Intensity vs.Forward Current Fig.5 Luminous Intensity vs.Ambient Temperature

50 0° 10° 20°

Forward Current IF(mA)

30°

40

30 40°

1.0

25

0.9 50°

20

0.8 60°

10 70°

0.7 80°

0 90°

0 20 40 60 80 100 0.5 0.3 0.1 0.2 0.4 0.6

Ambient Temperature Ta(℃)

Fig.6 Forward Current Derating Curve Fig.7 Relative Intensity vs.Angle

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 5 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z Label Explanation

CUS. PART NO: To be denominated.

CUSTOMER: To be denominated.

PART NO: Refer to P14

IV --- Luminous Intensity Code

VF --- Forward Voltage Code

WD --- Dominant Wavelength Code

LOT NO: E L S 6 8 0001

A B C D E F

A---E: For series number

B---L: Local F: Foreign

C---S:SMD

D---Year

E---Month

F---SPEC.

PACKING QUANTITY OF BAG :

3000pcs for 150、170、110、155、115 series

4000pcs for 191 series

5000pcs for 192 series

DATE CODE:2006 06 08

G H I

G--- Year

H--- Month

I --- Day

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 6 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z Typical Electro-Optical Characteristics Curves

Fig.1 Relative Intensity vs. Wavelength

z Reel Dimensions

Notes:

1. Taping Quantity : 3000pcs

2. The tolerances unless mentioned is±0.1mm, Angle±0.5°, Unit : mm.

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 7 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z Package Dimensions Of Tape And Reel

P ro gressive d irectio n

P o la rity

Notes:All dimensions are in millimeters.

Moisture Resistant Packaging

? .jpg

\± ê ? °

°ü×

\SMD

SMD

H:\SMD\

H:\SMD\SMD\SMD° ü × ° \± ê ? ? .jpg

H:\SMD\SMD\SMD° ü × ° \± ê ? ? .jpg

Label Reel

Label

Aluminum moistue-proof bag Desiccant

240

H:\SM

D\SM

D\SM

D° ü

×°

\± ê ?

? .jpg

210

145

5

25 Label Box

435

Carton

Notes : One reel in a bag, one bag in a inner box, ten inner boxes in a carton. Unit : mm.

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 8 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z Cleaning

½ If cleaning is required , use the following solutions for less than 1 minute and less than 40℃.

½ Appropriate chemicals: Ethyl alcohol and isopropyl alcohol.

½ Effect of ultrasonic cleaning on the LED resin body differs depending on such factors as

the oscillator output, size of PCB and LED mounting method. The use of ultrasonic

cleaning should be enforced at proper output after confirming there is no problem.

z Suggest Soldering Pad Dimensions

Direction of PWB camber

and go to reflow furnace

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 9 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

● Suggest Sn/Pb IR Reflow Soldering Profile Condition:

● Suggest Pb-Free IR Reflow Soldering Profile Condition:

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 10 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z CAUTIONS

1.Application Limitation :

The LED’s described here are intended to be used for ordinary electronic equipment (such as office equipment,

communication equipment and household application).Consult PARA’s sales in advance for information on

application in which exceptional quality and reliability are required, particularly when the failure or malfunction of

the LED’s may directly jeopardize life or health (such as airplanes, automobiles, traffic control equipment, life

support system and safety devices).

2.Storage :

Before opening the package :

The LEDs should be store kept at 5°C to 30°C or less and 85%RH or less.

After opening the package :

The LEDs should be kept at 5°C to 30°C or less and 70%RH or less. The LEDs should be soldered

within 168 hours(7 days) after opening the package.

Please avoid rapid transitions in ambient temperature in high humidity environments where

condensation may occur.

LEDs stored out of their original packaging for more than a week should be baked at 30°C for at 24 hours before

solder assembly.

3.Soldering

Do not apply any stress to the lead frame during soldering while the LED is at high temperature.

Recommended soldering condition.

Reflow Soldering :

Pre-heat 120~150°C, 120sec. MAX., Peak temperature : 240°C Max. Soldering time : 10 sec Max.

Soldering Iron : (Not recommended)

Temperature 300°C Max., Soldering time : 3 sec. Max.(one time only), power dissipation of iron : 20W Max. use

SN60 solder of solder with silver content and don’t to touch LED lens when soldering.

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 11 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

Wave soldering :

Pre-heat 100°C Max, Pre-heat time 60 sec. Max, Solder wave 260°C Max, Soldering time 5 sec. Max. preformed

consecutively cooling process is required between 1st and 2nd soldering processes.

4. Lead-Free Soldering

For Reflow Soldering :

1、Pre-Heat Temp:150-180℃,120sec.Max.

2、Soldering Temp:Temperature Of Soldering Pot Over 230℃,40sec.Max.

3、Peak Temperature:260℃,5sec.

4、Reflow Repetition:2 Times Max.

5、Suggest Solder Paste Formula 93.3 Sn/3.1 Ag/3.1 Bi /0.5 Cu

For Soldering Iron (Not Recommended) :

1、Iron Tip Temp:350℃ Max.

2、Soldering Iron:30w Max.

3、Soldering Time:3 Sec. Max. One Time.

For Dip Soldering :

1、Pre-Heat Temp:150℃ Max. 120 Sec. Max.

2、Bath Temp:265℃ Max.

3、Dip Time:5 Sec. Max.

5. Drive Method

Circuit model A Circuit model B

(A)Recommended circuit.

(B)The difference of brightness between LED`s could be found due to the Vf-If characteristics of LED.

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 12 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

6.Reliability Test

Classification Test Item Test Condition Reference Standard

Ta= Under Room Temperature As Per Data

MIL-STD-750D:1026 (1995)

Sheet Maximum Rating

Operation Life MIL-STD-883D:1005 (1991)

*Test Time= 1000HRS

JIS C 7021:B-1 (1982)

(-24HRS,+72HRS)*@20mA.

High Temperature IR-Reflow In-Board, 2 Times

MIL-STD-202F:103B(1980)

Endurance Test High Humidity Ta= 65±5℃,RH= 90~95%

JIS C 7021:B-11(1982)

Storage *Test Time= 1000HRS±2HRS

High Temperature Ta= 105±5℃ MIL-STD-883D:1008 (1991)

Storage Test Time= 1000HRS (-24HRS,72HRS) JIS C 7021:B-10 (1982)

Low Temperature Ta= -55±5℃

JIS C 7021:B-12 (1982)

Storage *Test Time=1000HRS (-24HRS,72H RS)

MIL-STD-202F:107D (1980)

Temperature 105±5℃ -55±5℃ MIL-STD-750D:1051(1995)

Cycling 10mins 10mins 100 Cycles MIL-STD-883D:1010 (1991)

JIS C 7021:A-4(1982)

IR-Reflow In-Board, 2 Times MIL-STD-202F:107D(1980)

Thermal

105±5℃ -55℃±5℃ MIL-STD-750D:1051(1995)

Shock

10mins 10mins 100 Cycles MIL-STD-883D:1011 (1991)

Environmental

Test MIL-STD-202F:210A(1980)

Solder Tsol= 260 ± 5℃

MIL-STD-750D:2031(1995)

Resistance Dwell Time= 10 ± 1sec

JIS C 7021:A-1(1982)

MIL-STD-202F:208D(1980)

Tsol= 235 ± 5℃

MIL-STD-750D:2026(1995)

Immersion time 2±0.5 sec

Solder ability MIL-STD-883D:2003(1991)

Immersion rate 25±2.5 mm/sec

IEC 68 Part 2-20

Coverage ≧95% of the dipped surface

JIS C 7021:A-2(1982)

7.Others:

The appearance and specifications of the product may be modified for improvement without notice.

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 13 of 14

PARA-FOR-068

Downloaded from Arrow.com.

SURFACE MOUNT DEVICE LED

Part No. : L-S110LGCT REV:B / 4

z PART NO. SYSTEM : XXXX : Special specification for

customer

L–S 1 1 0 X C X X - X X X X

T : Taping for 7 inch reel

TC : Taping for 13 inch reel

TH : IV half binning

TP : Wavelength binning

Lens color

C : Water Clear

W : White Diffused

T : Color Transparent

D : Color Diffused

G : Gap 570nm Green

Y : GaAsp 585 nm Yellow

E : GaAsp 620 nm Orange

SR : GaAlAs 634 nm Red

KG : AlInGap 570nm Super Green

KY : AlInGap 590nm Super Yellow

KF : AlInGap 605nm Super Amber

KR : AlInGap 630 nm Super Red

LB : InGaN 470nm Blue

LG: InGaN 525nm Green

0 : Single chip

1/2 : Super thin single chip

5/6 : Dual chip

F : Three chip(Full color)

150 : 1206 1.1T Type

170 : 0805 0.8T Type

191 : 0603 0.6T Type

C : Top View Type 192 : 0603 0.4T Type

S : Side View Type 110 : 1206 1.0T Type

DRAWING NO. : DS-73-04-0001 DATE : 2009-11-26 PAGE 14 of 14

PARA-FOR-068

Downloaded from Arrow.com.

You might also like

- Baker Off-Line Testing Compared To PdMA's Off-Line UnitDocument3 pagesBaker Off-Line Testing Compared To PdMA's Off-Line UnitLuisMilton100% (1)

- Technical Data Sheet Power LED @150ma Current: 34-03UYC/S599Document8 pagesTechnical Data Sheet Power LED @150ma Current: 34-03UYC/S599Jeannot MpianaNo ratings yet

- Display 7 Segmentos 7mm Da03-11srwaDocument4 pagesDisplay 7 Segmentos 7mm Da03-11srwaDJ_CROWNNo ratings yet

- Lites06889-1 0Document5 pagesLites06889-1 0edward blancoNo ratings yet

- SMBJ 1Document8 pagesSMBJ 1Omar MelchorNo ratings yet

- 0.52 Inch (13.20mm) Single Digit Numeric Led Displays: PDT52-CADR22Document3 pages0.52 Inch (13.20mm) Single Digit Numeric Led Displays: PDT52-CADR22api-62031994No ratings yet

- KingbrightDocument5 pagesKingbrightEazhil PreethiNo ratings yet

- Kingbright: 2X5Mm Rectangular Led LampDocument6 pagesKingbright: 2X5Mm Rectangular Led LampGorea GrigNo ratings yet

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290StuxnetNo ratings yet

- Surface Mount Switching Diode M1MA174Document4 pagesSurface Mount Switching Diode M1MA174JesusNo ratings yet

- Led VermelhoDocument4 pagesLed Vermelhocaio felipeNo ratings yet

- LTC561E Liteon LED DisplayDocument6 pagesLTC561E Liteon LED DisplayRafa GasconNo ratings yet

- T-1 3/4 (5mm) SOLID STATE LAMPDocument6 pagesT-1 3/4 (5mm) SOLID STATE LAMPGiuseppe ZuffelatoNo ratings yet

- D5250G NBDocument6 pagesD5250G NBcharlydigitalNo ratings yet

- BN44 00852a L48MSF FdyDocument53 pagesBN44 00852a L48MSF FdyRaimundo SantanaNo ratings yet

- TC15 11srwaDocument6 pagesTC15 11srwagildas sariNo ratings yet

- Technical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290Document8 pagesTechnical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290StuxnetNo ratings yet

- 2.5 Amp Output Current IGBT Gate Drive Optocoupler With Rail-to-Rail Output Voltage, High CMRDocument14 pages2.5 Amp Output Current IGBT Gate Drive Optocoupler With Rail-to-Rail Output Voltage, High CMRNae CarNo ratings yet

- SR5150 Won TopDocument4 pagesSR5150 Won TopRafael LehmkuhlNo ratings yet

- Itr8307 S17 TR8Document10 pagesItr8307 S17 TR8cointoinNo ratings yet

- Bav70 (A4w32)Document5 pagesBav70 (A4w32)Emilio QuijanoNo ratings yet

- WCN 11039 SRC 21Document3 pagesWCN 11039 SRC 21Davis GuimarNo ratings yet

- Technical Data Sheet: Everlight Electronics Co., LTDDocument12 pagesTechnical Data Sheet: Everlight Electronics Co., LTDNhân Hồ ChíNo ratings yet

- Lite-On Technology CorporationDocument7 pagesLite-On Technology CorporationHung Nguyen NgocNo ratings yet

- T6 DiodeDocument4 pagesT6 DiodeDataNo ratings yet

- SMD Led: Product Data SheetDocument14 pagesSMD Led: Product Data SheetManu MathewNo ratings yet

- 10.92mm (0.43INCH) SINGLE DIGIT NUMERIC DisplayDocument4 pages10.92mm (0.43INCH) SINGLE DIGIT NUMERIC DisplayoscarNo ratings yet

- SPF 1G BX20D 5531 T02#151005Document7 pagesSPF 1G BX20D 5531 T02#151005GLsun MallNo ratings yet

- IRM8601Document9 pagesIRM8601Oprina MonicaNo ratings yet

- WCN3-1056SR-A11R Rev.A0Document4 pagesWCN3-1056SR-A11R Rev.A0BlablacarNo ratings yet

- Galaxy Electrical MMBD4148A/CA/CC/SE: Surface Mount Switching Diode FeaturesDocument4 pagesGalaxy Electrical MMBD4148A/CA/CC/SE: Surface Mount Switching Diode Featuresmauricio alfonsoNo ratings yet

- 8x8 Matrix LED 2388asrDocument4 pages8x8 Matrix LED 2388asrOmar Perez0% (1)

- Foto Diodo Infrarrojo Receptor 5mmDocument7 pagesFoto Diodo Infrarrojo Receptor 5mmkevin arreaga miñoNo ratings yet

- Led VerdeDocument4 pagesLed Verdecaio felipeNo ratings yet

- 1N5400 THRU 1N5408: FeaturesDocument3 pages1N5400 THRU 1N5408: FeaturesWijaya TeknikNo ratings yet

- 1000BASE TX1550nm/RX1310nm 40KM SFP TransceiverDocument7 pages1000BASE TX1550nm/RX1310nm 40KM SFP TransceiverGLsun MallNo ratings yet

- T-1 3/4 (5mm) SOLID STATE LAMPDocument6 pagesT-1 3/4 (5mm) SOLID STATE LAMPAnkit SrivastavaNo ratings yet

- DatasheetDocument2 pagesDatasheetMario Alberto Saavedra MeridaNo ratings yet

- Display - ELD-511SURWB-S530-A3Document5 pagesDisplay - ELD-511SURWB-S530-A3guibsgvNo ratings yet

- Galaxy Electrical MMSD914: Fast Speed Switching Diode FeaturesDocument4 pagesGalaxy Electrical MMSD914: Fast Speed Switching Diode Featurespaulo gustavo melo de siqueiraNo ratings yet

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysDocument5 pagesEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.4" Dual Digit DisplaysStuxnetNo ratings yet

- Everlight Electronics Co., LTD.: 5mm PhototransistorDocument7 pagesEverlight Electronics Co., LTD.: 5mm PhototransistorFrancisco Javier González HernándezNo ratings yet

- Galaxy Electrical 1N4148W: Silicon Epitaxial Planar Diode FeaturesDocument4 pagesGalaxy Electrical 1N4148W: Silicon Epitaxial Planar Diode Featurescecep encepNo ratings yet

- TC20-11GWA: 50 MM (2.0 Inch) 5 X 7 Dot Matrix DisplayDocument5 pagesTC20-11GWA: 50 MM (2.0 Inch) 5 X 7 Dot Matrix DisplayAdrian GarciaNo ratings yet

- DatasheetDocument6 pagesDatasheetGlaucio GomesNo ratings yet

- Of smd2012bDocument4 pagesOf smd2012bIoanaa BadiuNo ratings yet

- Ltl2r3sek 002Document11 pagesLtl2r3sek 002Pro ProNo ratings yet

- 19-217 - BHC-ZL1M2RY - 3T DatasheetDocument10 pages19-217 - BHC-ZL1M2RY - 3T DatasheetAdri AVNo ratings yet

- DSE 0023016 HNB2727W OS06 (EMM) - v4Document12 pagesDSE 0023016 HNB2727W OS06 (EMM) - v4Ranadheer BNo ratings yet

- Subminiature Solid State Lamp: AttentionDocument5 pagesSubminiature Solid State Lamp: Attentionn tanevarNo ratings yet

- 1.25G SFP Transceiver Module With DDM Function: RTXM191-404Document14 pages1.25G SFP Transceiver Module With DDM Function: RTXM191-404H_pandaNo ratings yet

- 1N4148WS (T4)Document4 pages1N4148WS (T4)DuanReisNo ratings yet

- SFP 1G Bx20u 3155 T02#151006Document7 pagesSFP 1G Bx20u 3155 T02#151006GLsun MallNo ratings yet

- SR22 Won TopDocument4 pagesSR22 Won TopIgor Rocha PauloNo ratings yet

- SFP 20kmDocument10 pagesSFP 20kmHậu NguyễnNo ratings yet

- LED Chip LGDocument18 pagesLED Chip LGMinh Khuê Nguyễn ThịNo ratings yet

- SMAJ5.0 - Inyector Poe 48-24 Datasheetz PDFDocument4 pagesSMAJ5.0 - Inyector Poe 48-24 Datasheetz PDFAntoni MonteroNo ratings yet

- HF/VHF Applications RF & Microwave Transistors: Pin ConnectionDocument5 pagesHF/VHF Applications RF & Microwave Transistors: Pin Connectionbellscb100% (1)

- Mmbd4448ht Series GalaxyDocument4 pagesMmbd4448ht Series GalaxyCarlos Javier Pincay PincayNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Switch, Sp3T 0.225 - 3.0 GHZ 100W: DescriptionDocument5 pagesSwitch, Sp3T 0.225 - 3.0 GHZ 100W: DescriptionmuaadhNo ratings yet

- Key Features: DS-D5055UC 54.6" 4K MonitorDocument3 pagesKey Features: DS-D5055UC 54.6" 4K MonitormuaadhNo ratings yet

- Rs Pro Metal XLR Plugs: DatasheetDocument3 pagesRs Pro Metal XLR Plugs: DatasheetmuaadhNo ratings yet

- 10 Amp Digital Low Resistance: Dlro10HdxDocument4 pages10 Amp Digital Low Resistance: Dlro10HdxmuaadhNo ratings yet

- Minirider 76 SD: 4,9 L MTD, 1 Cylinder 8,2 / 3.000 420 CMDocument1 pageMinirider 76 SD: 4,9 L MTD, 1 Cylinder 8,2 / 3.000 420 CMmuaadhNo ratings yet

- Ds-Pdmck-Eg2-We Wireless Magnet Shock Detector: Key FeaturesDocument3 pagesDs-Pdmck-Eg2-We Wireless Magnet Shock Detector: Key FeaturesmuaadhNo ratings yet

- Fujitsu Celvin® Nas Q902 Storage: Data SheetDocument7 pagesFujitsu Celvin® Nas Q902 Storage: Data SheetmuaadhNo ratings yet

- The Hunter 45 DS - : A Modern Design For Comfortable CruisingDocument2 pagesThe Hunter 45 DS - : A Modern Design For Comfortable CruisingmuaadhNo ratings yet

- Myers: WHR SeriesDocument4 pagesMyers: WHR SeriesmuaadhNo ratings yet

- JD Edwards Enterpriseone Buyer Workspace DatasheetDocument102 pagesJD Edwards Enterpriseone Buyer Workspace DatasheetmuaadhNo ratings yet

- Quadruplexer 700-900 / 1800 / 2100 / 2600: Data SheetDocument3 pagesQuadruplexer 700-900 / 1800 / 2100 / 2600: Data SheetmuaadhNo ratings yet

- TSTM-DC / TSTMH-DC: Torque Test StandDocument3 pagesTSTM-DC / TSTMH-DC: Torque Test StandmuaadhNo ratings yet

- CMS1500Document1 pageCMS1500muaadhNo ratings yet

- Drink Menu: Warm DrinksDocument6 pagesDrink Menu: Warm DrinksmuaadhNo ratings yet

- Xifos 33 Ds Iss1 en 009Document2 pagesXifos 33 Ds Iss1 en 009muaadhNo ratings yet

- Codigos de Fallas Otis 3200: Jufeng Elevator Technology Co., LTDDocument3 pagesCodigos de Fallas Otis 3200: Jufeng Elevator Technology Co., LTDmuaadhNo ratings yet

- 3M Economy Vinyl Electrical Tape 1400: Data Sheet February 2010Document2 pages3M Economy Vinyl Electrical Tape 1400: Data Sheet February 2010muaadhNo ratings yet

- Residential Mortgage Application With AddendumDocument12 pagesResidential Mortgage Application With AddendummuaadhNo ratings yet

- RS-232 Controlled RS-232 Controlled Retrofi T Relay Panels Retrofi T Relay PanelsDocument6 pagesRS-232 Controlled RS-232 Controlled Retrofi T Relay Panels Retrofi T Relay PanelsmuaadhNo ratings yet

- Midi Industrial Relay Type RMI. 4-5 5A MonostableDocument2 pagesMidi Industrial Relay Type RMI. 4-5 5A MonostablemuaadhNo ratings yet

- Products - Learn - Support - Company 1-800-321-OPTODocument3 pagesProducts - Learn - Support - Company 1-800-321-OPTOmuaadhNo ratings yet

- Multi-Functional Current Relay For AC CurrentsDocument4 pagesMulti-Functional Current Relay For AC CurrentsmuaadhNo ratings yet

- High Power Relay H-550: Technical DataDocument5 pagesHigh Power Relay H-550: Technical DatamuaadhNo ratings yet

- Discontinued LT 0110 770771 Install GuideDocument4 pagesDiscontinued LT 0110 770771 Install GuidemuaadhNo ratings yet

- Gedi420has SpecDocument37 pagesGedi420has SpecmuaadhNo ratings yet

- What Would Cause A Contactor To Burn in A 14 Month Old Goodman Air Conditioning UnitDocument3 pagesWhat Would Cause A Contactor To Burn in A 14 Month Old Goodman Air Conditioning UnitdocrafiNo ratings yet

- Experiments in Principles of Electronic Devices and Circuits (PDFDrive)Document321 pagesExperiments in Principles of Electronic Devices and Circuits (PDFDrive)Ralph Jason Alvarez100% (1)

- Review Paper On Vco - FinalDocument4 pagesReview Paper On Vco - FinalPunitAgrawalNo ratings yet

- Chapter Extra-2 Micro-Fabrication ProcessDocument27 pagesChapter Extra-2 Micro-Fabrication ProcessPritam OjhaNo ratings yet

- TN1215 TN1220 Tyn612 Tyn812 Tyn1012 PDFDocument13 pagesTN1215 TN1220 Tyn612 Tyn812 Tyn1012 PDFePotyNo ratings yet

- Efbdac 49Document90 pagesEfbdac 49Rea RebenqueNo ratings yet

- A Low Phase Noise GM Boosted DTMOS VCO Desi 2018 Karbala International JournDocument9 pagesA Low Phase Noise GM Boosted DTMOS VCO Desi 2018 Karbala International JournSAFA'A AL-HAREERINo ratings yet

- Product Card R-200 ADV RU D1Document2 pagesProduct Card R-200 ADV RU D1zhukzhukovskyNo ratings yet

- CH2 Diode Ckts and AppsDocument7 pagesCH2 Diode Ckts and AppsCharles Adrian CervaniaNo ratings yet

- Infineon IRLML6401 DataSheet v01 01 enDocument10 pagesInfineon IRLML6401 DataSheet v01 01 enMohammad kazem DehghaniNo ratings yet

- 1.john Lau - ASM-CSIA - Recent Advances in PackagingDocument148 pages1.john Lau - ASM-CSIA - Recent Advances in Packagingyang100% (1)

- Edc Question BankDocument6 pagesEdc Question BankManoj KumarNo ratings yet

- Intel 80286: Produced Common Manufacturer(s) MaxDocument3 pagesIntel 80286: Produced Common Manufacturer(s) MaxaaaNo ratings yet

- Fall 2009: EE5323 VLSI Design I Using Cadence: Setting Up Your AccountDocument21 pagesFall 2009: EE5323 VLSI Design I Using Cadence: Setting Up Your Accountbin_xiangNo ratings yet

- SRAM Adi TemanDocument98 pagesSRAM Adi TemanAlice WilliamsNo ratings yet

- Old Engineering Physics Question PaperDocument1 pageOld Engineering Physics Question PaperHithes PathiyilNo ratings yet

- Diode Diffusion CapacitanceDocument20 pagesDiode Diffusion Capacitancegirishkumardarisi254No ratings yet

- PPTDocument20 pagesPPTronak7patel-15No ratings yet

- AP9T15GHDocument4 pagesAP9T15GHJose M PeresNo ratings yet

- 2) OP921 - Optical Smoke Detector - SiemensDocument4 pages2) OP921 - Optical Smoke Detector - SiemensMosin Bin MahammedNo ratings yet

- Computer History CSSDocument28 pagesComputer History CSSho are yoNo ratings yet

- Beeg Anna No CopperDocument7 pagesBeeg Anna No CopperMichael LaugierNo ratings yet

- Eee 141 Lab 1Document11 pagesEee 141 Lab 1KameelNo ratings yet

- ChemistryDocument24 pagesChemistryJimmy OrajayNo ratings yet

- NCP 81174Document18 pagesNCP 81174techgamebr85No ratings yet

- LG192641 Sflyh6vDocument20 pagesLG192641 Sflyh6vPunchis PanchisNo ratings yet

- Unisonic Technologies Co., LTD: NPN Silicon TransistorDocument5 pagesUnisonic Technologies Co., LTD: NPN Silicon TransistorJuan Leonardo SanabriaNo ratings yet

- Catalogo TiristorDocument224 pagesCatalogo TiristorPablo Acapulco Guerrero50% (2)

- Electrochemical Properties of Thin Li4Mn5O12 Electrode On Li1.5Al0.5Ge1.5 (PO4) 3 Solid ElectrolyteDocument5 pagesElectrochemical Properties of Thin Li4Mn5O12 Electrode On Li1.5Al0.5Ge1.5 (PO4) 3 Solid ElectrolyteSEP-PublisherNo ratings yet