Professional Documents

Culture Documents

Table A Commonly Used Material Specification Reference Chart

Table A Commonly Used Material Specification Reference Chart

Uploaded by

Phong TongCopyright:

Available Formats

You might also like

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- Ductile Iron Casting Specfications and Details All Standards PDFDocument15 pagesDuctile Iron Casting Specfications and Details All Standards PDFSiriusNo ratings yet

- Selectalloy 307cDocument1 pageSelectalloy 307cJuan Carlos RodriguezNo ratings yet

- SAE AMS5628F Steel, Corrosion-Resistant, Bars, Wire, Forgings, and Tubing 16Cr-2.5Ni (SAE 51431) (Composition Similar To UNS S43100)Document13 pagesSAE AMS5628F Steel, Corrosion-Resistant, Bars, Wire, Forgings, and Tubing 16Cr-2.5Ni (SAE 51431) (Composition Similar To UNS S43100)loebNo ratings yet

- 2211Document4 pages2211liuyx866No ratings yet

- Pinnacle Alloys ER2594Document2 pagesPinnacle Alloys ER2594Federico Quintana100% (1)

- 309-16 Data SheetDocument1 page309-16 Data Sheetdapp.70No ratings yet

- Welding ProcessesDocument28 pagesWelding ProcessesAnaswarpsNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Stainless Steel EN Equivalent Cross ReferenceDocument5 pagesStainless Steel EN Equivalent Cross ReferenceagrovadoNo ratings yet

- ME 205 - 432 - Assignment 1Document9 pagesME 205 - 432 - Assignment 1جعفر السلطانNo ratings yet

- ASTM A193 Specification - Portland BoltDocument3 pagesASTM A193 Specification - Portland BoltJesús Alberto Díaz CostaNo ratings yet

- C63000 (CDA 630) Nickel Aluminum Bronze - AMS 4640 - UNS C63000 - Aviva MetalsDocument5 pagesC63000 (CDA 630) Nickel Aluminum Bronze - AMS 4640 - UNS C63000 - Aviva MetalsCHAITANYANo ratings yet

- Bolts SpacificationsDocument6 pagesBolts SpacificationsSaleem JaradatNo ratings yet

- Valve Material Application PDFDocument16 pagesValve Material Application PDFSudherson Jagannathan100% (1)

- Threaded Union: Length of Thread Screwed Into FittingDocument1 pageThreaded Union: Length of Thread Screwed Into FittingBalaji KanduriNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- Bonded Seals BrochureDocument8 pagesBonded Seals BrochureembasianNo ratings yet

- AlMg 4.5Mn Product-SheetDocument1 pageAlMg 4.5Mn Product-SheetLuca MemoliNo ratings yet

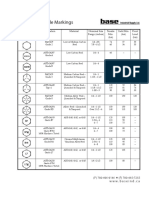

- Bolt & Stud Grade MarkingsDocument2 pagesBolt & Stud Grade MarkingsJacobNo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Pinnacle ER316L Tig Welding Wire DATA SHEETDocument2 pagesPinnacle ER316L Tig Welding Wire DATA SHEEThsuyan2000No ratings yet

- Power Plant: Better Life Created by SteelDocument4 pagesPower Plant: Better Life Created by SteelAlejandro Jose Garcia FernandezNo ratings yet

- Weld Consumable SelectionDocument25 pagesWeld Consumable SelectionNisarg PandyaNo ratings yet

- Er70S-6 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-6 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Appendix C. Conduit and Tubing Fill Tables For Conductors and Fixture Wires of The Same SizeDocument1 pageAppendix C. Conduit and Tubing Fill Tables For Conductors and Fixture Wires of The Same SizeONG, Chester Z.No ratings yet

- Filettature Tiranti ASTM-A193Document25 pagesFilettature Tiranti ASTM-A193markoredsNo ratings yet

- Duplex-Alloy-2205-Stress ValuesDocument5 pagesDuplex-Alloy-2205-Stress ValuesShiniNo ratings yet

- SPECIFICATIONS. C.S.A. G40.21M Steels - Page 123 C.S.A. G40.21 Steels - Page 134 A.S.T.M. Steels - Page 143Document56 pagesSPECIFICATIONS. C.S.A. G40.21M Steels - Page 123 C.S.A. G40.21 Steels - Page 134 A.S.T.M. Steels - Page 143PAMELA LEENo ratings yet

- American FastenersDocument6 pagesAmerican Fastenersashraf elsayedNo ratings yet

- A2 Vs A4 Stainless Steel BoltsDocument3 pagesA2 Vs A4 Stainless Steel BoltsmamahsenNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationme100% (1)

- Ss304 Valves for Duplex StlDocument8 pagesSs304 Valves for Duplex Stlajarekarga ajarekarNo ratings yet

- Sae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsDocument3 pagesSae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsAnonymous 7ZTcBn100% (1)

- Butterfly Valves Gd-381: SpecificationDocument2 pagesButterfly Valves Gd-381: SpecificationJOSE GABRIELNo ratings yet

- ASTM-A564-A564M-13e1-Age Hardening SS Bars Hot Rolled Cold FinishedDocument4 pagesASTM-A564-A564M-13e1-Age Hardening SS Bars Hot Rolled Cold FinishedAjay GuptaNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings PDFDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings PDFnate anantathatNo ratings yet

- TitaniumDocument7 pagesTitaniumNitinNo ratings yet

- Nutron TM Trunnion Mounted Ball Valve FlyerDocument2 pagesNutron TM Trunnion Mounted Ball Valve FlyerAlbert RubianoNo ratings yet

- Duplex SSDocument2 pagesDuplex SSsjk_akolNo ratings yet

- CastMaterials E00510Document6 pagesCastMaterials E00510samir basuniNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- Grades of Bolts - Bolt Grade Marking Chart - AFT FastenersDocument3 pagesGrades of Bolts - Bolt Grade Marking Chart - AFT FastenersheartofdixieNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Alloy C-4300MDocument1 pageAlloy C-4300Malex diazNo ratings yet

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocument10 pagesMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNo ratings yet

- Piping Material Specification 3C605 Carbon Steel, Class 300 Issue Date: Feb 17, 2014Document12 pagesPiping Material Specification 3C605 Carbon Steel, Class 300 Issue Date: Feb 17, 2014azilahnazriNo ratings yet

- A Guide To Nickel Alloys PDFDocument2 pagesA Guide To Nickel Alloys PDFAnonymous lmCR3SkPrKNo ratings yet

- Classif AçosDocument7 pagesClassif AçoslavascudoNo ratings yet

- rb7550 APLTONE01221 - 669Document1 pagerb7550 APLTONE01221 - 669soayNo ratings yet

- Forged Stainless AlloyDocument8 pagesForged Stainless AlloymsajanjNo ratings yet

- Bolt Grades Strength Chart - Imperial Steel BoltsDocument5 pagesBolt Grades Strength Chart - Imperial Steel BoltsEduardo LunaNo ratings yet

- Ductile Iron Casting Specfications and Details All StandardsDocument15 pagesDuctile Iron Casting Specfications and Details All StandardsN.Palaniappan100% (1)

- Fig.101-102 Bronze & Brass Gate ValveDocument1 pageFig.101-102 Bronze & Brass Gate ValveDỰ ÁN TD SCHOOL TDMENo ratings yet

- Butterfly ValveDocument2 pagesButterfly ValveKELVIN TECHNOLOGIESNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- MPPL PT Calendar 2024 2025Document6 pagesMPPL PT Calendar 2024 2025Joby GeorgeNo ratings yet

- DT RM Materials Mind MapDocument1 pageDT RM Materials Mind MapDRAGONMASTER ZNo ratings yet

- 31380112Document5 pages31380112Pedro Luis Choque MamaniNo ratings yet

- Effect of Impurities On Cast Iron Impurities:: SiliconDocument16 pagesEffect of Impurities On Cast Iron Impurities:: SiliconMD. ZUBAIR ISLAMNo ratings yet

- Engineering Materials-Istanbul .Technical UniversityDocument21 pagesEngineering Materials-Istanbul .Technical UniversitybuggrraaNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument5 pagesEquivalents of Carbon Steel QualitiesInaamNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Plant Design Solutions Master Contents and Updates: Pds Master Catalog For Cadworx 2015Document2 pagesPlant Design Solutions Master Contents and Updates: Pds Master Catalog For Cadworx 2015calebneltonNo ratings yet

- Equivalent Standard For Grey Iron & Ductile IronDocument2 pagesEquivalent Standard For Grey Iron & Ductile Ironariefihsan100% (1)

- DIN 17100 ST 37-2 SteelDocument1 pageDIN 17100 ST 37-2 Steelisaaa100% (1)

- Equivalent of Carbon SteelDocument10 pagesEquivalent of Carbon SteelprabakaranNo ratings yet

- Stoody 965GDocument1 pageStoody 965GARTHURS316No ratings yet

- Stainless Steel International Grade CompositionDocument2 pagesStainless Steel International Grade Compositiongnino2No ratings yet

- Ksp-Instrument Impulse Piping & TubingDocument18 pagesKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNo ratings yet

- Typical Propertie of MaterialsDocument1 pageTypical Propertie of MaterialsChan ThornNo ratings yet

- DelCorte - AccesoriosDocument56 pagesDelCorte - AccesoriosespanolasaNo ratings yet

- Steel Design IntroDocument16 pagesSteel Design IntroSherina Juliane LimNo ratings yet

- Iso15510 PDFDocument3 pagesIso15510 PDFthritaNo ratings yet

- TECHNICALDocument48 pagesTECHNICALPuneeth KumarNo ratings yet

- Sl. No. State Name of Unit Address Status - Online Emission & Effluent Monitoring System (As On 16.06.2017)Document13 pagesSl. No. State Name of Unit Address Status - Online Emission & Effluent Monitoring System (As On 16.06.2017)Ranjan BeheraNo ratings yet

- SUMODocument1 pageSUMOPaulo César BritoNo ratings yet

- Roller Bracket AssemblyDocument1 pageRoller Bracket AssemblyRishikesh GunjalNo ratings yet

- Price Trend of Foundry Raw MaterialsDocument4 pagesPrice Trend of Foundry Raw Materialsnayan205No ratings yet

- American Welding Society User 039 S Guide To Filler MetalsDocument127 pagesAmerican Welding Society User 039 S Guide To Filler MetalsCarlos Bermejo Alvarez100% (1)

- Hitesh Metal (India) Introduction & Profile 1.2.18 PDFDocument5 pagesHitesh Metal (India) Introduction & Profile 1.2.18 PDFHMI MumbaiNo ratings yet

- TP UpdatedDocument10 pagesTP UpdatedRizky SetiawanNo ratings yet

- GRWGRGRGRDocument2 pagesGRWGRGRGRAlexyz33No ratings yet

- Shape Memory AlloysDocument12 pagesShape Memory AlloysLAKKANABOINA LAKSHMANARAONo ratings yet

- Bab Iv Data Dan PembahasanDocument9 pagesBab Iv Data Dan Pembahasancindyokt_No ratings yet

- Daftar Pustaka Skripsi Muhammad Firdaus A.SDocument6 pagesDaftar Pustaka Skripsi Muhammad Firdaus A.SFrdssNo ratings yet

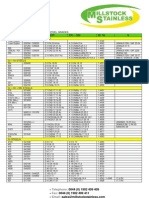

Table A Commonly Used Material Specification Reference Chart

Table A Commonly Used Material Specification Reference Chart

Uploaded by

Phong TongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table A Commonly Used Material Specification Reference Chart

Table A Commonly Used Material Specification Reference Chart

Uploaded by

Phong TongCopyright:

Available Formats

Table A

Commonly Used material specification reference chart

Typical size ranges

SAE Typical Ball for various grades

Material Common Standard unified Number Hardness (1)(2) grade mm inch

3 0,8-25 1/32 - 1

5,10 0,3-38 1/64 – 1-1/2

Chrome alloy steel AISI/SAE E52100 G–52986 Rc 60-67 (3,5) 16,24

AISI/SAE E51100 48-100

200 0,8-75 1/32 – 2-7/8

500

1000 10-115 3/8 – 4-1/2

3

Alloy tool steel AISI/SAE M50 T-44004 Rc 58-65(4,5) 5,10,16 0,8-12 1/32 –1/2

24,48 0.8-40 1/32 – 1-5/8

AISI/SAE T1 T 12001 Rc 60-65 (3,5)

AISI/SAE 440C S-44004 Rc 58-65 (4,5)

Corrosion resisting AISI/SAE 4408 S-44003 Rc 55-62 (4,5) 3,5,10.16 0,3-19 1/64 – ¾

Hardened steel AISI/SAE 420 S-42000 Rc 52min (4,5) 24 0,8-25 1/32 – 1

AISI/SAE 410 S-41000 Rb 97 Rc 41 (4,5) 48 0,8-50 1/32 – 2

AISI/SAE329 S-32900 Rb 45 min (4,5) 100,200 0,8-115 1/32 – 4-1/2

AISI/SAE 302 S-30200 Rc 25-39 (5,6)

Corrosion resisting AISI/SAE 304 S-30400 Rc 25-39 (5,6) 100,200

Unhardened steel AISI/SAE 305 S-30500 Rc 25-39 (5,6) 500 1,5-19 1/16 – ¾

AISI/SAE 316 S-31600 Rc 25-39 (5,6)

AISI/SAE 430 S-43000 Ra 48-63 (5)

AISI/SAE 1008 G-10080 Rc 60min (2)

AISI/SAE 1013 G-10130 Rc 60minb (2) 100,200

Carbon steel (7) AISI/SAE 1018 G-10180 Rc 60min (2) 500 1,5-38 1/16 – 1-1/2

AISI/SAE 1022 G-10220 Rc 60min (“) 1000

Silicon molybdenum

Steel AISI/SAE S 2 T-41902 Rc 52-60 (3) 200 6,5-28 1/4- 1-1/8

Aluminium AA-2017 A-92017 Rb 54-72 300 1,5-25 1/16 – 1

Aluminium bronze CDA-624 C- 62400 Rb 94-98

CDA-630 C-63000 Rb 94-98 200 20-100 13/16 – 4

100,200

Brass CDA –260 C-26000 Rb 75-87 500 1,5-19 1/16 –3/4

1000

200,500

Bronze CDA-464 C-46400 Rb 75-98 1,5-19 1/16 – 3/4

1000

100,200

Monel 400 AMS-4730 N-04400 Rb 85-92 1,5-19 1/16 – 3/4

500

Monel K-500 OA-N-286 N-05500 Rc 27min 100 1,5-19 1/16 – 3/4

200 1,5-45 1/16 – 1-11/16

5 1,2-12 3/64 – 1/2

Tungsten carbide JIC Carbide Not applicable Ra 84-91,5 10 1,2-19 3/64 – 3/4

Classification 16 1,2-25 3/64 – 1

24 1,2-32 3/64 – 1-1/4

Notes:

1. Rockwell hardness tests shall be conducted on paralle flats in accordance with ASTM Standar E-18 unless otherwise specified.

2. Hardness readings taken on spherical surfaces are subject to the corrections shown in table H, appendix B3. hardness readings for carbon

steel balls smaller than 6mm(1/8 inch) shall be taken by the microhardness method or as agreed between manufacturer and perchaser.

3. Hardness of balls in any one lot shall be within 3 points on Rockwell C scale.

4. Hardness of balls in any one lot shall be within 4 points on Rockwell C scale.

5. Where microhardness is used see appendix B1. When microhardness method is used the Rockwell hardness values given above are

converted to DPH in accordance with ASTM Standard E-140 “Standard Hardness Conversion tables for metals.”

6. Annealed hardness of Rb 75-90 is available when specified.

7. Choice of carbon steels shown to be at ball manufacturer’s option

You might also like

- Product Description Wire RodDocument3 pagesProduct Description Wire RodEngr Farrukh RehanNo ratings yet

- Ductile Iron Casting Specfications and Details All Standards PDFDocument15 pagesDuctile Iron Casting Specfications and Details All Standards PDFSiriusNo ratings yet

- Selectalloy 307cDocument1 pageSelectalloy 307cJuan Carlos RodriguezNo ratings yet

- SAE AMS5628F Steel, Corrosion-Resistant, Bars, Wire, Forgings, and Tubing 16Cr-2.5Ni (SAE 51431) (Composition Similar To UNS S43100)Document13 pagesSAE AMS5628F Steel, Corrosion-Resistant, Bars, Wire, Forgings, and Tubing 16Cr-2.5Ni (SAE 51431) (Composition Similar To UNS S43100)loebNo ratings yet

- 2211Document4 pages2211liuyx866No ratings yet

- Pinnacle Alloys ER2594Document2 pagesPinnacle Alloys ER2594Federico Quintana100% (1)

- 309-16 Data SheetDocument1 page309-16 Data Sheetdapp.70No ratings yet

- Welding ProcessesDocument28 pagesWelding ProcessesAnaswarpsNo ratings yet

- E 7016 Product-SheetDocument1 pageE 7016 Product-SheetAlireza TakrimiNo ratings yet

- Stainless Steel EN Equivalent Cross ReferenceDocument5 pagesStainless Steel EN Equivalent Cross ReferenceagrovadoNo ratings yet

- ME 205 - 432 - Assignment 1Document9 pagesME 205 - 432 - Assignment 1جعفر السلطانNo ratings yet

- ASTM A193 Specification - Portland BoltDocument3 pagesASTM A193 Specification - Portland BoltJesús Alberto Díaz CostaNo ratings yet

- C63000 (CDA 630) Nickel Aluminum Bronze - AMS 4640 - UNS C63000 - Aviva MetalsDocument5 pagesC63000 (CDA 630) Nickel Aluminum Bronze - AMS 4640 - UNS C63000 - Aviva MetalsCHAITANYANo ratings yet

- Bolts SpacificationsDocument6 pagesBolts SpacificationsSaleem JaradatNo ratings yet

- Valve Material Application PDFDocument16 pagesValve Material Application PDFSudherson Jagannathan100% (1)

- Threaded Union: Length of Thread Screwed Into FittingDocument1 pageThreaded Union: Length of Thread Screwed Into FittingBalaji KanduriNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- Bonded Seals BrochureDocument8 pagesBonded Seals BrochureembasianNo ratings yet

- AlMg 4.5Mn Product-SheetDocument1 pageAlMg 4.5Mn Product-SheetLuca MemoliNo ratings yet

- Bolt & Stud Grade MarkingsDocument2 pagesBolt & Stud Grade MarkingsJacobNo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Pinnacle ER316L Tig Welding Wire DATA SHEETDocument2 pagesPinnacle ER316L Tig Welding Wire DATA SHEEThsuyan2000No ratings yet

- Power Plant: Better Life Created by SteelDocument4 pagesPower Plant: Better Life Created by SteelAlejandro Jose Garcia FernandezNo ratings yet

- Weld Consumable SelectionDocument25 pagesWeld Consumable SelectionNisarg PandyaNo ratings yet

- Er70S-6 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-6 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Appendix C. Conduit and Tubing Fill Tables For Conductors and Fixture Wires of The Same SizeDocument1 pageAppendix C. Conduit and Tubing Fill Tables For Conductors and Fixture Wires of The Same SizeONG, Chester Z.No ratings yet

- Filettature Tiranti ASTM-A193Document25 pagesFilettature Tiranti ASTM-A193markoredsNo ratings yet

- Duplex-Alloy-2205-Stress ValuesDocument5 pagesDuplex-Alloy-2205-Stress ValuesShiniNo ratings yet

- SPECIFICATIONS. C.S.A. G40.21M Steels - Page 123 C.S.A. G40.21 Steels - Page 134 A.S.T.M. Steels - Page 143Document56 pagesSPECIFICATIONS. C.S.A. G40.21M Steels - Page 123 C.S.A. G40.21 Steels - Page 134 A.S.T.M. Steels - Page 143PAMELA LEENo ratings yet

- American FastenersDocument6 pagesAmerican Fastenersashraf elsayedNo ratings yet

- A2 Vs A4 Stainless Steel BoltsDocument3 pagesA2 Vs A4 Stainless Steel BoltsmamahsenNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationme100% (1)

- Ss304 Valves for Duplex StlDocument8 pagesSs304 Valves for Duplex Stlajarekarga ajarekarNo ratings yet

- Sae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsDocument3 pagesSae j468-1988 Zinc Alloy Ingot and Die Casting CompositionsAnonymous 7ZTcBn100% (1)

- Butterfly Valves Gd-381: SpecificationDocument2 pagesButterfly Valves Gd-381: SpecificationJOSE GABRIELNo ratings yet

- ASTM-A564-A564M-13e1-Age Hardening SS Bars Hot Rolled Cold FinishedDocument4 pagesASTM-A564-A564M-13e1-Age Hardening SS Bars Hot Rolled Cold FinishedAjay GuptaNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade Markings PDFDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markings PDFnate anantathatNo ratings yet

- TitaniumDocument7 pagesTitaniumNitinNo ratings yet

- Nutron TM Trunnion Mounted Ball Valve FlyerDocument2 pagesNutron TM Trunnion Mounted Ball Valve FlyerAlbert RubianoNo ratings yet

- Duplex SSDocument2 pagesDuplex SSsjk_akolNo ratings yet

- CastMaterials E00510Document6 pagesCastMaterials E00510samir basuniNo ratings yet

- ZXDocument6 pagesZXPedro SilvaNo ratings yet

- Grades of Bolts - Bolt Grade Marking Chart - AFT FastenersDocument3 pagesGrades of Bolts - Bolt Grade Marking Chart - AFT FastenersheartofdixieNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Alloy C-4300MDocument1 pageAlloy C-4300Malex diazNo ratings yet

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocument10 pagesMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNo ratings yet

- Piping Material Specification 3C605 Carbon Steel, Class 300 Issue Date: Feb 17, 2014Document12 pagesPiping Material Specification 3C605 Carbon Steel, Class 300 Issue Date: Feb 17, 2014azilahnazriNo ratings yet

- A Guide To Nickel Alloys PDFDocument2 pagesA Guide To Nickel Alloys PDFAnonymous lmCR3SkPrKNo ratings yet

- Classif AçosDocument7 pagesClassif AçoslavascudoNo ratings yet

- rb7550 APLTONE01221 - 669Document1 pagerb7550 APLTONE01221 - 669soayNo ratings yet

- Forged Stainless AlloyDocument8 pagesForged Stainless AlloymsajanjNo ratings yet

- Bolt Grades Strength Chart - Imperial Steel BoltsDocument5 pagesBolt Grades Strength Chart - Imperial Steel BoltsEduardo LunaNo ratings yet

- Ductile Iron Casting Specfications and Details All StandardsDocument15 pagesDuctile Iron Casting Specfications and Details All StandardsN.Palaniappan100% (1)

- Fig.101-102 Bronze & Brass Gate ValveDocument1 pageFig.101-102 Bronze & Brass Gate ValveDỰ ÁN TD SCHOOL TDMENo ratings yet

- Butterfly ValveDocument2 pagesButterfly ValveKELVIN TECHNOLOGIESNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- MPPL PT Calendar 2024 2025Document6 pagesMPPL PT Calendar 2024 2025Joby GeorgeNo ratings yet

- DT RM Materials Mind MapDocument1 pageDT RM Materials Mind MapDRAGONMASTER ZNo ratings yet

- 31380112Document5 pages31380112Pedro Luis Choque MamaniNo ratings yet

- Effect of Impurities On Cast Iron Impurities:: SiliconDocument16 pagesEffect of Impurities On Cast Iron Impurities:: SiliconMD. ZUBAIR ISLAMNo ratings yet

- Engineering Materials-Istanbul .Technical UniversityDocument21 pagesEngineering Materials-Istanbul .Technical UniversitybuggrraaNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument5 pagesEquivalents of Carbon Steel QualitiesInaamNo ratings yet

- Type Inserts With Hole: TCMT 09 02 02-FPDocument2 pagesType Inserts With Hole: TCMT 09 02 02-FPTungstenCarbideNo ratings yet

- Plant Design Solutions Master Contents and Updates: Pds Master Catalog For Cadworx 2015Document2 pagesPlant Design Solutions Master Contents and Updates: Pds Master Catalog For Cadworx 2015calebneltonNo ratings yet

- Equivalent Standard For Grey Iron & Ductile IronDocument2 pagesEquivalent Standard For Grey Iron & Ductile Ironariefihsan100% (1)

- DIN 17100 ST 37-2 SteelDocument1 pageDIN 17100 ST 37-2 Steelisaaa100% (1)

- Equivalent of Carbon SteelDocument10 pagesEquivalent of Carbon SteelprabakaranNo ratings yet

- Stoody 965GDocument1 pageStoody 965GARTHURS316No ratings yet

- Stainless Steel International Grade CompositionDocument2 pagesStainless Steel International Grade Compositiongnino2No ratings yet

- Ksp-Instrument Impulse Piping & TubingDocument18 pagesKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNo ratings yet

- Typical Propertie of MaterialsDocument1 pageTypical Propertie of MaterialsChan ThornNo ratings yet

- DelCorte - AccesoriosDocument56 pagesDelCorte - AccesoriosespanolasaNo ratings yet

- Steel Design IntroDocument16 pagesSteel Design IntroSherina Juliane LimNo ratings yet

- Iso15510 PDFDocument3 pagesIso15510 PDFthritaNo ratings yet

- TECHNICALDocument48 pagesTECHNICALPuneeth KumarNo ratings yet

- Sl. No. State Name of Unit Address Status - Online Emission & Effluent Monitoring System (As On 16.06.2017)Document13 pagesSl. No. State Name of Unit Address Status - Online Emission & Effluent Monitoring System (As On 16.06.2017)Ranjan BeheraNo ratings yet

- SUMODocument1 pageSUMOPaulo César BritoNo ratings yet

- Roller Bracket AssemblyDocument1 pageRoller Bracket AssemblyRishikesh GunjalNo ratings yet

- Price Trend of Foundry Raw MaterialsDocument4 pagesPrice Trend of Foundry Raw Materialsnayan205No ratings yet

- American Welding Society User 039 S Guide To Filler MetalsDocument127 pagesAmerican Welding Society User 039 S Guide To Filler MetalsCarlos Bermejo Alvarez100% (1)

- Hitesh Metal (India) Introduction & Profile 1.2.18 PDFDocument5 pagesHitesh Metal (India) Introduction & Profile 1.2.18 PDFHMI MumbaiNo ratings yet

- TP UpdatedDocument10 pagesTP UpdatedRizky SetiawanNo ratings yet

- GRWGRGRGRDocument2 pagesGRWGRGRGRAlexyz33No ratings yet

- Shape Memory AlloysDocument12 pagesShape Memory AlloysLAKKANABOINA LAKSHMANARAONo ratings yet

- Bab Iv Data Dan PembahasanDocument9 pagesBab Iv Data Dan Pembahasancindyokt_No ratings yet

- Daftar Pustaka Skripsi Muhammad Firdaus A.SDocument6 pagesDaftar Pustaka Skripsi Muhammad Firdaus A.SFrdssNo ratings yet