Professional Documents

Culture Documents

Design and Fabrication of Groundnut Thresher Machine

Design and Fabrication of Groundnut Thresher Machine

Uploaded by

Bhanu HiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design and Fabrication of Groundnut Thresher Machine

Design and Fabrication of Groundnut Thresher Machine

Uploaded by

Bhanu HiCopyright:

Available Formats

© 2019 JETIR May 2019, Volume 6, Issue 5 www.jetir.

org (ISSN-2349-5162)

DESIGN AND FABRICATION OF GROUNDNUT

THRESHER MACHINE

Rajnish R Dubey[1], Ravi M[2], Nandhu T[3], Nithin S A[4], Vijai R[5]

[1],[2],[3],[4]

Scholar of Sri Sairam College of Engineering.

[5]

Associate Professor, Department of Mechanical Engineering, Sri Sairam College of Engineering.

Abstract :- Groundnut is rich in protein and lipids and has a high energy valve. Groundnut is used commonly as eatable oil and commonly

used for cooking purpose. At the present scenario there is a less worker at the field due to this cost of extraction increases. Due to the above

factors, farmers are not involved in groundnut cultivation. The removing of groundnut pods is a time consuming process and cost expensive.

Temperature is very high at harvesting time so people finds difficult to work. To overcome these difficulties groundnut thresher is used in

groundnut pod removing process which minimize the time and cost. In this paper we have explained about our groundnut thresher machine

design and fabrication.

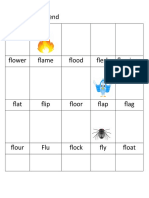

Keywords : Groundnut, Groundnut Pods, Thresher machine,

1. INTRODUCTION

1.1 GROUNDNUT

Groundnut or peanuts is a species in the legume or

"bean" family. The peanut was probably first domesticated and

cultivated in the valleys of Paraguay. It is an annual herbaceous

plant growing 30 to 50 cm tall. The leaves are opposite, pinnate

with four leaflets two opposite pairs; no terminal leaflet, each

leaflet 1 to 7 cm long and 1 to 3 cm broad. Peanuts are known Figure 1 Groundnut legume

by many other local names such as earthnuts, ground nuts,

goober peas, monkey nuts, pygmy nuts and pig nuts. Despite its

name and appearance, the peanut is not a nut, but rather a

legume. India is the second largest producer of groundnuts in

the world in the order shown in the table 1. Indian groundnuts

are available in different varieties as bold or Runner, Java or

Spanish and Red Natal.

Table 1. Production of groundnuts in different countries.

Sl. PRODUCTION PRODUCTION

Figure 2 Groundnut pod

NO. (MILLON

TONNES)

Apart from raw edible peanuts, India is also in a position to

1 China 17

supply Blanched Peanuts, Roasted Salted Peanuts and Dry

2 India 9.5 Roasted Peanuts and a variety of peanut based products. The

3 Nigeria 3 major growing state for groundnut is Gujarat, Andhra Pradesh,

4 United State 1.9 Tamil Nadu, Karnataka, Maharashtra Rajasthan, Madhya

Pradesh, Orissa, and Uttar Pradesh.

5 Myanmar 1.4

1.2 CULTIVATION AND HARVESTING

They have a rich nutty flavour, sweet taste, crunchy texture and

above a relatively longer shelf life. Soil conditions in some Peanuts grow best in light, sandy loam soil with a pH of 5.9–7.

producing regions are ideally suited for dry, clean and spotless Their capacity to fix nitrogen and they improve soil fertility.

Groundnuts in Shell. Groundnut is the major oil seed crop in The crop cultivation land view is shown in the figure 3.

India and it plays a major role in bridging the Vegetable oil Therefore, they are valuable in crop rotations. Also, the yield of

deficit in the country. Groundnuts in India are available the peanut crop itself is increased in rotations, through reduced

throughout the year due to a two-crop cycle harvested in March diseases, pests and weeds. Adequate levels of phosphorus,

and October. Groundnuts are important protein crops in India potassium, calcium, magnesium, and micronutrients are also

grown mostly under rain-fed conditions. The awareness and necessary for good yields. Figure 3. Groundnut Farm If it is too

concern for quality amongst the Indian groundnut sellers and early, too many pods will be unripe. If too late, the pods will

processors are growing steadily. Multiple sorting and grading snap off at the stalk, and will remain in the soil. For harvesting,

are fast becoming a norm. Indian manufacturer have the the entire plant, including most of the roots, is removed from

capability to prepare and supply edible peanuts conforming to the soil. The fruits have wrinkled shells that are constricted

highest standards. Figure 1. shows the groundnut legume and between pairs of the one to four seeds per pod. Harvesting

Figure 2. show the groundnut pod. occurs in two stages: In mechanized systems, a machine is used

to cut off the main root of the peanut plant by cutting through

the soil just below the level of the peanut pods. The machine

JETIRCJ06008 Journal of Emerging Technologies and Innovative Research (JETIR) www.jetir.org 33

© 2019 JETIR May 2019, Volume 6, Issue 5 www.jetir.org (ISSN-2349-5162)

lifts the "bush" from the ground and shakes it, then inverts the variables affect the threshing losses also seed separation

bush, leaving the plant upside down on the ground to keep the efficiency.

peanuts out of the soil. This allows the peanuts to dry slowly to WR Nave et. al[3] Observed that the threshing

a little less than a third of their original moisture level over a efficiency increased with increasing drum speed and decreasing

period of three to four days. Traditionally, peanuts were pulled feed rate. The threshing efficiency attains the maximum value

and inverted by hand. Harvesting usually consists of a series of as 99.76 % at drum speed of 21.25 m/s (1400 rpm), and feed

operations comprising digging, lifting, windrowing, stocking rate of 15 kg/min. The grain damage was 0.90 % of visible

and threshing. Some of these tasks can be combined or grains under operating condition.

eliminated depending on the system applied. Among the field Gol and Nada et. al[4] Concluded that the important

operations concerned with groundnut cultivation, harvesting is factors affecting the efficiency of mechanical pod stripping

the most laborious and costly endeavor. The actual method of elements are operation speed and crop conditions. Percentage of

harvest employed depends upon the type of groundnut grown. stripping pods increased by increasing of peripheral drum speed

In bunch types, pod development is confined to the base of the which ranged from (473 rpm) 0.1m/s to (675 rpm) 3 m/s.

plant and the pegs carrying the pods into the soil are thick and

strong. Almost all the pods are recovered with the plants when 3. COMPONENT OF GROUNDNUT THRESHER

they are pulled out of the soil. The bunch type of groundnut is MACHINE

mostly harvested by pulling out the plants with manual labour

in India. The diversity of the labour employed to harvest the

crop depends on the location. For instance male laborers are

used in Tamil Nadu and in Gujarat both male and female

laborers' are employed. Usually 12 to 14 laborers' can harvest

one-hectare area of groundnut crop in one day. Harvesting may

sometimes become a problem especially when the crop has

passed the stage of full maturity and the soil has hardened. In

this case, it is customary to lift the plants by loosening the soil

either by working a hand hoe, a plough or a blade harrow along

the plant rows. If after lifting the crop manually it is observed

that a good percentage of the pods have been left in the soil, the

same implements may be used to pick the leftover pods. In the

latter case, additional labour will be required. In the case of the

spreading type, the process of uprooting the crop from the soil

is a rather difficult operation as pod formation takes place all Figure 4 Groundnut thresher machine

along the creeping branches of the plant. The pegs are

comparatively thinner and more delicate.

The component used in our groundnut thresher machine are :

1. Table

2. Feeder

3. Threshing Drum

4. Plumber block

5. Perforated sheet

6. Fan and Blower

7. Motor

3.1 TABLE

Figure 3 Groundnut farm All the part of the machine are mounted on the table. Table

acts as a foundation and all the load acts on the table. Hence it

2. LITERATURE SURVEY must be strong enough to bear all the loads.

Yasir Mahmood et al[1] Designed a modified

thresher machine for minimizing the problem of choking in the

concave. As surveyed in the district of Dantaramgarh,

Rajasthan, the major hitch faced by the farmers in employing

multi-crop thresher machine is the choking of straw and chaffin

concave clearance as the speed of feed is increased. As the feed

is increased, the chaff aggregate increases considerably and is Figure 5 Thresher table

forced down the clearance and chokes it subsequently. To

resolve the issue, a design was suggested that entailed a

concave frame to hold the concave instead of being an integral

part of mainframe of machine. The mechanism introduced to

move the concave frame was termed as anti-choking

mechanism.

Huynh et al[2] Stated that the seed separation from

stalks and passage of seed through the concave gate is a

function of some variables such as feed rate, threshing speed,

concave length, cylinder diameter and concave clearance. These

JETIRCJ06008 Journal of Emerging Technologies and Innovative Research (JETIR) www.jetir.org 34

© 2019 JETIR May 2019, Volume 6, Issue 5 www.jetir.org (ISSN-2349-5162)

3.2 FEEDER 3.7 MOTOR

The groundnut legume is fed through this part. Motor are used to convert the electrical energy to mechanical

energy. It is used as the driver. It rotate the threshing drum

through the chain transmission. the sprocket is provided with

required ratio.

4. DESIGN OF THE THRESHER MACHINE

4.1 GROUNDNUT SPECIFICATION

Figure 6 Feeder

A single groundnut plant contains 20 to 30 groundnuts.

On average,

3.3 THRESHING DRUM Length of groundnut root = 30 mm

It is the active or rotating portion of the machine. It consist of Length of groundnut = 20 mm

the cylindrical drum which is spirally bolted with bolts and it Width of groundnut = 10 mm

also consist of Shaft and two covering plate.

4.2 THRESHING DRUM SPECIFICATION

Drum Dia = Ф265 mm

Drum length = 1061mm

Figure 7 Threshing drum

3.4 PLUMBER BLOCK

It is used for the supporting of the rotating shaft.

4.3 PLUMBER BLOCK

Inner dia =40 mm

Figure 8 Plumber block

3.5 PERFORTED SHEET

With the help of this sheet the groundnut pod and plant get

separated.

4.4 CALCULATION OF TORQUE

A research paper by J.M.Troeger, E.J.William and J.L.Butler

the peg attachment force or the tensile force required to separate

peg from pod is 22.26 N.

Here we use up to ten ground nut plants so the maximum force

that is required to remove groundnut pod is up to 300 N with

considering the weight of shaft and other mountings.

Torque, T = Force x Perpendicular distance

Force, F = 250 N

Perpendicular distance is the distance from the axis of the drum

to bolt mounted on the periphery of the drum is 132.5mm.

Figure 9 Perforated sheet Torque T = 250*132.5= 33.125N-mm

T = 33.125-mm

3.6 FAN AND BLOWER

It is used for blowing away the dust and other plants parts. The 4.5 POWER CALCULATION

air flow is maintained in such a speed that the groundnut pod

will fall to ground and the dust particle will flow away from the Power , P= 2∏ NT/ 60

groundnut falling area. Such that only clean pod we can get Speed required N = 330 rpm

easily thus removing the cleaning process. P= 2∏* 330*33.125/60

P= 1144.71 W

P= 1.5HP

So we are using 1.5 HP motor.

JETIRCJ06008 Journal of Emerging Technologies and Innovative Research (JETIR) www.jetir.org 35

© 2019 JETIR May 2019, Volume 6, Issue 5 www.jetir.org (ISSN-2349-5162)

providing the covering and way for feeding the groundnut

4.6 SHAFT DESIGN legume. At the bottom of the threshing drum the perforated

Torque T = ∏Ʈd3/16 sheet is also assembled. Finally the motor is mounted on the

Allowable stress Ʈ = 40N/ mm2 table. And the chain and sprocket also fitted. The fan and

34= 3.14*40* d3/16 blower along with the switch is mounted. Thus the complete

d = 1.62 m = 16mm(approx) fabrication is done.

The obtained shaft diameter is 16.11 mm. In order to do weld

attachment on the shaft, diameter of the shaft is chosen to 40

mm.

Diameter of shaft, d = 40 mm.

Shaft length used, L = 1368 mm

Figure 10 Fabrication process

4.6 TABLE SPECIFICATION

Figure 11 Spirally bolted threshing drum

6. FUTURE WORK

1. Performance analysis of the machine has to be done.

2. As the power supply is not possible everywhere, to supply

the power all the time Solar panels are to be added along with

the storage battery.

7. CONCLUSION

Groundnut thresher machine is a useful machine . It saves time

and energy of the farmer also it reduces the cost and time. The

Length L = 1370mm feeder and spirally bolted threshing drum reduces the human

Breadth B = 300mm intervention. The farmer has to feed the groundnut legume and

Height = 912 mm the machine will take entire plant inside and thresh the pod by

the spiral mechanisms. Also this machine are low cost and

5. FABRICATON reliable for our farmer. The area occupied by this machine is

The first step in our fabrication is preparation of the threshing less therefore it can be used anywhere thus it can be used in

drum . The hole was drilled in the cylindrical drum for bolting unconditional climatic condition also. If solar panels are added

spirally. After the hole the 154 bolts were bolted into the it will be more advantage for our farmer.

cylinder. After that the drum has to be closed at the both end by

the plate. Before closing the drum the first plate was machined 8. REFERENCES

from 304.8mm to 260m by lathe and the second plate was cut

by gas cutting method. In the plate 40mm hole was made for [1] Design Modification for Anti-choking Mechanism in

shaft mounting. After this both the plate was welded at both end Thresher Machine, Yasir Mahmood, Gowripathi Rao, Prem

of the drum. Singh and Himanshu Chaudhary

Frame for table has been prepared by cutting the L angle frame. https://www.researchgate.net/publication/327287297_Design_

And the shaft was machined from 41mm to 40mm dia also the Modification_for_Antichoking_Mechanism_in_Thresher_Mach

key also made for assembling the sprocket. The shaft was ine

assembled into the threshing drum.

The feeder plate was prepared and perforated sheet also [2] Huynh, V. M; T. Powell and J. N. Siddal, Threshing and

prepared parellely. After preparation of all the parts assembly separating process- A mathematical model. Trans. ASAE, 25

was done. Firstly the threshing drum along with plumber block (1): 62-73.

has been assembled on the table. After this the sprocket of 68

teeth is fitted. The feeder plate is assembled on the top thus

JETIRCJ06008 Journal of Emerging Technologies and Innovative Research (JETIR) www.jetir.org 36

© 2019 JETIR May 2019, Volume 6, Issue 5 www.jetir.org (ISSN-2349-5162)

[3] Kaul, R. N. and C. O. Egbo: Introduction to Agricultural

Mechanization. First edition. Macmillan Education Ltd. [19] Sunil K. Mathanker a , Tony E. Grift a, Alan C. Hansen a,b

London. , Effect of blade oblique angle and cutting speed on cutting

energy for energycane stems, biosystems engineering 133

[4] Gol, A. K. and S. K. Nada: Performance of power operated (2015) 64 e7 0

groundnut stripper. AMA, 22(3): 25-28.

[20] Y. D. Yiljep1 and U.S. Mohammed, Effect of Knife

[5] El-Behairy, A. A; M. I. Ward and A. M. El-sherbiny: Velocity on Cutting Energy and Efficiency during Impact ,

Performance evaluation of some wheat thresher machines under Agricultural Engineering International: the CIGR EJournal.

different conditions. Misr J. Ag. Eng., 14(4): 149–160. Manuscript PM 05 004. Vol. VII. December, 2005.

[6] Afify, M. K. (1998): Development of a simple flax thresher. [21] Reza Tabatae Color and Ghaffair Kiani , Soyabean stem

Ph.D. Thesis. Agric. Eng. Dep., Fac. of Agric. Zagazig Univ. cutting energy and effect of blade parametes on it .Journal of

Rahul S. Warghane, Rajkumar E, Vaibhav K. Bhagat and Biological science 10(9) , 1532-1535 2007 , ISSN 1028-8880.

Swapnil B. Nawale http://www.iaeme.com/IJMET/index.asp

1028 editor@iaeme.com [22] Ali Mirzazadeh, Shamsollah Abdollahpour and Asghar

Mahmoudi, Ali Ramazani Bukat Intelligent modeling of

[7] Paulsen M. R; R. S. Newberry and W. R. Nave (1980): Soya material separation in combine harvester’s thresher by ANN,

bean quality with rotary and conventional threshing. International Journal of Agriculture and Crop Sciences. ISSN

Transaction of ASAE 23(2):303-308. 2227-670X ©2012 IJACS Journal

[8] El-Nono, M. A. and A. H. A. Mohammed: A study on [23] Victor Ifeanyichukwu , A mathematical model for

power requirements for wheat threshing. Egypt. J. Agric. Res. predicting output capacity of selected stationary spike tooth

78(5): 2169-2176. grain threshers , American Society of Agricultural and

Biological Engineers ISSN 0883−8542

[9] Mamdouh A. H; S. I. Yousef and A. M. Badawy :

Performance evaluation of some sunflower thresher. Egyptian [24] Dynamic Optimization: The Calculus of

Journal of Agricultural Research, 78(2): 969 – 973.

Variations and Optimal Control by Mortain A

[10] Simonyan K. J. and K. C. Oni: Performance evaluation of Kamian & Nancy L. Schwatz, Second Edition.

a motorized locust bean decorticator. Journal of Agricultural Chapter 12 pg 702 -735.

Technology 9(1): 55 - 65.

[25] Jafaar Fahad A. Rida, A. K. Bhardwaj, A. K.

[11] Badawy, M. E.: Modification and evaluation of paddy rice

thresher to suit flax deseeding. Misr J. Ag. Eng., 19 (4): 881–

Jaiswal, Design Optimization of Optical Wireless

900. Communication (Owc) Focusing on Light Fidelity

(Li-Fi) Using Optical Code Division Multiple Access

[12] El-Ashry, A. S; A. El-Rayes and G. R. Gomma: A (Ocdma) Based on Carbon Nanotubes (Cnts),

comparative study of flax threshing systems and their effects on International Journal of Advanced Research In

yield component quality. Misr J. Ag. Eng., 20(3): 691– 701.

[13] Zakaria, M. I: Modification of the thresher drum of Engineering And Technology (IJARET), Volume 5,

stationary thresher to suit separating of flax crop. Misr J. Ag. Issue 10, October (2014), pp. 69-103

Eng., 23(2): 324-345.

[26] R. Giridharan, Pankaj Kumar, P. Vijayakumar

[14] Zaky, W. M: Engineering studies on threshing of black and R. Tamilselvan. Experimental Investigation and

seed (Nigella Sativa). M. Sc. Thesis. Agric. Eng. Dep., Fac. of

Agric., Mansoura Univ. Design Optimization of End Milling Process

Parameters on Monel 400 by Taguchi Method.

[15] Rafik Polat , Amram Atey , Sevdet Saglam , Some thysical International Journal of Mechanical Engineering and

and aerodynamic properties of Soyabean.Journal of agrmonomy Technology, 8(2), 2017, pp. 113–122.

, 5(1) 74-78 2006

[16] Piotr Kuźniar1, Ewa Szpunar-Krok1, Pavol Findura2, Jan

Buczek1, Dorota Bobrecka-Jamro1 , Physical and chemical

properties of soybean seeds determine their susceptibility to

mechanical damage, Zemdirbyste-Agriculture, vol. 103, No. 2

(2016), p. 183‒192 DOI 10.13080/za.2016.103.024

[17] H. Kibar and T. Öztürk , Physical and mechanical

properties of soybean, Int. Agrophysics, 2008, 22, 239-244

[18] Liang Li , Guo Yuming , Relationship Between Stalk

Shear Strength and Morphological Traits of Stalk Crops1 ,

Research Fund for the Doctoral Program of Higher Education

(20060113002)

JETIRCJ06008 Journal of Emerging Technologies and Innovative Research (JETIR) www.jetir.org 37

You might also like

- Impulse 2 SB Answer KeyDocument62 pagesImpulse 2 SB Answer Keywisniewskisergiusz4No ratings yet

- Fedral Urdu University Arts Science and Technology: Assigments of Different TopicsDocument35 pagesFedral Urdu University Arts Science and Technology: Assigments of Different TopicsRida ZehraNo ratings yet

- Design and Fabrication of Groundnut ShellerDocument7 pagesDesign and Fabrication of Groundnut ShellerIJRASETPublications100% (1)

- Grass Cutting Machine 27Document71 pagesGrass Cutting Machine 27Efa AdugnaNo ratings yet

- Design and Development of Manually Operated ReaperDocument8 pagesDesign and Development of Manually Operated ReaperIOSRjournalNo ratings yet

- .Design and Analysis of Battery Powered WeederDocument4 pages.Design and Analysis of Battery Powered WeederKrrish Suraj100% (1)

- Pedal Operated Flour MillDocument49 pagesPedal Operated Flour MillYidenek Ngussie100% (1)

- Maize ShellerDocument13 pagesMaize ShellerPrevilageNo ratings yet

- Solar Rice Dehusking Machine 2 PHASEDocument16 pagesSolar Rice Dehusking Machine 2 PHASEDeiva K100% (1)

- Fabrication of Low-Cost Manualcrop Harvesting MachineDocument9 pagesFabrication of Low-Cost Manualcrop Harvesting Machinepratik g100% (1)

- Design Analysis Fabrication and Testing of Composite Leaf Seminar ReportDocument26 pagesDesign Analysis Fabrication and Testing of Composite Leaf Seminar Reportyash1239100% (1)

- Wireless Multiple Agriculture Robot - SynopsisDocument10 pagesWireless Multiple Agriculture Robot - SynopsisShailesh RanawareNo ratings yet

- My Project New EditDocument38 pagesMy Project New Editmuhammad m butuNo ratings yet

- Industrial Visit ReportDocument3 pagesIndustrial Visit ReportBarzeen Mehr AfareenNo ratings yet

- Design and Implementation of Automatic Lawn CutterDocument6 pagesDesign and Implementation of Automatic Lawn CutterIJSTENo ratings yet

- Semi Automated Paddy ThresherDocument26 pagesSemi Automated Paddy Thresherksati311No ratings yet

- Weeder SynopsisDocument8 pagesWeeder SynopsisParas ChauhanNo ratings yet

- DEBRE BERHAN UNIVERSITY ThesisDocument27 pagesDEBRE BERHAN UNIVERSITY Thesishayliyesus100% (1)

- JaphethDocument20 pagesJaphethDco ThugnificentNo ratings yet

- Groundnut ThrasherDocument27 pagesGroundnut ThrasherBoopathi KalaiNo ratings yet

- Design of A Bike Chain Sprocket ProjectDocument38 pagesDesign of A Bike Chain Sprocket Projectvishnukumar muruganNo ratings yet

- Design and Fabrication of Multi-Purpose Sieving MachineDocument6 pagesDesign and Fabrication of Multi-Purpose Sieving MachineMICHEL RAJ MechNo ratings yet

- Ijsetr Vol 4 Issue 5 1269 1273Document5 pagesIjsetr Vol 4 Issue 5 1269 1273naqeeb na3No ratings yet

- Timetable IEI Summer 2019Document4 pagesTimetable IEI Summer 2019AabidNo ratings yet

- Design and Fabrication of Crop Cutting Machine IJERTV8IS060212 PDFDocument6 pagesDesign and Fabrication of Crop Cutting Machine IJERTV8IS060212 PDFHaritha ChowdaryNo ratings yet

- Debre Tabor University Faculty of Technology Department of Mechanical Engineering Project On: - Design and Fabrication of Hand Operated Maize ShellerDocument122 pagesDebre Tabor University Faculty of Technology Department of Mechanical Engineering Project On: - Design and Fabrication of Hand Operated Maize Shelleryoseph GetnetNo ratings yet

- Design and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter EngineDocument10 pagesDesign and Fabrication of Multipurpose Agricultural Mini Farm Vehicle Using Scooter EngineTony StarkNo ratings yet

- Coconut Dehusking MachineDocument16 pagesCoconut Dehusking MachineArjuncv100% (4)

- Design of WeederDocument26 pagesDesign of Weederarsojol100% (2)

- A Comparison Between The Old and New Indian Codes For Concrete Mix DesignDocument10 pagesA Comparison Between The Old and New Indian Codes For Concrete Mix DesigntheijesNo ratings yet

- 3.road MarkingDocument9 pages3.road MarkingMalith De SilvaNo ratings yet

- Design and Fabrication of A Motorized Rice HullingDocument11 pagesDesign and Fabrication of A Motorized Rice HullingridwanmuhammadtajudeenNo ratings yet

- Discussion and ConclusionDocument4 pagesDiscussion and ConclusionApostrophe Fareez ImprezzaNo ratings yet

- Design of Crop Cutter Machine Ijariie5257Document6 pagesDesign of Crop Cutter Machine Ijariie5257Vijay PulavarthiNo ratings yet

- Design and Analysis of Crop CutterDocument48 pagesDesign and Analysis of Crop Cuttersathish100% (3)

- Milling of Legume PulsesDocument7 pagesMilling of Legume Pulsessuresh100% (1)

- Battery Drive Motorized Agriculture WeederDocument2 pagesBattery Drive Motorized Agriculture WeederANAND KRISHNANNo ratings yet

- Performance Characteristics of A CoconutDocument14 pagesPerformance Characteristics of A CoconutNeil TaneoNo ratings yet

- Motorized Vegtable Cutting MahineDocument21 pagesMotorized Vegtable Cutting MahineP24 Innovation CenterNo ratings yet

- Corn ThresherDocument3 pagesCorn ThresherAnonymous 1P2S4tbMNo ratings yet

- AGRIDocument15 pagesAGRISantosh DineshNo ratings yet

- .Fabrication and Testing of Battery Powered Weeder PDFDocument3 pages.Fabrication and Testing of Battery Powered Weeder PDFKrrish SurajNo ratings yet

- Design and Fabrication of Geneva ConveyorDocument22 pagesDesign and Fabrication of Geneva ConveyorBhumit HambireNo ratings yet

- Hydraulic Cutting MachineDocument19 pagesHydraulic Cutting Machineanon_776112819100% (1)

- Project Report Hybrid Electric VehicleDocument19 pagesProject Report Hybrid Electric VehicleMeet MehtaNo ratings yet

- Project Report On Composite Sleepers (17102023) - Maam CorrectionDocument44 pagesProject Report On Composite Sleepers (17102023) - Maam Correctionsmitirupa.pradhanfmeNo ratings yet

- Literature Review On Fabrication of Battery-Operated Motorized Screw JackDocument7 pagesLiterature Review On Fabrication of Battery-Operated Motorized Screw JackIJRASETPublicationsNo ratings yet

- Jaggery Manufacturing Unit Jaggery Unit Investment MachinesDocument4 pagesJaggery Manufacturing Unit Jaggery Unit Investment MachinesFarooq Ameer Jordan WalaNo ratings yet

- Design and Fabrication of Multipurpose Agriculture Vehicle - Shaan Narjinary - 26100718001Document13 pagesDesign and Fabrication of Multipurpose Agriculture Vehicle - Shaan Narjinary - 26100718001Ringkhang MushahariNo ratings yet

- Mini Project Se A Mech 14-2Document22 pagesMini Project Se A Mech 14-2Rahul Shirodkar100% (1)

- Jan. 19, 1971 J. E. Orme 3,555,615: Rotational Moulding MachinesDocument6 pagesJan. 19, 1971 J. E. Orme 3,555,615: Rotational Moulding MachinesG DragonNo ratings yet

- Untitled PDFDocument6 pagesUntitled PDFBemn BayuNo ratings yet

- Rotovator Blade DesignDocument7 pagesRotovator Blade DesignFrancis SalviejoNo ratings yet

- Automatic Garrage SystemDocument11 pagesAutomatic Garrage SystemTalha NayyarNo ratings yet

- Fabrication of Battery Operated WeederDocument9 pagesFabrication of Battery Operated WeederSelvamuthu Kumaran100% (2)

- Development and Performance Evaluation of A Combined Maize Shelling and Cleaning MachineDocument6 pagesDevelopment and Performance Evaluation of A Combined Maize Shelling and Cleaning MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Final Year Project ReportDocument20 pagesFinal Year Project ReportAnkit PatelNo ratings yet

- Rice Milling and PolishingDocument4 pagesRice Milling and PolishingAhmed zia tahir100% (1)

- PublishedPaper Automatic Onion Peeling and Cutting MachineDocument5 pagesPublishedPaper Automatic Onion Peeling and Cutting Machineዘረአዳም ዘመንቆረርNo ratings yet

- Chapter 1 - Introduction: SR No. 1 3 3 4 7Document15 pagesChapter 1 - Introduction: SR No. 1 3 3 4 7Pratik VishwakarmaNo ratings yet

- Chapter Six CRDocument30 pagesChapter Six CRsebsiking35No ratings yet

- Recipes PDF White Sauce PastaDocument1 pageRecipes PDF White Sauce PastaTanuj AroraNo ratings yet

- 3is Work Immersion BuquelDocument19 pages3is Work Immersion BuquelJohn Chester ANo ratings yet

- Soal PAS B.inggris 9 - KKM OkeMDocument4 pagesSoal PAS B.inggris 9 - KKM OkeMmtsalidruskalanganyarNo ratings yet

- Daily Inventory Bahan Baku Kitchen - OutletDocument11 pagesDaily Inventory Bahan Baku Kitchen - OutletDavina FristantryNo ratings yet

- Rice, Pasta and Noodles in Vietnam DatagraphicsDocument4 pagesRice, Pasta and Noodles in Vietnam DatagraphicsDoan MinhquanNo ratings yet

- Paneeer Tikka Masala ReceipeDocument2 pagesPaneeer Tikka Masala ReceipeAakash SharmaNo ratings yet

- Cookery 10 - QuizDocument2 pagesCookery 10 - QuizRoselleAntonioVillajuanLinsanganNo ratings yet

- 2017 Wedding Packages For WebsiteDocument6 pages2017 Wedding Packages For WebsiteAnne Besin-LaquianNo ratings yet

- Dealing With Homesickness Is Part of FreshersDocument2 pagesDealing With Homesickness Is Part of FreshersAnia PiekutowskaNo ratings yet

- UASA FORMAT English Year 4 2024Document9 pagesUASA FORMAT English Year 4 2024Ling Sue ZhenNo ratings yet

- English: Quarter 4 - Module 4: (Week 4) Using The Most Frequently Occurring PrepositionDocument16 pagesEnglish: Quarter 4 - Module 4: (Week 4) Using The Most Frequently Occurring PrepositionMary Grace PinedaNo ratings yet

- Bart Simpsons Daily RoutineDocument3 pagesBart Simpsons Daily RoutineJOSÉ ELKIN BERRÍO MARTÍNEZNo ratings yet

- Historical Changes in Food Technology PPT 1416wfcfDocument13 pagesHistorical Changes in Food Technology PPT 1416wfcfRich Chelle RelenteNo ratings yet

- Industrial Training ReportDocument43 pagesIndustrial Training ReportChetan SonawaneNo ratings yet

- All BlendsDocument25 pagesAll Blendsmary grace musniNo ratings yet

- Kitchen Design and LayoutDocument9 pagesKitchen Design and LayoutCecelien Salgado AntonioNo ratings yet

- Analysis of Fishing Ports in The PhilippinesDocument60 pagesAnalysis of Fishing Ports in The PhilippinesJodelyn VillahermosaNo ratings yet

- 101 Best Chuck Norris Jokes - Parade - Entertainment, Recipes, Health, Life, HolidaysDocument6 pages101 Best Chuck Norris Jokes - Parade - Entertainment, Recipes, Health, Life, HolidaysLucas MonteNo ratings yet

- Descriptive TextDocument27 pagesDescriptive TextJojoNo ratings yet

- Crop DryingDocument76 pagesCrop DryingJoshie WishyNo ratings yet

- Early Harvest: Bienvenido N. SantosDocument14 pagesEarly Harvest: Bienvenido N. SantosJerneth Nyka FloresNo ratings yet

- Lecturas II Parcial InglessssssssssssDocument4 pagesLecturas II Parcial InglessssssssssssAndres Barreto0% (1)

- Reading Exercise: Dragon Boat FestivalDocument2 pagesReading Exercise: Dragon Boat FestivalAngler TorresNo ratings yet

- Service Manual: SJ-58L-A2G/A2B/A2L/A2A SJ-63L-A2G/A2B/A2L/A2A SJ-68L-A2G/A2B/A2L/A2ADocument52 pagesService Manual: SJ-58L-A2G/A2B/A2L/A2A SJ-63L-A2G/A2B/A2L/A2A SJ-68L-A2G/A2B/A2L/A2AFabian FrigobertNo ratings yet

- IEF Tristan English Level QuizDocument5 pagesIEF Tristan English Level QuizTristanNo ratings yet

- Readworks Grade 5 - Shawn The Speedy SnailDocument5 pagesReadworks Grade 5 - Shawn The Speedy SnailCamille RespicioNo ratings yet

- Bday ScriptDocument2 pagesBday Scriptalfea doroinNo ratings yet

- First Summative Test: T.L.E. 6 (Week 1 & 2) Second QuarterDocument4 pagesFirst Summative Test: T.L.E. 6 (Week 1 & 2) Second QuarterzyiNo ratings yet